Monitoring and control system for commodity loading

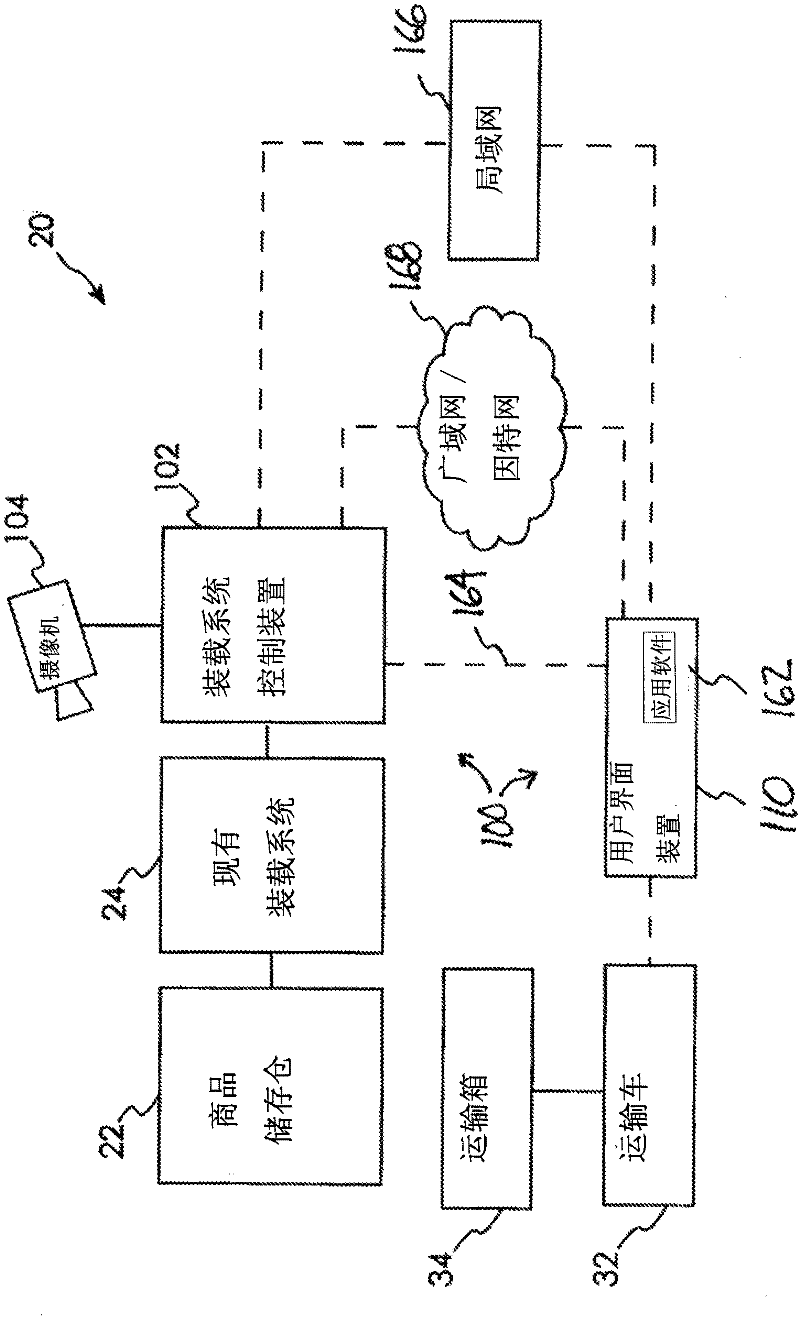

A technology for loading systems and commodities, applied in the directions of loading/unloading, CCTV systems, components of TV systems, etc., can solve problems such as reducing the quality of commodities to be loaded, prolonging loading time, increasing risks, etc., to overcome health problems, improve Efficiency and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

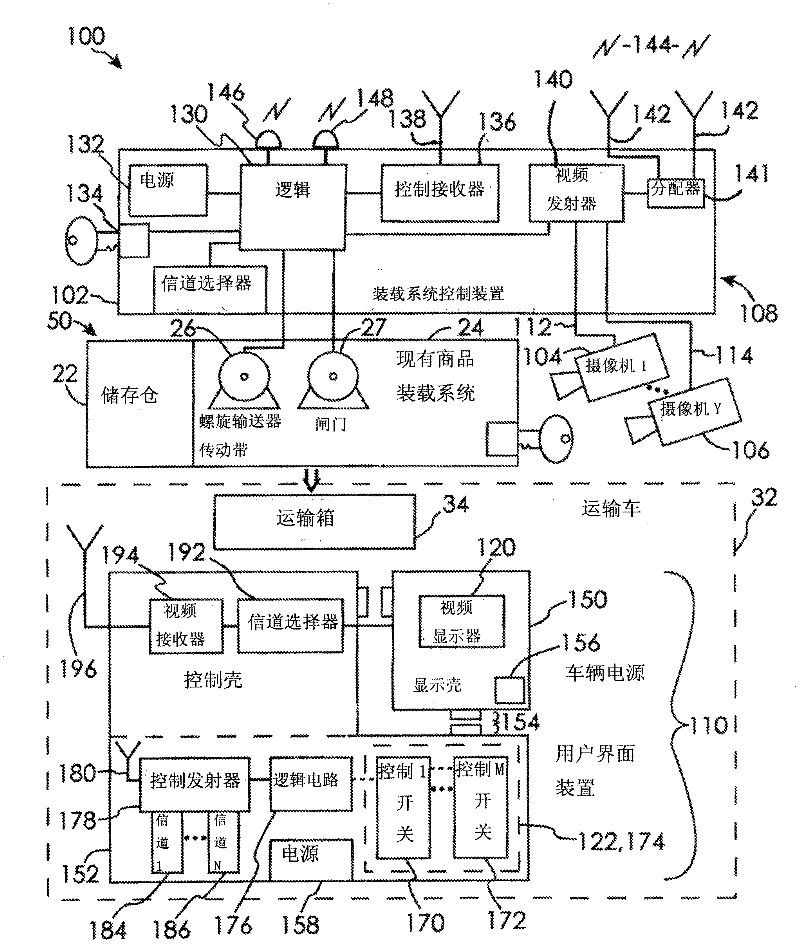

[0022] For the purposes of developing and understanding the invention, detailed language will now be used to describe the same by reference to one or more illustrative embodiments shown in the drawings.

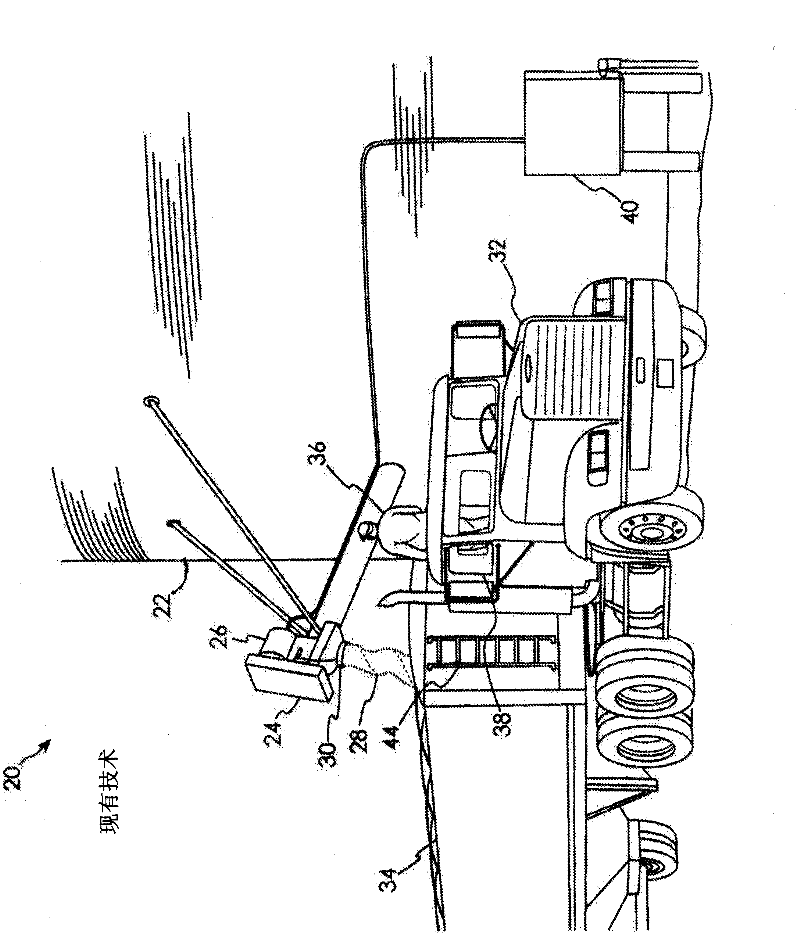

[0023] refer to image 3 , a typical prior art commodity storage and loading device 20, including a storage bin 22, a loading system 24, a transmission device 26 for controlling the flow of commodities 28, and a commodity discharge port 30. The merchandise discharge port 28 is generally located above the open area where the transport cart 32 with the transport case 34 is located, allowing the transport case to be filled with merchandise 28 . The loading system 24 generally includes an existing control box 40 with components such as the power supply system and motor and / or door controllers such as starters, relay switches or PLCs. The operator 36 typically must leave the vehicle cab 38 and open the loading system 24 at the control box 40 to control the drives for opening / clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com