A 3D assembly process design system and operation method based on cyber-physical fusion

A technology of cyber-physical fusion and assembly technology, which is applied in the field of 3D assembly process design based on cyber-physical fusion, can solve the problems of inability to feedback and process online optimization and adjustment, poor consistency, passive browsing of assembly process files or simulation video animations, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

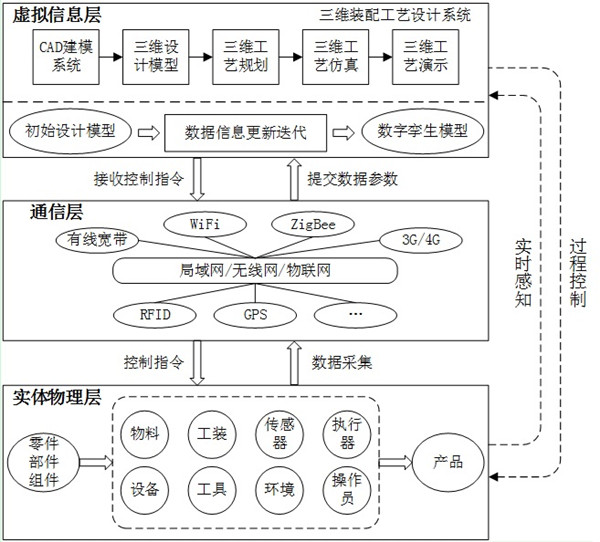

[0029] Embodiment 1: as figure 1 , 2 A 3D assembly process design system based on cyber-physical fusion shown in and 5, the 3D assembly process design system is composed of a three-layer cyber-physical fusion framework, including a physical physical layer, a virtual information layer and a communication layer. The physical physical layer realizes interconnection through the communication layer and the virtual information layer.

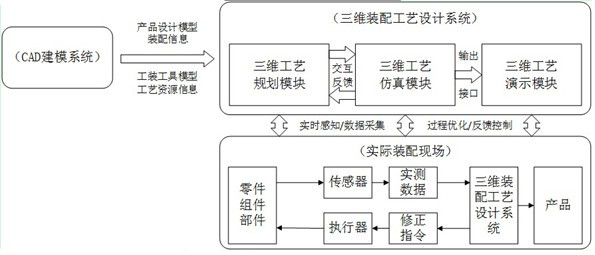

[0030]The entity physical layer mentioned in the present invention refers to the physical entities involved in the actual assembly process of the product, including parts, components, parts, materials, equipment, tooling, tools, sensors, actuators, environment, operators and final assembly Semi-finished products or finished products; the virtual information layer refers to the three-dimensional assembly process design system software platform that realizes the virtual assembly process of the product, including a CAD modeling system, a three-dimension...

Embodiment 2

[0031] Embodiment 2: as figure 1 , 2 A three-dimensional assembly process design method based on cyber-physical fusion shown in and 5 is mainly supported by the three-layer framework structure of the product assembly cyber-physical fusion system, that is, the physical physical layer, the virtual information layer and the communication layer, which are suitable for 3D assembly process design and field application for the actual assembly process of products.

[0032] In the virtual information layer, virtual assembly design models (including product design models, tooling tool models, etc.) can be created according to the CAD modeling system, imported into the virtual assembly 3D process design system to plan each assembly process, and enter the product assembly 3D model as needed The process simulation module simulates the assembly process of this process;

[0033] In the physical physical layer, according to the product assembly 3D process design and the actual assembly proc...

Embodiment 3

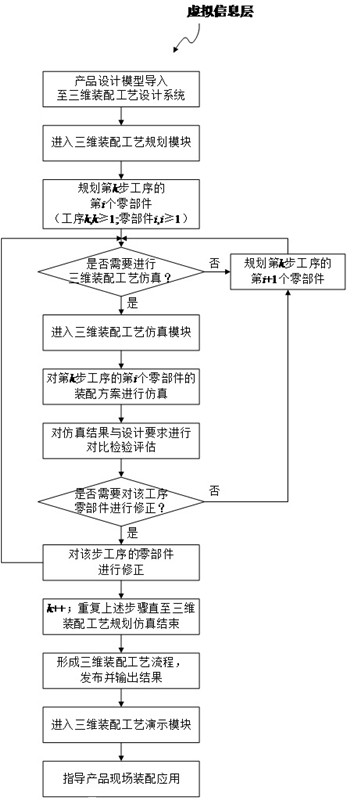

[0035] Embodiment 3: as figure 1 , 2 , 3, 4 and 5 show a kind of operation method of the three-dimensional assembly process design system based on cyber-physical fusion provided by the present invention, and the operation method includes the following steps:

[0036] 1) if image 3 As shown, the product assembly design model file is imported into the virtual information layer, and the product assembly information model is created by extracting the product hierarchy, geometric information and labeling information of parts, components, and components.

[0037] 2) Carry out three-dimensional process planning according to the assembly technical documents of the product, the assembly hierarchical relationship and the assembly process knowledge base, determine the operation content, operation sequence, operation mode and process resource information of a certain process k, and compile the assembly information of this process The model mapping is the assembly process model of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com