Vertical continuous PCB nickel or gold plating equipment

A PCB board and nickel-plating technology, applied in the field of vertical continuous PCB nickel-plating and gold-plating equipment, can solve the problems of PCB board consistency, poor uniformity, low work efficiency, increased labor costs, etc., to improve consistency and uniformity, ensure Consistency and uniformity, the effect of reducing the difficulty of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

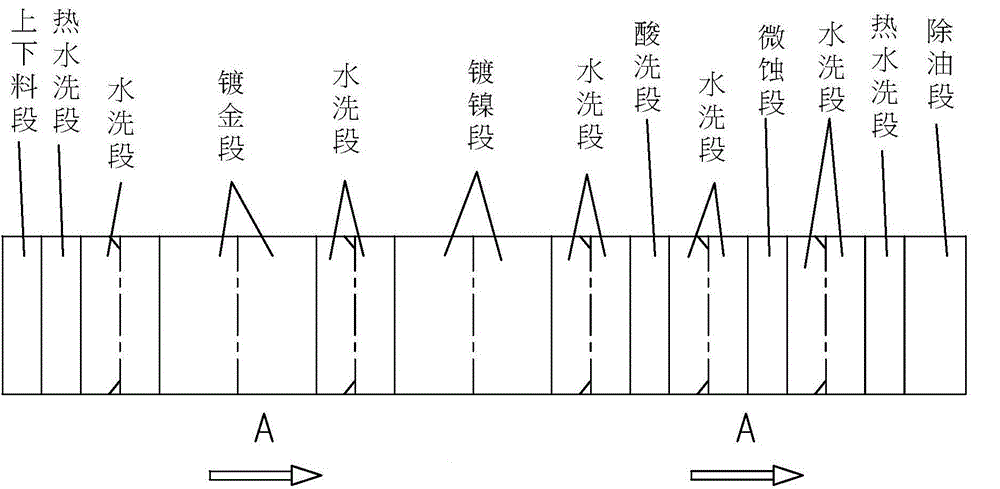

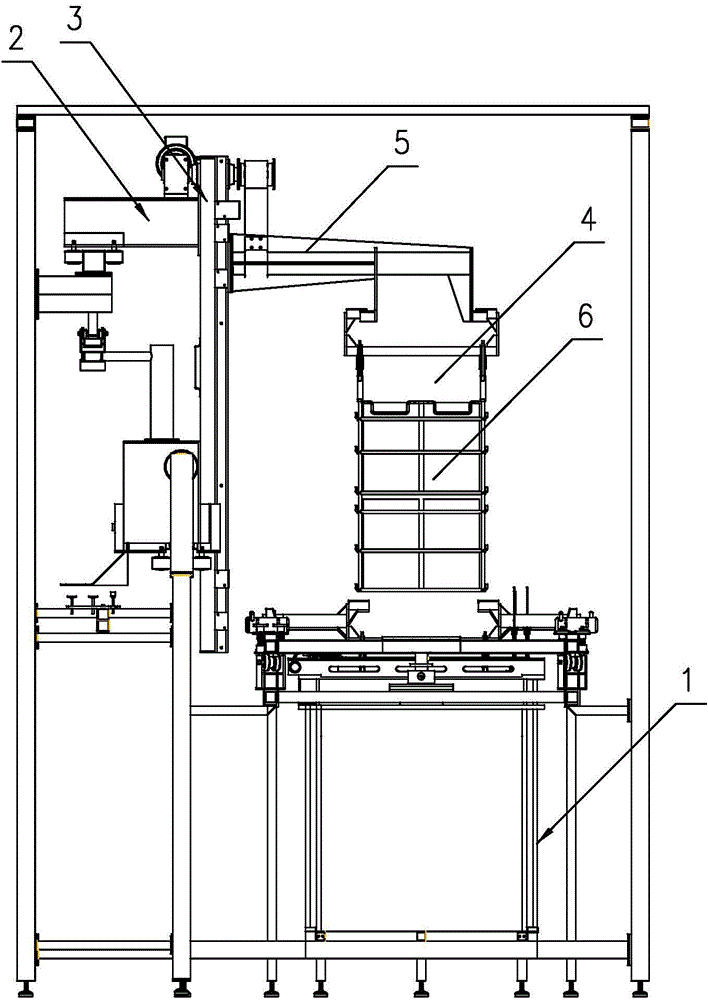

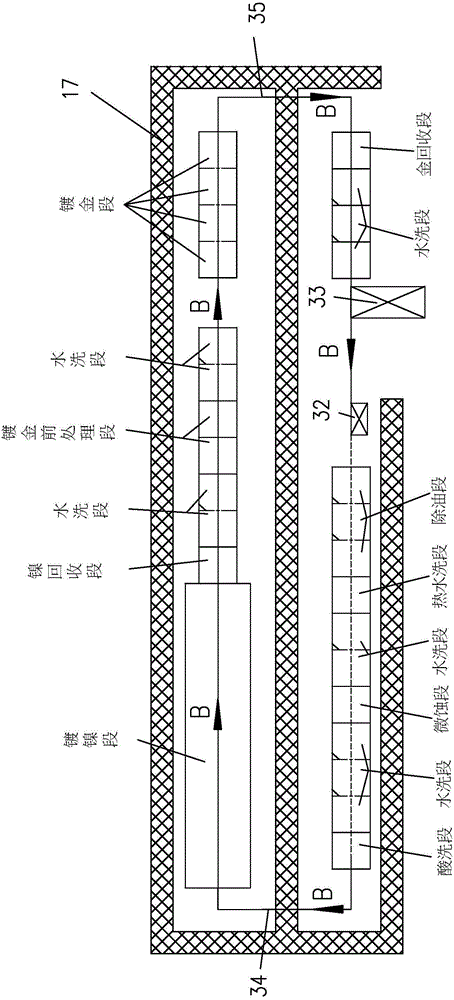

[0039] Such as Figure 3-6 Shown, is a kind of vertical continuous PCB nickel-plated gold-plated equipment of the present invention, comprises electric control device, nickel-plating groove 7, gold-plated groove 8, frame 9, the delivery mechanism that is installed on the frame 9, respectively by several different grooves Nickel plating pretreatment tank, nickel plating posttreatment tank, gold plating pretreatment tank and gold plating posttreatment tank, nickel plating pretreatment tank, nickel plating tank, nickel plating post treatment tank, gold plating pretreatment tank, gold plating tank and gold plating The tanks of the post-processing tank are arranged in sequence according to the process flow. The conveying mechanism is located above each tank. The electronic control device controls the PCB board 10 to be transported to the corresponding processing tank for immersion or lifting one by one. The nickel-plating tank 7 is elongated. Tank body, the length direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com