Rail pulling and aligning device

A sliding mechanism, longitudinal technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of complicated operation and low efficiency, and achieve the effect of flexible operation, reliable performance and reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

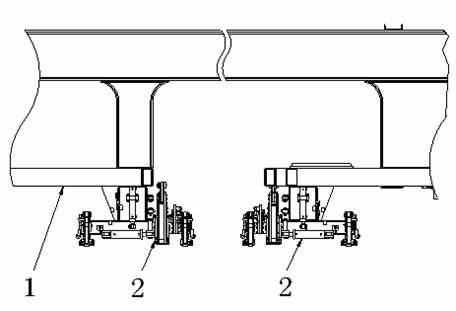

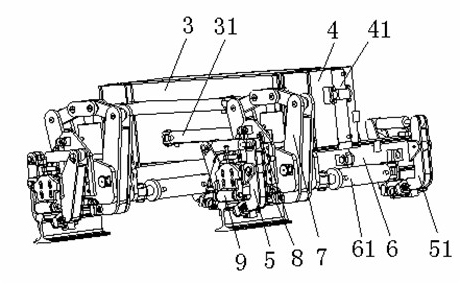

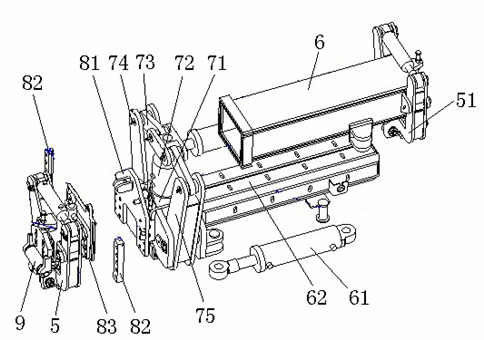

[0022] The rail alignment device 2 provided by the present invention is respectively installed at the front and rear positions of the vehicle frame 1 during use, and two sets are installed in total, as figure 1 , each set includes a lateral sliding mechanism 3 fixed on the vehicle frame 1, the lateral sliding mechanism 3 is formed by socketing the inner and outer sleeves, and an oil cylinder 31 is installed on the outer sleeve, the piston rod of the oil cylinder 31 is connected to the The inner sleeves are connected to complete the lateral sliding under the drive of the oil cylinder 31. The two sides of the lateral sliding mechanism 3 are respectively fixed with the vertical sliding mechanism 4. The vertical sliding mechanism 4 is formed by socketing the inner and outer casings. And an oil cylinder 41 is installed on the outer casing, the piston rod of the oil cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com