A quantum dot light-emitting diode and its preparation method

A quantum dot light-emitting and diode technology, which is applied in the manufacture of semiconductor/solid-state devices, organic semiconductor devices, electric solid-state devices, etc., can solve the problems of low luminous efficiency and unbalanced charge injection of quantum dot light-emitting diodes, so as to improve the luminous efficiency, The effect of reducing electron mobility and electron-hole injection rate balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

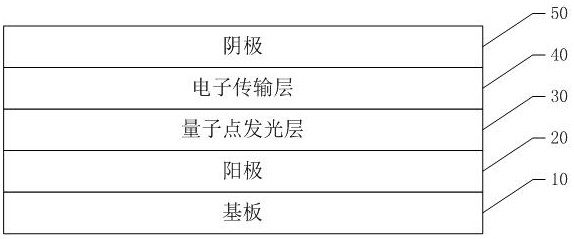

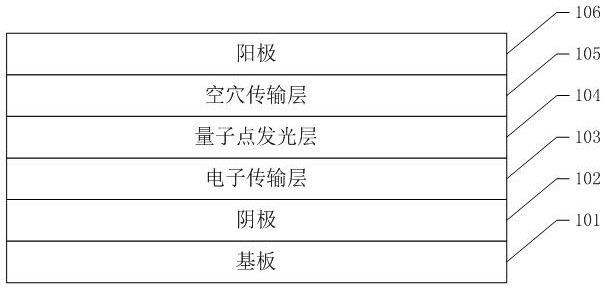

[0060] A quantum dot light-emitting diode, which includes an anode substrate, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer, and a cathode stacked from bottom to top, wherein the material of the electron transport layer is made of the fifth generation PAMAM A hybrid material composed of dendrimers and nano-zinc oxide. The preparation method of the quantum dot light-emitting diode comprises the steps of:

[0061] 1) Preparation of nano-zinc oxide: Disperse 0.5mol of zinc acetate hydrate in 25ml of dimethyl sulfoxide to make it completely dispersed, and disperse 0.55mol of tetramethylammonium hydroxide in 30ml of ethanol to make it completely Disperse, mix and stir the two mixtures at room temperature for 1 hour, and perform centrifugal cleaning to obtain nano-zinc oxide;

[0062] 2) Preparation of colloidal solution: Add 20mg of fifth-generation PAMAM dendrimers and 50mg of nano-zinc oxide into 1ml of ethanol, and mix to prepare a coll...

Embodiment 2

[0069] A quantum dot light-emitting diode, which includes an anode substrate, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer and a cathode stacked from bottom to top, wherein the electron transport layer is made of a second-generation PAMAM tree A hybrid material composed of shape molecules and nano-nickel oxide. The preparation method of the quantum dot light-emitting diode comprises the steps of:

[0070] 1) Preparation of nano-nickel oxide: Disperse 0.5mol of nickel acetate hydrate in 25ml of dimethyl sulfoxide to make it completely dispersed, and disperse 0.55mol of tetramethylammonium hydroxide in 30ml of ethanol to make it completely Disperse, mix and stir the two mixtures at room temperature for 1 hour, and perform centrifugal cleaning to obtain nano-nickel oxide;

[0071] 2) Preparation of colloidal solution: Add 30mg of second-generation PAMAM dendrimers and 70mg of nano-nickel oxide into 1ml of ethanol, and mix to prepare a c...

Embodiment 3

[0078] A quantum dot light-emitting diode, which includes an anode substrate, a hole transport layer, a quantum dot light-emitting layer, an electron transport layer and a cathode stacked from bottom to top, wherein the electron transport layer is made of a first-generation PAMAM tree A hybrid material composed of dendrimers, fourth-generation PAMAM dendrimers and nano-nickel oxide. The preparation method of the quantum dot light-emitting diode comprises the steps of:

[0079] 1) Preparation of nano-nickel oxide: Disperse 0.5mol of nickel acetate hydrate in 25ml of dimethyl sulfoxide to make it completely dispersed, and disperse 0.55mol of tetramethylammonium hydroxide in 30ml of ethanol to make it completely Disperse, mix and stir the two mixtures at room temperature for 1 hour, and perform centrifugal cleaning to obtain nano-nickel oxide;

[0080] 2) Preparation of colloidal solution: Add 10 mg of the first-generation PAMAM dendrimer, 20 mg of the fourth-generation PAMAM de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com