Method and device for determining liquid output rules of commingled producing well

A well-production and regular technology, applied in the fields of production of fluids, earth-moving drilling, wellbore/well components, etc., can solve the problem of increasing production difficulty, remaining oil distribution and unclear understanding of strong seepage channels, affecting ultimate recovery and Recoverable geological reserves and other issues, to achieve the effect of improving economic benefits, improving water injection efficiency and ultimate recovery factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing:

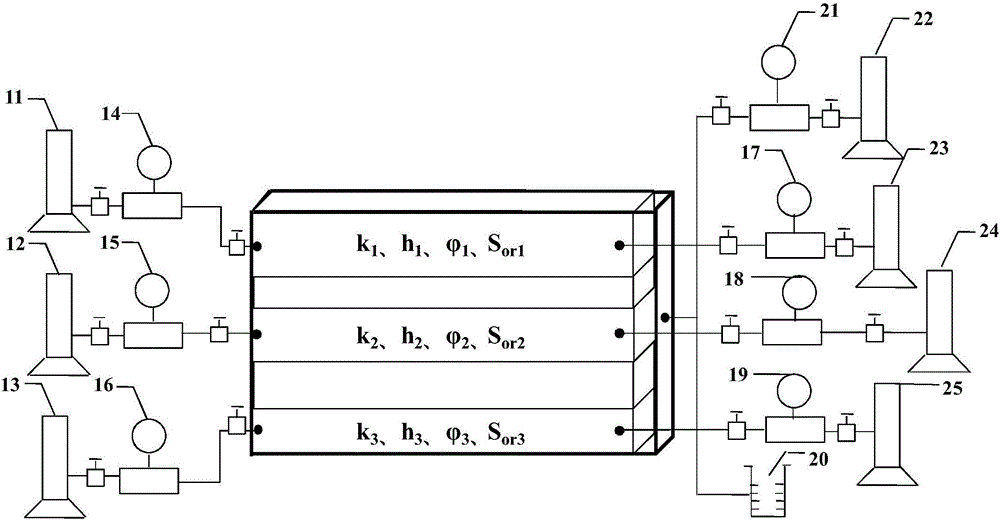

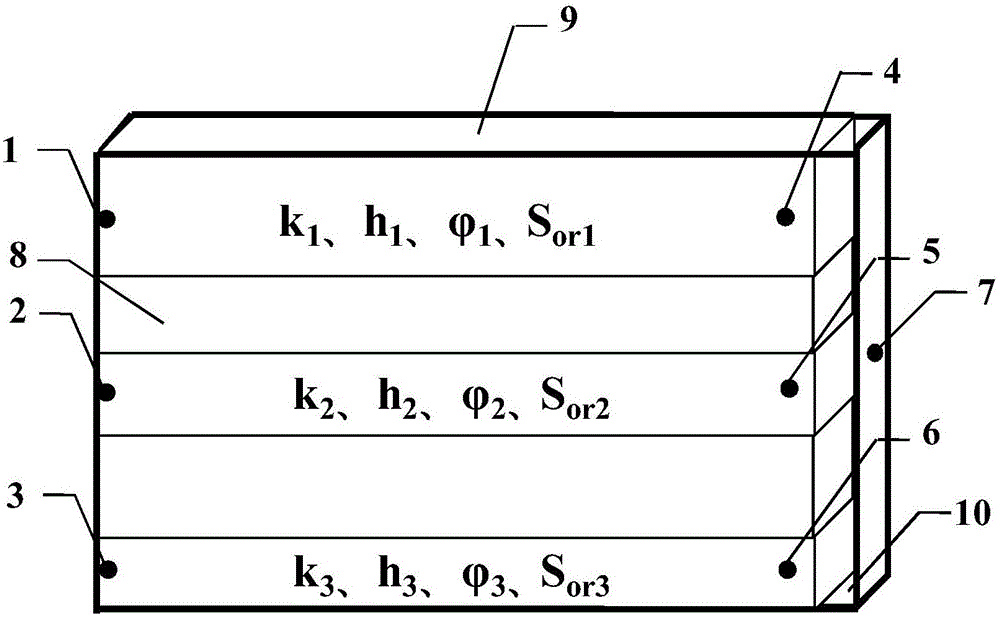

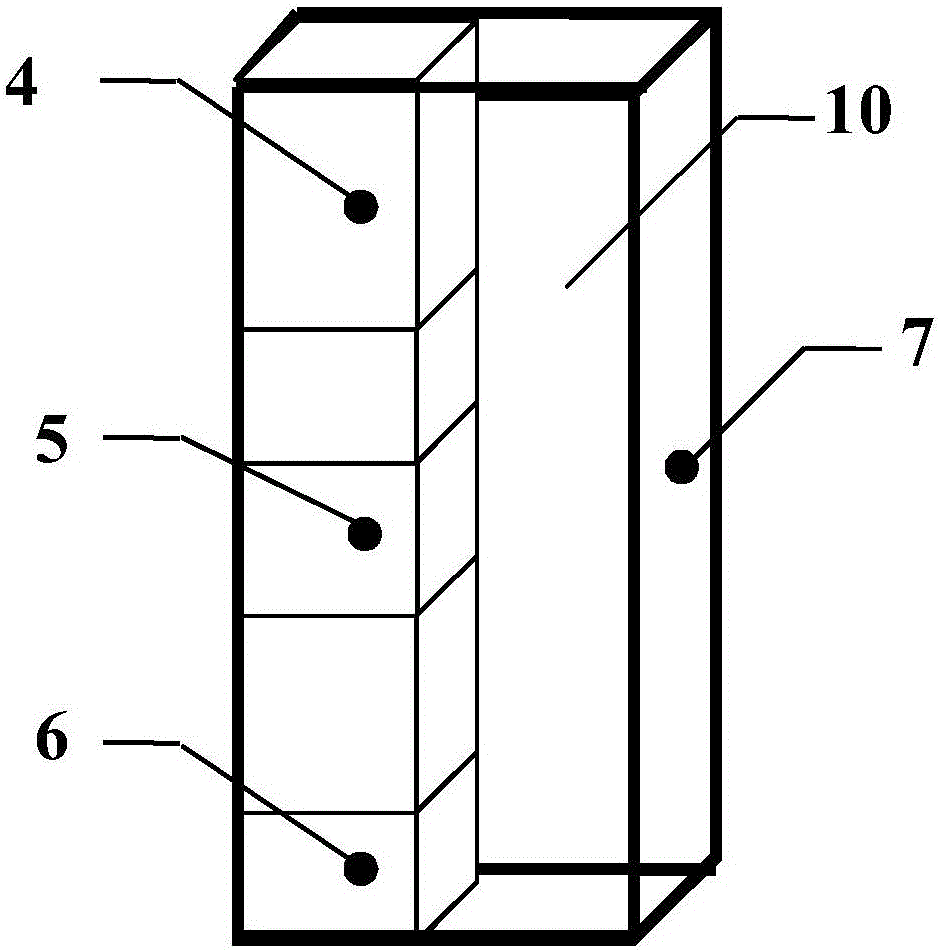

[0056] Depend on Figure 1 to Figure 3 As shown, this kind of device for determining the fluid flow law of the joint production well is composed of a multi-layer porous medium model, an injection system and an output measurement system. Its unique features are:

[0057] The multilayer porous medium model determines the physical parameters of each small layer with reference to the situation of the formation where the actual joint production well is located, and adds an interlayer between each small layer of the multilayer porous medium model; the multilayer porous medium Epoxy resin is poured around the outside of the model to form an epoxy resin jacket, but there is a cavity with a width of 1 cm between its right end and the epoxy resin jacket, and the cavity is used to simulate the joint production well in the actual production process The wellbore working system; the por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com