A water injection pipe for offshore water injection wells

A technology for water injection pipes and water injection wells, applied in the direction of drilling pipes, casings, drilling equipment, etc., can solve the problems of low working efficiency, shutdown for maintenance, and short continuous working life of offshore water injection wells, so as to prevent severe erosion and large-area Scaling, reducing the frequency of downtime and maintenance, good anti-corrosion and anti-scaling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

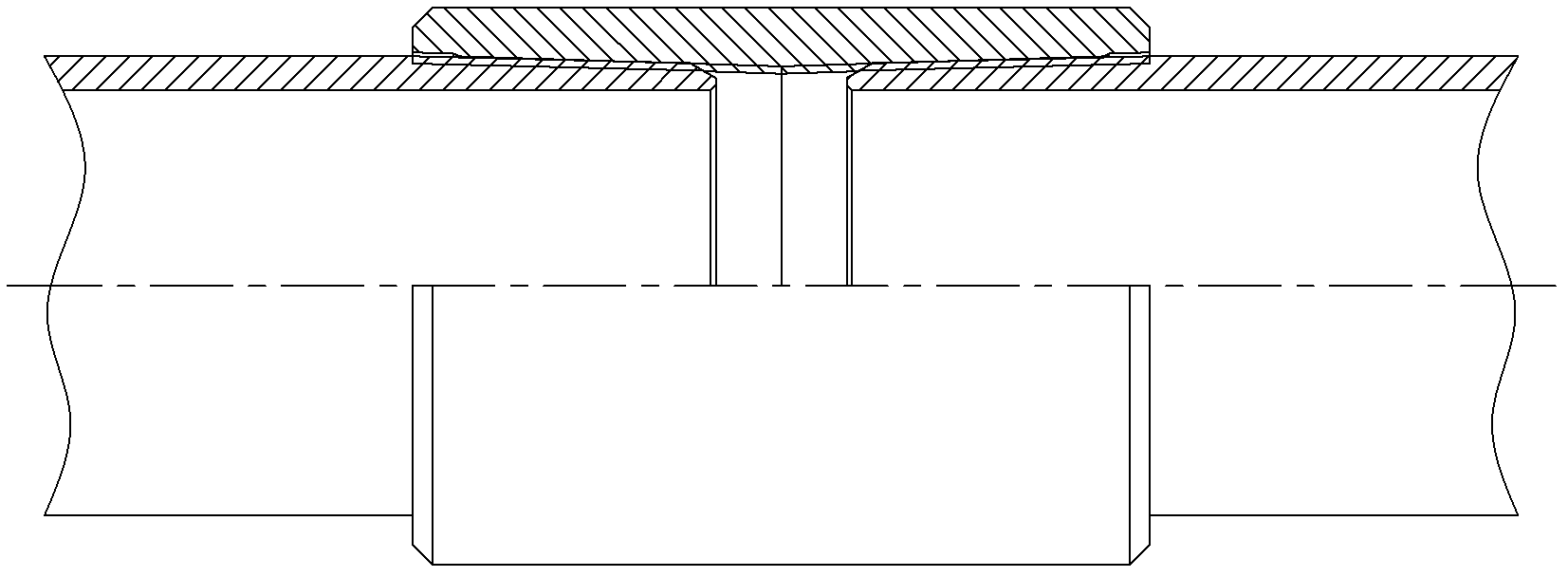

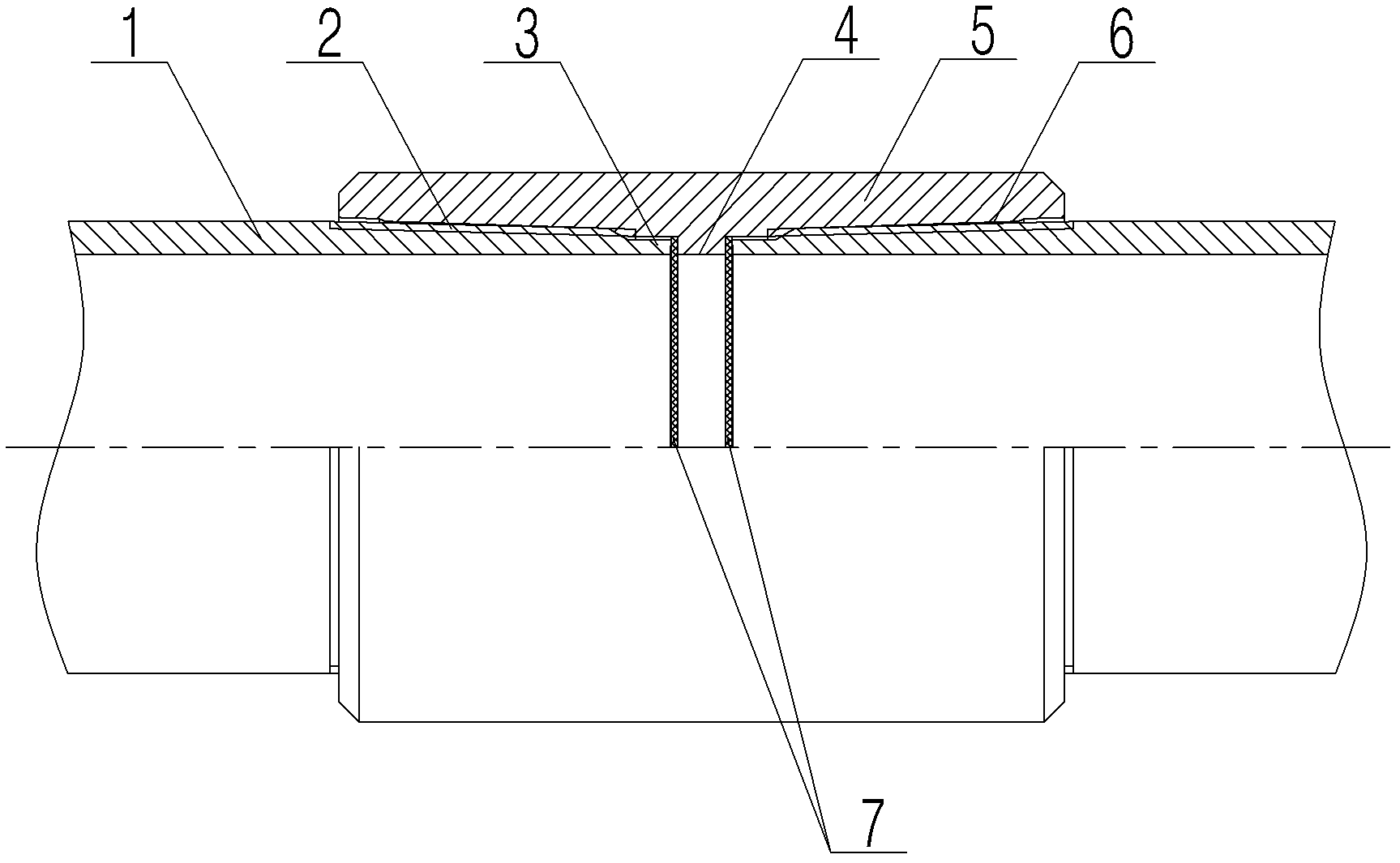

[0020] Such as figure 2 As shown, this embodiment discloses a water injection pipe for offshore water injection wells, which includes a pipe body 1 with external threads 2 at both ends, and a coupling 5 with internal threads 6 passing between each two sections of pipe body 1 to connect.

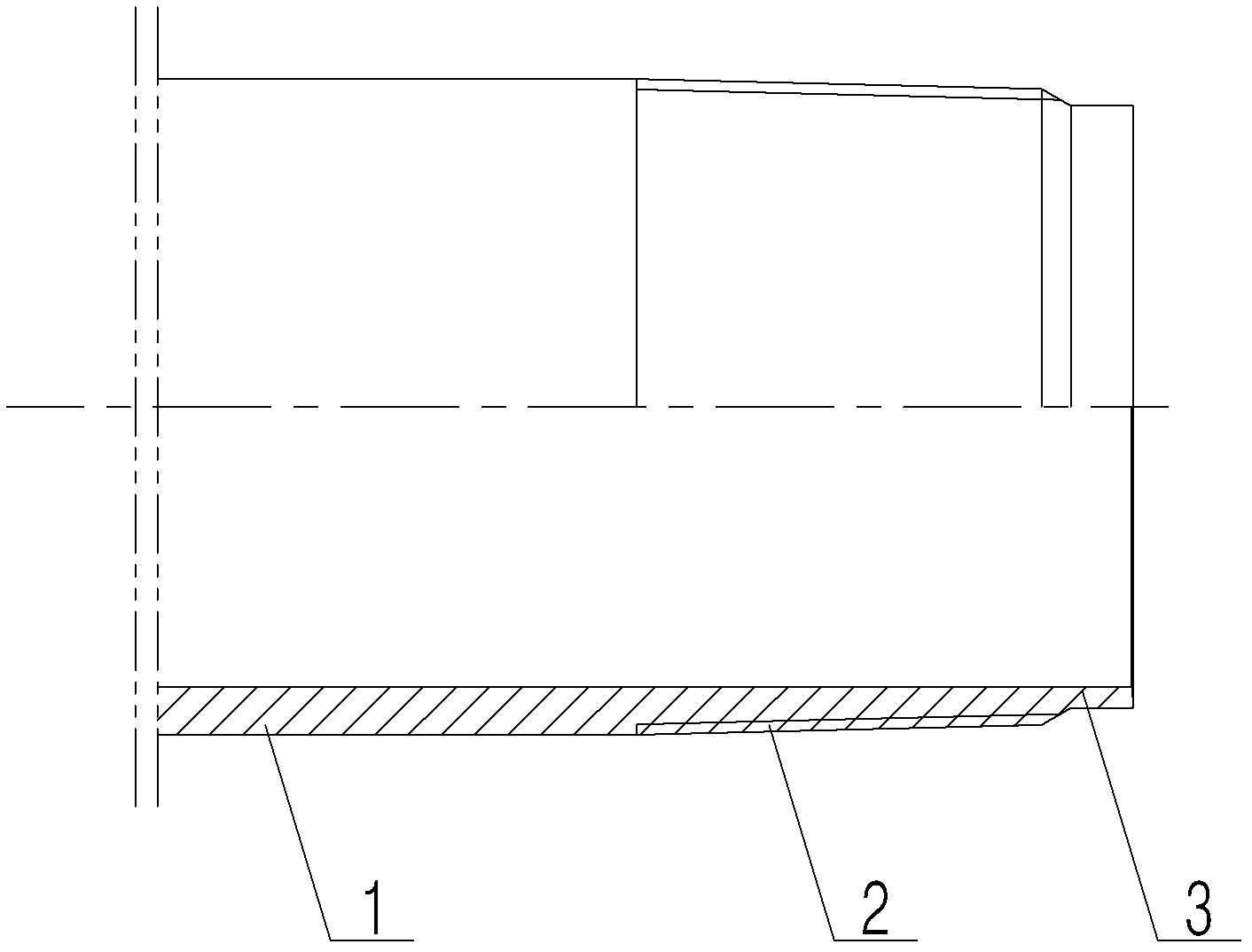

[0021] Such as image 3 As shown, the end of the external thread 2 of the pipe body 1 is provided with a nose end 3 , and the nose end 3 is elongated along the axial direction of the pipe body 1 .

[0022] Such as Figure 4 As shown, the inner wall in the middle of the collar 5 is provided with a radial inner boss 4, combined with figure 2 , the thickness of the upper nose end 3 of the pipe body 1 should be consistent with the height of the radially inner boss 4 on the collar 5, so that after the pipe body 1 is connected with the collar 5 to form a water inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com