Zinc oxide nanocrystal, preparation method thereof, zinc oxide nanocrystal ink and electro-luminescence device

A technology of zinc oxide nanocrystals and inks, applied in nano optics, electrical solid devices, chemical instruments and methods, etc., can solve problems such as surface defects of zinc oxide nanocrystals, reduce electron mobility, alleviate imbalance problems, The effect of improving electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In another typical embodiment of the present application, a method for preparing the above-mentioned zinc oxide nanocrystals is provided. The preparation method includes: step S1, preparing a solution of initial zinc oxide nanocrystals by a solution method, and the initial zinc oxide nanocrystals Carboxylate surface ligands; step S2, reacting the solution with a sulfur precursor at 50-200°C to form zinc oxide nanocrystals, the sulfur precursor being S Solution, wherein, R1, R2 and R3 are each independently selected from C 1~10 Any one of the alkyl groups, and the pH value of the reaction system is controlled between 7 and 10 during the reaction

[0028] Using the above method, ligand modification is carried out on the initial zinc oxide nanocrystals with carboxylate surface ligands prepared by the solution method of the prior art, and the sulfur precursor S is utilized solution (i.e. sulfur dissolved in solution) reacts with zinc ions on the surface to form a layer...

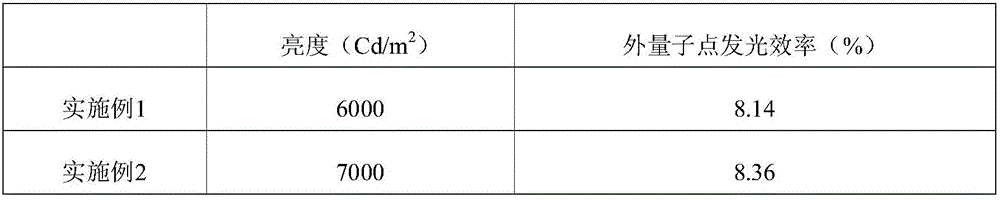

Embodiment 1

[0044] Synthesis of initial ZnO nanocrystals:

[0045] Preparation of solution A: Add 3 mmol of zinc acetate dihydrate and 30 ml of DMSO (dimethyl sulfoxide) into a 100 ml three-neck flask, heat in a water bath at 30° C. and stir magnetically.

[0046] Prepare solution B: take another small beaker, add 5mmolTMAH (tetramethylammonium hydroxide) and 10ml ethanol, shake well and mix well, then seal it with a sealing film.

[0047] Add solution B dropwise to solution A (completed in about 10 minutes), then continue magnetic stirring, and stir for 1 hour in a water bath at 30°C.

[0048] Dissolve the initial zinc oxide nanocrystals obtained after purification of the mixed solution after the reaction in ethylene glycol to form an ethylene glycol solution of initial zinc oxide nanocrystals. The specific process is: take 5ml of the mixed solution in a centrifuge tube, add 5ml Ethyl acetate, centrifuge at 3000rpm+3min, pour off the supernatant and add 3ml ethylene glycol to dissolve. ...

Embodiment 2

[0054] The difference from Example 1 is that zinc oxide nanocrystals are prepared: add 10 mmol S-TBP (a solution of sulfur dissolved in tributylphosphine) solution to the ethylene glycol solution of initial zinc oxide nanocrystals and react at 100° C. 30min, the product system containing the zinc oxide nanocrystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com