Double-closing and double-opening plugging device

A technology of plug and nozzle core, which is applied in the field of layered water injection tools in oilfields, to achieve the effects of reducing workload, reducing nozzle damage and eliminating backlash gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

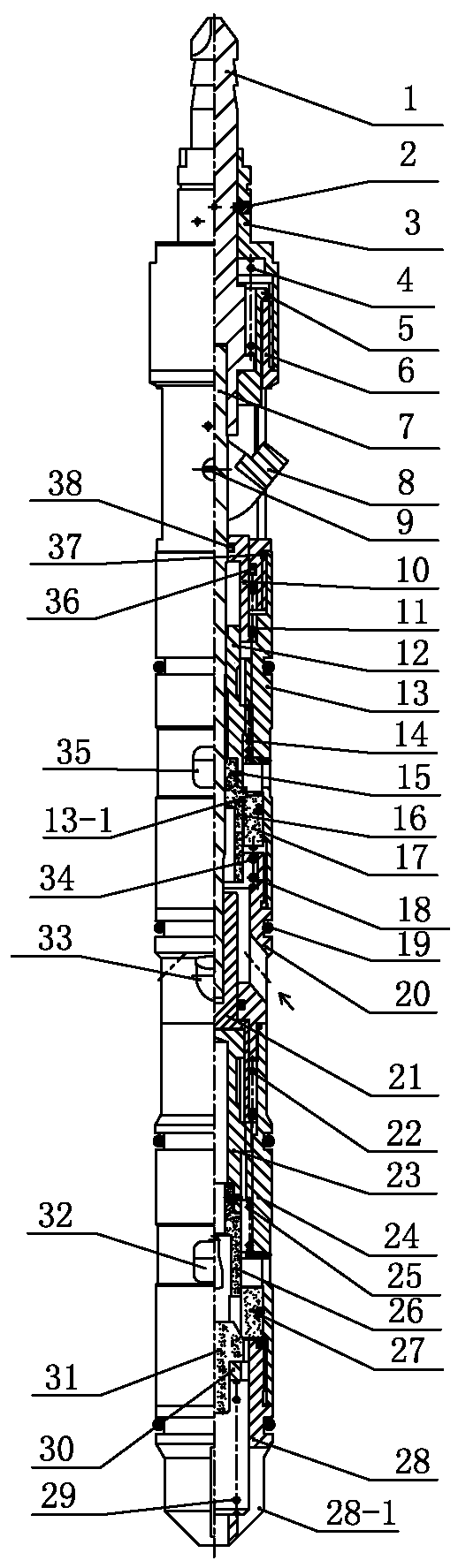

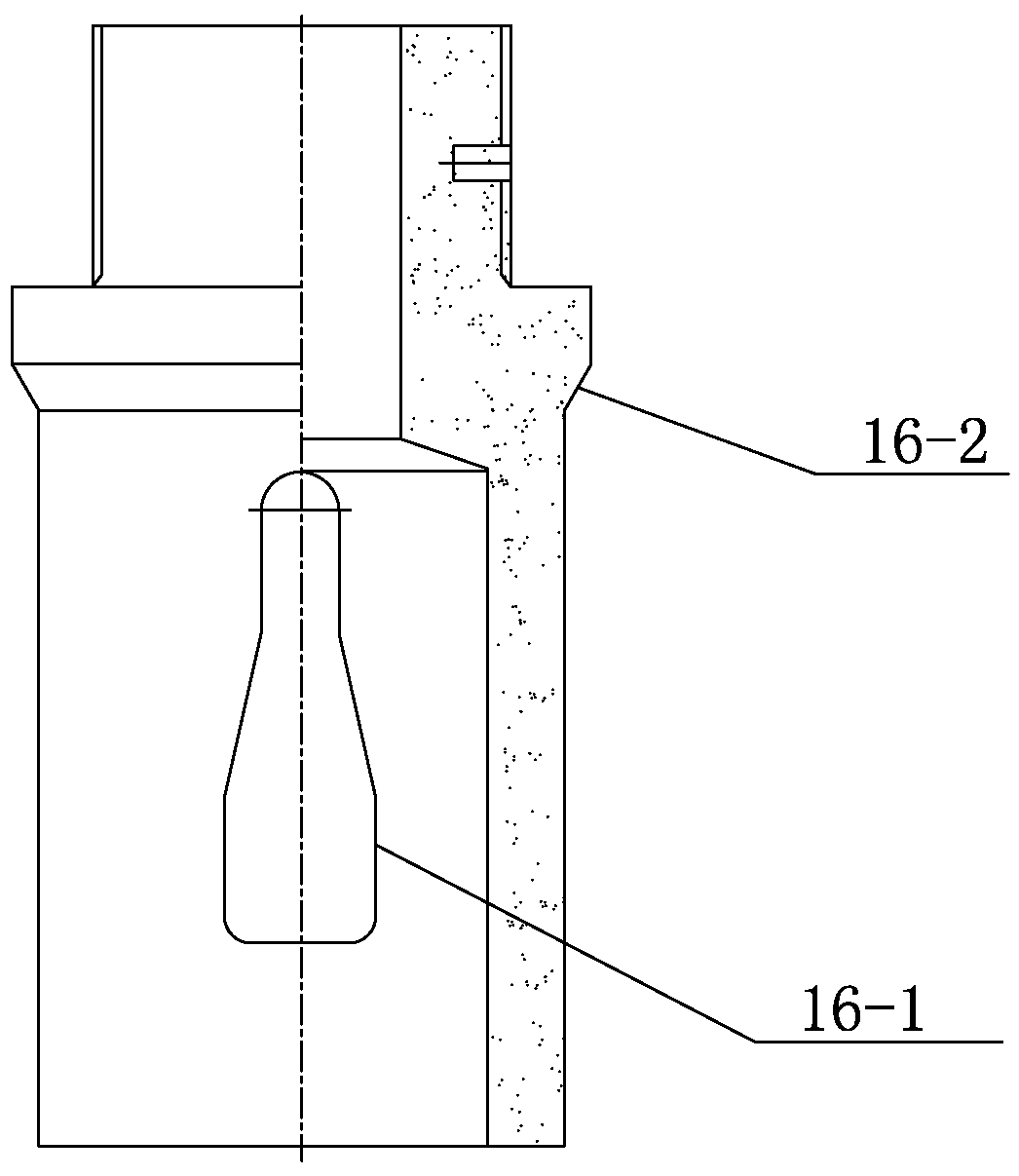

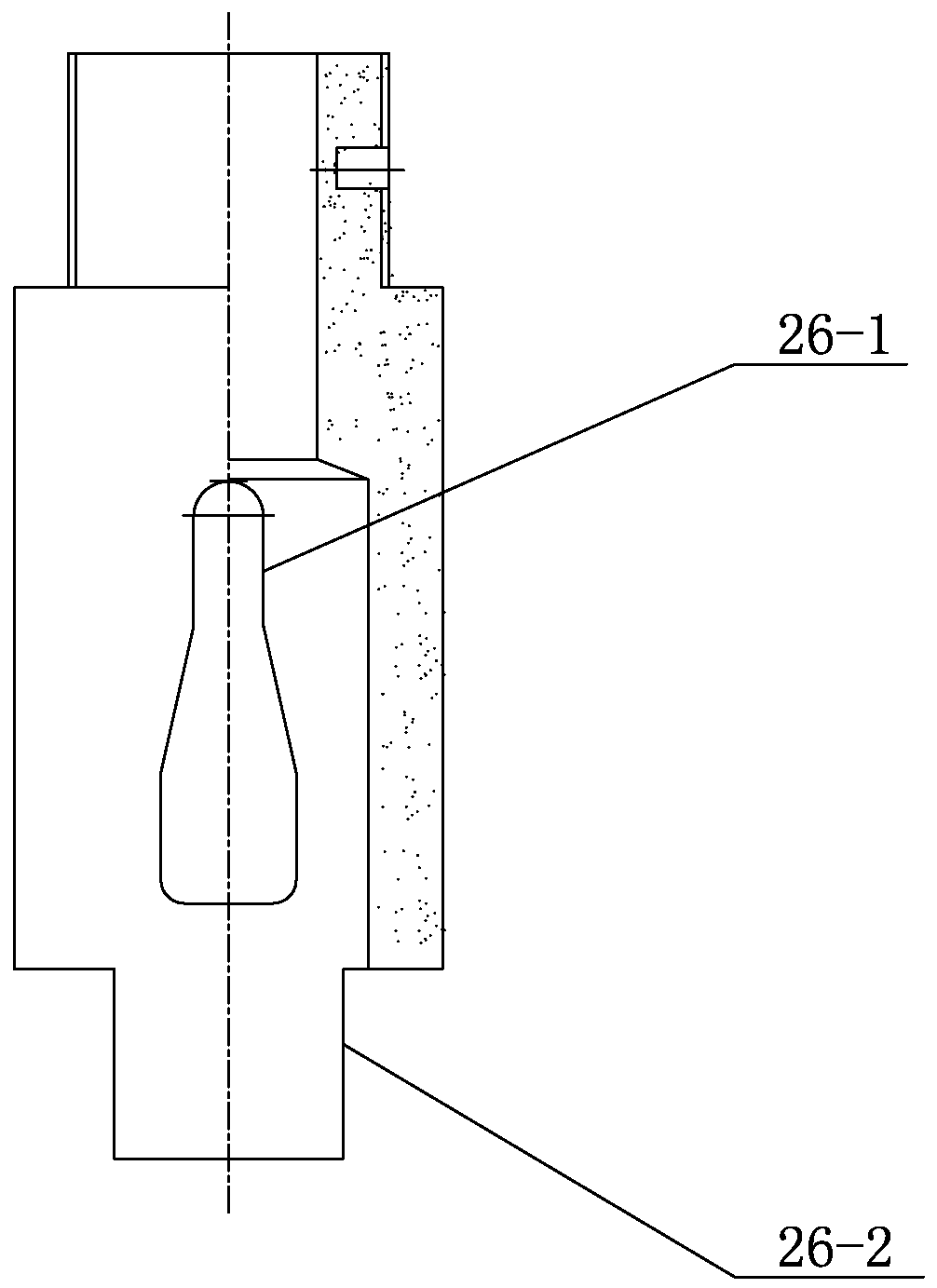

[0022] Such as figure 1 — image 3Shown is a double-closed double-open plug of this embodiment, including a salvage assembly, the main drive shaft 7 is slidably connected to the lower part of the salvage assembly, and an upper silk shell 13 is provided on the outer periphery of the middle part of the main drive shaft 7, and the lower part of the upper silk shell 13 is The middle shell 20 and the lower silk shell 24 are connected successively, the lower end of the lower silk shell 24 is connected with a lower pressure cap 28, the middle shell 20 is provided with an upper water inlet 20-1 circumferentially, the upper silk shell 13 is circumferentially provided with an upper water outlet 35, and the lower silk shell 24 The lower water outlet 32 is arranged in the circumferential direction, the lower water inlet 28-1 is arranged in the lower pressure cap 28 circumferential direction, and the upper mouth cover 17 is provided for sliding sealing in the upper silk shell 13 on the l...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that the structure of the valve assembly at the bottom of the lower mouth cover 27 is different, such as Figure 4 As shown, the valve assembly includes a ball valve 40 that abuts against the matching taper surface at the lower end of the lower mouth cover 27. The lower part of the ball valve 40 is provided with a ball holder 39, and an axial pressure is provided between the ball holder 39 and the lower pressure cap 28. Tight spring 29, the circumferential direction that ball valve 40 and ball holder 39 cooperate with pressing down cap 28 are provided with the passage that communicates with the water inlet passage of bottom. In this structure, the lower water nozzle is closed through the sealing cooperation between the ball valve 40 and the cone valve port of the lower mouth cover 27. When the lower nozzle core axis moves downward to push the ball valve open, the water inlet channel of the lower nozzle core is op...

Embodiment 3

[0031] Such as figure 1 , Figure 5 Shown is a double-closed double-open plug of this embodiment, the spring 29, the cone sleeve 30, and the cone valve 31 are removed; the lower mouthpiece adopts the same structure as the upper mouthpiece; the upper mouthpiece 16 and the lower mouthpiece 26 are set at the same time It is in a fully open state, and the direction of the bottle-shaped water outlet of the upper mouth core is the bottle mouth upward, and the direction of the bottle-shaped water outlet of the lower mouth core is the bottle mouth downward. The direction of rotation of the internal transmission threads is the same; when the main drive shaft 7 rotates, the upper nozzle core 16 and the lower nozzle core 26 are driven downward at the same time. Since the direction of the water outlet 16-3 is opposite to that of the water outlet 26-1, the water outlet 16-3 is slowly closed. , The water outlet 26-1 is quickly closed, realizing the synchronous control of the water volume o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com