Aluminum alloy hub visual identification system

An aluminum alloy wheel hub and visual recognition technology, applied in the field of visual recognition systems, can solve problems such as setting errors, low work efficiency, and heavy labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

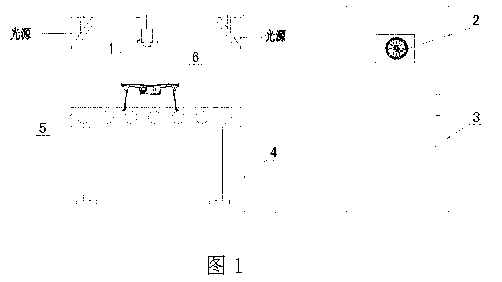

[0007] Depend on figure 1 As known, the aluminum alloy wheel hub visual recognition system includes a camera 1, an integrated control box 3 and an overall frame 5, a camera 1 is arranged on the upper part of the overall frame 5, and a wheel hub 6 is arranged on the middle working table, and the integrated control box 3 is controlled by a monitor 2, Composed of a controller and an operator, the integrated control box 3 is connected to the overall frame 5 through a communication control line 4, the camera 1 takes pictures to extract wheel hub characteristic data, and feeds back to the controller to automatically adjust the parameters of the processing equipment.

[0008] The invention changes the original manual recognition of the wheel hub into machine vision recognition of the wheel hub, and changes the original manual operation into automatic operation. The hub 6 feeds the material into the material inlet, and the camera 1 takes pictures to extract the data and transmits it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com