A high-precision workpiece component and an assembly method of the high-precision workpiece component

An assembly method and high-precision technology, applied in the field of assembly of high-precision workpiece components and high-precision workpiece components, can solve problems such as prolonging the assembly cycle, affecting production efficiency, reducing yield, etc., achieving simple and clear principles, optimizing the assembly process, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0098] In this example, W 1 =15,W 2 = 10mm, W 3 = 4mm, W 4 =100.

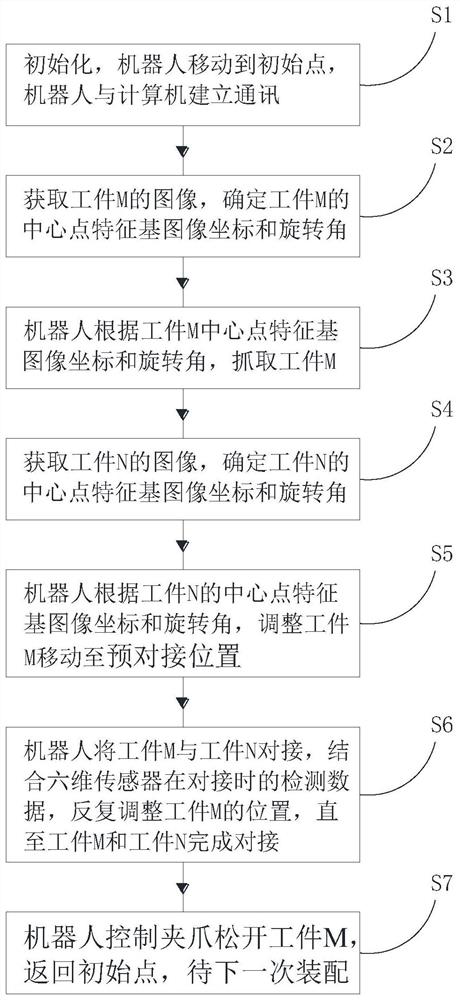

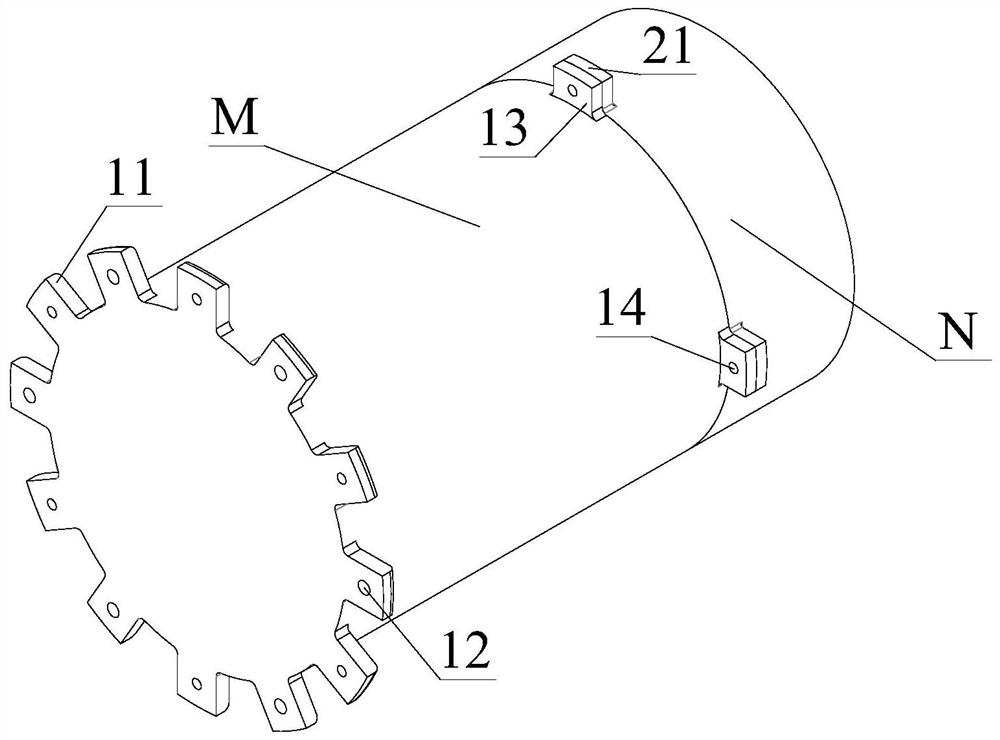

[0099] from figure 1 It can be seen that an assembly method of a high-precision workpiece assembly includes a workpiece assembly, the workpiece assembly includes a workpiece M and a workpiece N, and the workpiece M and workpiece N are assembled according to the following steps:

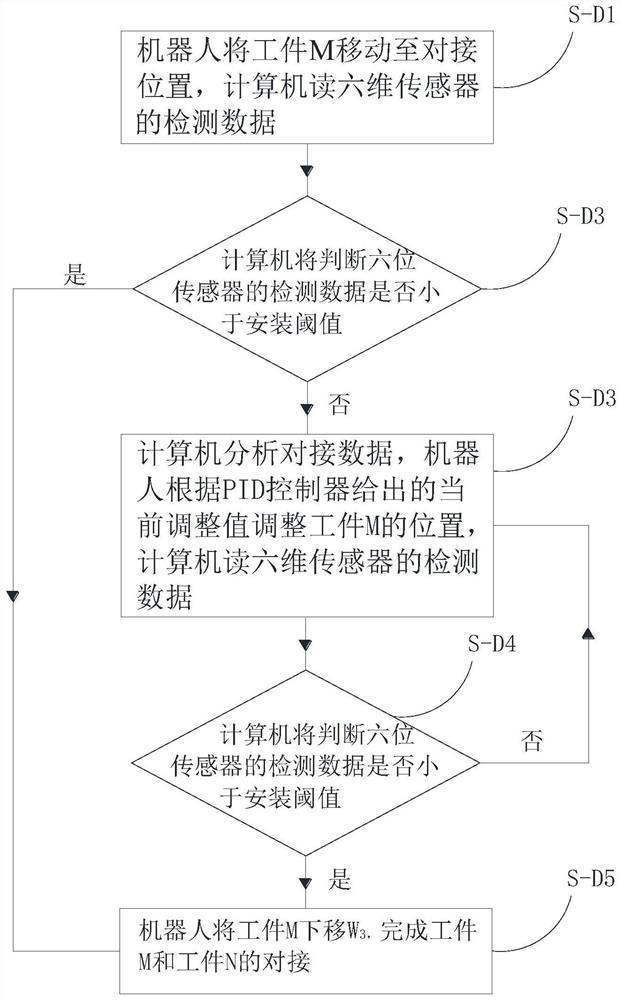

[0100] Preprocessing: place the workpiece M on the tooling to be grasped, and place the workpiece N on the docking tooling; install the image collector and the six-dimensional sensor on the robot, and set the image collector to take pictures of the workpiece M and workpiece N respectively point; set the alignment position and grasping position of the robot jaws to the workpiece M in the computer, set the pre-docking position and docking position of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com