Intelligent LCM assembly machine

An assembly machine and intelligent technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems of difficulty in ensuring module assembly accuracy, product quality impact, and low assembly efficiency, so as to save the number of operators and improve production assembly efficiency , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

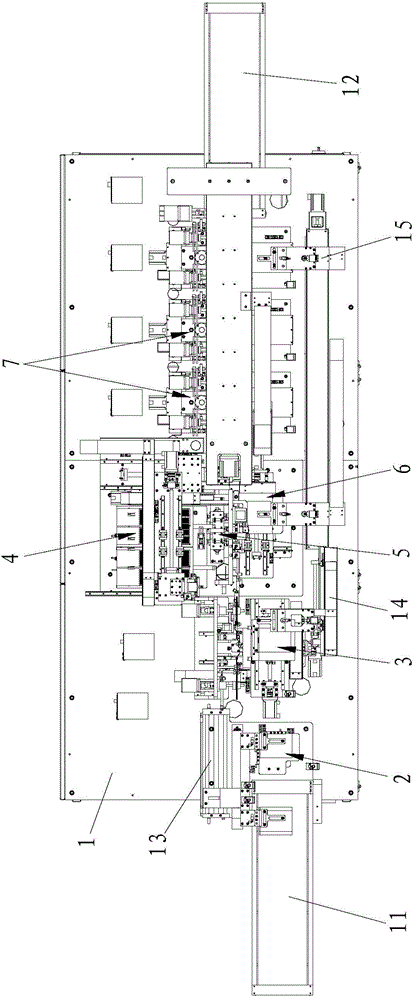

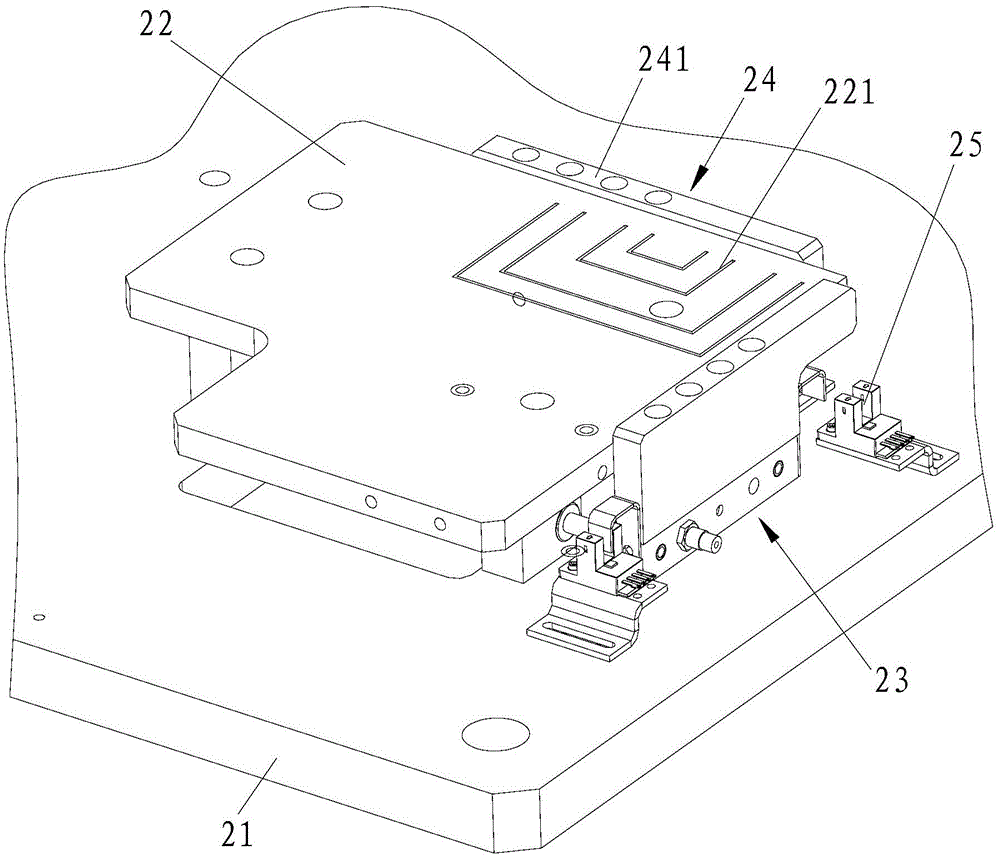

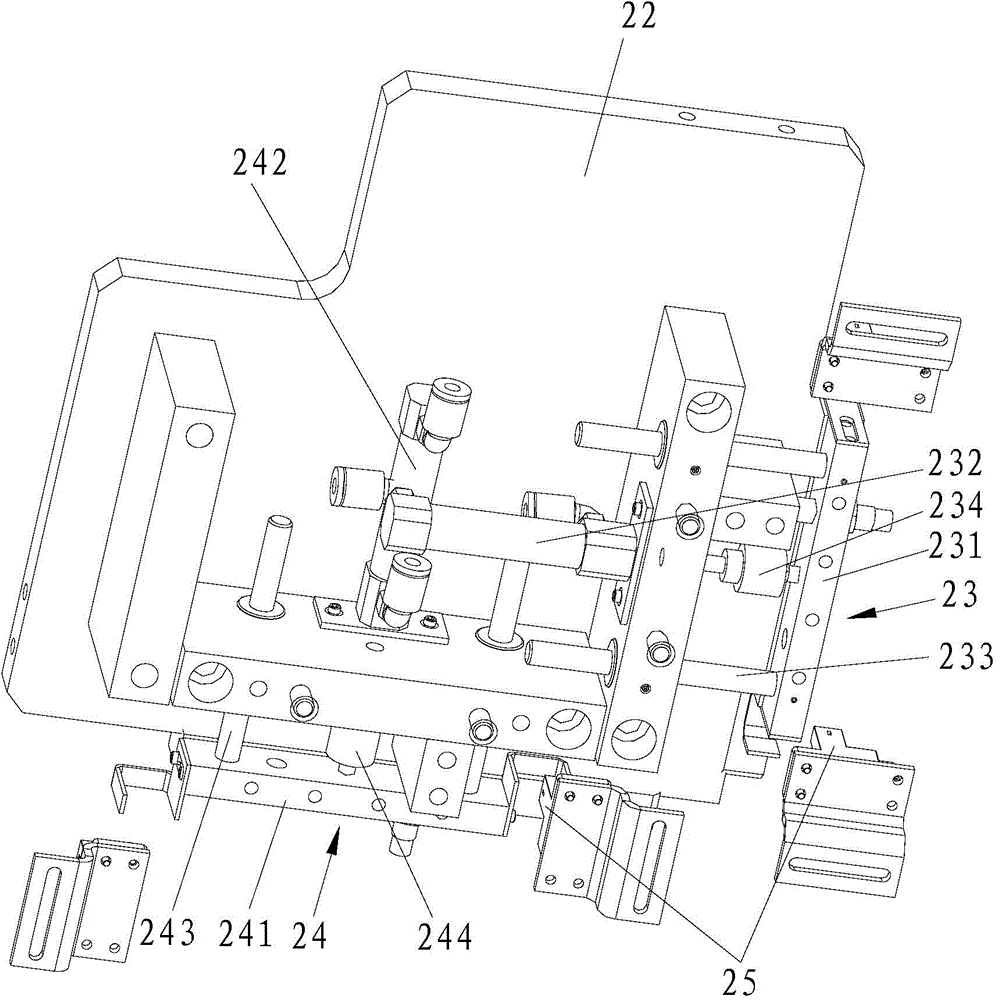

[0035] The present invention will be further described below in conjunction with accompanying drawing and preferred embodiment, see Figure 1-18 As shown, the present invention includes a frame 1, which is characterized in that: the frame 1 is sequentially provided with an LCM module feeding device 11, a feeding automatic correction device 2, an ACF film sticking device 3, an IC pre-set The pressing assembly device, the LCM module pressing device 7, the LCM module unloading device 12, and the frame 1 are provided with a material transfer system for transferring materials between various assembly processes. Both the LCM module loading device 11 and the LCM module unloading device 12 are conveyor belt conveying mechanisms, which are convenient for loading and unloading.

[0036] The material transmission system includes the first material transmission mechanism 13 that moves the LCM module from the LCM module feeding device 11 to the feeding automatic correction device 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com