Aluminium alloy door and window prefabricating device

A technology of aluminum alloy doors and windows placed horizontally, applied in the direction of assembly machines, manufacturing tools, metal processing equipment, etc., can solve problems such as long-time high-altitude operations, unstable falls, and dangerous technologies, so as to achieve convenient movement and avoid injuries People, good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

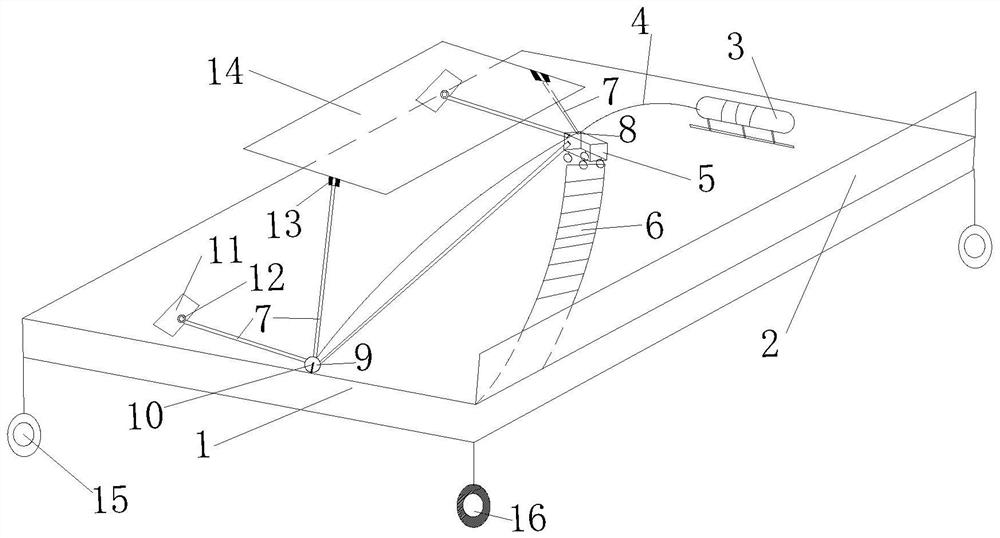

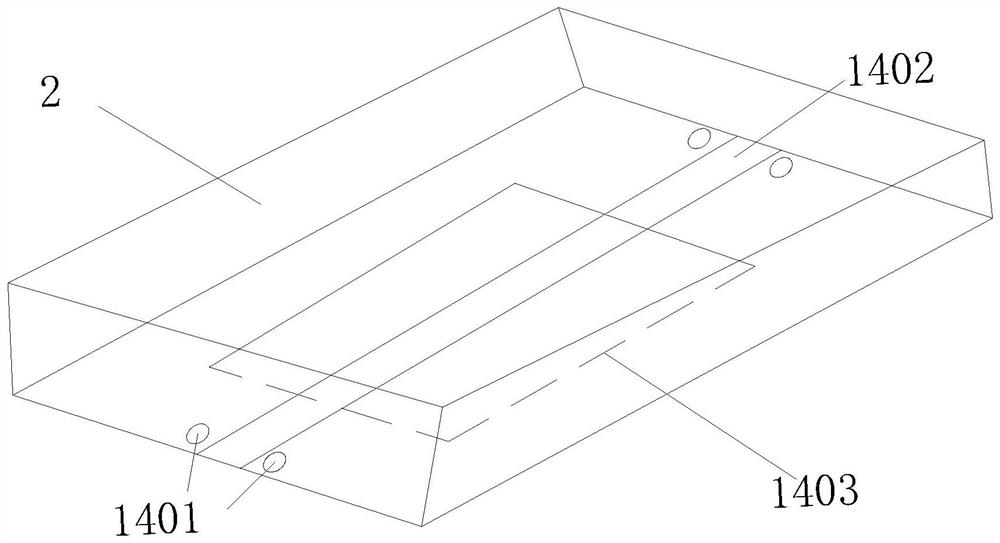

[0038] as attached figure 1 to attach Figure 4 As shown, the present invention provides an aluminum alloy door and window prefabrication device, which includes a support platform 1 , a baffle plate 2 , a rotary drive motor 3 , a rail 6 , a loading groove 7 , and an operating panel 14 .

[0039] A baffle 2 is arranged on the outside of the support platform 1, and the rotary drive motor 3 is fixed on the right side of the support platform 1. The loading groove 7 and the operation panel 14 are loaded on the upper part of the support platform 1, and the support platform 1 is arranged with rails 6 along the diagonal direction. .

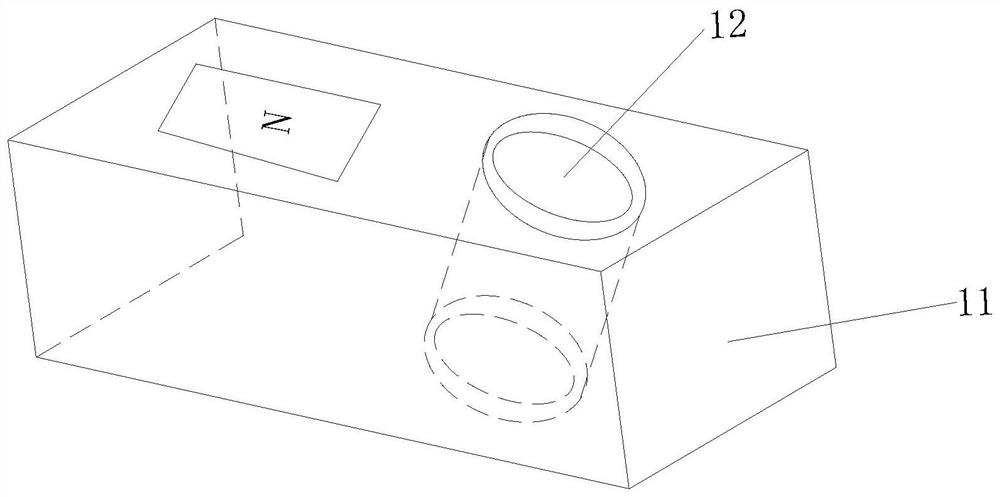

[0040] as attached figure 1 And attached figure 2 As shown, in the above embodiment, specifically, one end of the loading groove (7) away from the side of the rotary drive motor (3) is fixedly connected to the support platform (1) by means of a sphere (9), and the other end is fixedly connected to the support platform (1) by means of a ferrule ( 13)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com