Oil field water flooding monitoring system based on PROFIBUS fieldbus

A monitoring system and oil field water injection technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problem of not being able to achieve smooth water injection, quantitative water injection and accurate water injection, unable to automatically inspect remote injection of data, weak signal strength, etc. problem, to achieve stable and reliable data transmission, easy to promote and use, and solve the effect of poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

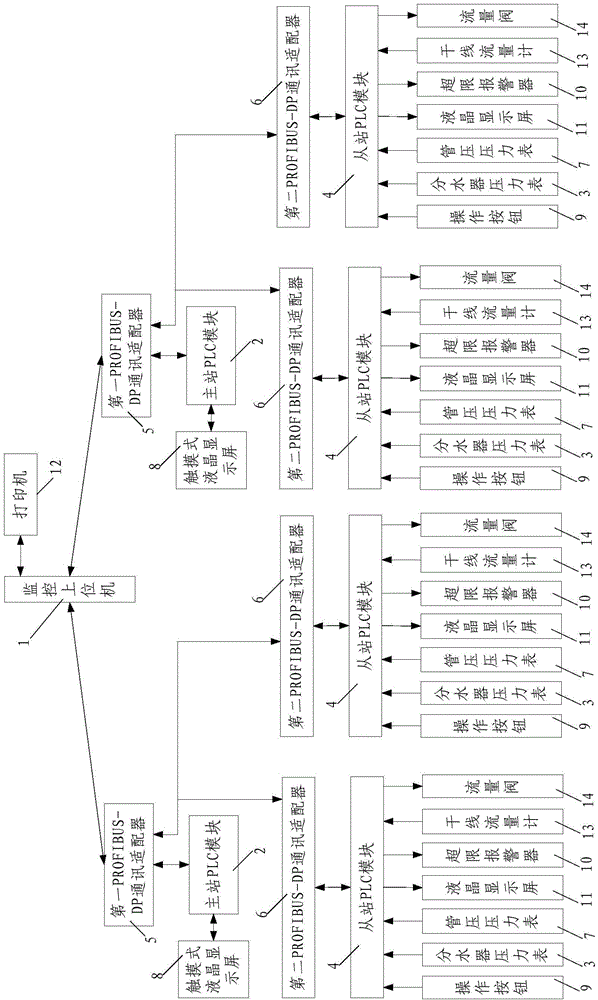

[0024] Such as figure 1 As shown, the present invention includes a monitoring host computer 1 arranged in a monitoring machine room, a plurality of master station PLC modules 2 arranged in a monitoring field and a plurality of slave station PLC modules 4 arranged in a plurality of oil wells in a monitoring field. The upper computer 1 is connected with a printer 12 for printing monitoring files, and each of the master station PLC modules 2 is connected with a first PROFIBUS-DP communication adapter 5 and a touch-screen liquid crystal display 8 for human-computer interaction. A second PROFIBUS-DP communication adapter 6 is connected to each of the slave station PLC modules 4, and each of the master station PLC modules 2 is monitored by the PROFIBUS bus connected to the first PROFIBUS-DP communication adapter 5 and the host computer The system 1 is connected and communicated, and each of the slave station PLC modules 4 is connected and communicated with the master station PLC mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com