Semi-automatic timely-guidance cleanser filling pipe for motor vehicles

A semi-automatic, cleaning fluid technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems affecting the battery, engine settings, cumbersome filling process, occupying the hood, etc., to avoid the inconvenience of adding water and easy operation. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

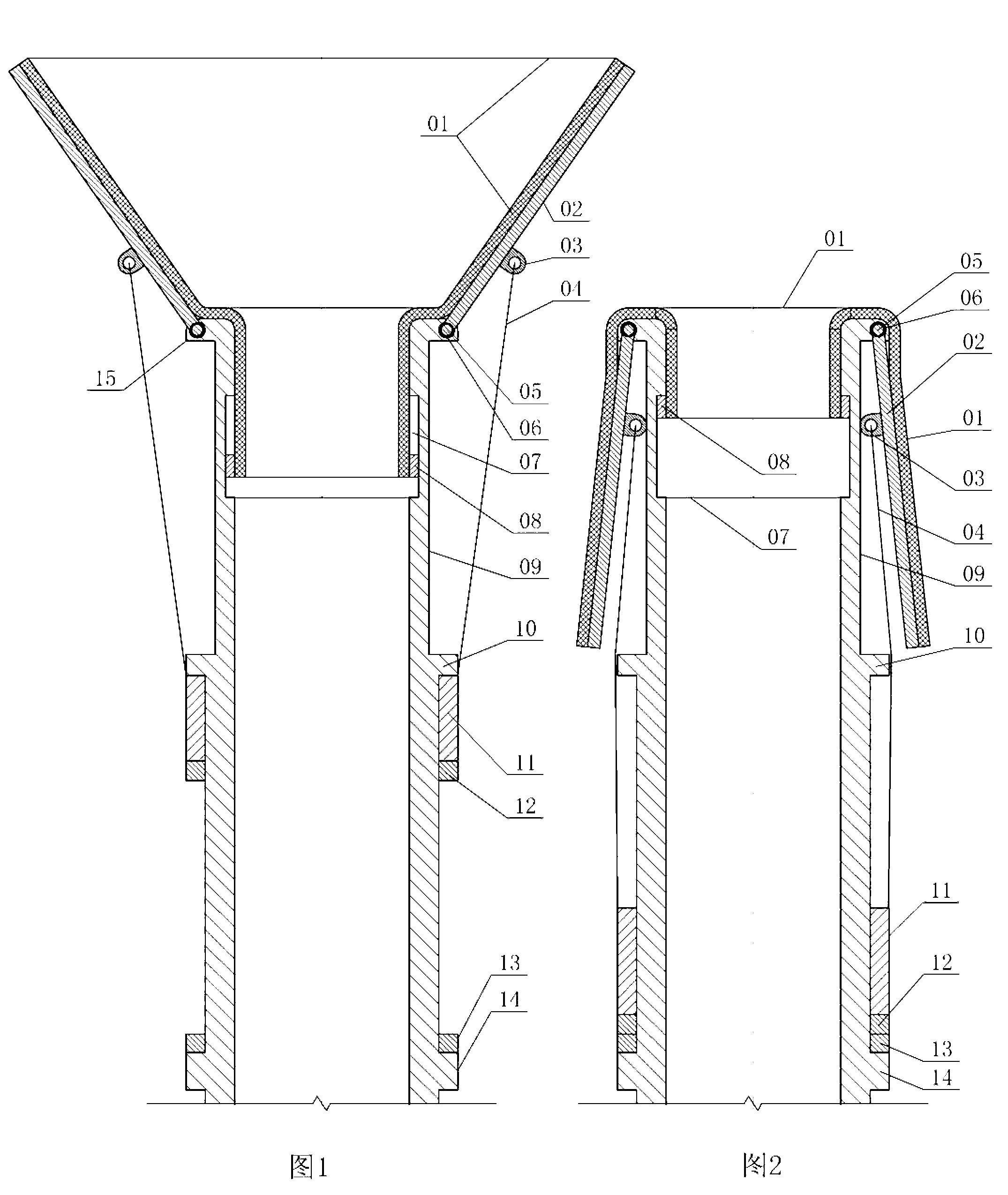

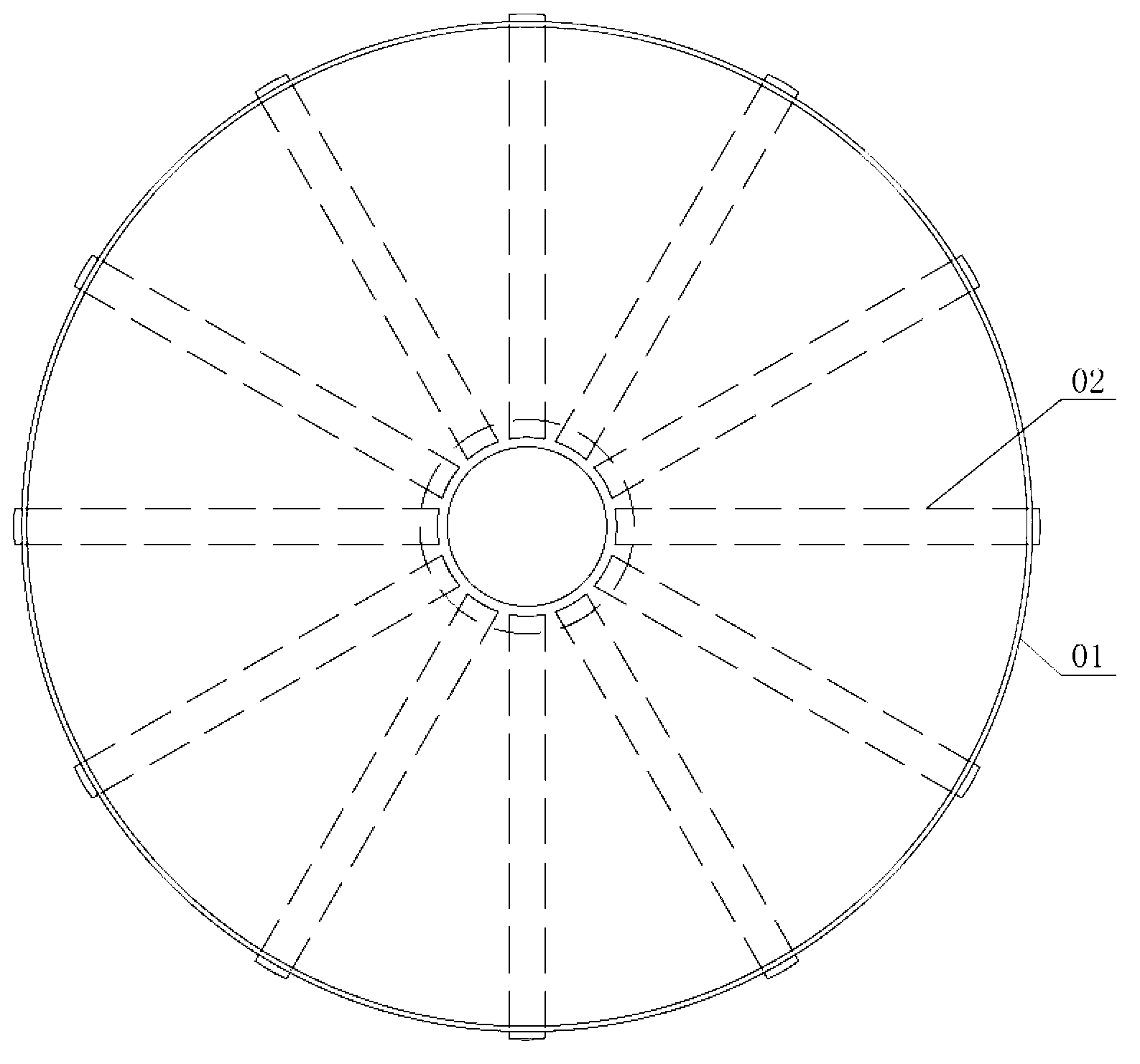

[0017] Motor vehicle semi-automatic timely diversion type cleaning liquid perfusion pipe, composed of diversion film 01, support rib 02, collar 03, stainless steel wire 04, rotating shaft 05, torsion spring 06, chute 07, slip ring 08, pipe body 09, upper limit Bit ring 10, sleeve 11, upper ring magnet 12, lower ring magnet 13, lower positioning ring 14 and shaft frame 15 constitute. Wherein, on the top of the tube body 09 there are a plurality of shaft brackets 15 that are evenly distributed along the circumference of the tube body 09 and integral with the tube body 09, and each shaft bracket 15 is fixed to a horizontally arranged shaft 05 as a whole. The perpendicular bisector of the axis line of each rotating shaft 05 intersects the axis line of the pipe body 09 . On the outer wall of the middle part of the pipe body 09, there is an upper limit ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com