Non-alveolar splicing stator of servo motor and assembly process of non-alveolar splicing stator

A servo motor and assembly process technology, applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the cost of stator molds, material costs, high production stamping costs, operators cannot effectively control wiring consistency, Problems such as long dipping process cycle, to achieve the effect of improving efficiency, ensuring product consistency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

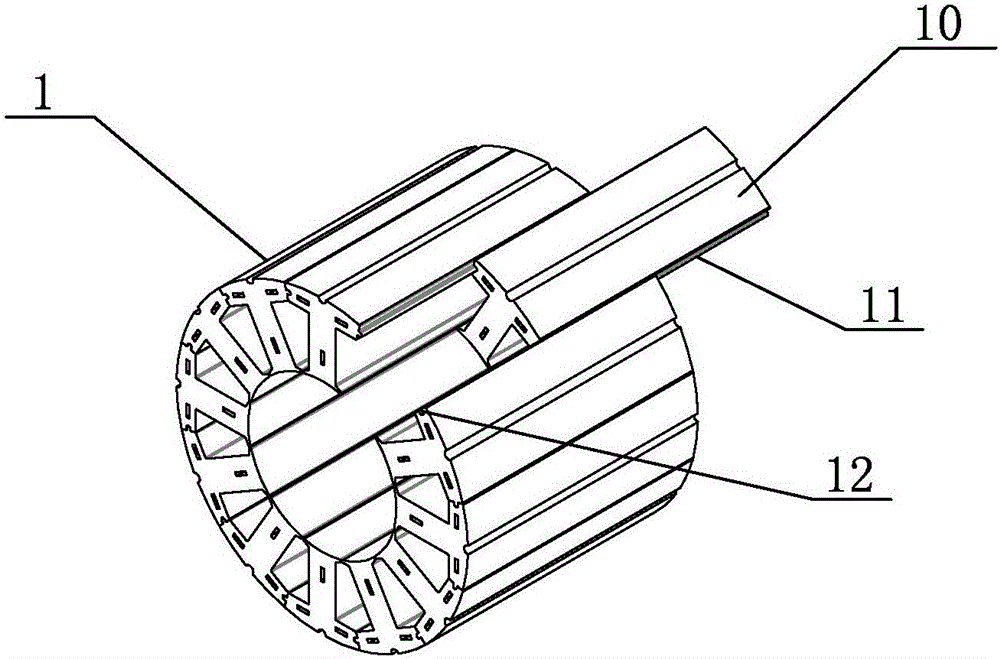

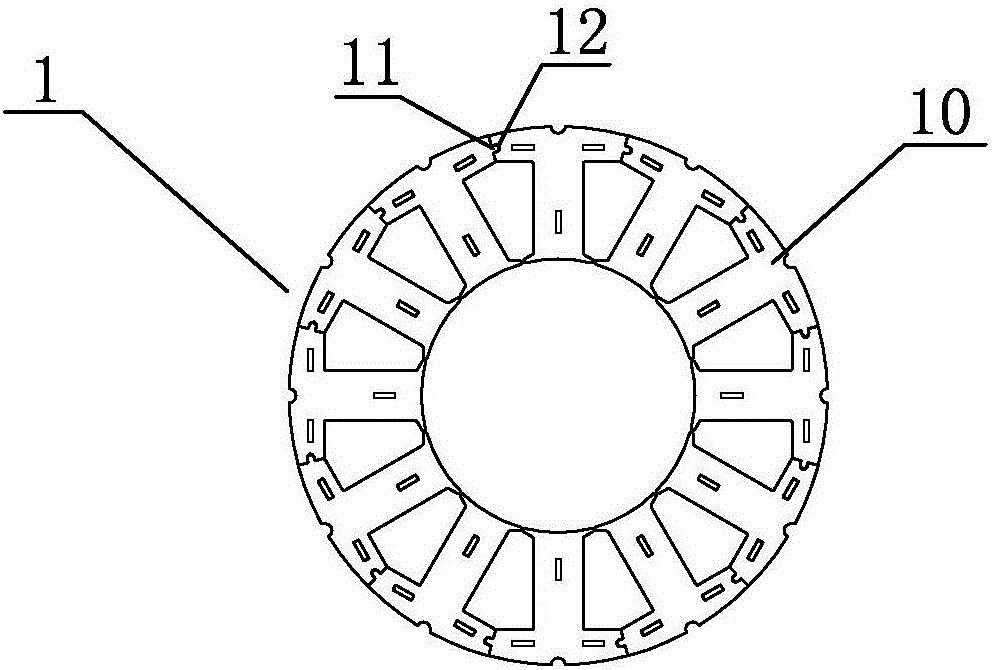

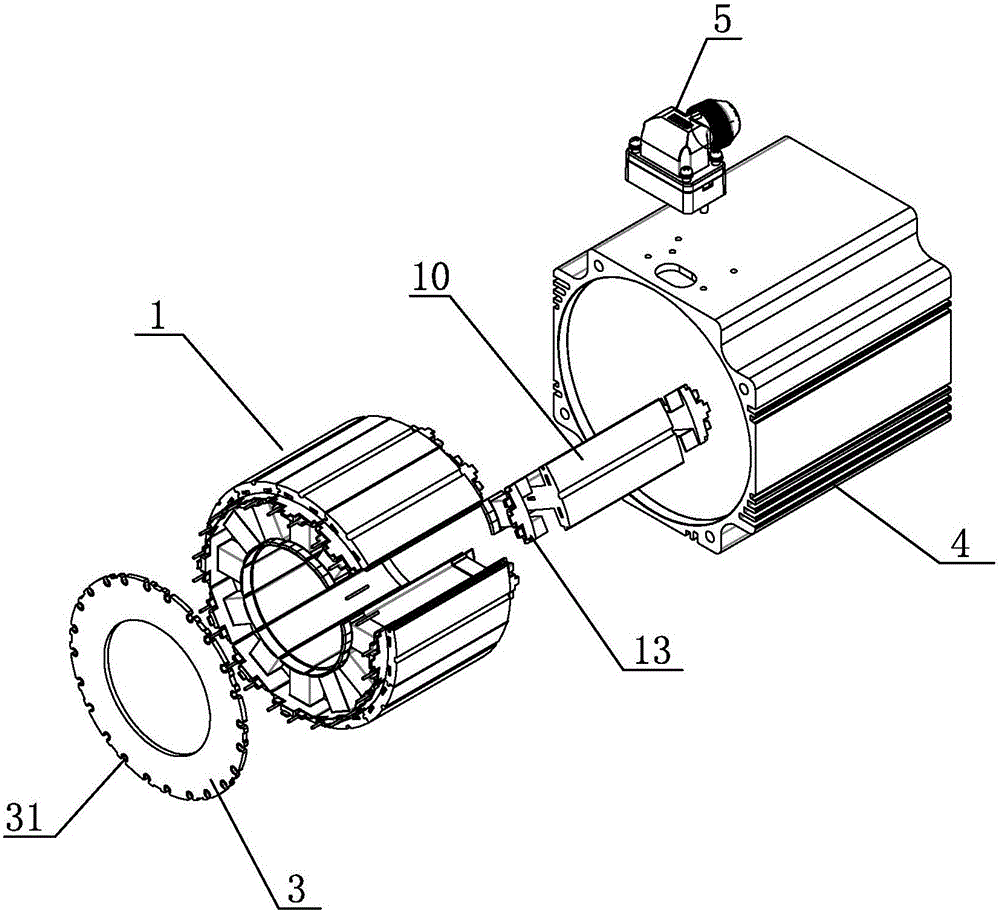

[0043] refer to Figure 1 to Figure 5 , the preferred embodiment provided by the present invention, a slotless assembled stator of a servo motor includes a motor casing 4 , a stator body 1 , a coil 2 and a PCB board 3 . The coil 2 is wound on the stator main body 1 , the PCB board 3 is fixed on one end of the stator main body 1 , and the stator main body 1 is installed in the motor casing 4 . An aviation connector 5 is also arranged outside the motor casing 4 .

[0044] The stator main body 1 is assembled from twelve T-shaped stator groups 10, and the angle between adjacent stator groups 10 is 30°. Corresponding ribs 11 and grooves 12 are respectively provided on the bonding surfaces of adjacent stator groups 10, and the stator groups 10 are assembled into a circular stator body 1 through self-riveting of the ribs 11 and grooves 12, Effectively control the verticality, parallelism and riveting force of the stator group 10. Coils 2 are respectively wound on the stator group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com