Permanent magnet motor stator and multi-parallel-soft-winding transposition coil inserting method

A technology for permanent magnet motors and stators, which is applied in the direction of windings, electric components, winding insulation materials, etc. It can solve the problems of increased temperature rise of motor windings, increased vibration noise, and magnetic field differences, so as to reduce the difficulty of winding, reduce circulation, The effect of reducing imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

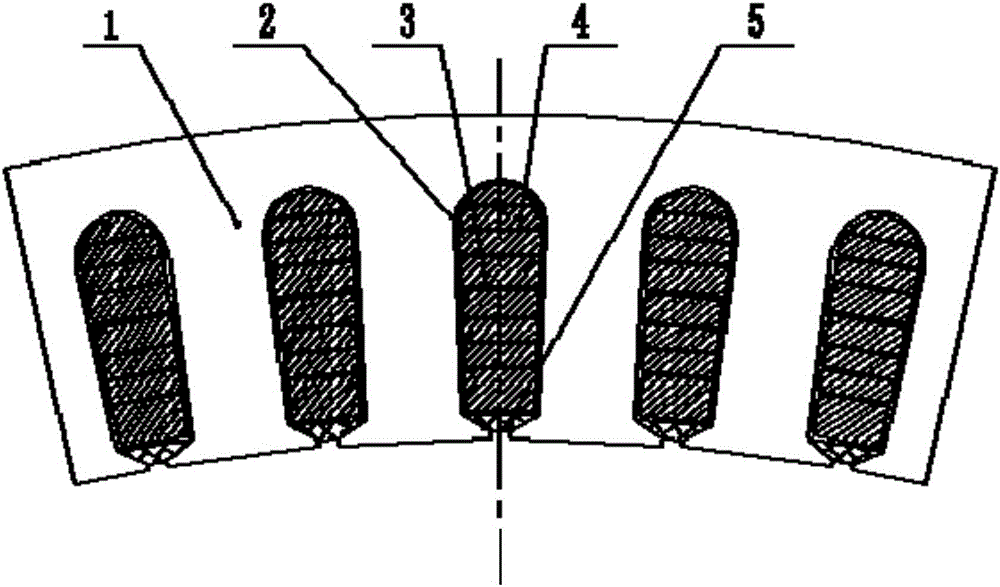

[0026] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

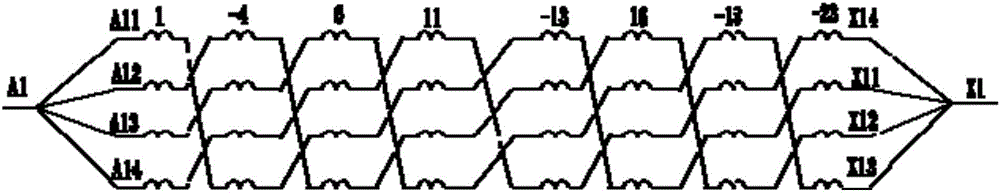

[0027] The embodiment provided by the present invention provides a method for transposing and embedding wires of a plurality of parallel winding soft windings of a permanent magnet motor stator, which specifically includes the following steps:

[0028] Step 1, set the number of windings per turn of the stator as N enameled wires, divide the N enameled wires into M groups; number the M groups of coils from 1 to M, and in step 1, divide the N enameled wires into M groups on average ; If it cannot be divided equally, it is divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com