Wheel axle assembly process method

An assembly process and axle technology, applied in assembly machines, metal processing, manufacturing tools, etc., can solve the problems of loose assembly of railway passenger axles, unguaranteed assembly accuracy, low organizational efficiency, etc., to achieve quality assurance, reduce thermal axis , the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

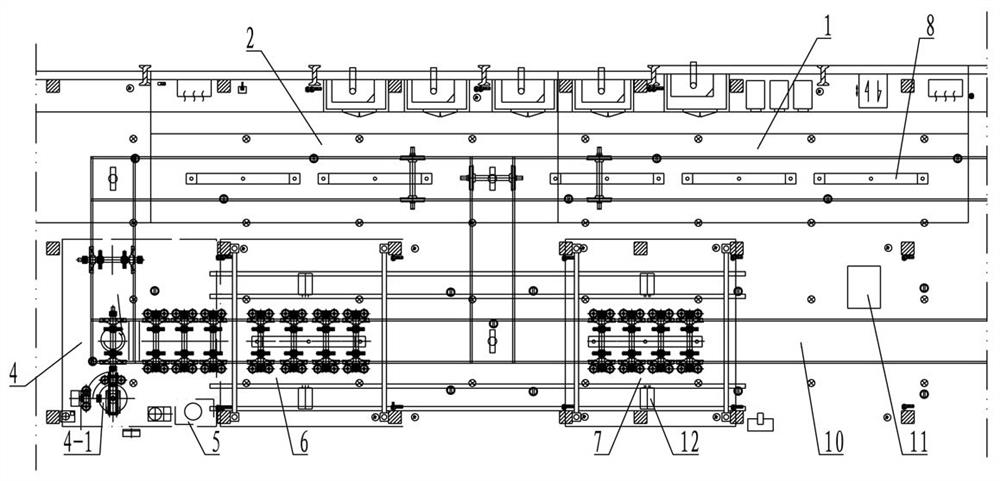

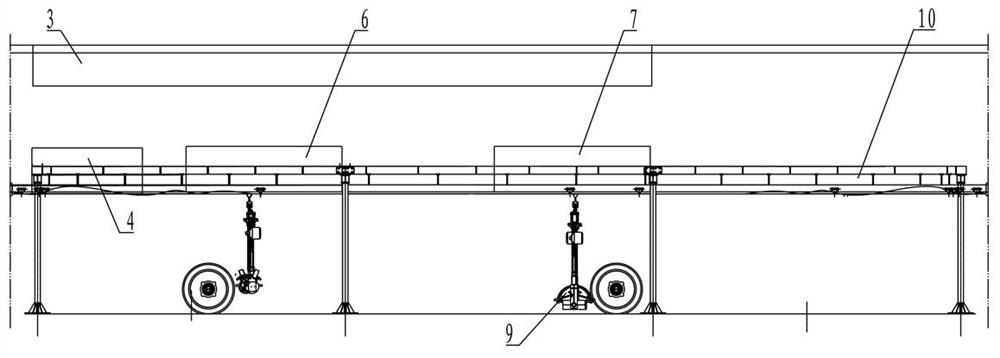

[0017] like figure 1 , figure 2 The shown wheel axle assembly process method includes the use of an integrated wheel axle assembly line for assembly.

[0018] The integrated axle assembly line includes a U-shaped conveying channel 10 for conveying wheel sets, dust-proof retaining ring assembly equipment 1 (including retaining ring drying oven, etc.), bearing inner ring assembly equipment 2 (including bearing inner ring drying oven, etc.) ), the bearing axle box assembly machine 4, the gland assembly equipment 6 (including the shaft end torque trigger, etc.) and the axle box cover assembly equipment 7 (including the front cover torque trigger, etc.) are all arranged on the U-shaped conveying channel 10 in sequence, The U-shaped conveying channel 10 is provided with a grease injection machine 5 on one side of the bearing shaft box assembly machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com