Stator component, motor and compressor

A technology for compressors and components, applied in the direction of electric components, windings, electrical components, etc., can solve the problems of large notch in the stator teeth and large torque ripple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

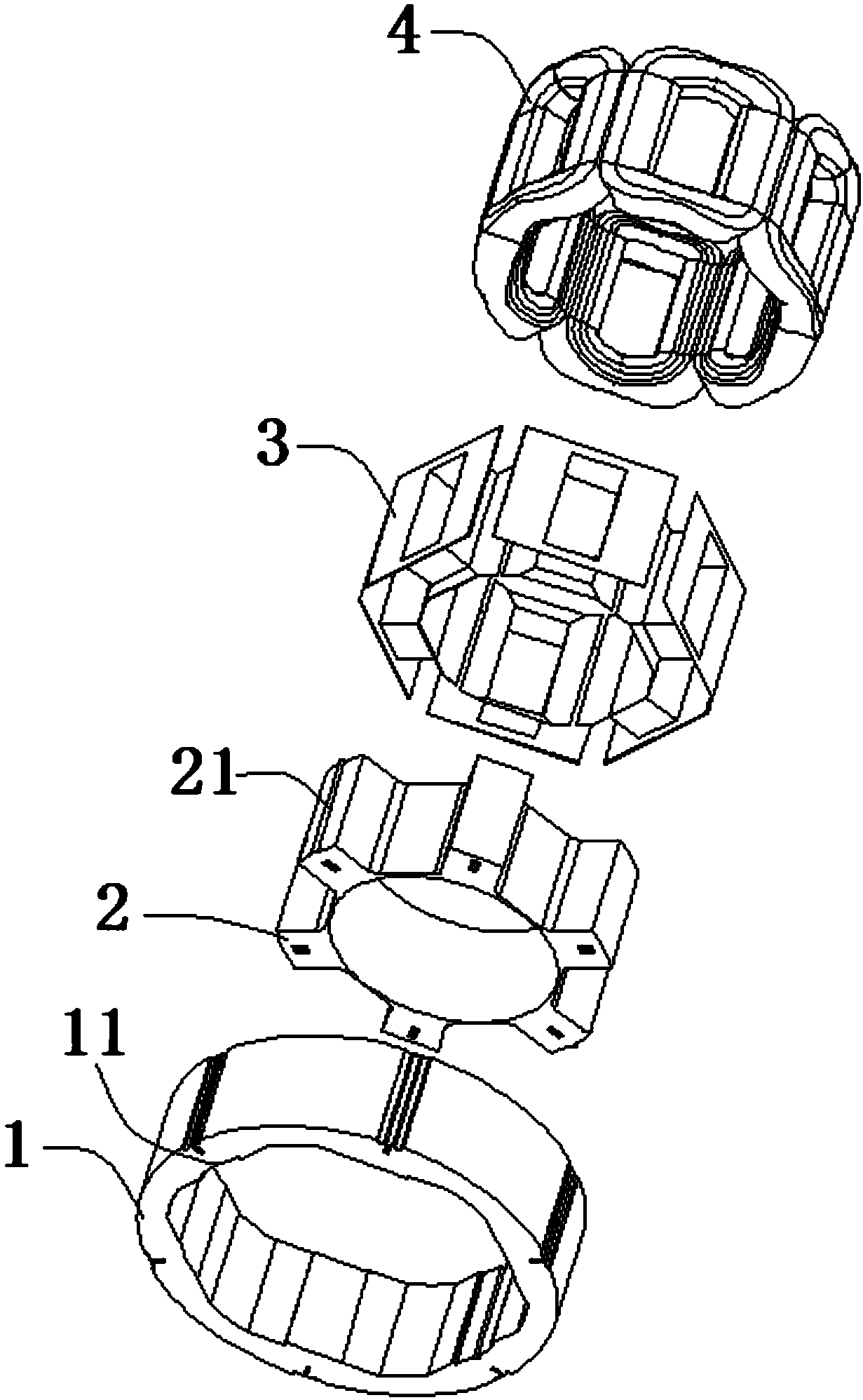

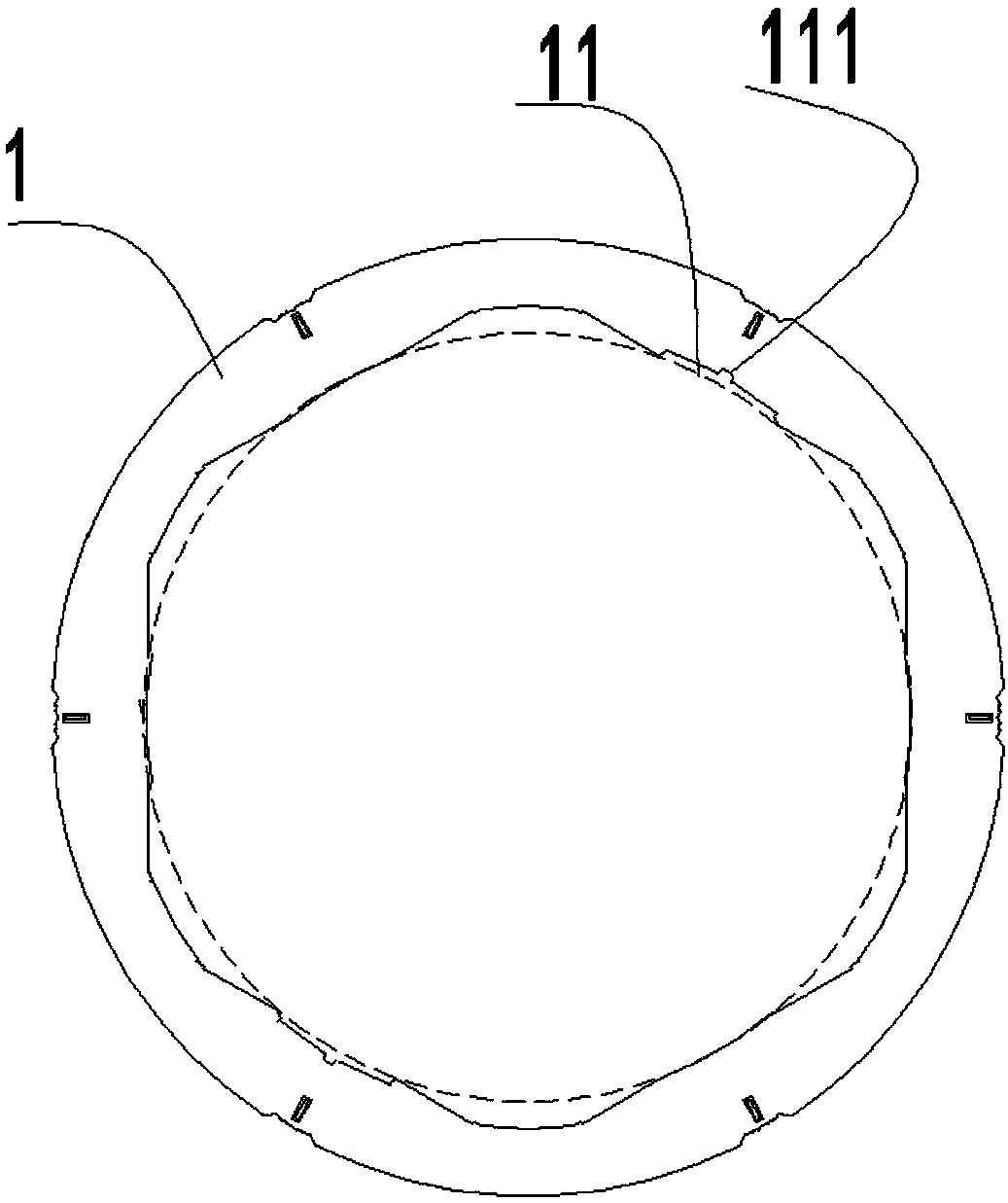

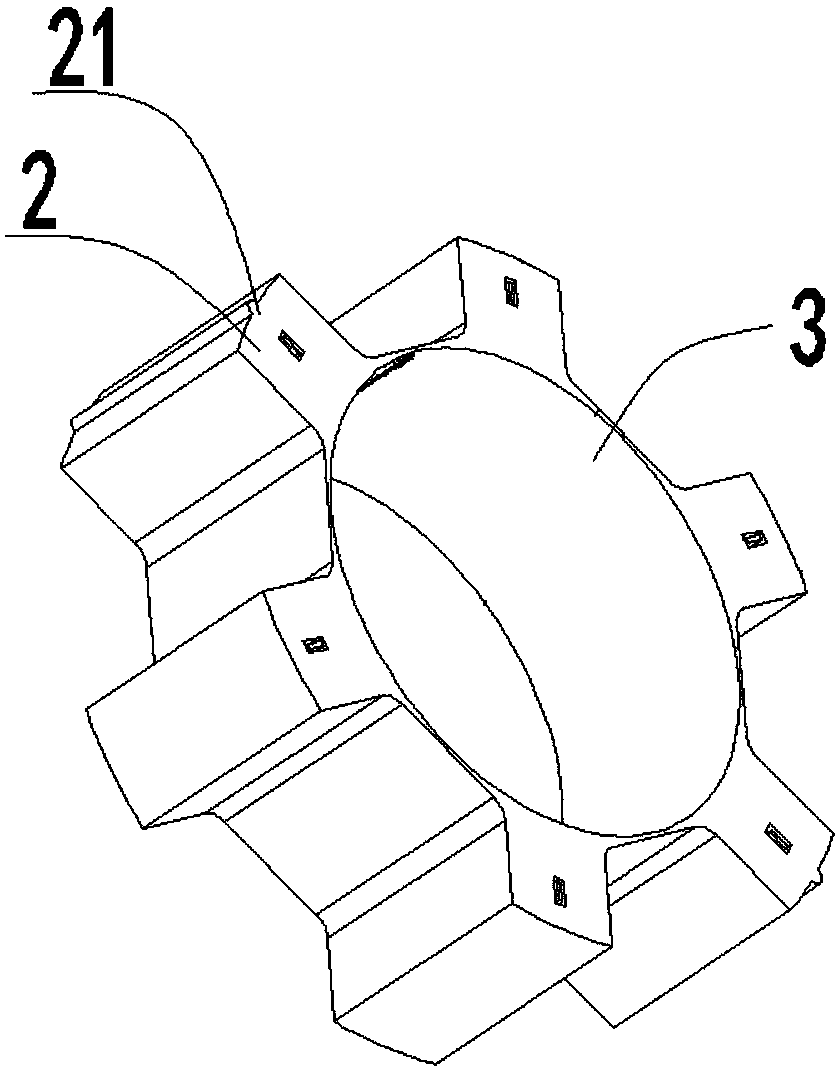

[0031] The present invention provides a stator assembly, wherein the stator assembly includes an annular stator yoke 1 , a connecting ring 3 coaxially arranged in the stator yoke 1 , and the outer periphery of the connecting ring 3 A plurality of stator teeth 2 protruding radially toward the stator yoke 1, the stator teeth 2 are detachably covered with a support sleeve 5, and the support sleeve 5 is provided with The coil 4 of the stator tooth part 2 and the connecting ring 3 can move axially relative to the stator yoke part 1, and the radially outer end of the stator tooth part 2 and the stator yoke part 1 are detachable from each other ground joint.

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com