Patents

Literature

33results about How to "Solve the "winding" problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A preparation method of a high-efficiency N-type double-sided battery with double-sided tunneling oxidation passivation

InactiveCN109216498ARaise VocExcellent selective tunneling effectFinal product manufacturePhotovoltaic energy generationGas phaseSingle crystal

The invention relates to a preparation method of a double-sided tunneling oxidation passivation high-efficient N-type double-sided battery, which comprises the following steps: cutting silicon wafer to remove damage layer for velveting; doping high-temperature vapor phase boron source to form p + emitting junction; growing ultra-thin tunnel oxide layer SiO2 and P-doped polycrystalline silicon layer on the back of the silicon wafer; Frontal tunneling oxidation passivation structure is formed on the p + emitting junction surface by thermal oxidation and polycrystalline deposition. A local heavily dope region is formed on that back side of the silicon wafer by laser doping or wet patterning etch method, and a hydride amorphous silicon nitride passivation antireflection layer is deposited on the front side / back side of the battery. At last, that front and back electrode metallize ohmic contact is formed by screen printing electrode grid line. A metal on that back of the battery is minimizeby the invention. Semiconductor surface recombination can obtain Voc enhancement of about 35mV, and the technology route is compatible with the existing traditional single crystal battery preparationprocess to improve the battery efficiency.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV +1

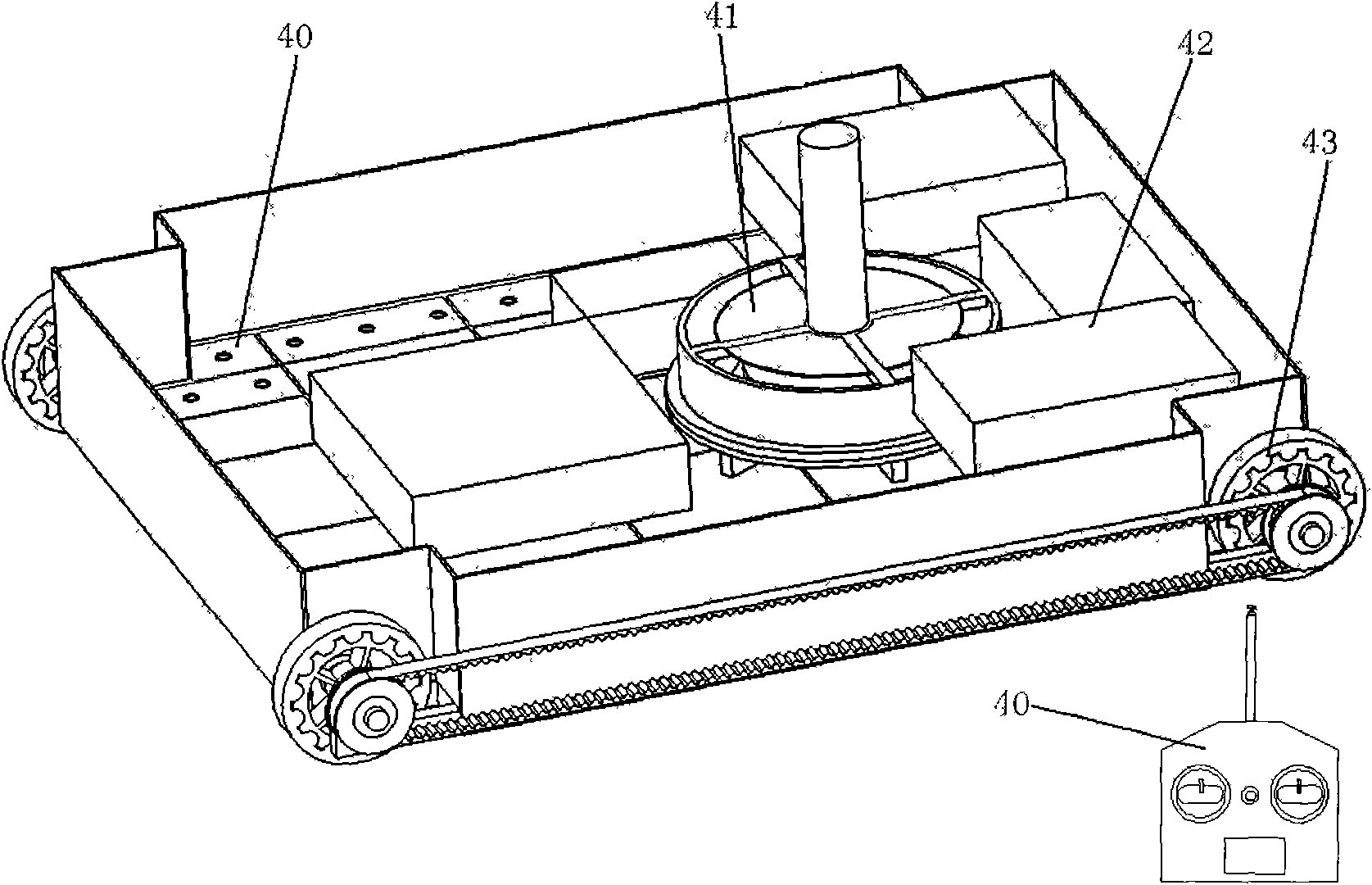

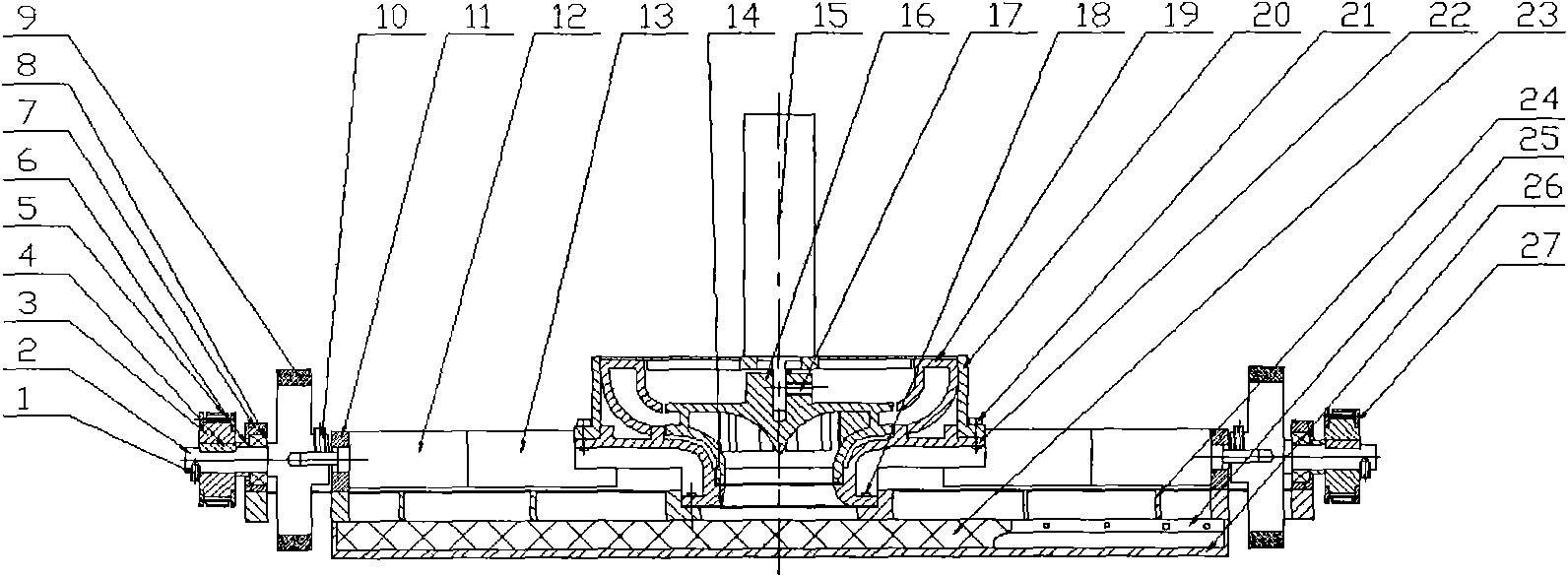

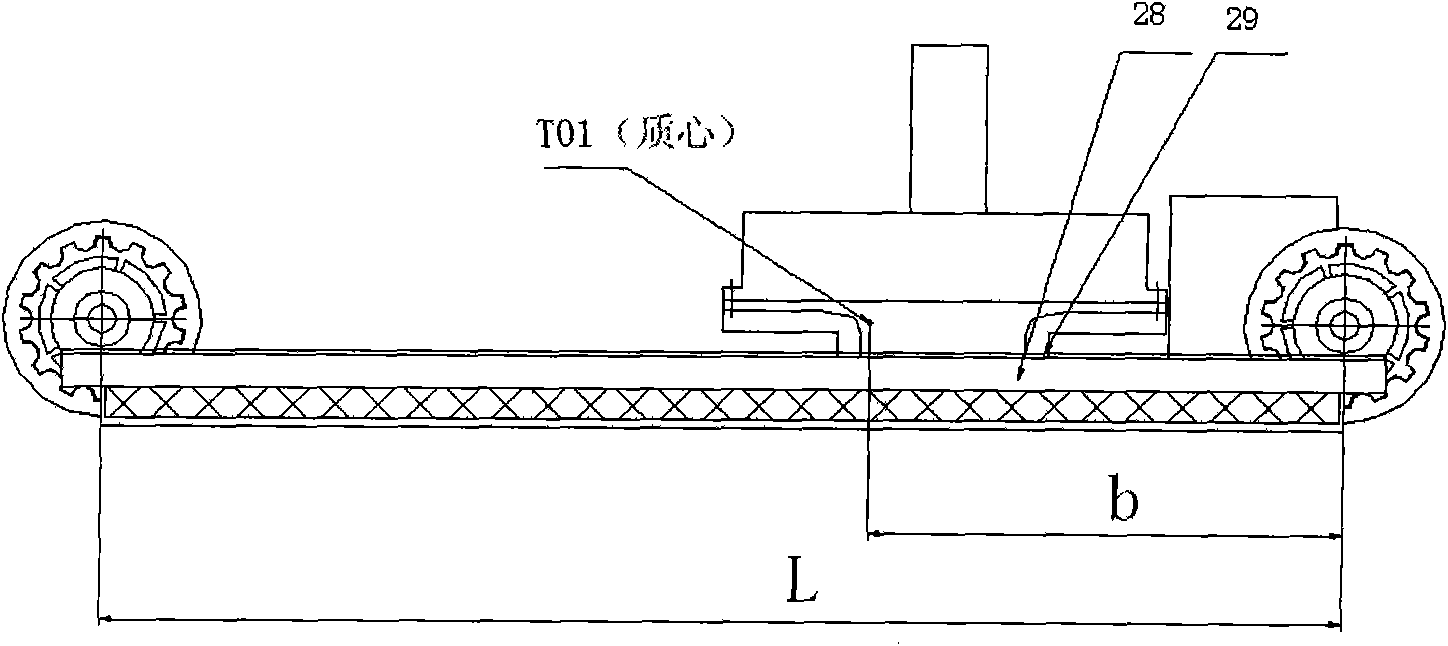

Negative pressure adsorption wall-climbing robot

The invention discloses a negative pressure adsorption wall-climbing robot, which comprises a negative pressure generating device, a control device, a supporting and sealing device and a moving device, wherein the range of the ratio of the distance between a human mass center of the robot and a rear wheel to the span between a front walking wheel and a rear walking wheel is less than or equal to 1 / 3. Two character-shaped maze type clearance seals are adopted between an impeller and a pump body in the negative pressure generating device of the robot. A sealing strip on an edge of a base plate of the robot is fixedly connected to the base plate, and the interior of the sealing strip is filled with sponge. The sealing strip is fixed on the base plate or adhered to the base plate through a mounting press batten, has a seamless integral structure and is made from rainproof silks, and the base plate of the robot is provided with a plurality of ventilation holes. The negative pressure adsorption wall-climbing robot has a simple structure, is small-sized and effective, and has a function of self-realization of switching a ground walking state to a wall-climbing state.

Owner:NANJING UNIV OF SCI & TECH

Bearing ring turning and cutting feed method

InactiveCN102626886AReduce distortionHigh dimensional accuracyAutomatic control devicesFeeding apparatusEngineeringMachining process

The invention discloses a bearing ring turning and cutting feed method, which belongs to the technology of turning processing. According to the existing cutting feed control method, a cutter is easy to break, materials are easy to block, and the deviation from circular form is large, while the bearing ring turning and cutting feed method is characterized in that a complete cutting feed process is divided into at least two sections of processes, and primary retracting is carried out so as to break cuttings after each process is finished. Particularly, a digitizing controller is used for controlling a servo motor to drive a carriage to realize cutting feed and retracting; a pneumatic actuating element is adopted for realizing feeding, blanking, clamping of a workpiece, fast moving of the carriage. According to the bearing ring turning and cutting feed method, through at least two times of cutting feed and retracting to break the cuttings, the problem of curling of the cuttings is solved; inner stress generated by power cutting is released, so that deformation of the workpiece caused by the inner stress is reduced; and due to the adoption of digitization programmed control technology, a segmented feeding mode in a bearing ring turning processing process is realized, the inner stress caused by large cutting volume is eliminated, and the dimensional accuracy and the shape precision of bearing ring turning processing are improved.

Owner:浙江进泰机械设备有限公司

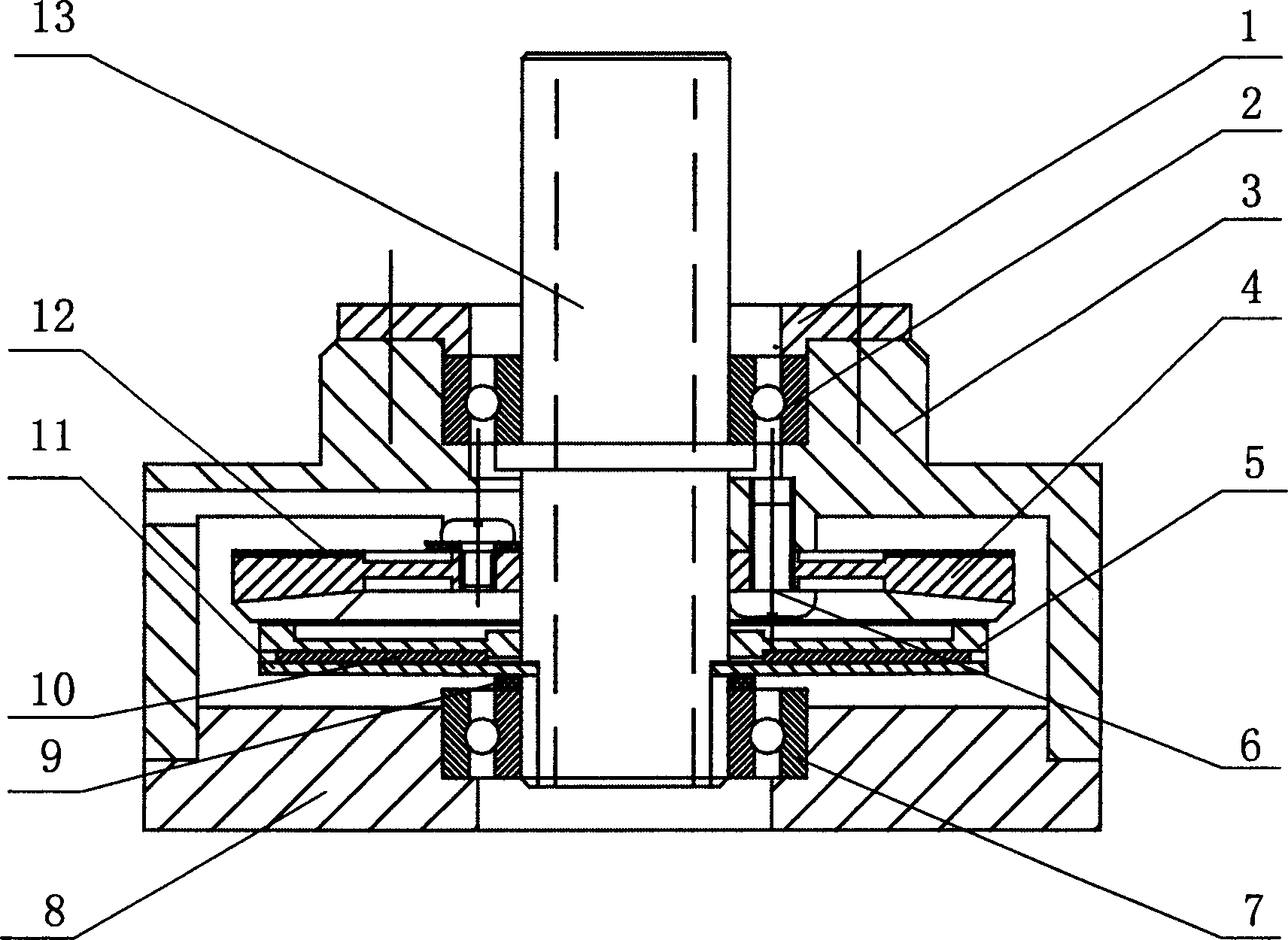

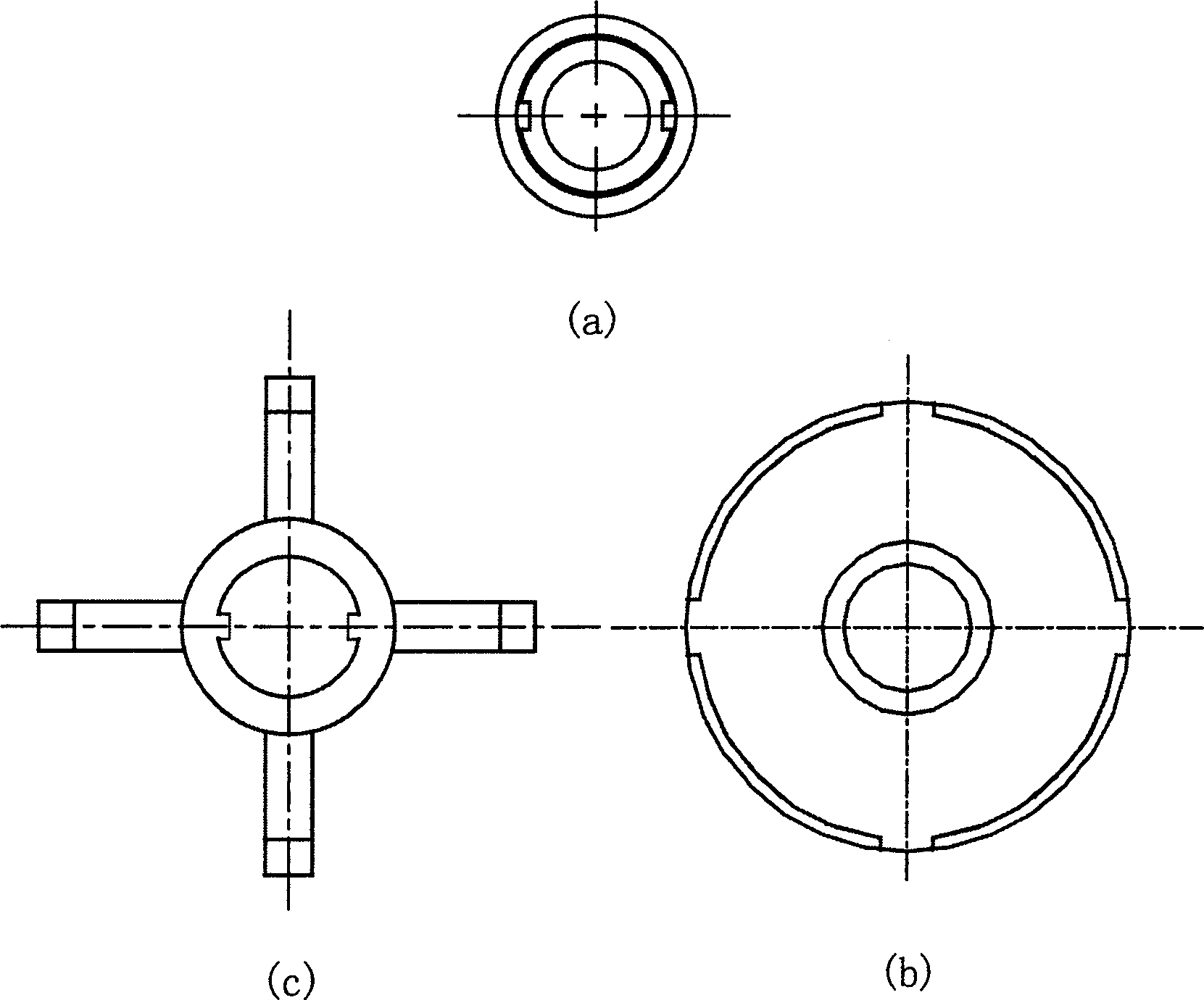

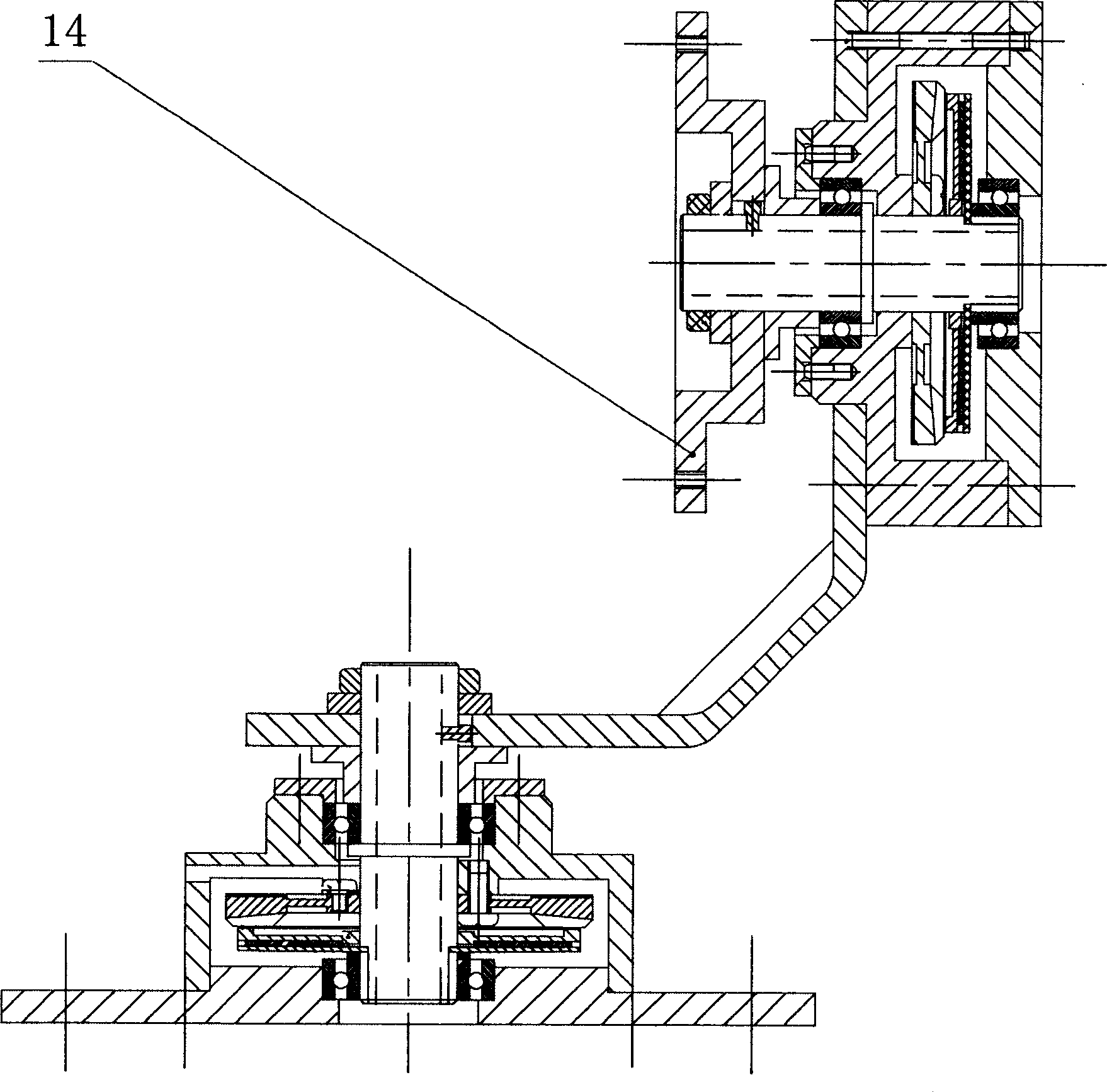

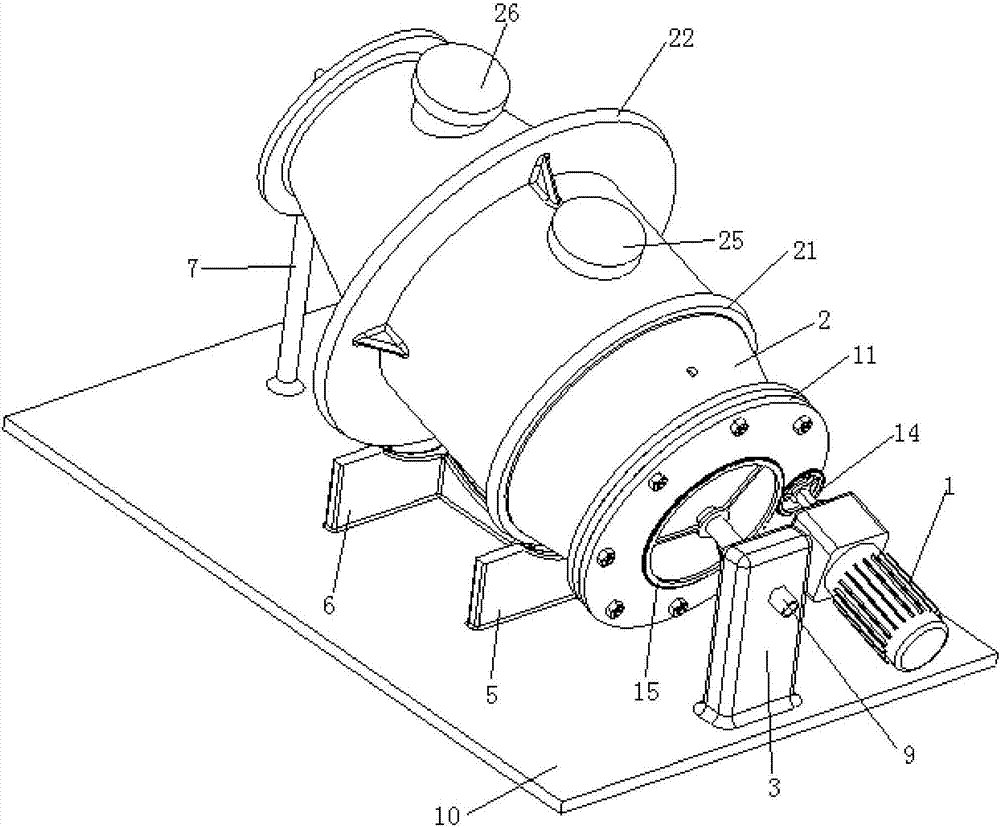

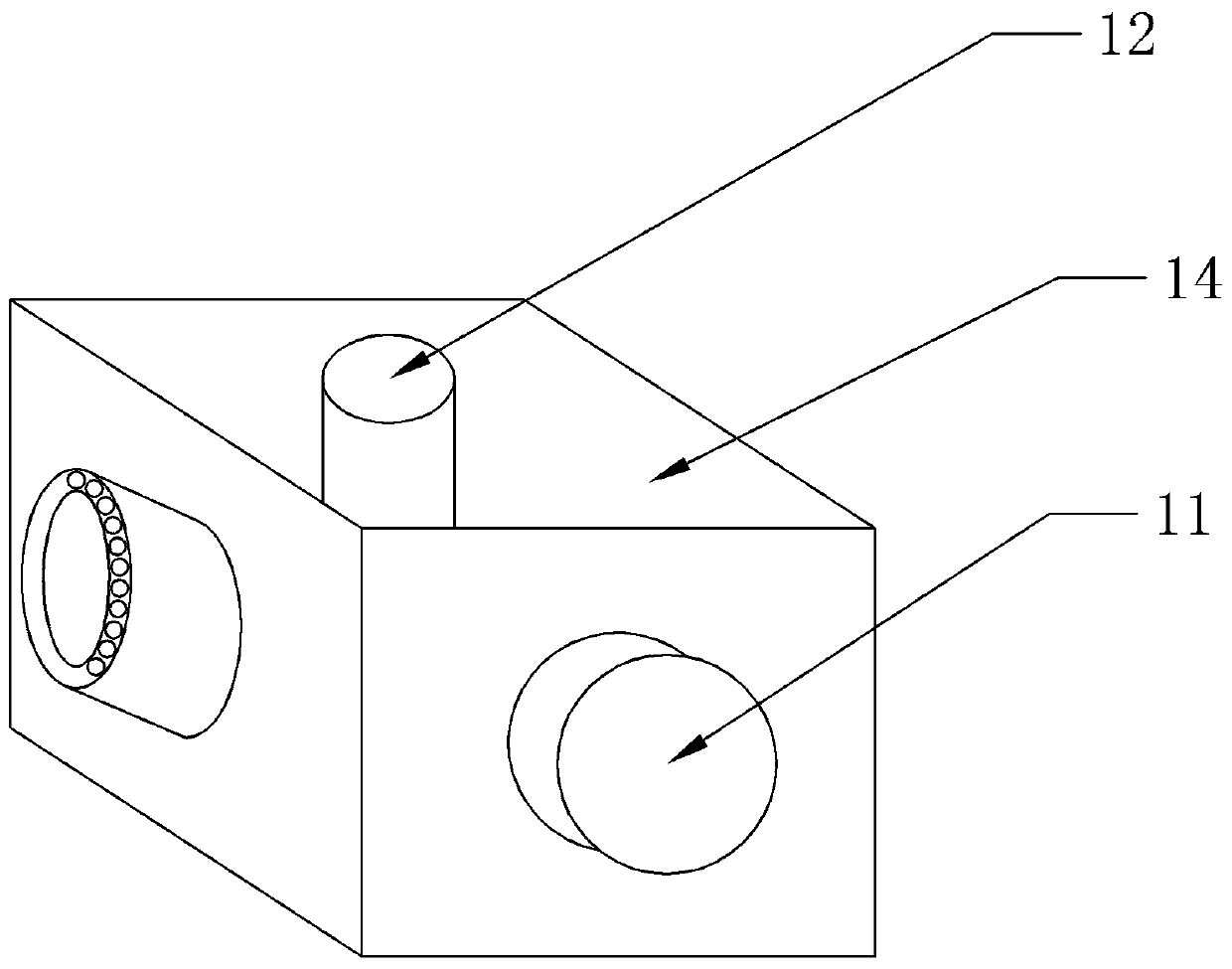

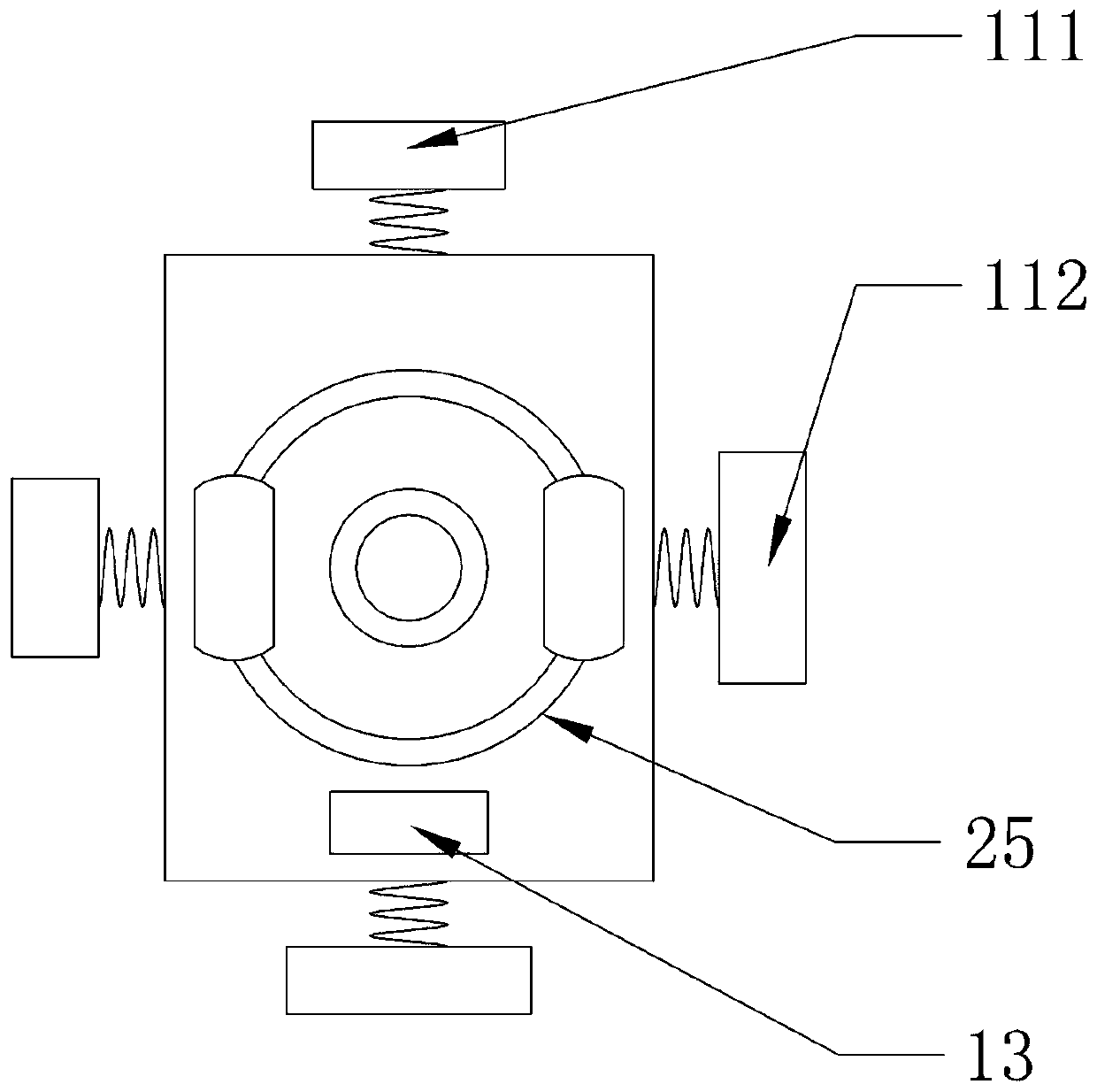

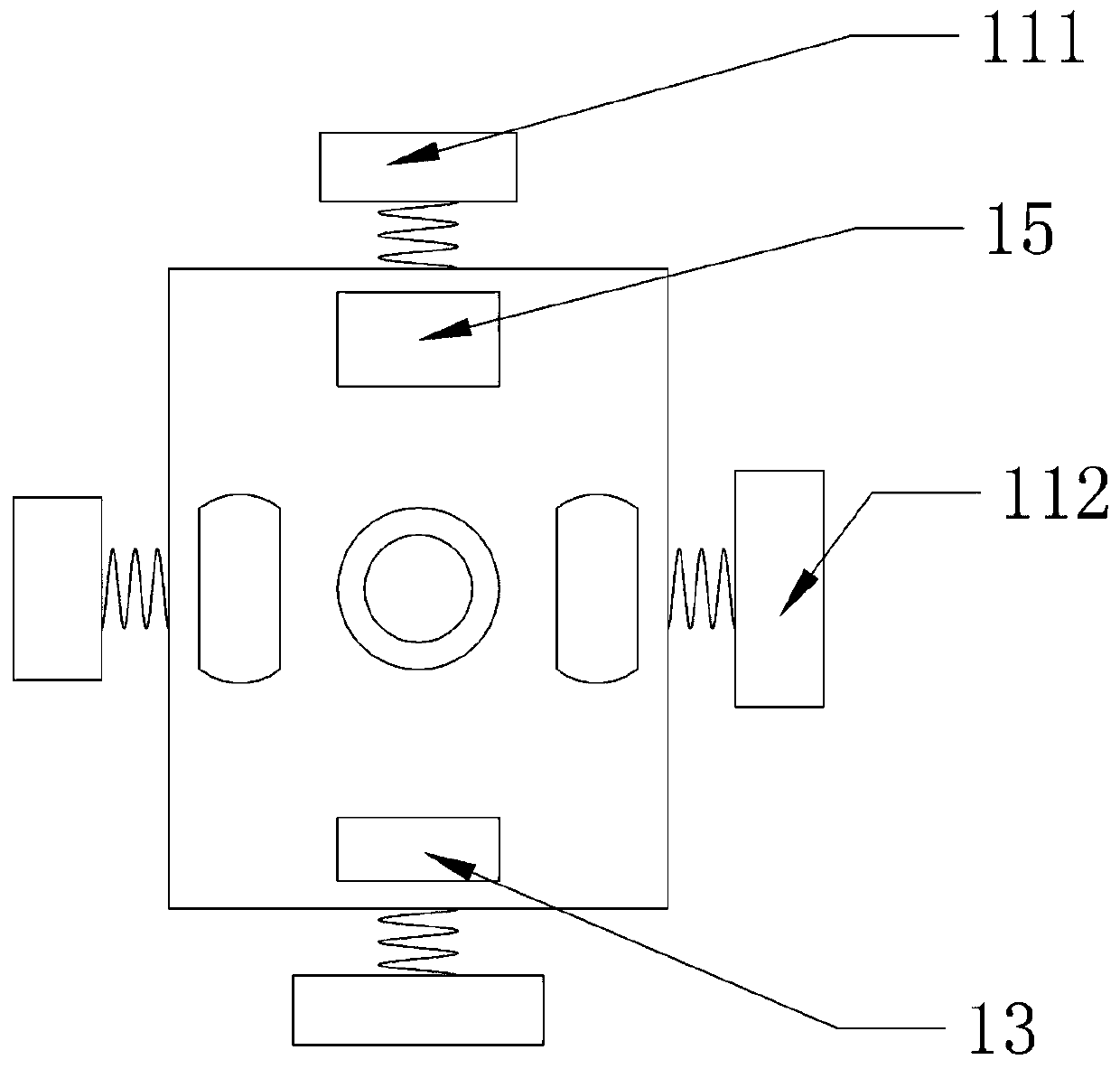

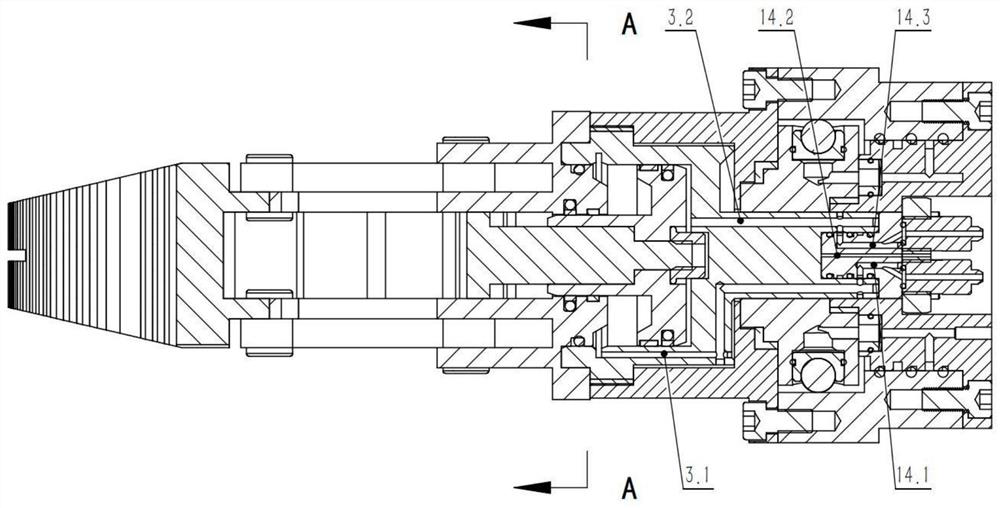

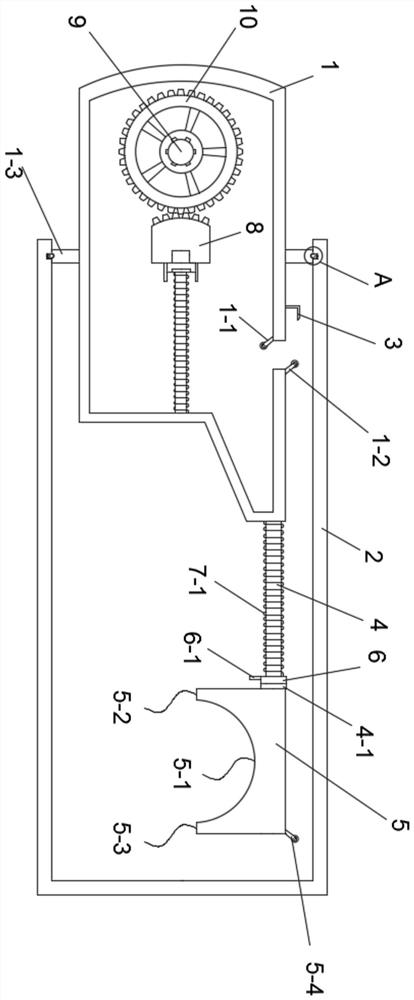

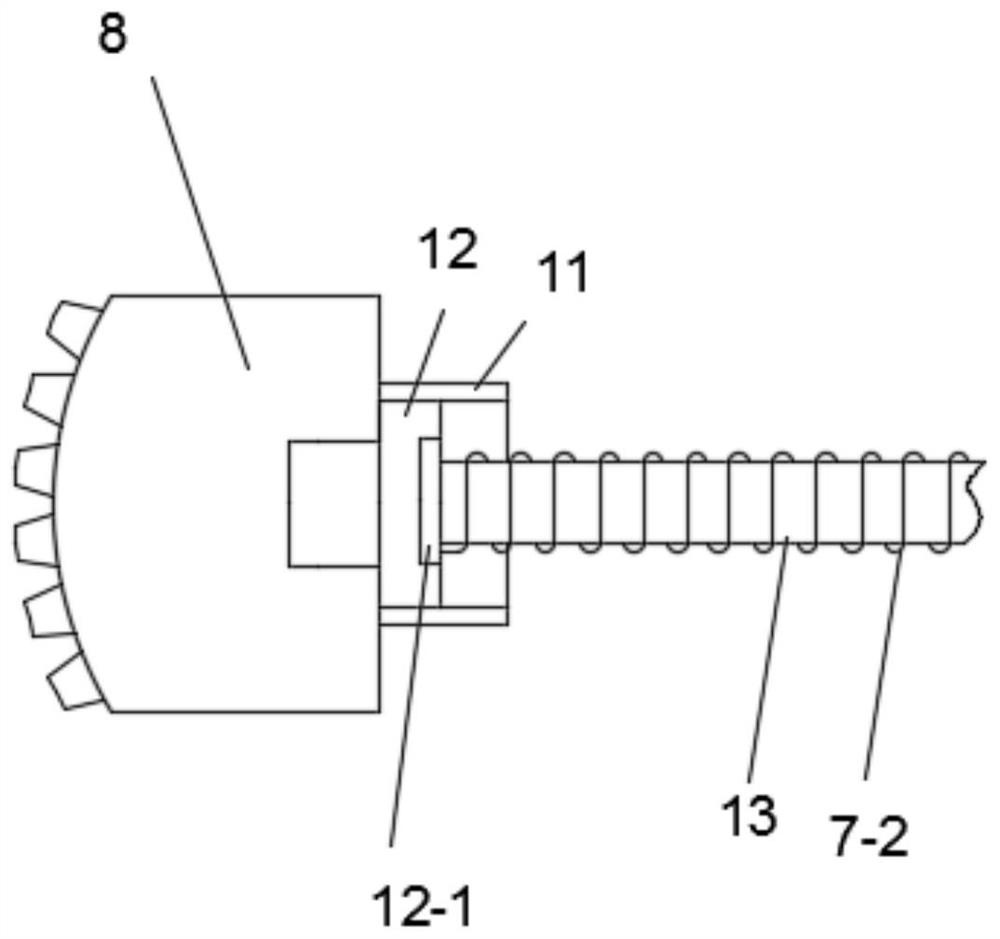

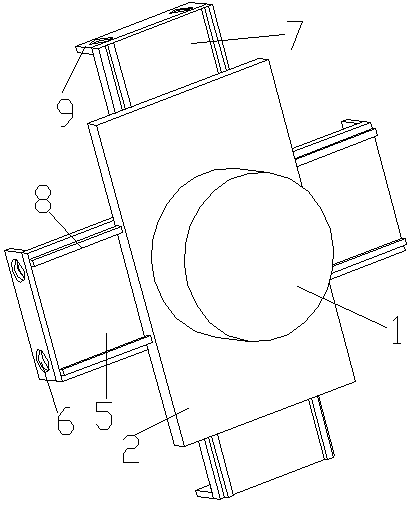

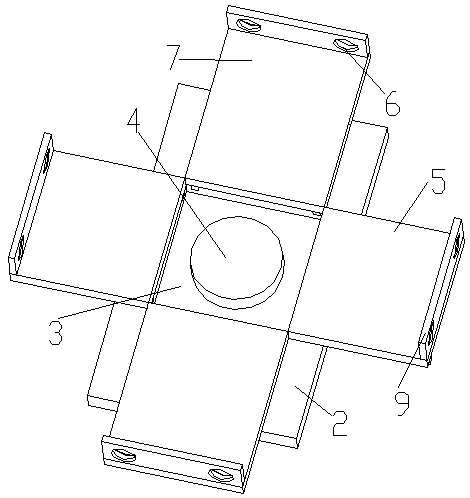

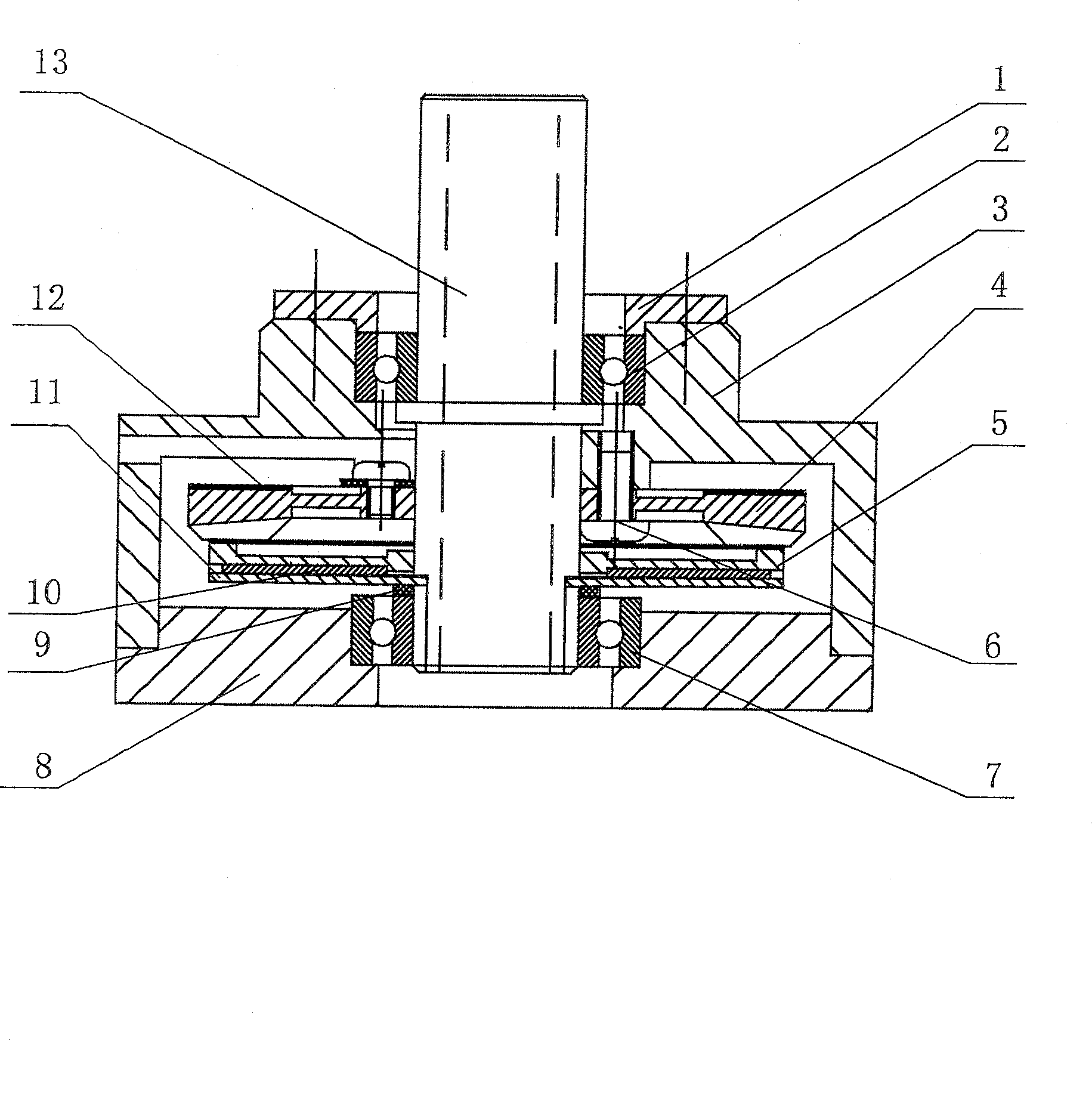

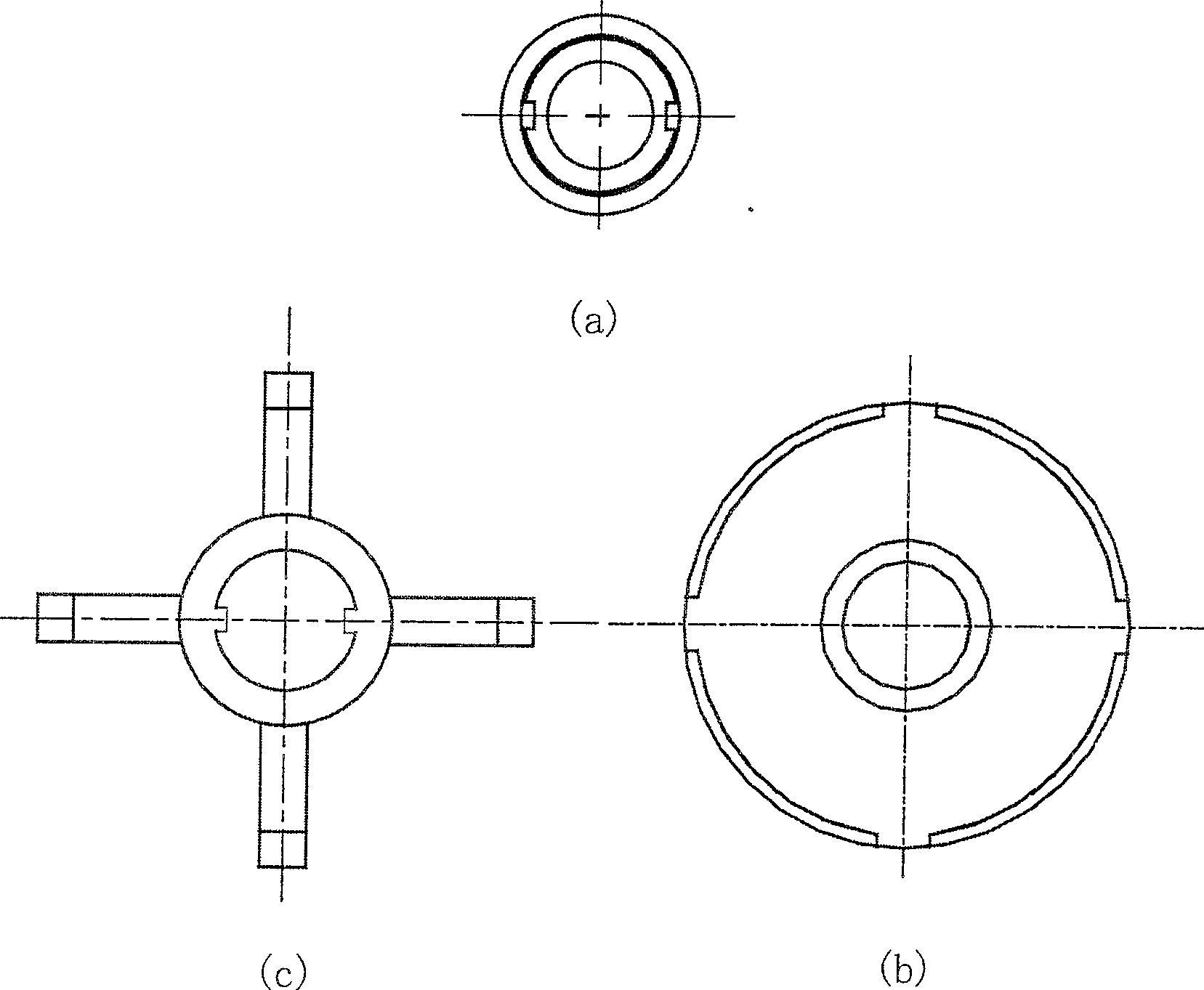

Ultrasonic motor for monitor cradle

InactiveCN1606225ASolve the winding problemSmooth support movementPiezoelectric/electrostriction/magnetostriction machinesPhase differenceUltrasonic motor

A monitor supersonic motor is composed of a rotor, a stator, spring plate, a hollow shaft, piezoelectric ceramic plates, the stator is fixed at the shell by screws, the rotor generates a pressure to press on the stator relying on the deformation of the spring plate, adjustment of pad thickness determines the deformation volume of the spring and the pre-pressure. The rotor and the spring, the spring and the shaft are driven by keyslot connection and the shaft applies a clamped way for bearings at both ends. When a sine- exciting signal with two-phase difference of 90deg.is inlet into the ceramic plate on the stator, mass points on its surface move elliptically to drive the rotor.

Owner:JIANGSU FENGKE ULTRASONIC MOTORS TECH

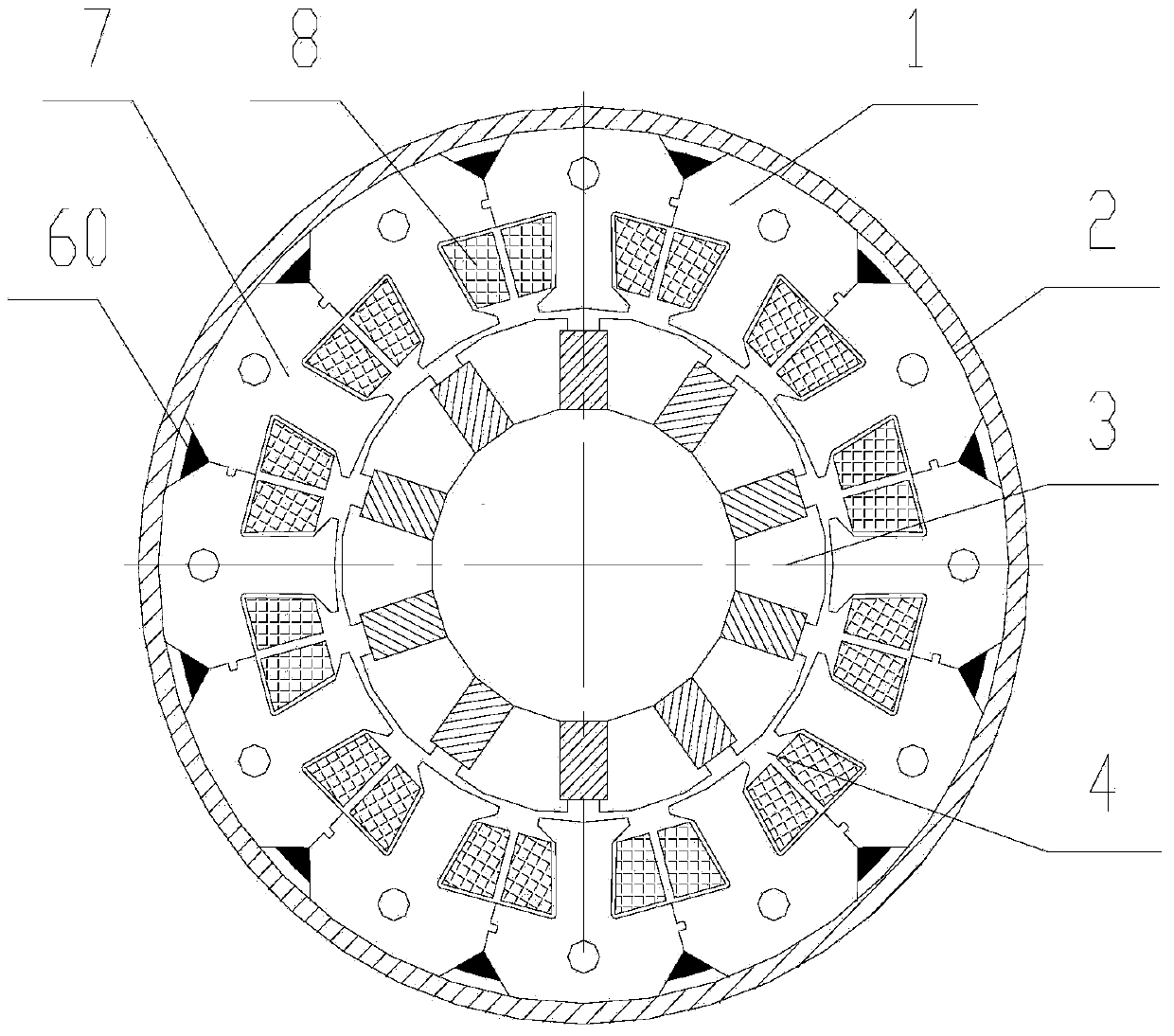

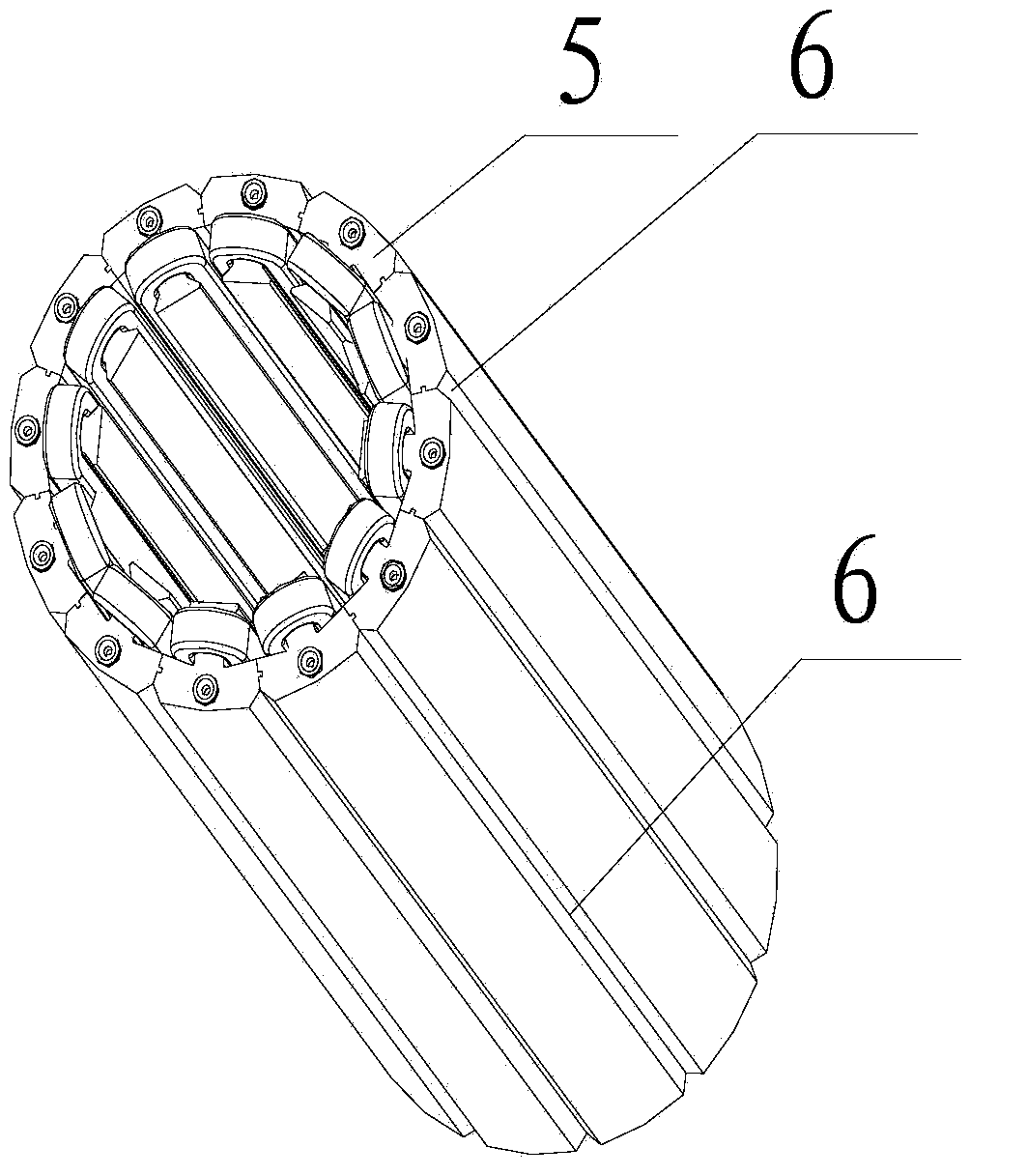

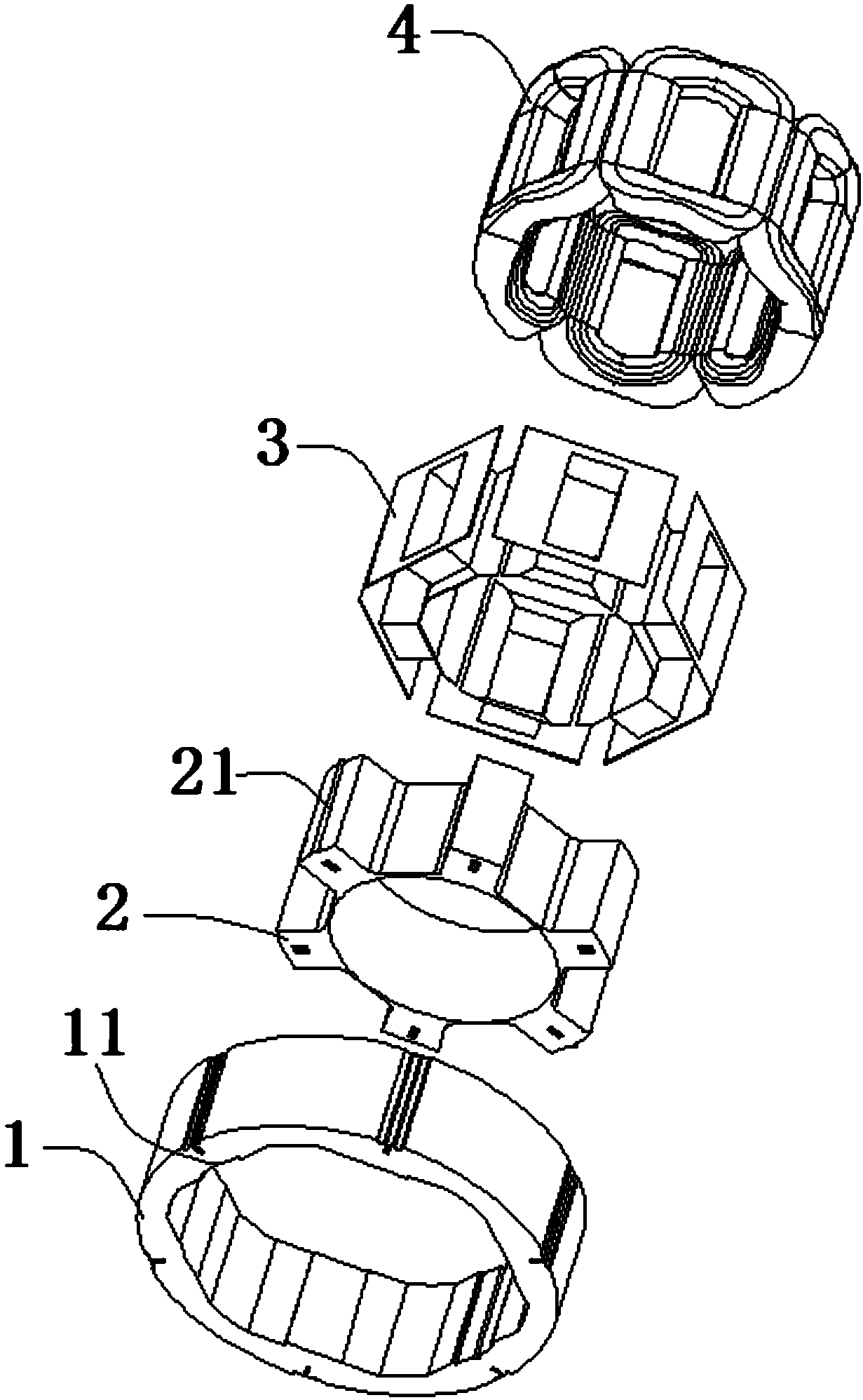

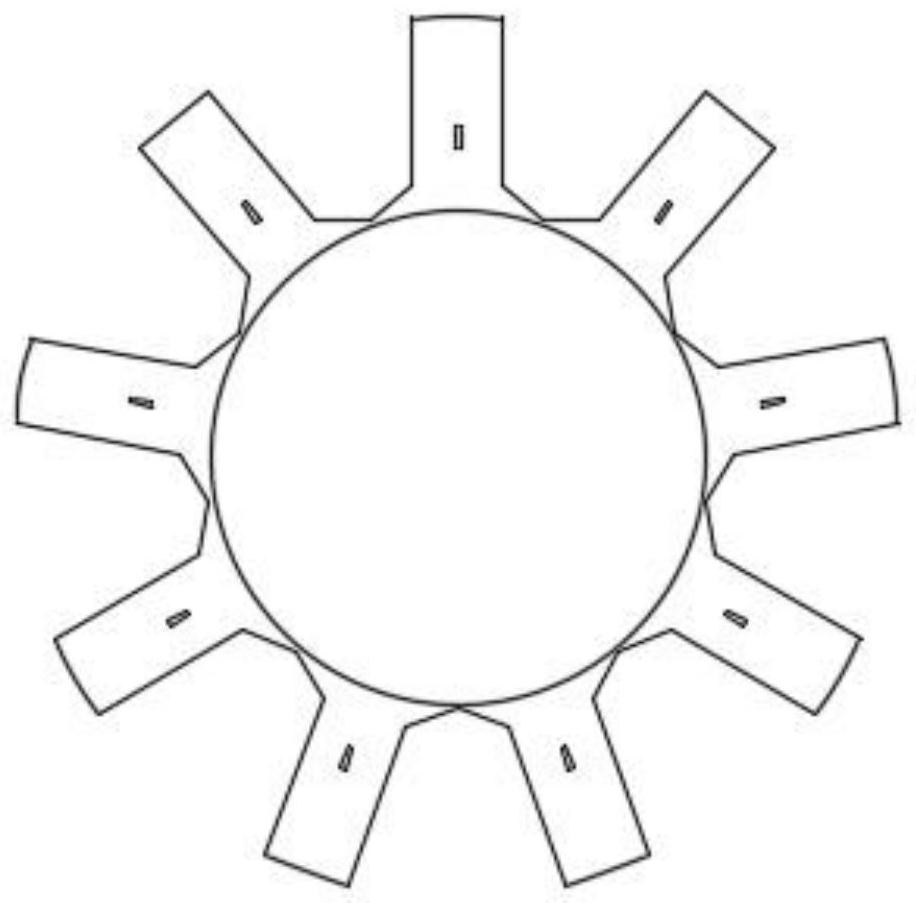

Oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor and manufacture method

InactiveCN103633755AImprove the winding methodIncrease the winding spaceMagnetic circuit stationary partsManufacturing stator/rotor bodiesCopper wirePermanent magnet motor

The invention provides an oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor and a manufacture method. The oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor comprises a motor unit, wherein the motor unit comprises a stator core of a split type structure, the stator core is assembled into an annular shape by multiple core blocks with windings, each core block with one winding comprises a slender core block and a winding copper wire, each slender core block is formed by overlaying T-shaped punched pieces and is provided with a stator tooth, and the winding copper wires are wound on the stator teeth. The manufacture method of the permanent magnet motor comprises the steps of overlaying the T-shaped punched pieces to form the slender core blocks, and winding the winding copper wires on the stator teeth to form the core blocks with the windings; connecting the multiple core blocks with the windings in sequence along the peripheral direction and assembling to form the annular stator core; arranging the annular stator core into an enclosure by press-fitting. The winding process of the core blocks with the windings is easy to realize, and the manufacturing is simple.

Owner:PETROCHINA CO LTD

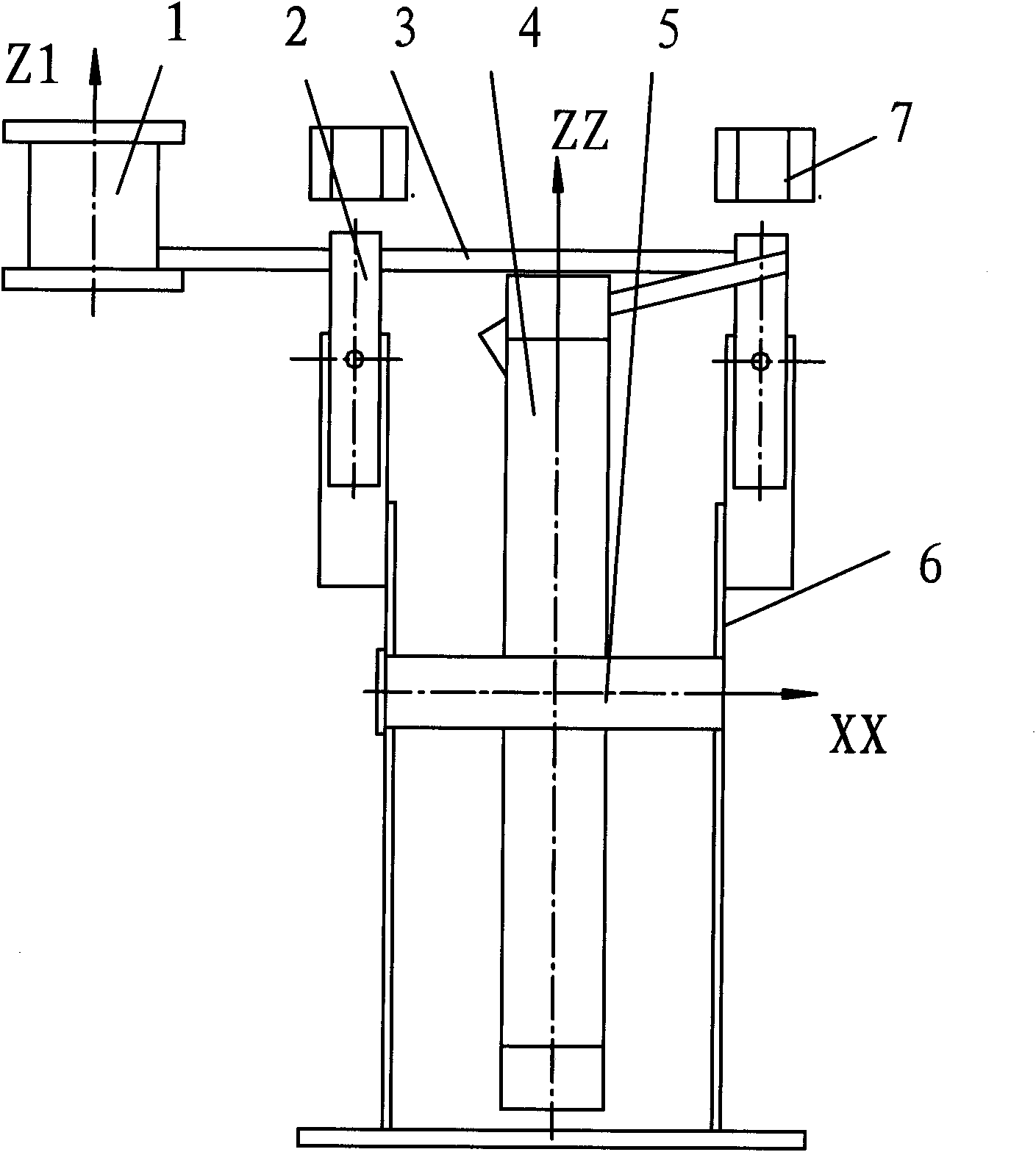

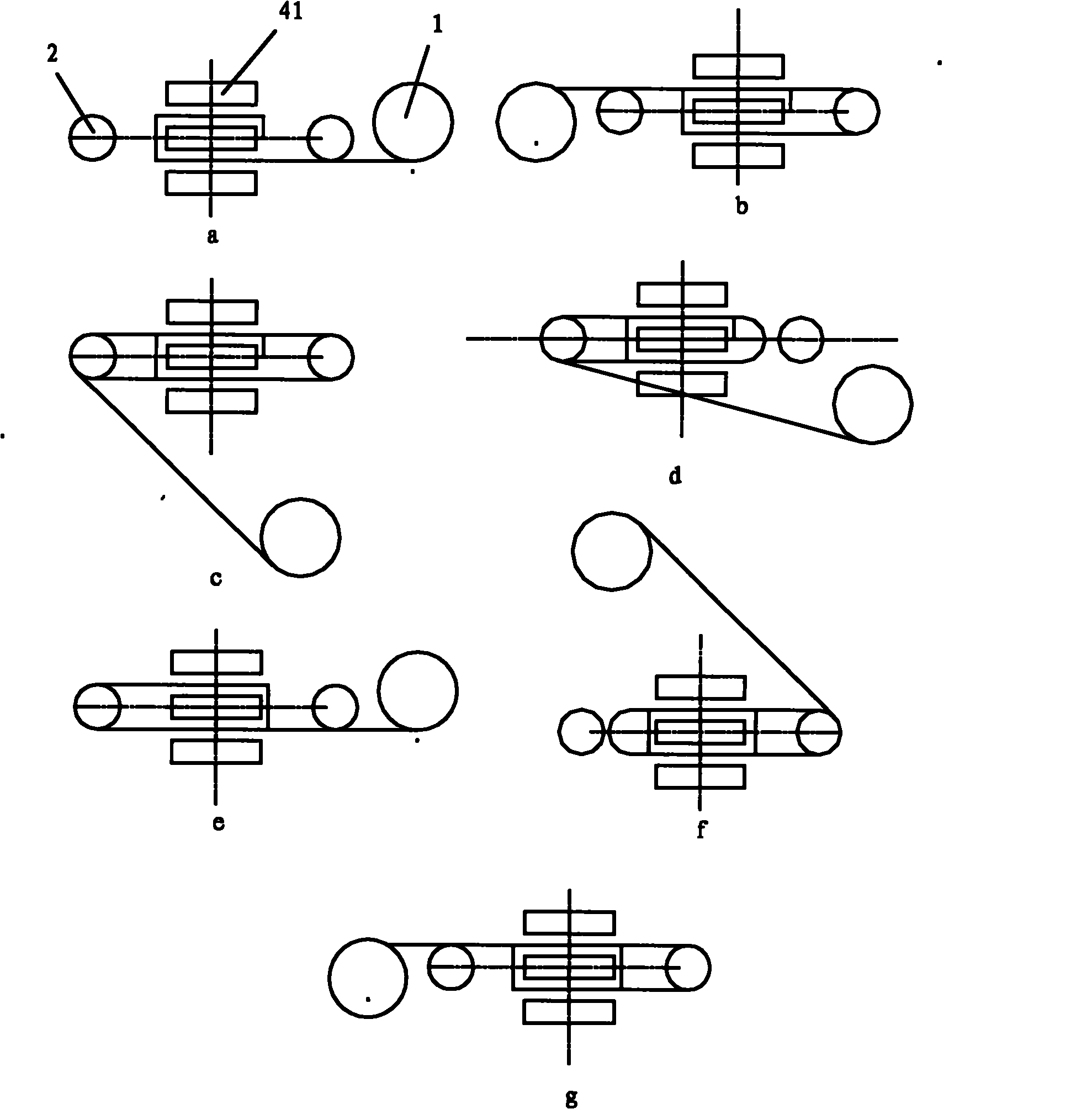

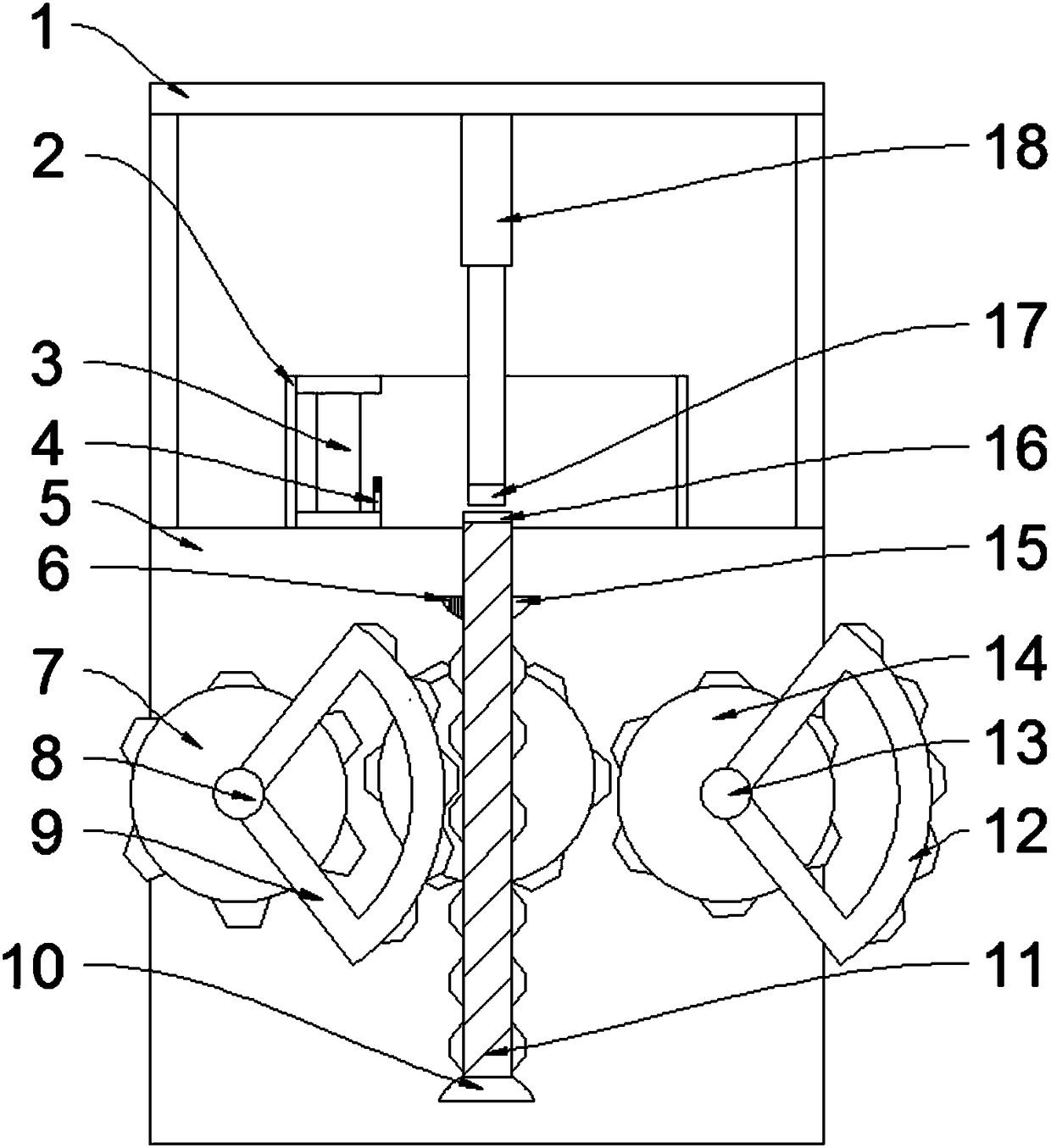

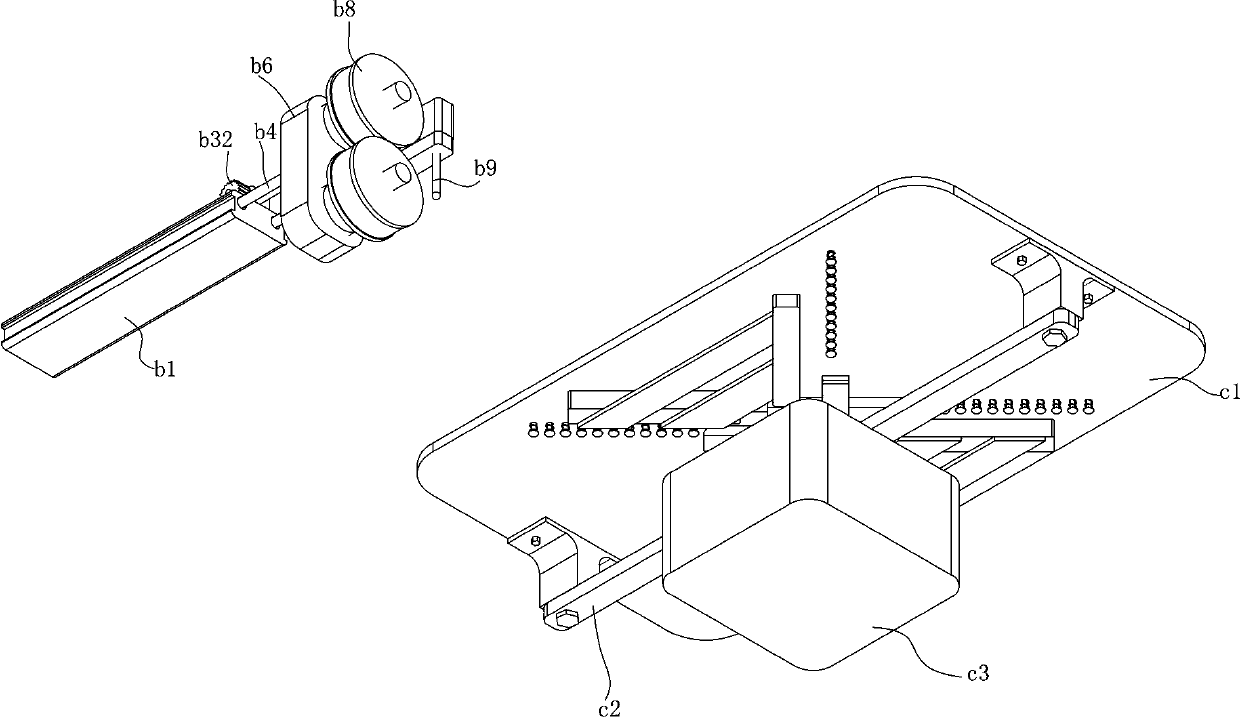

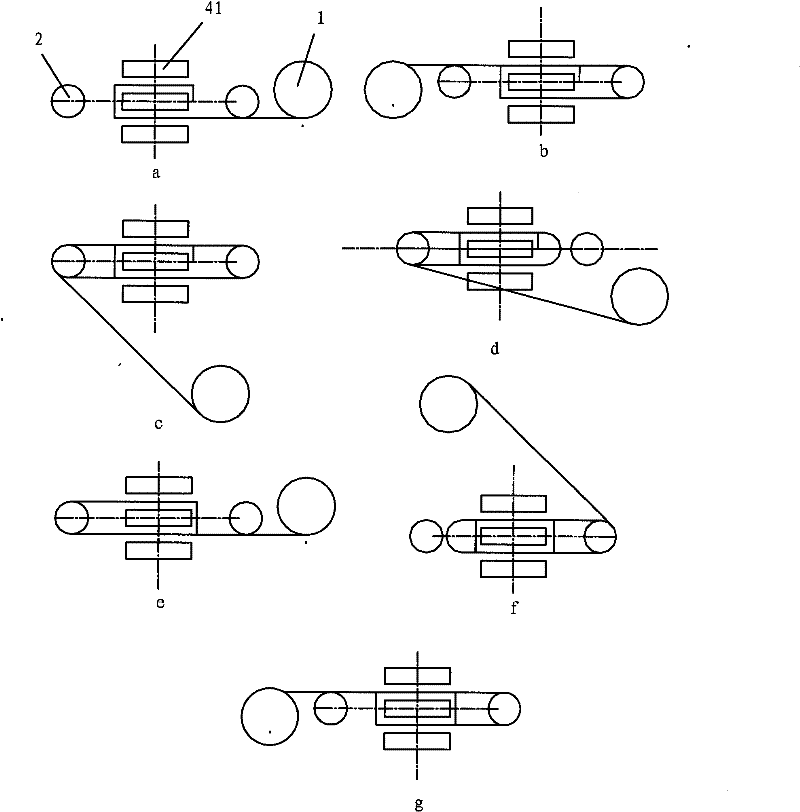

Winding device and winding method of motor armature of electric motor vehicle

InactiveCN101860145AEasy to windLabor savingElectric machinesManufacturing dynamo-electric machinesPower componentElectric vehicle

The invention discloses a winding device and a winding method of a motor armature of an electric motor vehicle. The winding device comprises a winding stand, a wire coil and an iron core fixed shaft which are arranged on the wire coil, the wire coil rotates around a winding shaft of the stand; two winding suspension mechanisms are respectively arranged on two sides of the stand; each winding suspension mechanism comprises a suspension part and a power component which is connected with the suspension part to control the suspension part to rotate; and each suspension part is provided with two stations, i.e. a first station for the upper end of the suspension part positioned in a paying-off plane of the wire coil to wind the winding and a second station for the upper end of the suspending mechanism of the winding to swing to the inner side of the stand and release the winding. Compared with the prior art, in the method, the winding to be wound is firstly wound on the suspension part of the suspending mechanism, the suspension part is swung by swinging the suspending mechanism to release the winding on the suspension part from the suspension part, the winding can be automatically furled into a wire trough under the action of the tension of the wire coil, the winding is convenient and fully automatic, the labor force is saved and the winding efficiency is high.

Owner:崔建伟

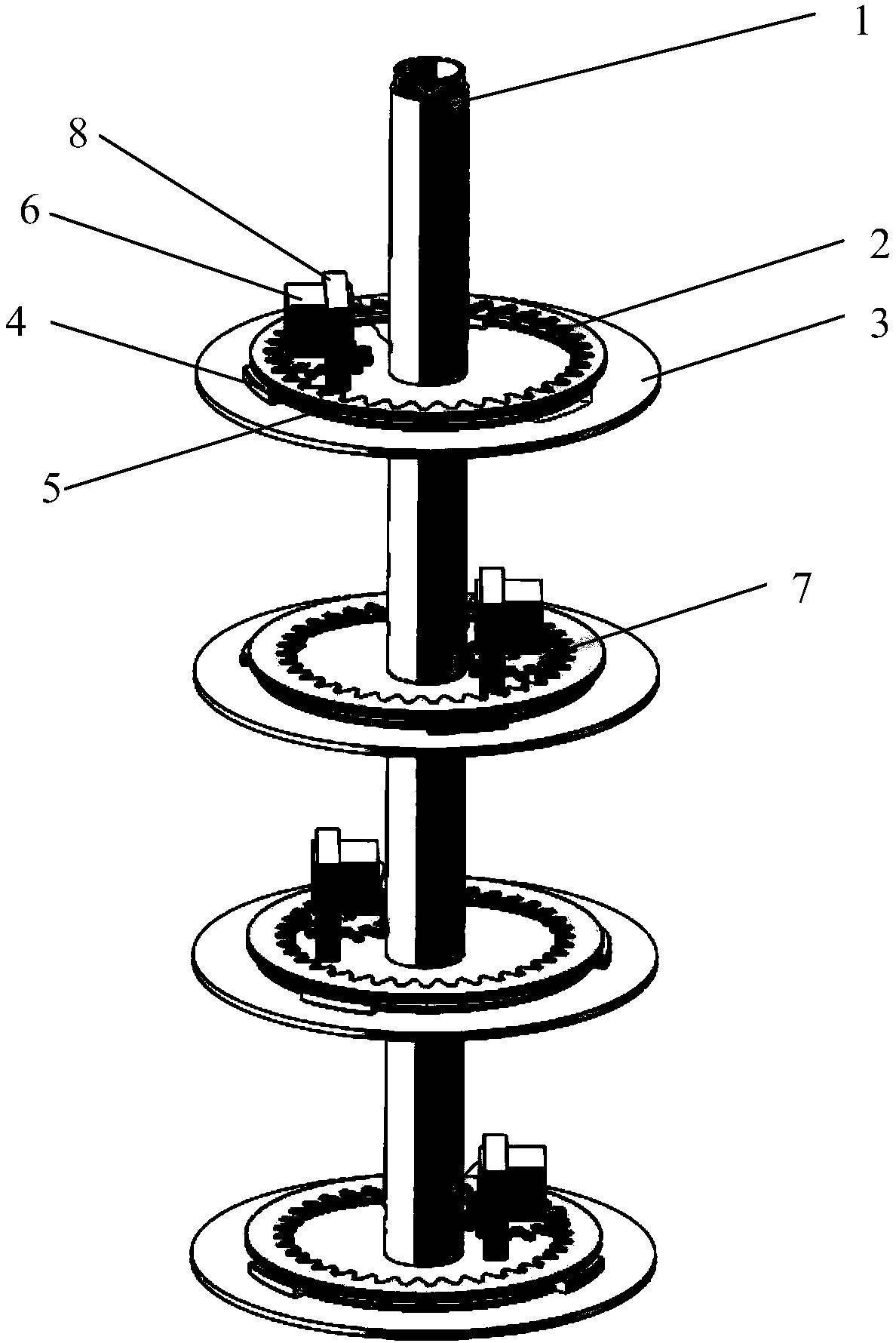

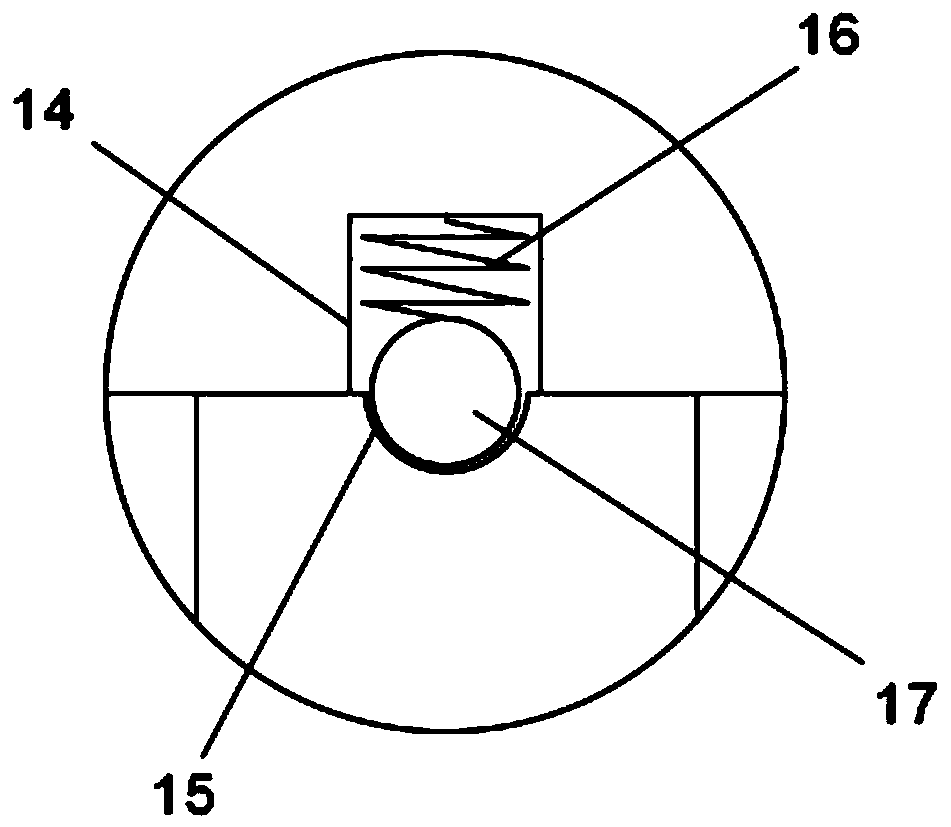

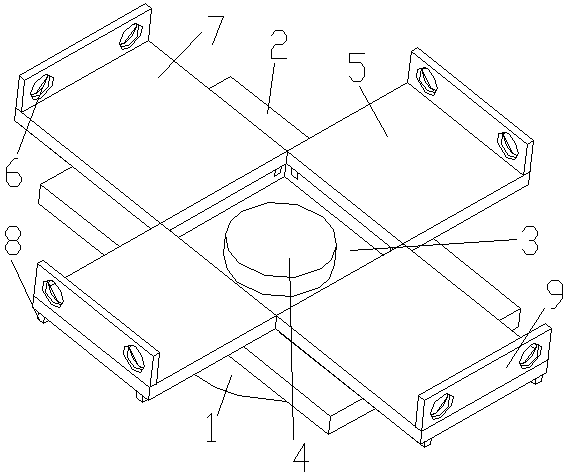

Multi-layer independent rotating platform

PendingCN107928257AEasy to assemble and disassembleChange the number of layers at willShow cabinetsShow shelvesGear wheelModularity

The invention provides a multi-layer independent rotating platform. The platform comprises a center column, internal gears, platform bodies, sliding blocks, annular guide rails, stepping motors, stepping motor gears, stepping motor supports, wire penetrating holes, stepping motor control lines and supporting beams. The platform has the advantages that the structure of the platform is modularized,the structures of all layers are completely different, the layers are connected in a threaded mode through the center column, assembling and disassembling are simple, the number of the layers can be changed freely, and if the number of the layers is changed, 50% of development time can be saved. Independent rotation is adopted, and each layer is controlled with an independent stepping motor, and can rotate independently. The motors will not rotate along with the platform bodies, and therefore the problem that the motors are wrapped with wires can be effectively solved.

Owner:TIANJIN CHENGJIAN UNIV +1

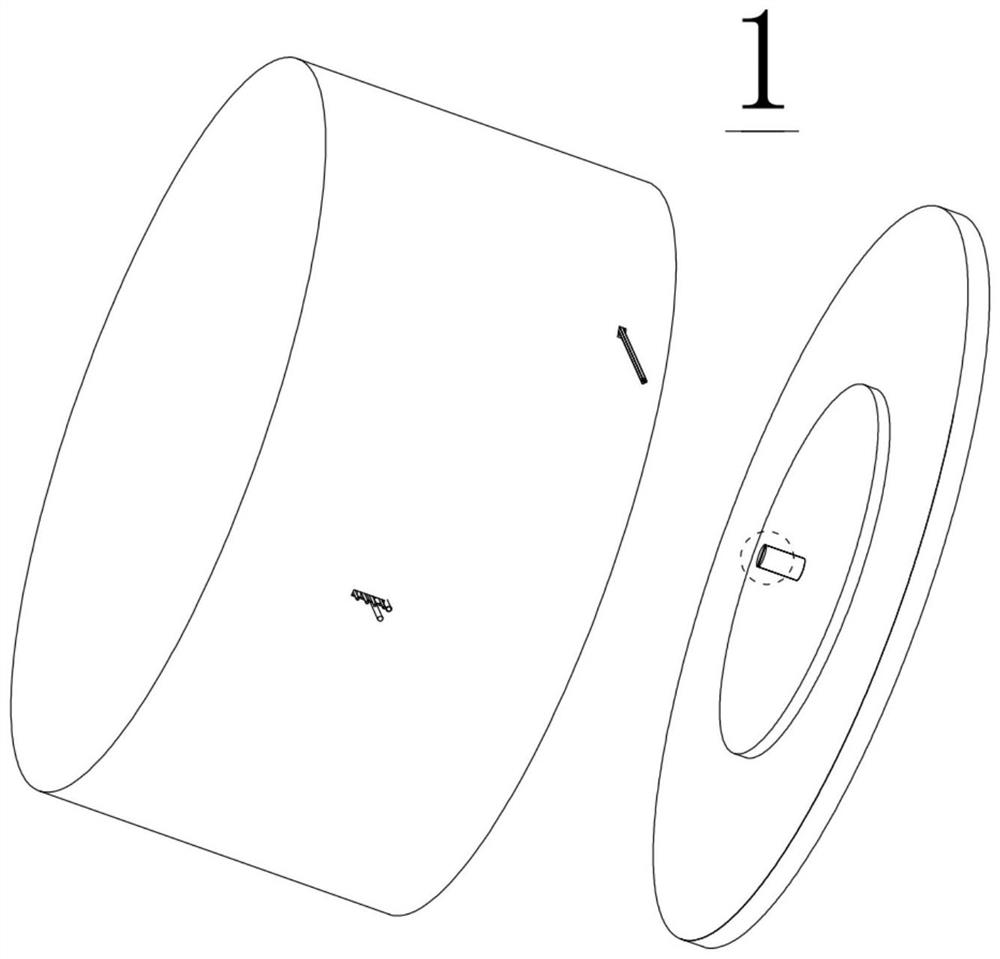

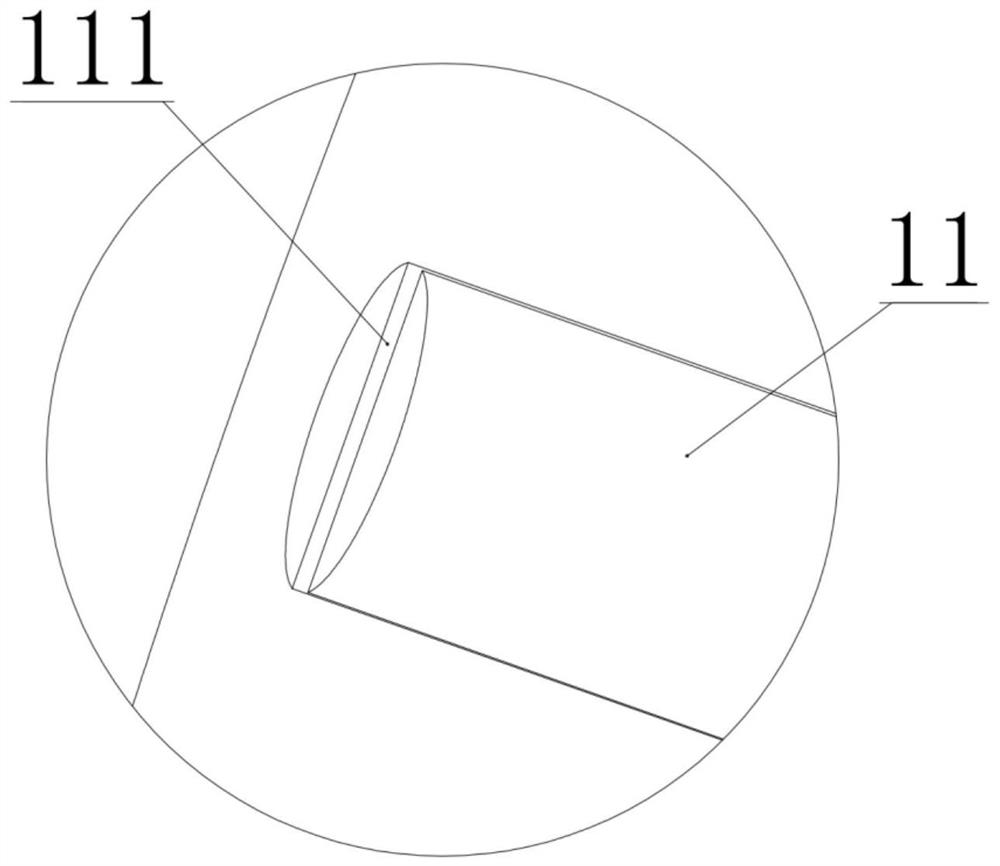

Spinning bobbin

The invention discloses a spinning bobbin, which comprises a bobbin body and bobbin covers, wherein the bobbin covers are arranged at the two ends of the bobbin body, the outer side of the bobbin body is provided with a press sheet which is tightly matched with the outer side of the bobbin body, one end of the press sheet is connected with the bobbin body, the other end of the press sheet is movably arranged, the yarn end of the initial end of the spinning yarn penetrates through and is pressed between the press sheet and the bobbin body, a fixing column is arranged on the inside surface of each bobbin cover and can slide along the radial direction of the bobbin body, and the yarn end of the tail end of the spinning yarn is fixedly arranged on the fixing column. The spinning bobbin has the advantages that the structure is simple, the yarn head of the yarn is effectively fixed, and the transportation and storage are convenient.

Owner:WUXI DANGKOU TONGHE TEXTILE MACHINERY PLANT

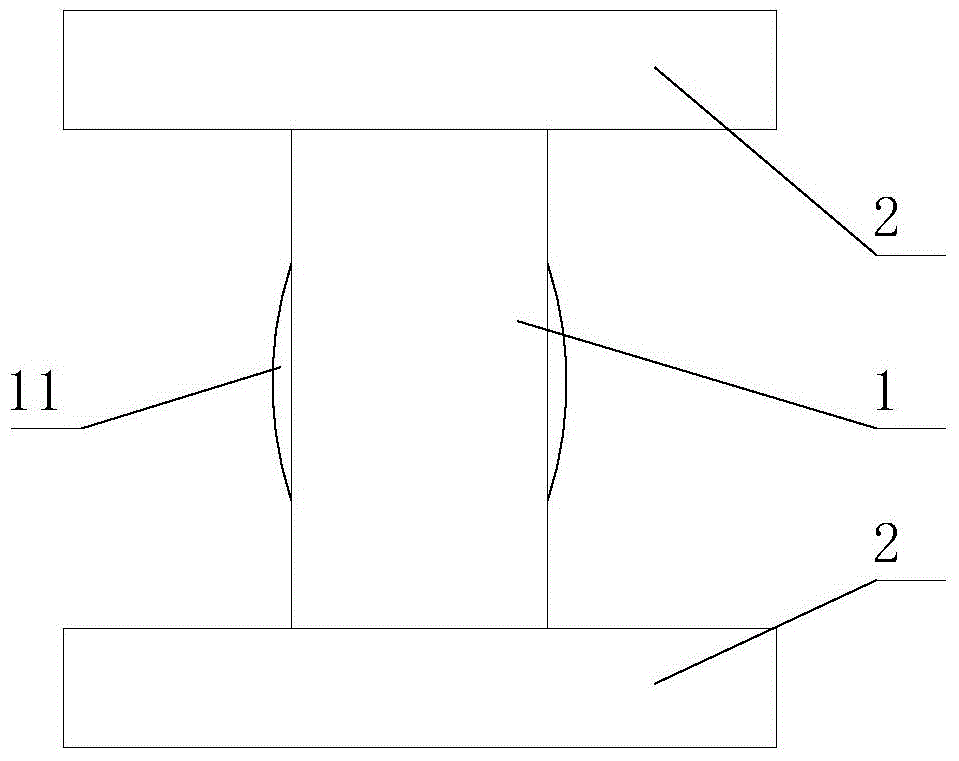

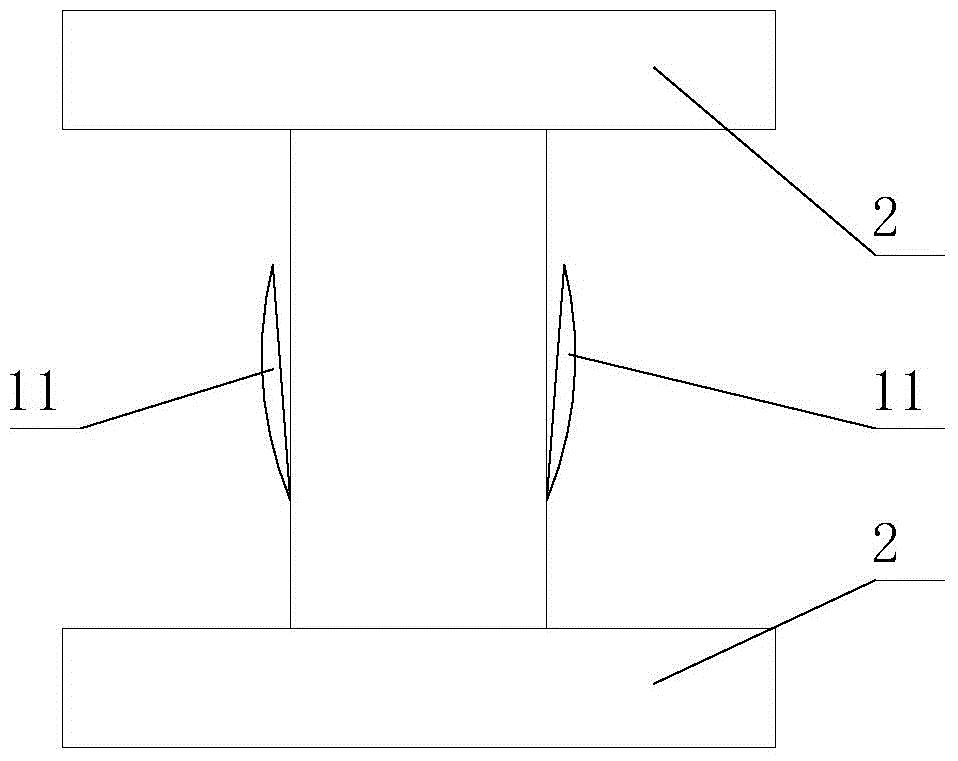

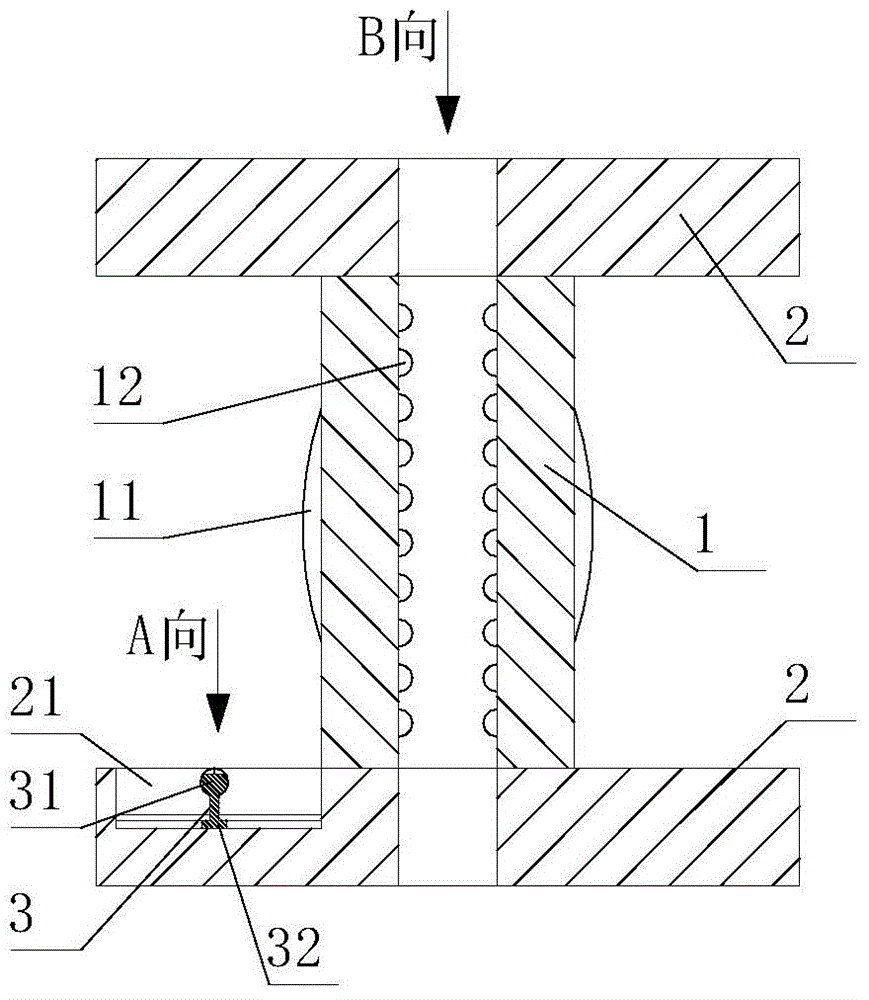

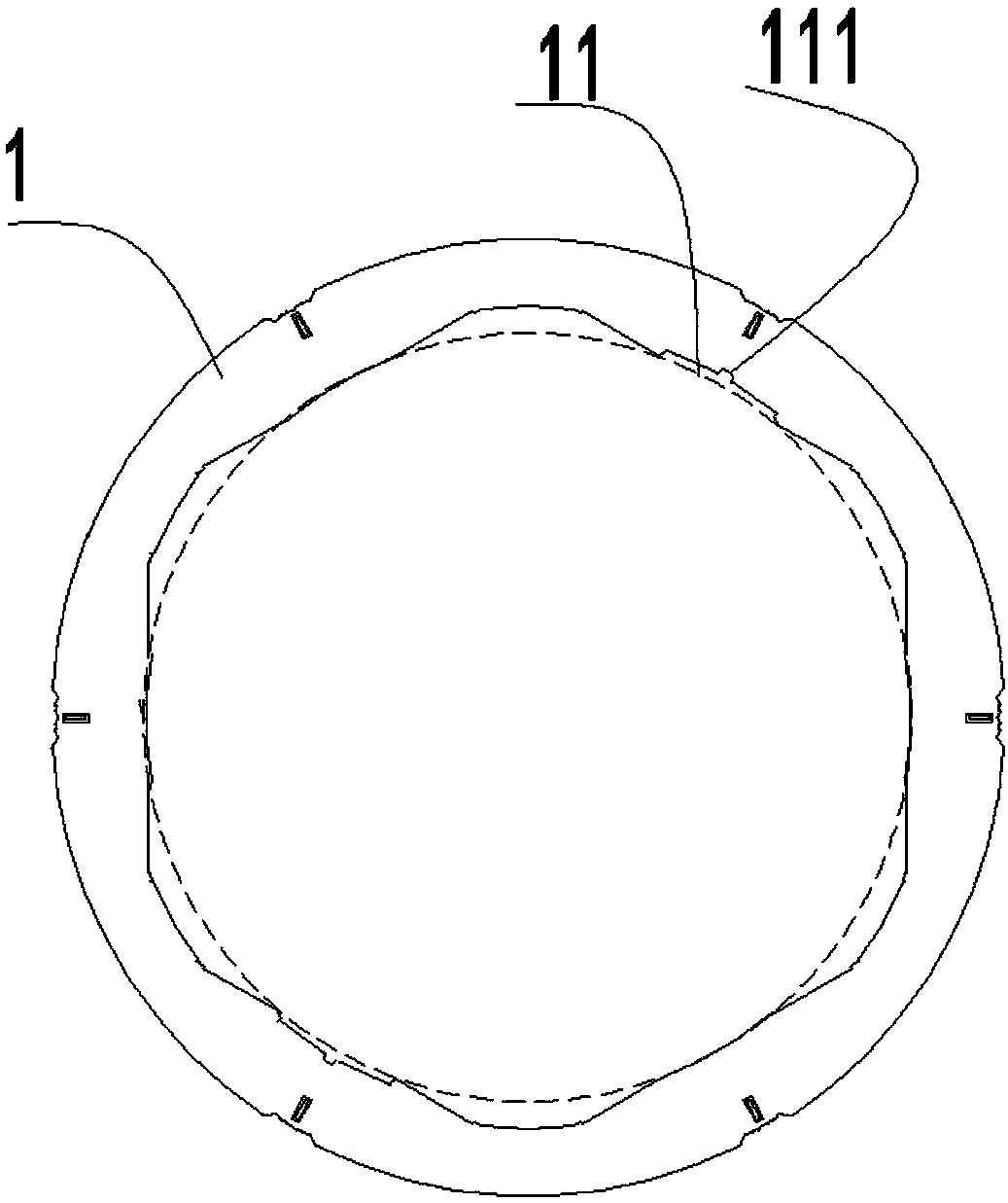

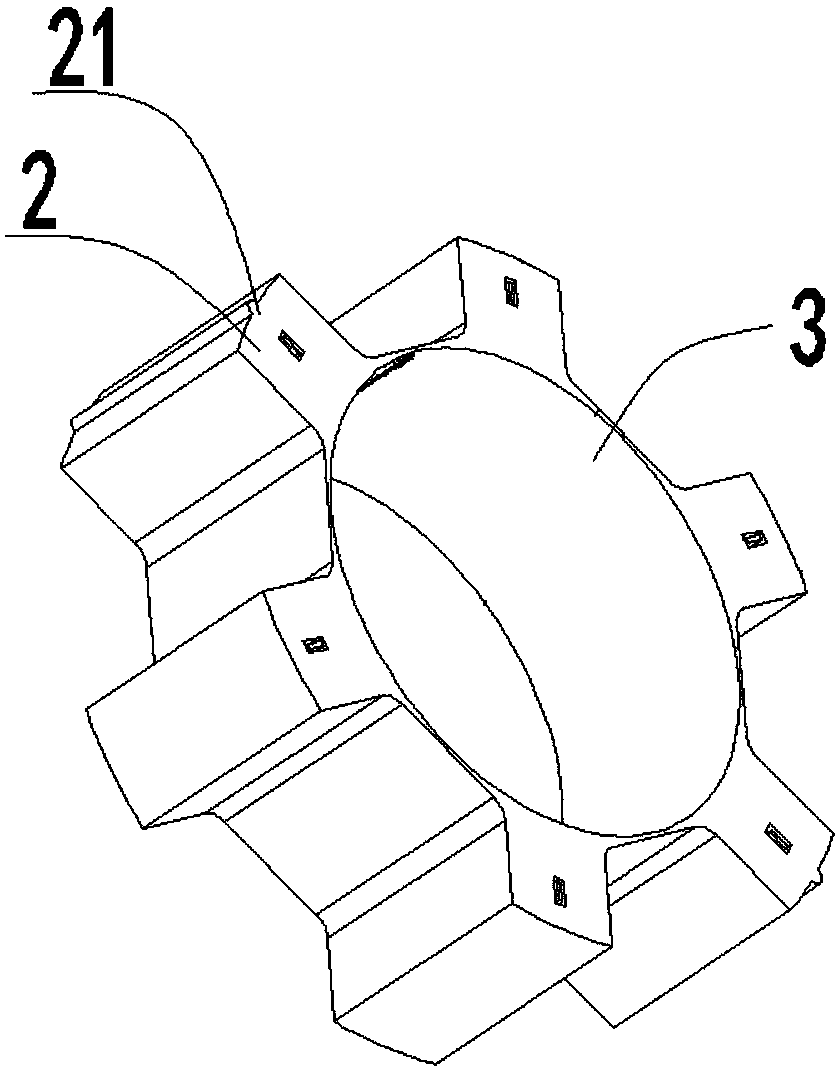

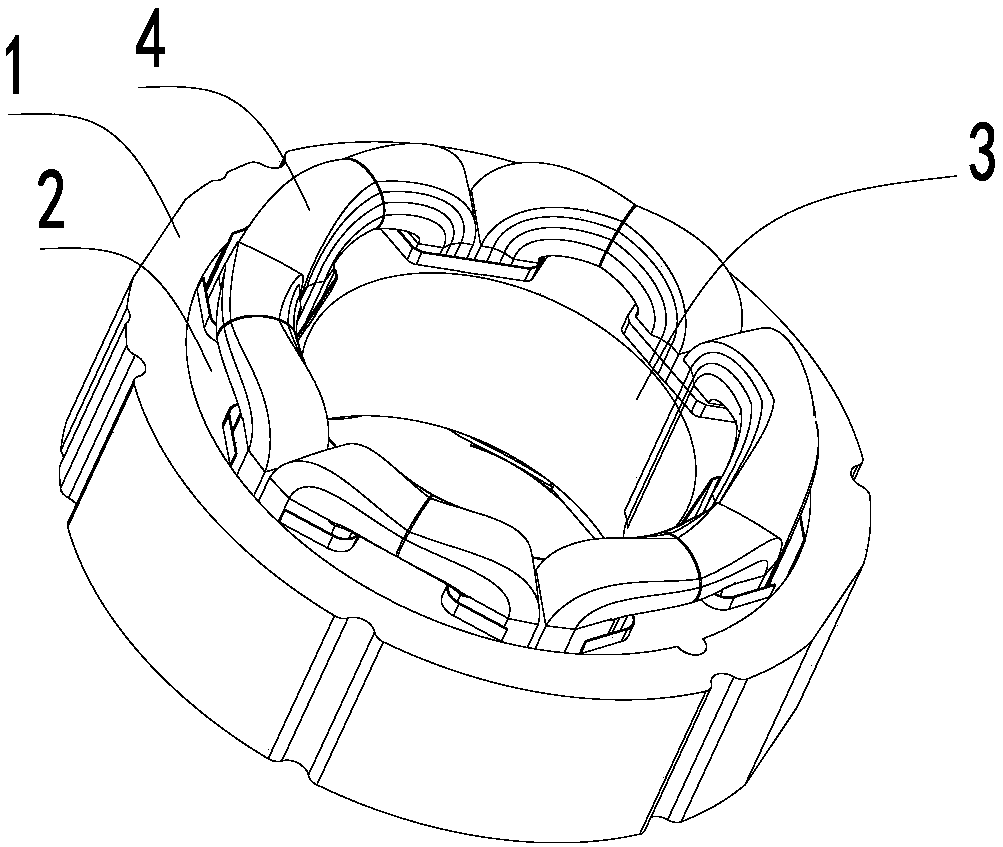

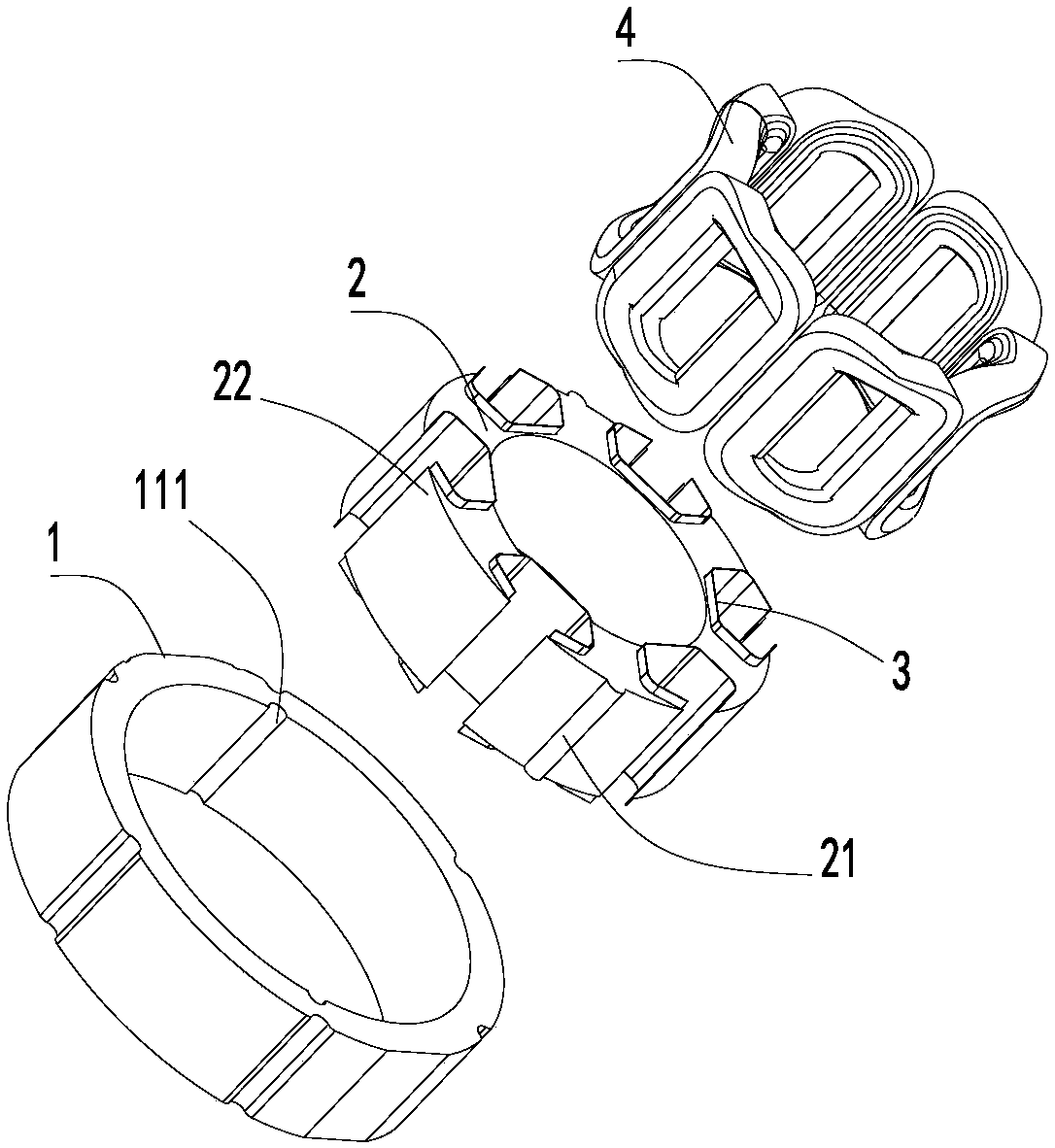

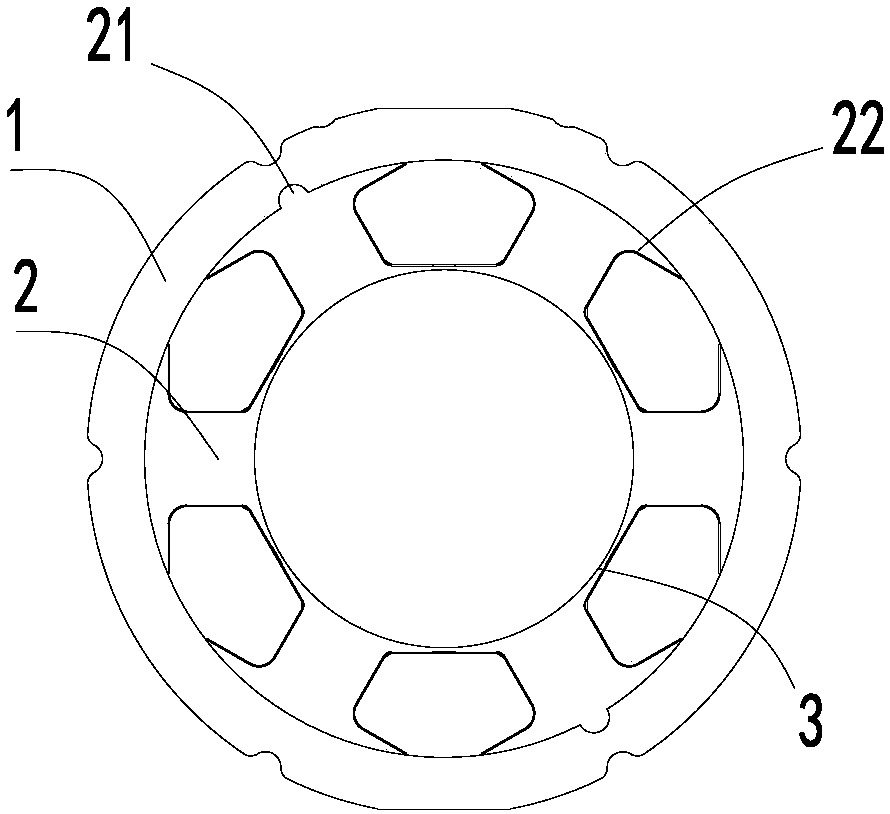

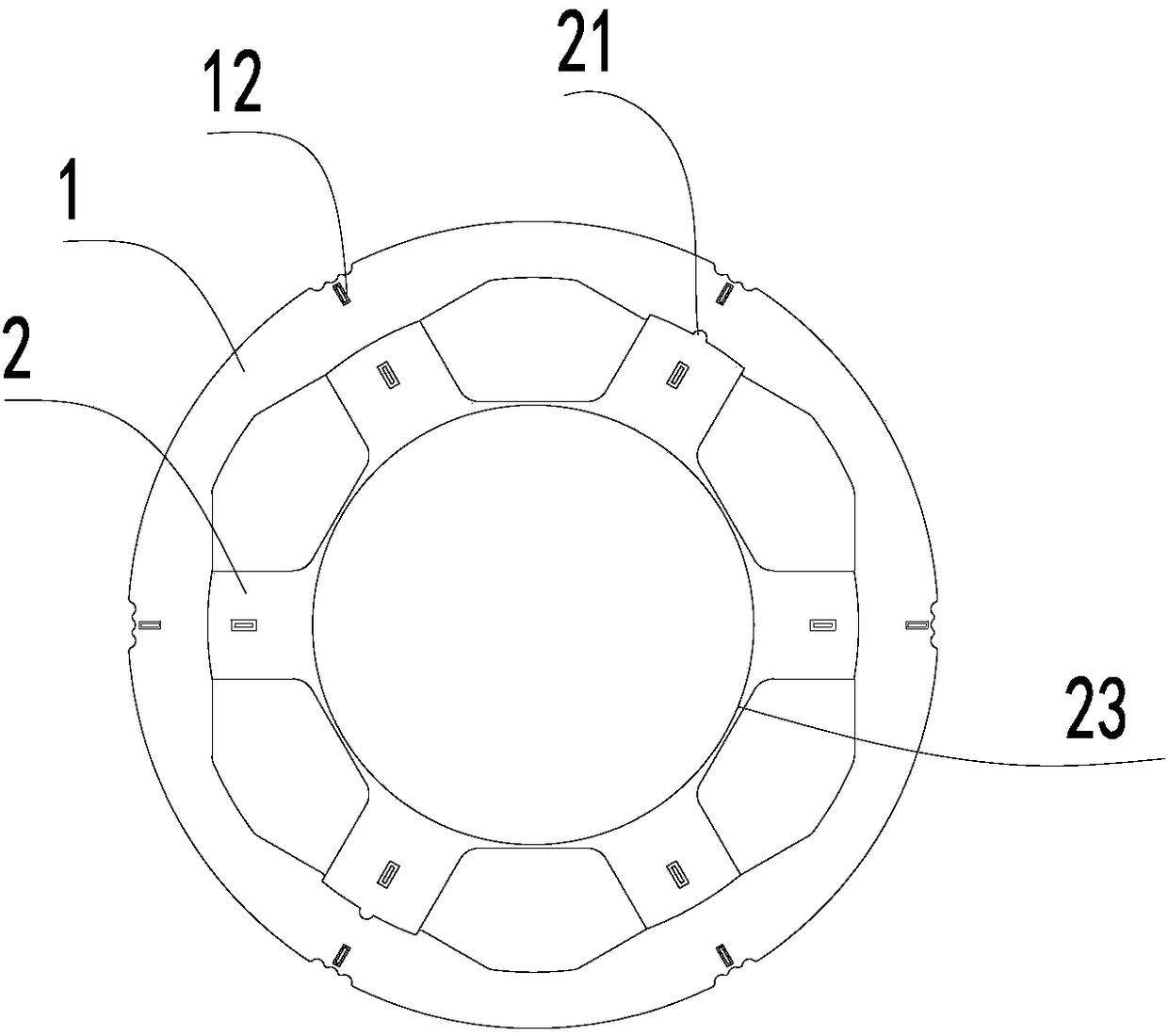

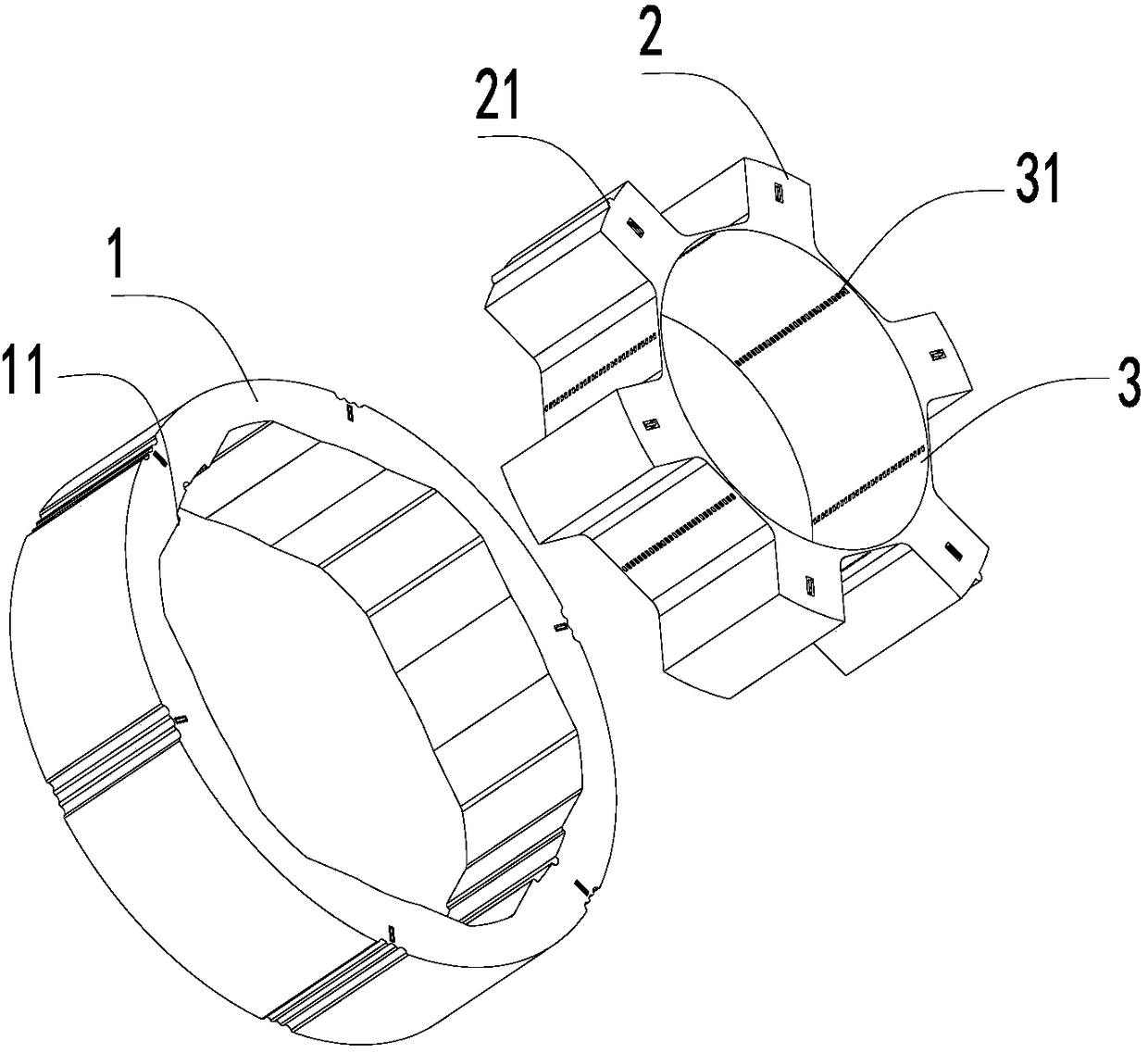

Stator component, motor and compressor

InactiveCN108429365AReduce winding difficultyEasy to set upMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineEngineering

The invention relates to the field of motors and discloses a stator component, a motor and a compressor. The stator component comprises a stator yoke part (1), a connecting ring (3) and a plurality ofstator tooth parts (2), wherein the plurality of the stator tooth parts (2) are detachably sleeved with a support sleeve (5); a coil (4) which surrounds the stator tooth parts (2) is arranged on thesupport sleeve (5); the stator tooth parts (2) and the connecting ring (3) are capable of moving relative to the stator yoke part (1) in an axial direction; the radial outer ends of the stator tooth parts (2) and the stator yoke part (1) are connected in a mutually detachable manner. By adopting the technical scheme of the invention, the stator tooth parts and the stator yoke part are arranged ina mutually detachable manner, and the coils can be relatively easily arranged on the stator tooth parts before the stator tooth parts are mounted at the stator yoke part, so that the coil winding difficulties can be reduced, the problem of too large magnetic pressure reduction caused by too large intervals of tooth parts can be solved, and the problem of too large winding and torque pulsation canbe solved.

Owner:ANHUI MEIZHI COMPRESSOR

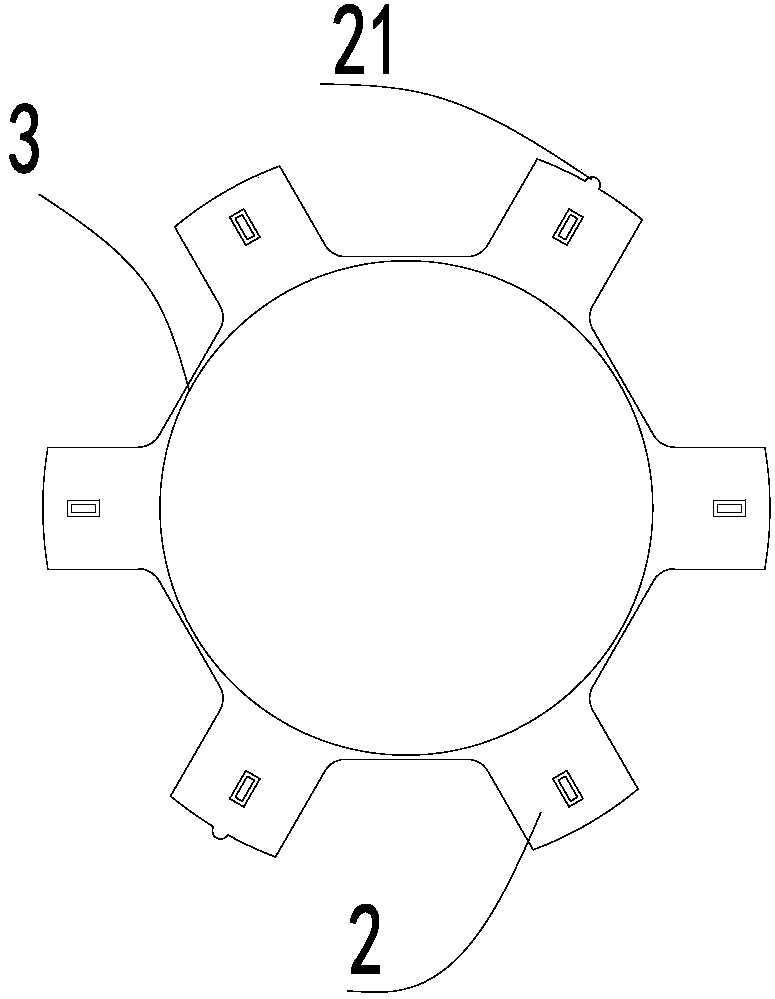

Stator assembly, motor and compressor

InactiveCN108521179AReduce winding difficultyEasy to set upMagnetic circuit stationary partsWindings conductor shape/form/constructionLarge toothElectric machine

The invention belongs to the motor field and discloses a stator assembly, a motor and a compressor. The stator assembly comprises a stator yoke portion (1), a connecting ring (3) and a plurality of stator tooth portions (2); the stator tooth portions (2) are provided with a coil (4) surrounding the stator tooth portion portions (2); the radial outer ends of the stator tooth portions (2) are provided with stopping portions (22); the stator tooth portions ( 2) and the connecting ring (3) can axially move relative to the stator yoke portion (1); and the stator tooth portions (2) are detachably connected with the stator yoke portion (1). With the above technical schemes of the invention adopted, the stator tooth portions and the stator yoke portion can be detachable from each other; the coil can be disposed on the stator tooth portions more easily before the stator tooth portions are mounted on the stator yoke portion; the winding difficulty of the coil can be reduced; excessive magnetic pressure drop caused by excessively large tooth intervals can be avoided; and winding problems and the problem of excessive torque ripples can be solved.

Owner:ANHUI MEIZHI COMPRESSOR

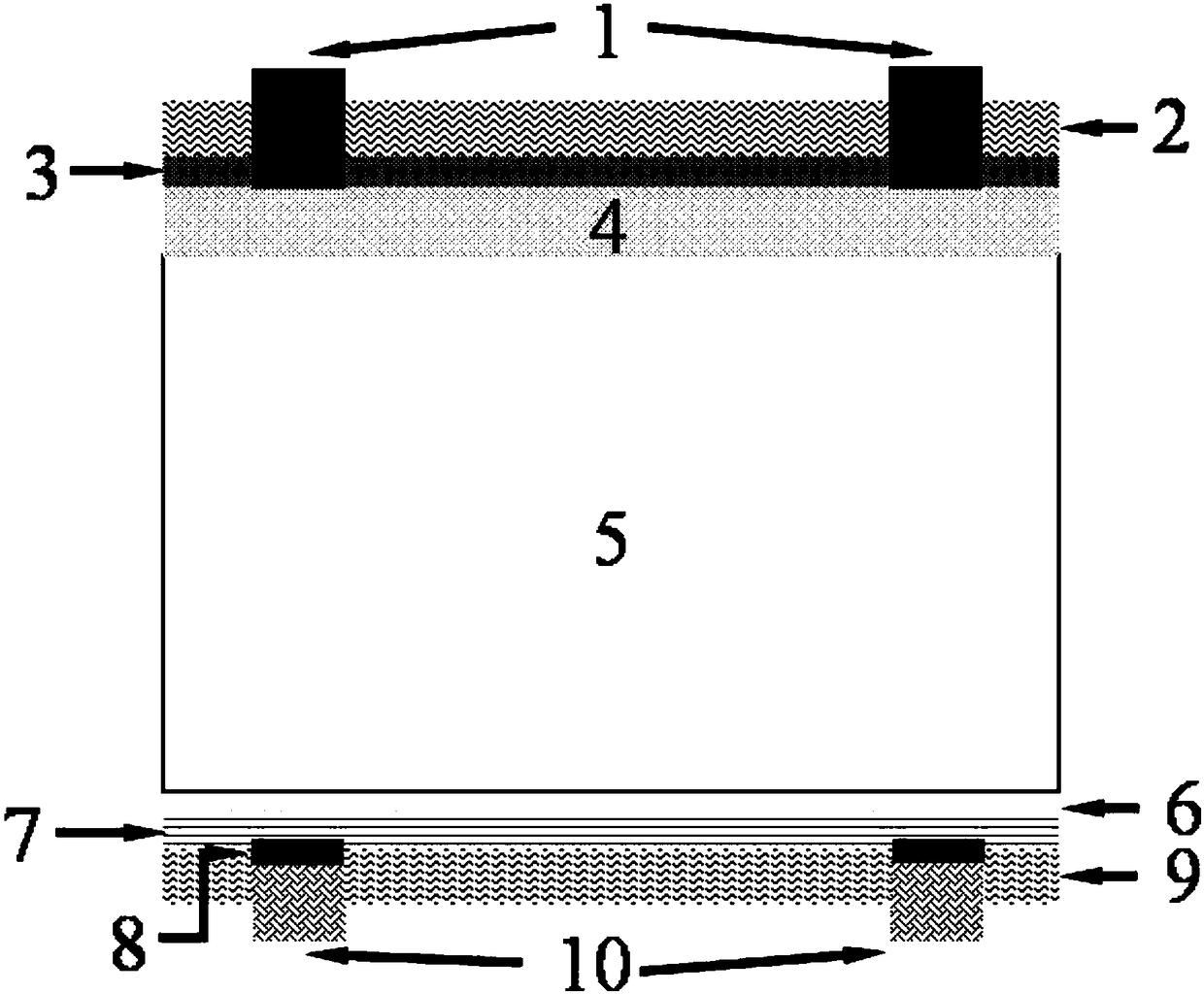

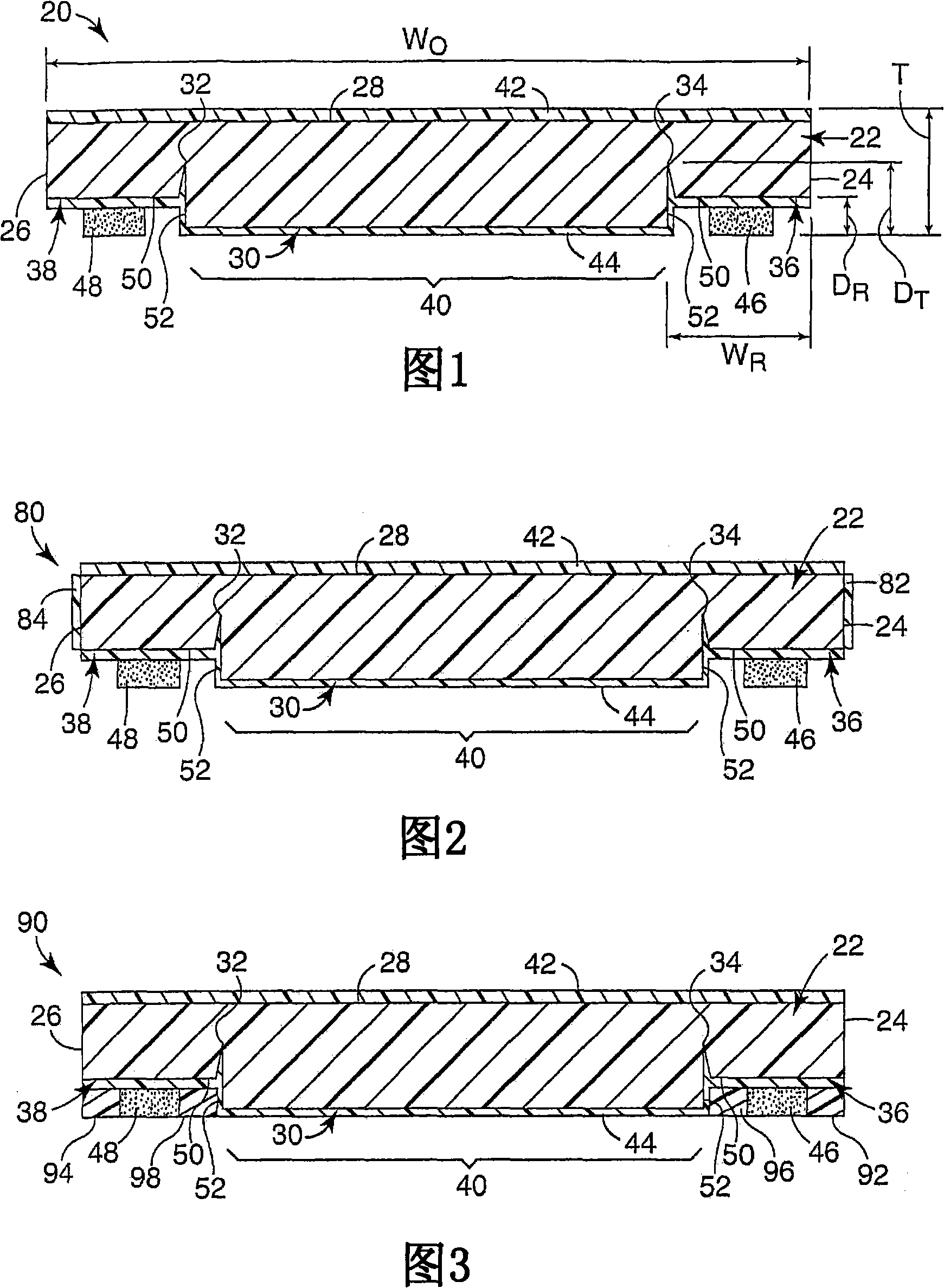

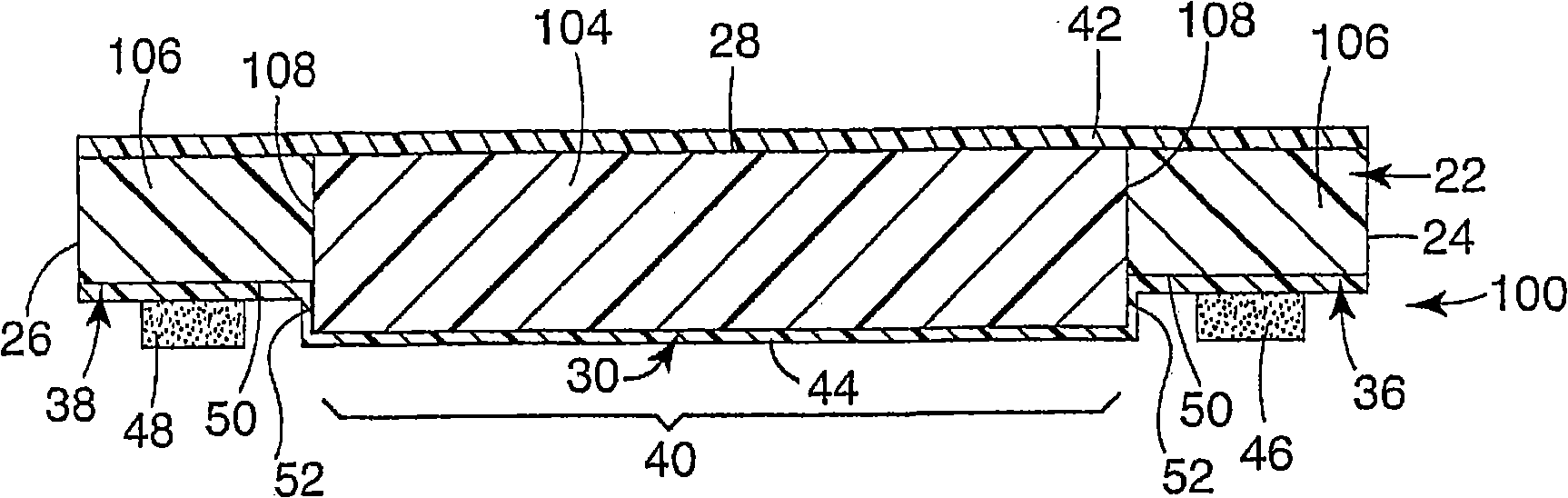

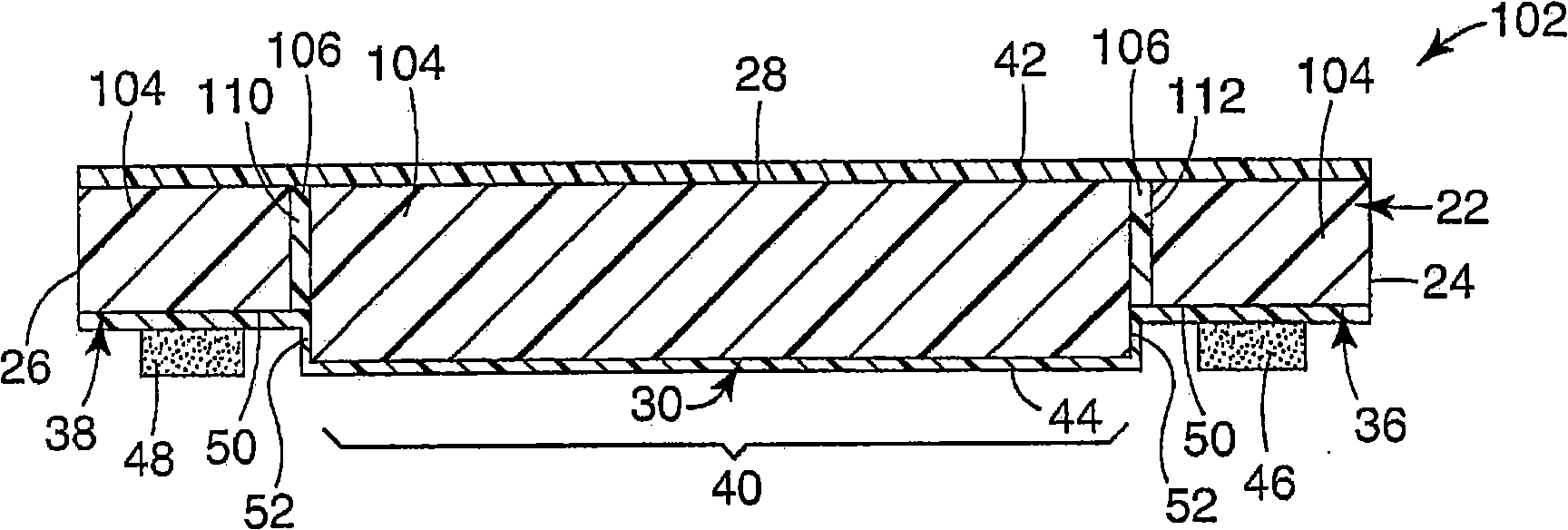

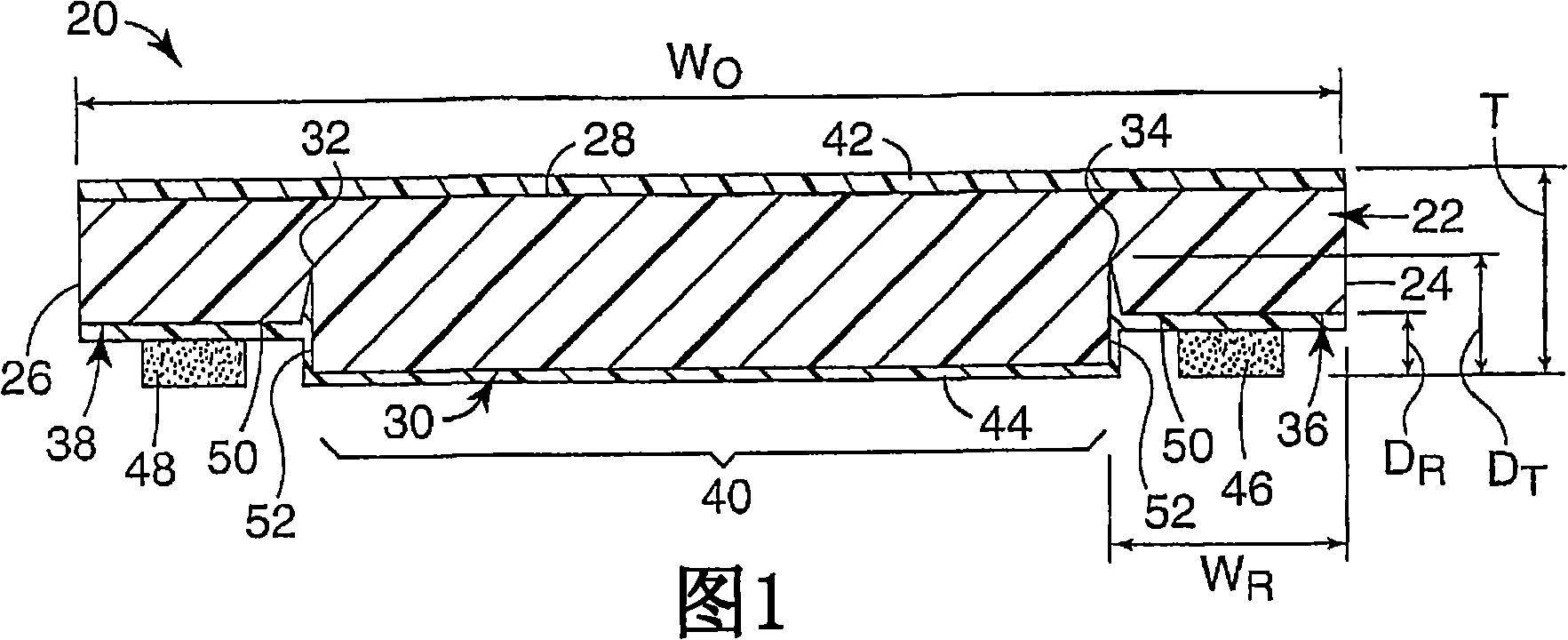

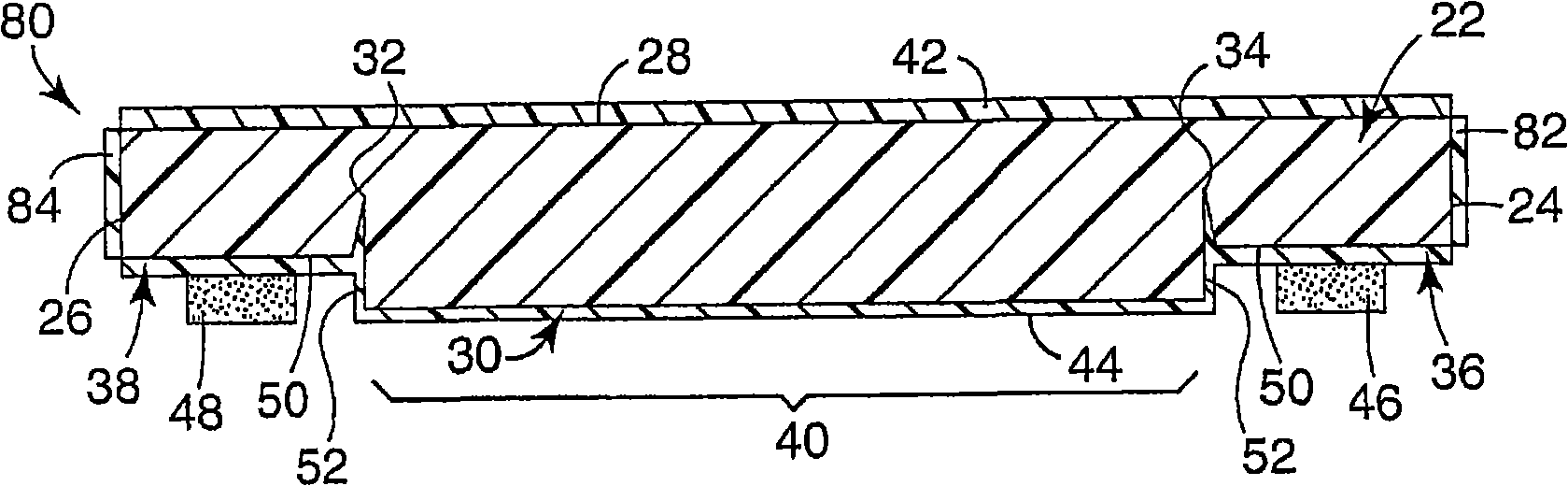

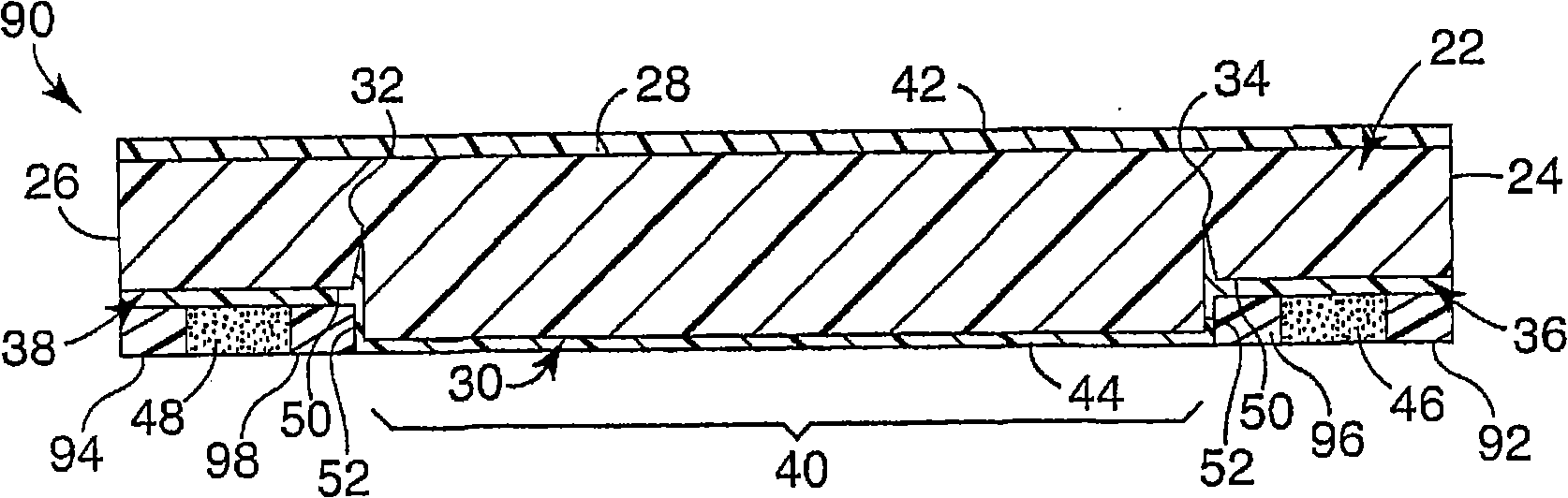

Cover tape and method for manufacture

InactiveCN101273678AUniform removal forceSolve the winding problemPackagingElectrical componentsAdhesiveEngineering

An article includes a cover tape, which includes a base film layer, recessed areas, tear enabling features, and an adhesive. The base film layer has opposed longitudinal edges. The recessed areas extend along the longitudinal edges of the base film layer. The tear enabling features are substantially parallel to the longitudinal edges. The adhesive is disposed on the recessed areas.

Owner:3M INNOVATIVE PROPERTIES CO

Stator component, motor and compressor

InactiveCN108429366AReduce winding difficultyEasy to set upMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineEngineering

The invention relates to the field of motors and discloses a stator component, a motor and a compressor. The stator component comprises a stator yoke part (1), a connecting ring (3) and a plurality ofstator tooth parts (2), wherein the plurality of the stator tooth parts (2) extend to the stator yoke part (1) from the outer circumference of the connecting ring (3) in a radial direction; the stator tooth parts (2) are sleeved with coils; the stator tooth parts (2) and the connecting ring (3) are axially movable relative to the stator yoke part (1); the radial outer ends of the stator tooth parts (2) and the stator yoke part (1) are connected in a mutually detachable manner. By adopting the technical scheme of the invention, the stator tooth parts and the stator yoke part are arranged in amutual detachable manner, and the coils can be relatively easily arranged on the stator tooth parts before the stator tooth parts are mounted at the stator yoke part, so that the coil winding difficulties can be reduced, the problem of too large magnetic pressure reduction caused by too large intervals of tooth parts can be solved, and the problem of too large winding and torque pulsation can be solved.

Owner:ANHUI MEIZHI COMPRESSOR

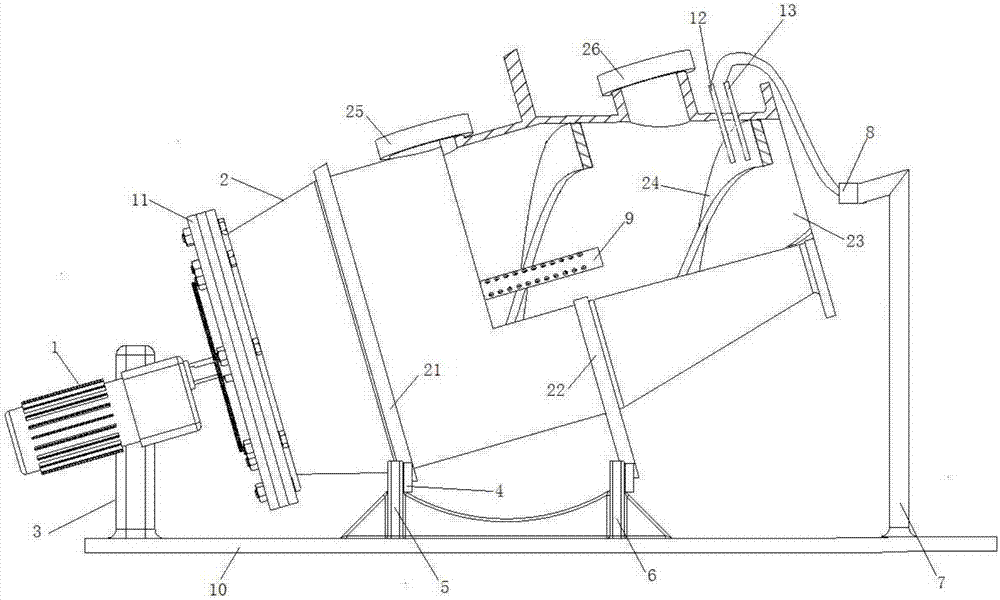

Horizontal roller aerobic composting reactor for ecological toilet

InactiveCN107082655ARealize the function of turning overThere is no stirring dead zoneClimate change adaptationExcrement fertilisersProcess engineeringMoisture sensor

The invention provides a horizontal roller aerobic composting reactor for an ecological toilet, and relates to an aerobic composting reactor. The horizontal roller aerobic composting reactor for the ecological toilet aims to solve the problems that in the reactor, partial oxygen supply is insufficient, the local temperature is too high and the local humidity is too large or the local humidity is too small due to the fact that an existing aerobic composting reactor is lack of a stirring device or the stirring device stirs unevenly. The reactor comprises an electric motor, a roller, a electric motor bracket, riding wheels, a first riding wheel bracket, a second riding wheel bracket, a conduit, a slip ring, an aerator pipe, a base and a roller sealing cover, a temperature sensor and a humidity sensor. The roller sealing cover is arranged on the end face of the roller, close to the electric motor bracket, and the inner wall of the roller is provided with a guide vane. The reactor has no stirring dead zone, can store more materials, ensures the oxygen supply of aerobic composting biochemical reaction, and is compact in structure, easy to assembly, and easy to clean and repair. The horizontal roller aerobic composting reactor for the ecological toilet is suitable for the preparation of aerobic composting.

Owner:青岛哈工程正和环保科技有限公司

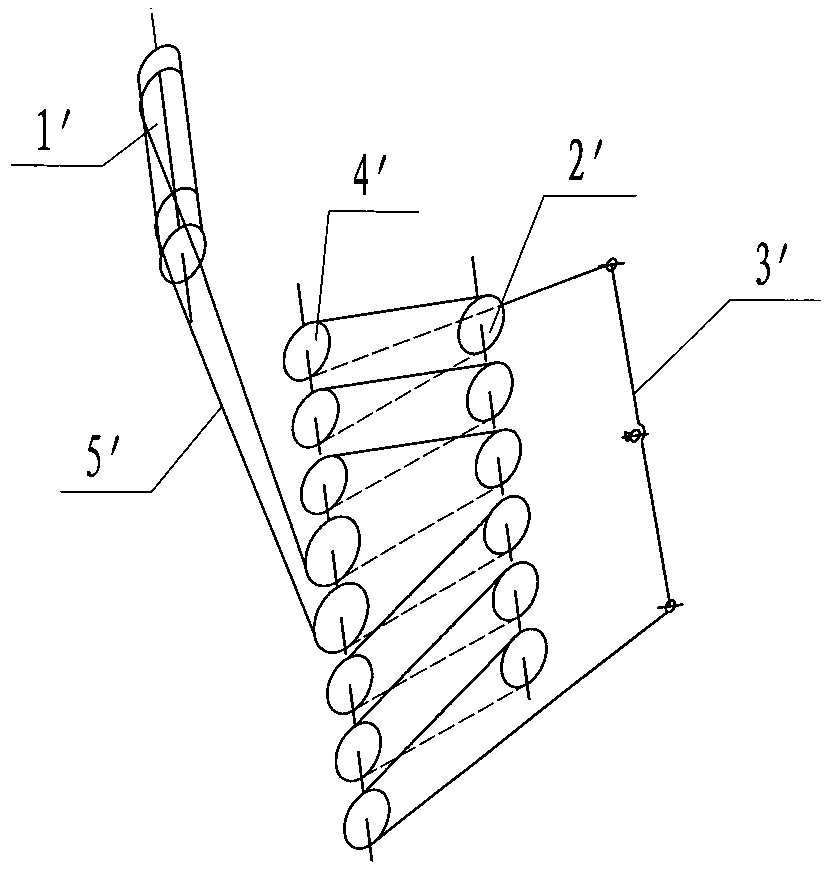

Non-conventional winding system for high-multiplying-power bridge crane

PendingCN108313885AEven by forceUniform force transmissionLoad-engaging elementsDeflection angleEngineering

The invention discloses a non-conventional winding system for a high-multiplying-power bridge crane. The system comprises a winding barrel, a fixed pulley block, a balanced pulley block, a movable pulley block and a steel wire rope, which are arranged from top to bottom, wherein a rope unwinding end and a rope winding end of the steel wire rope are fixed at two sides of the winding barrel respectively; a rope unwinding section of the steel wire rope sequentially winds around rope unwinding pulley combinations in the movable pulley block and the fixed pulley block in a mutual staggering manner;a rope winding section of the steel wire rope sequentially winds around rope winding pulley combinations in the movable pulley block and the fixed pulley block in the mutual staggering manner; the steel wire rope is located at a transition section between the rope unwinding section and the rope winding section and winds around the balanced pulley block. According to the non-conventional winding system disclosed by the invention, hoisting tonnages are improved through the increasing of multiplying power of the pulley blocks; the maximum deflection angle of an unwinding barrel of the steel wirerope is reduced through improving a rope winding manner, a transverse force on a side wall of a winding barrel rope groove is reduced, the abrasion of the steel wire rope is reduced, the safety and reliability of hoisting are improved and the winding problem of the high-tonnage and high-multiplying-power bridge crane is solved; the non-conventional winding system has the characteristics of economical efficiency, practicability, novelty and the like.

Owner:KERUN ELECTRO MECHANICAL ENG

Apparatus for manufacture of cover tape

InactiveCN101277795AUniform removal forceSolve the winding problemMetal working apparatusEngineeringMechanical engineering

Owner:3M INNOVATIVE PROPERTIES CO

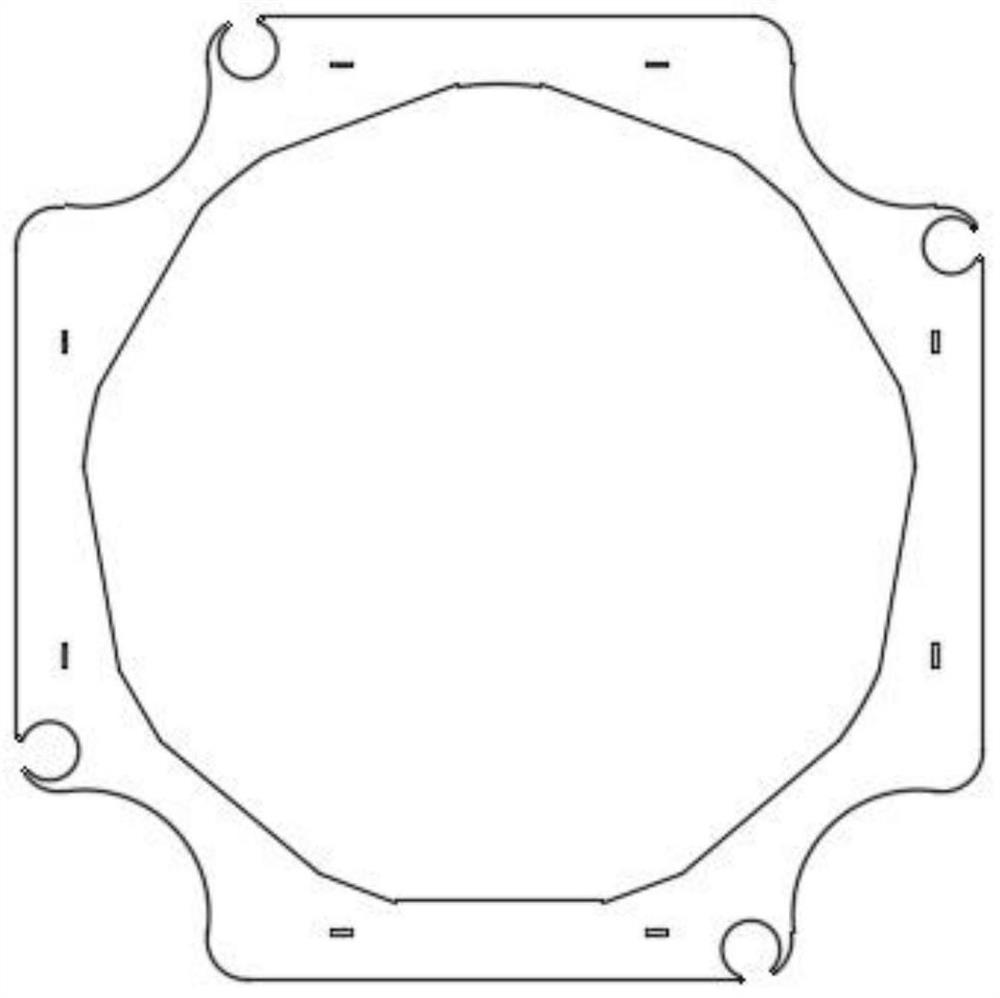

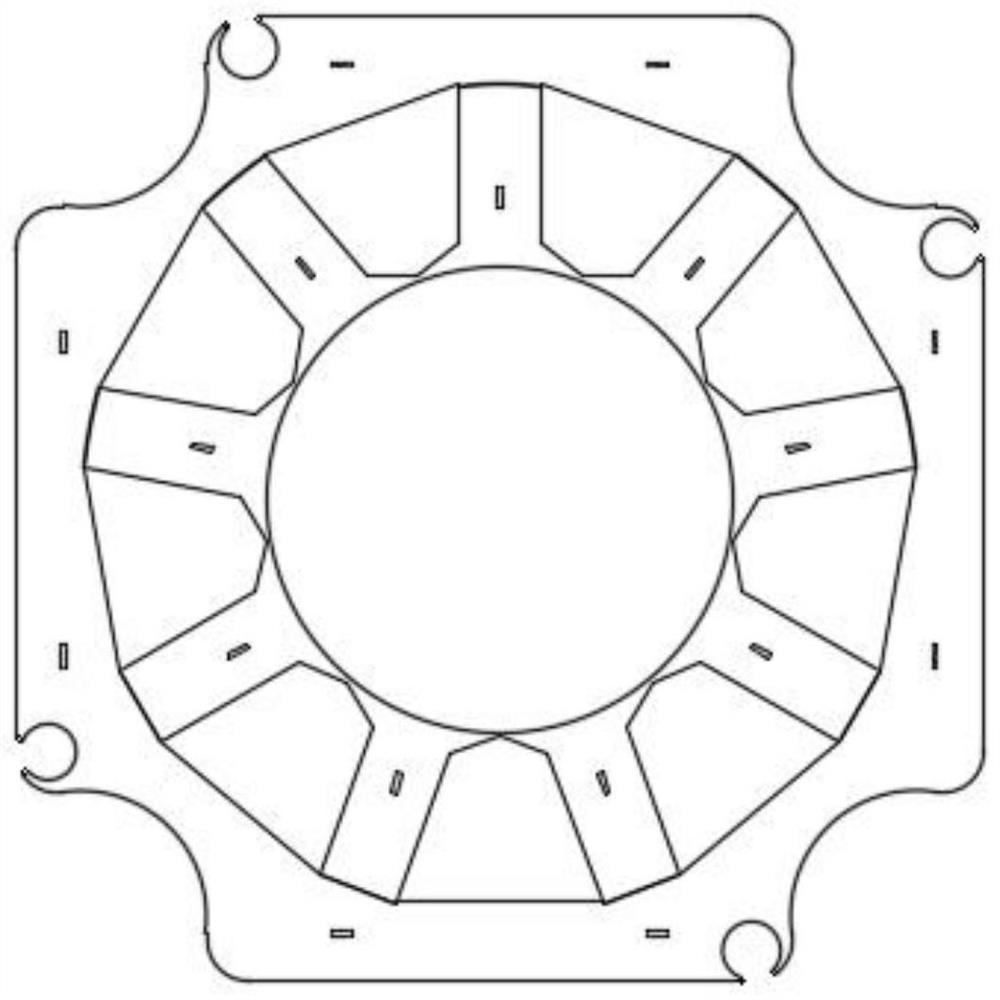

Tooth yoke separation type permanent magnet synchronous motor stator structure

PendingCN113328541APrevent rotationSolve the winding problemWindings insulation shape/form/constructionMagnetic circuit stationary partsPermanent magnet synchronous motorEngineering

The invention discloses a tooth yoke separation type permanent magnet synchronous motor stator structure, which comprises a stator yoke part and a stator tooth part, the stator yoke part and the stator tooth part are formed by punching and laminating cold-rolled silicon steel sheets, and the outer side of the stator tooth part is provided with a plurality of convex stator teeth arranged around the stator tooth part. The inner hole outline of the stator yoke part is formed by splicing a plurality of sections of arc lines, the arc lines are connected through line segments, and each section of arc line corresponds to one stator tooth on the stator tooth part. The inner hole outline of the stator yoke part is formed by splicing the multiple sections of arc lines, the arc lines are connected through the line segments, and each section of arc line corresponds to the stator teeth on the stator tooth part, so that the problems that an existing spliced block stator structure is complex in splicing process and the roundness of a whole circle is difficult to guarantee are solved, and the problem of large internal winding difficulty due to small inner diameter of an integrated stator structure can be solved. The structure greatly solves the problem of winding, and is simple to assemble and high in precision.

Owner:湖州禾宇科技有限公司

Transformer fly wire winding device

PendingCN108447679ASolve the problem of winding after manually fixing the flying wire headSolve the winding problemInductances/transformers/magnets manufactureDrive wheelTransformer

The invention discloses a transformer fly wire winding device in the technical field of transformers. The transformer fly wire winding device comprises a wire winding device body, a sliding rod, a fixed plate, a driving shaft, a driving wheel, a driving sector wheel, a transmission wheel, a transmission shaft, a location rod, a driven shaft, a driven wheel and a driven sector wheel, wherein the driven shaft and the driving shaft are arranged on the fixed plate, the transmission shaft is arranged on the fixed plate, the driving wheel and the transmission wheel are meshed with each other, the transmission wheel and the driven wheel are meshed with each other, a sliding groove is arranged on the sliding rod, a partition plate is arranged on the sliding rod, the sliding rod is divided into a smooth part and a meshed part by the partition plate, and the two sides of the meshed part are respectively meshed with the driving wheel and the driven wheel; the winding device body comprises an annular pipe, a wire winding rod and two stopping plates; the stopping plates are meshed with an inner wall of the annular pipe, and a first motor is connected to the wire winding rod; a fixed frame is arranged on the fixed plate, a telescopic rod is arranged on the fixed frame, an extruding block is arranged on the telescopic rod, and the driving shaft is connected with a second motor. A machine is utilized to replace the hand, the hand is prevented from contacting the rotating shaft, and operation can be safer.

Owner:贵州金林电子科技有限公司

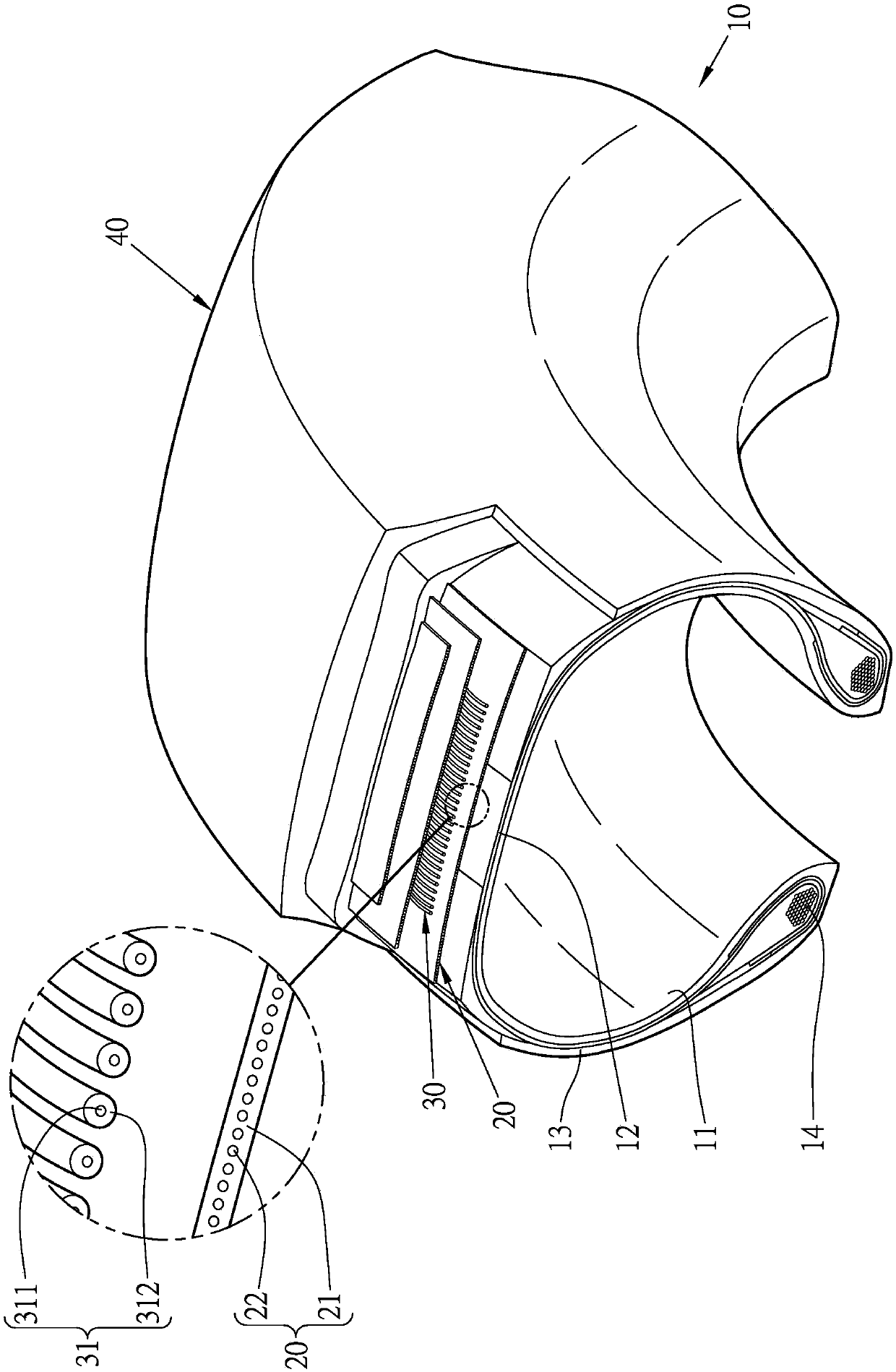

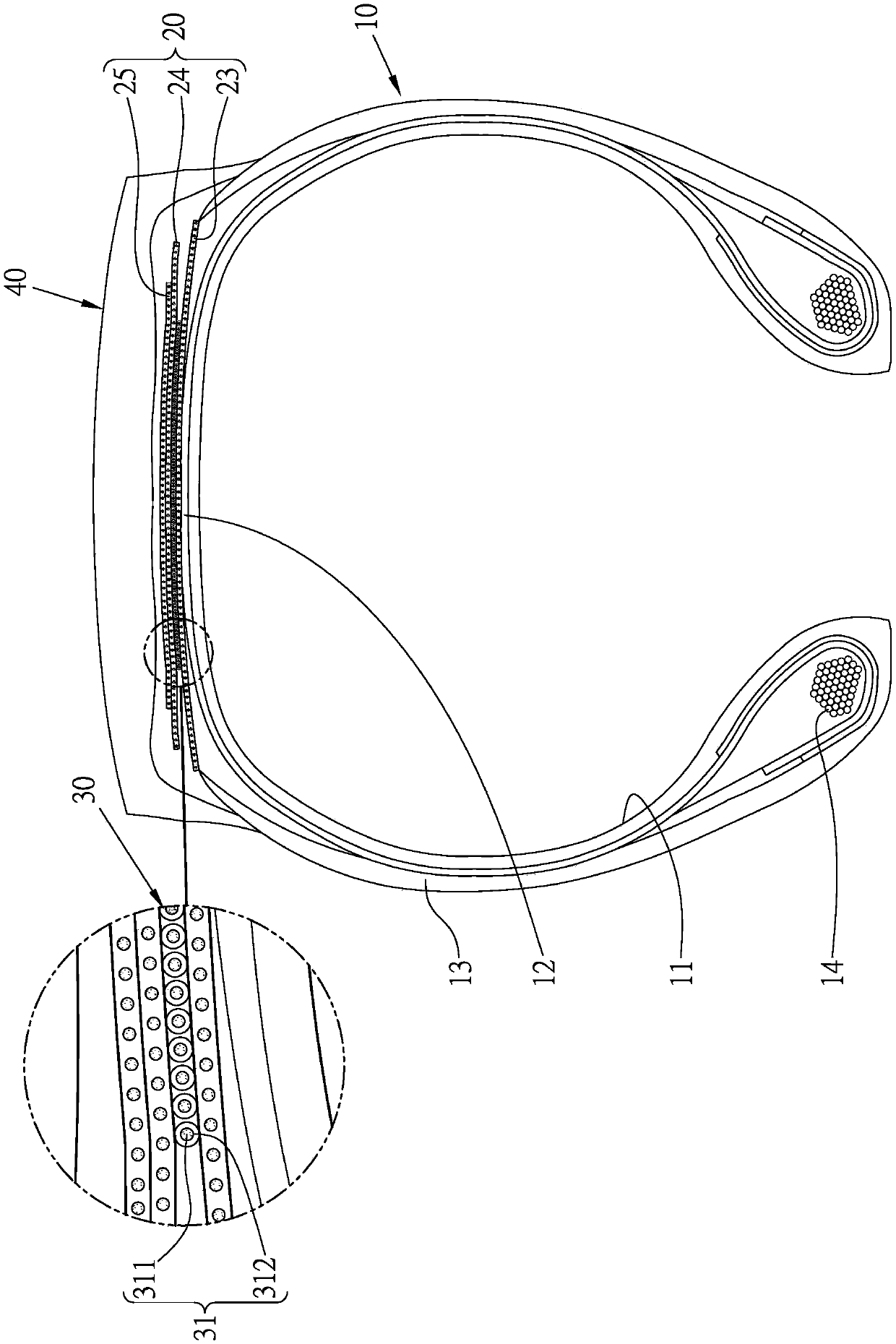

Dental floss device

The invention relates to a dental floss device including a dental floss device hand-holding part, a dental floss fixed part, a supporting rod and a dental floss. The dental floss device hand-holding part is formed by left-and-right detachable connection of a shell and a shell cover. The dental floss fixed part is fixed at the front end of the shell through the supporting rod, the shell body is internally provided with a dental floss unreeling mechanism, and one end of a dental floss is connected to the dental floss unreeling mechanism and is unreeled by the dental floss unreeling mechanism; the top of the shell is provided with a floss outlet hole, the other end of the floss extends out from the floss outlet hole and is fixed on the dental floss fixed part; the supporting rod is also provided with a dental floss length fixing mechanism; the top of the shell is also provided with a cutter. The dental floss device has the advantages of simple structure, easy manufacture, practicality andhigh in efficiency.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

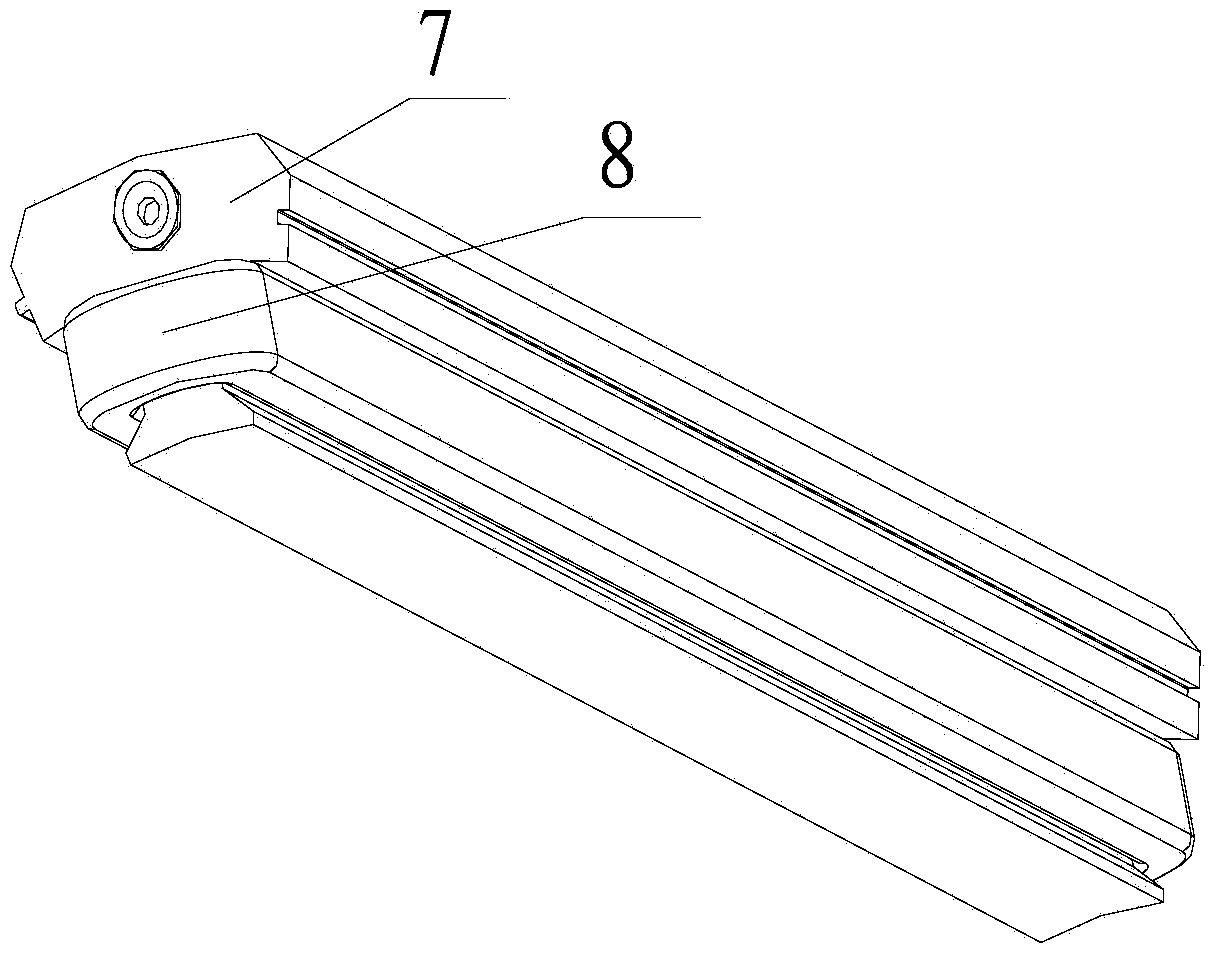

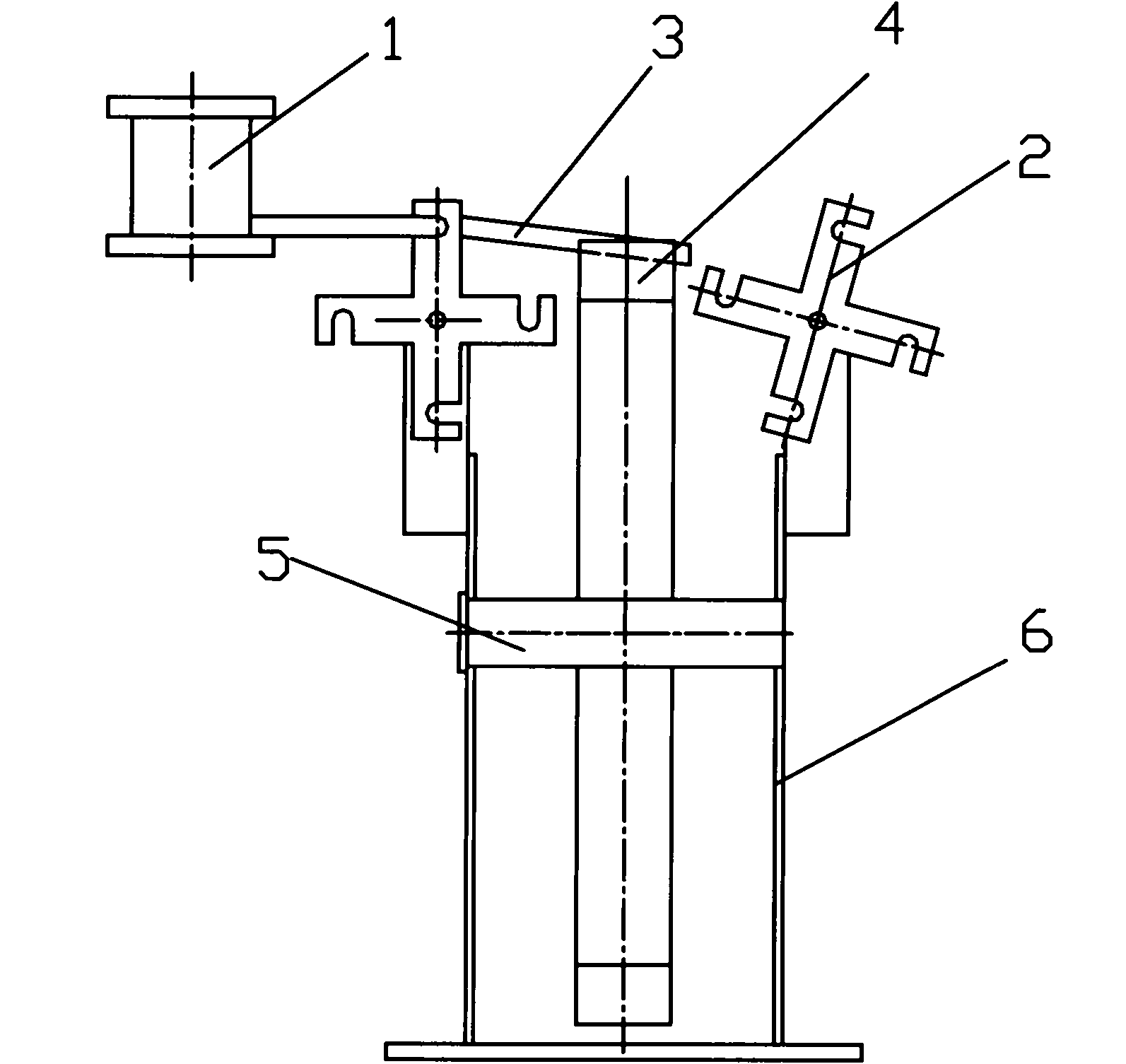

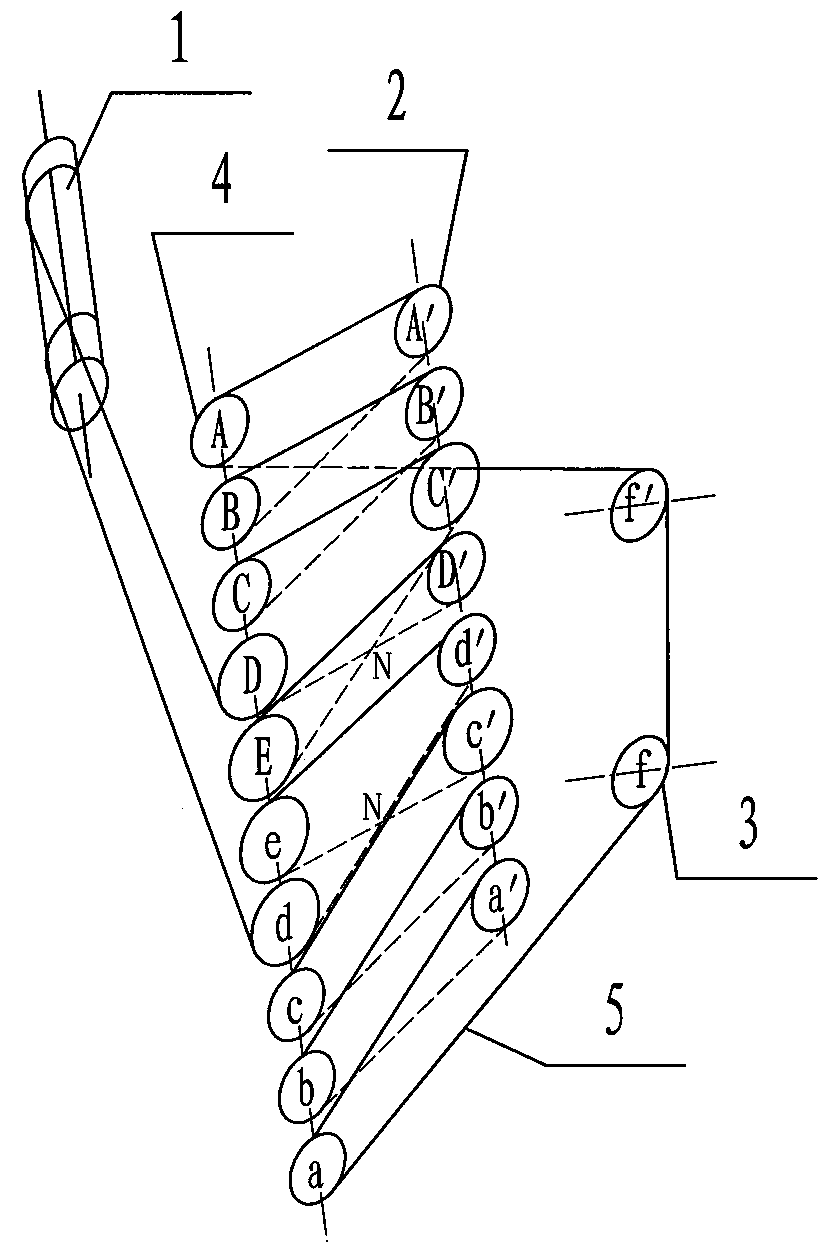

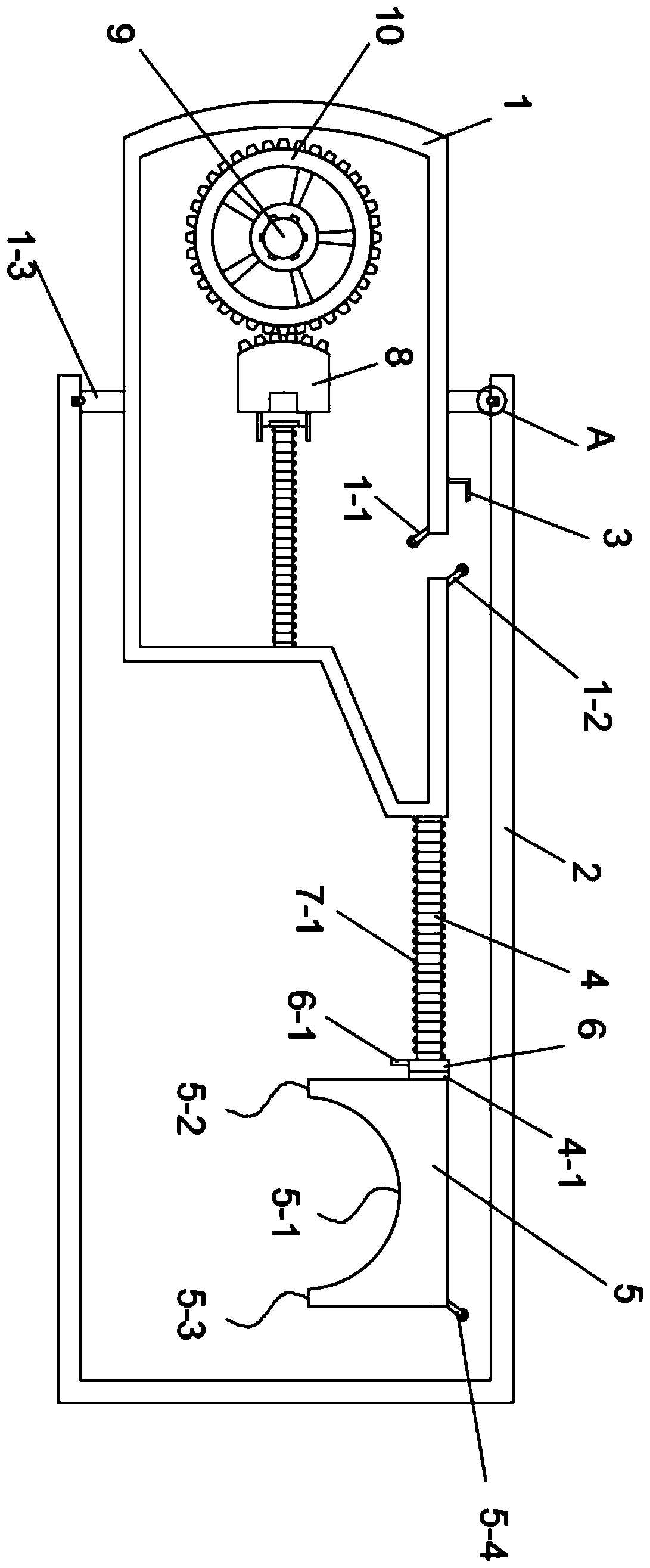

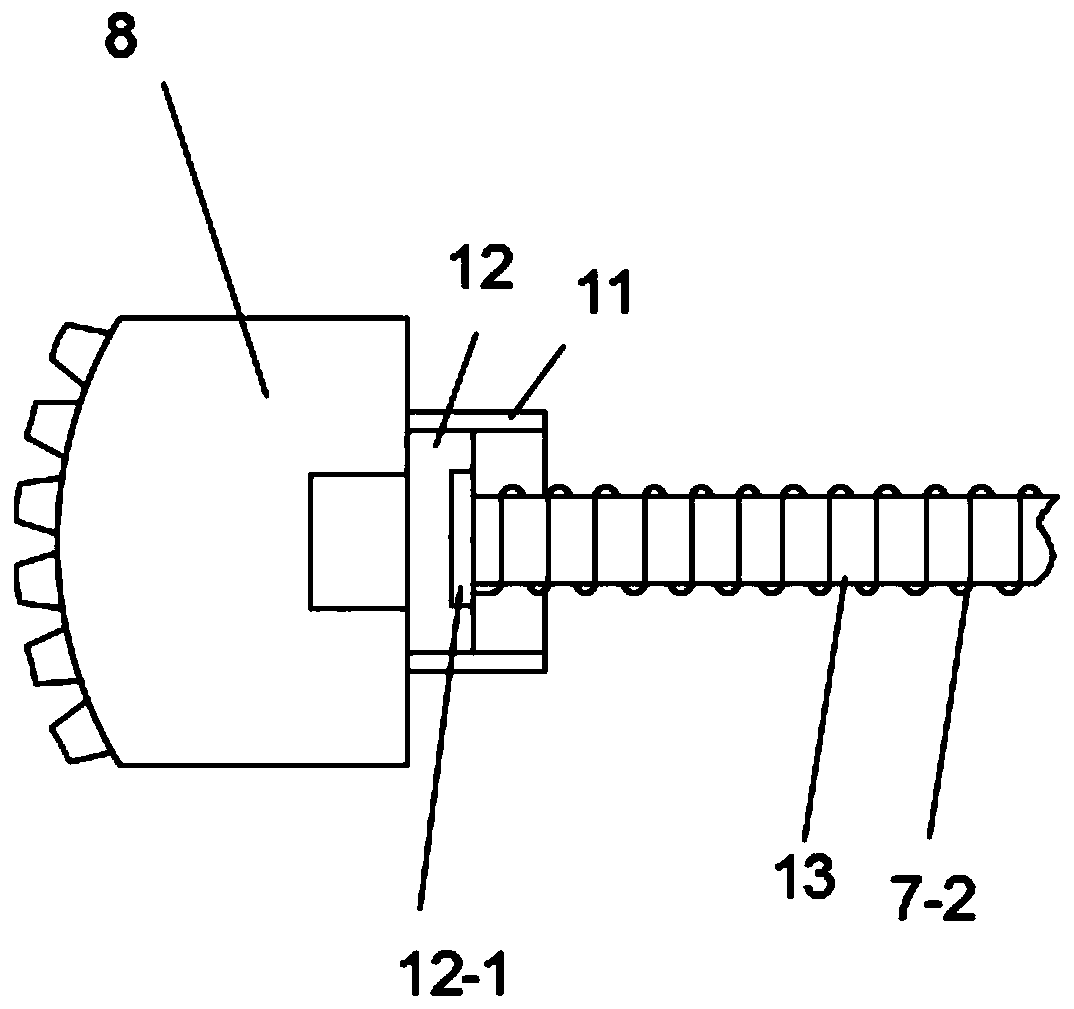

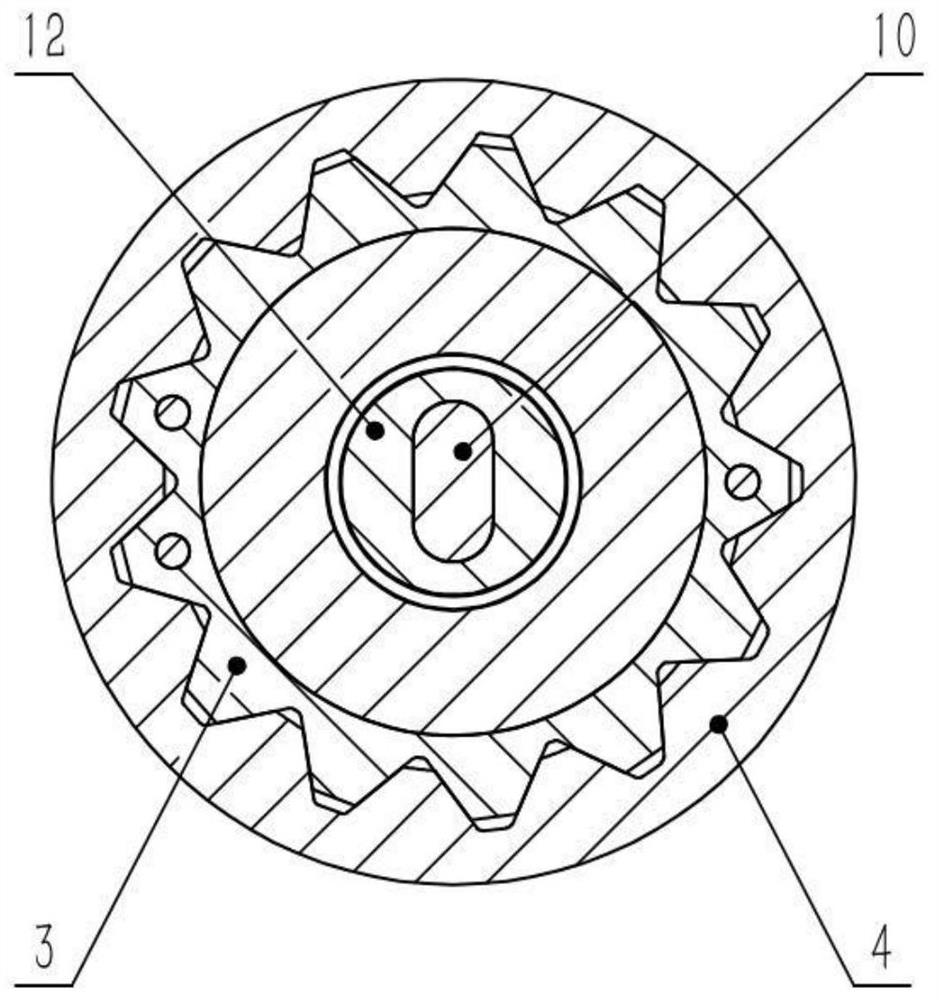

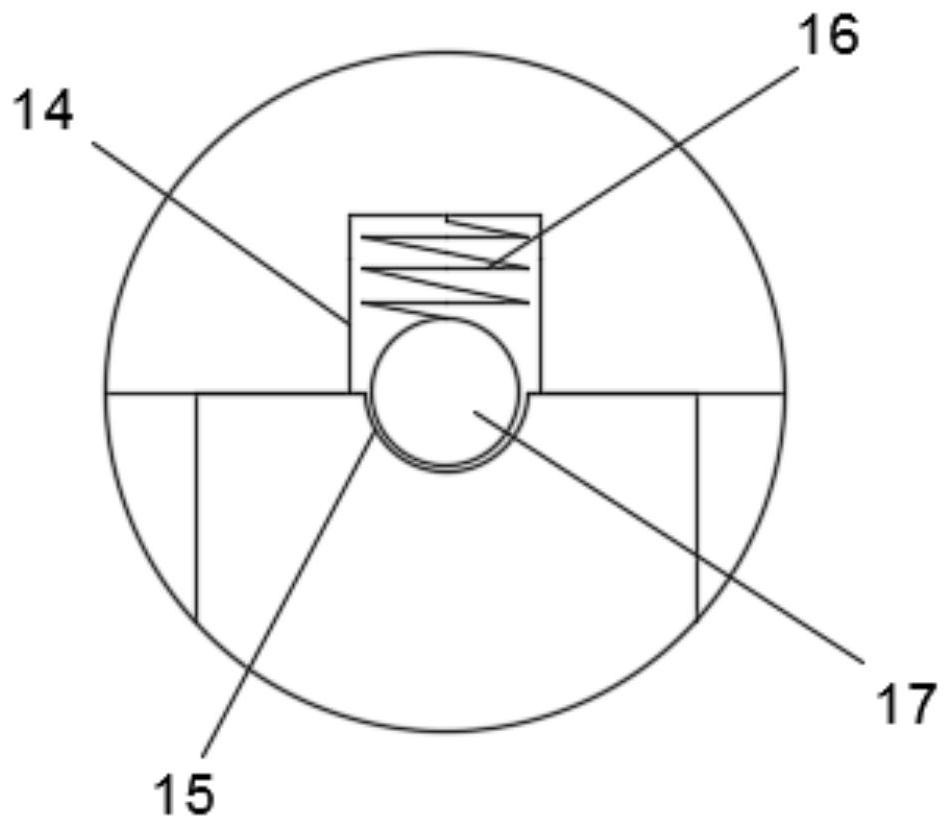

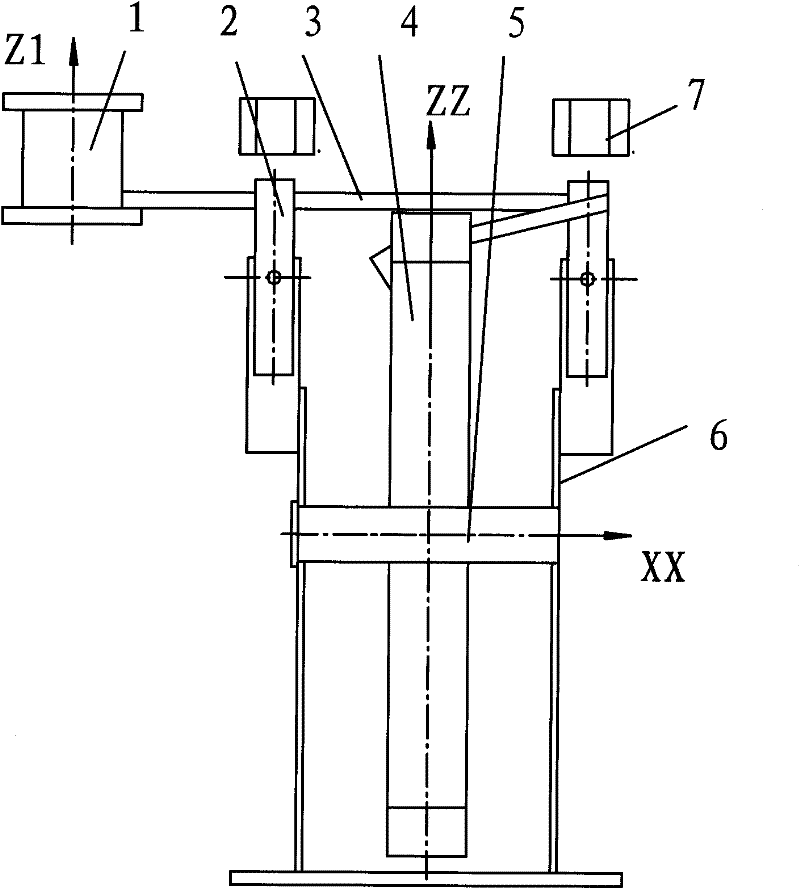

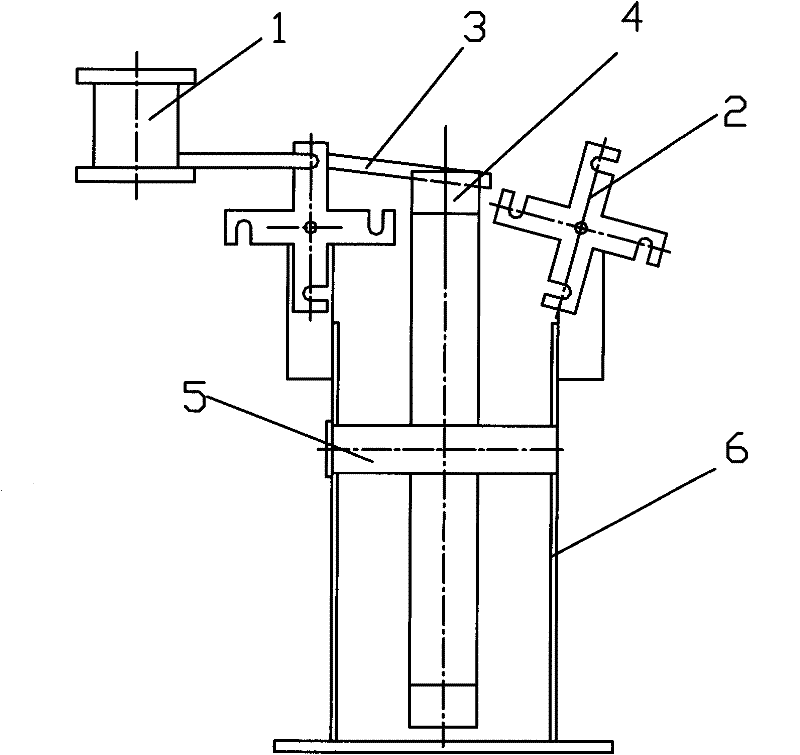

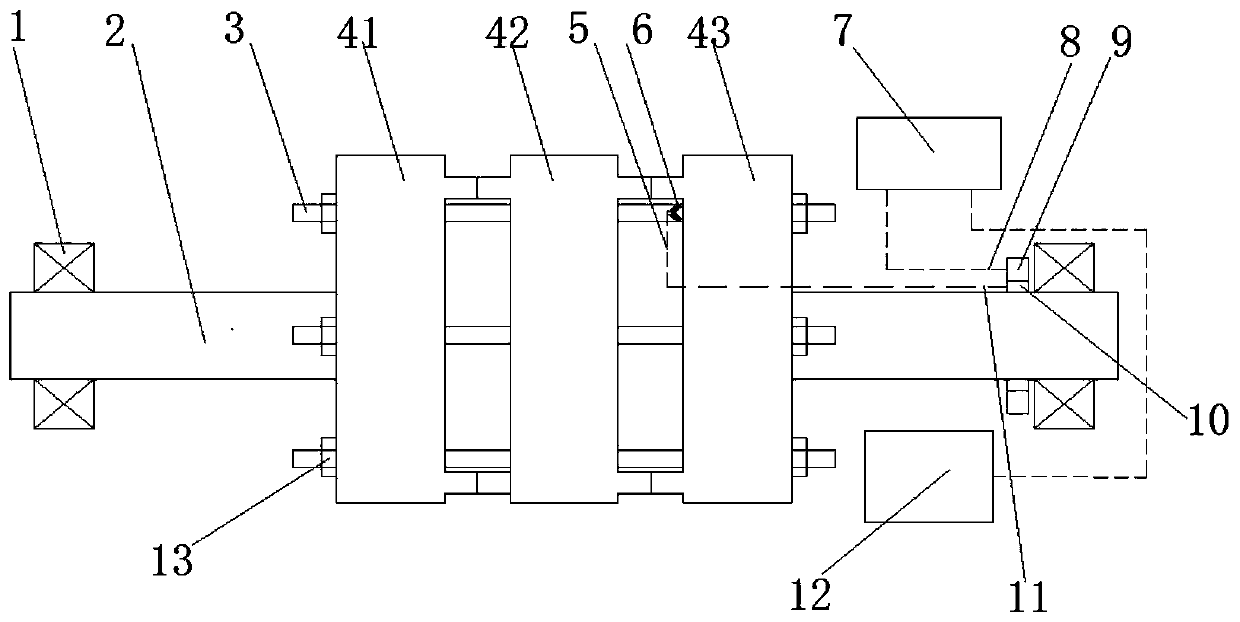

Synchronous die filling mechanism of winding machine

InactiveCN103296844BSolve the winding problemEasy winding and fully mechanizedManufacturing dynamo-electric machinesWinding machineRotary stage

The invention discloses a synchronous die filling mechanism of a winding machine. The synchronous die filling mechanism comprises a driven gear, a second driving gear, a fixed shaft, a fixed shaft rotating controller, a synchronous shaft, a first driving gear, a main transmission motor, a winding rotating table, a frame, an armature support frame, a motor armature, a wire arranging mechanism, a middle plate, an inner rotating table and a wire press base. An output shaft of the main transmission motor is fixedly connected with the synchronous shaft, the first driving gear is fixedly connected with the output shaft of the main transmission motor, the second driving gear is fixedly connected with the synchronous shaft, a tooth space of the winding rotating table is meshed with the first driving gear, the fixed shaft is fixedly connected with the motor armature, the driven gear is connected with the wire press base and meshed with the second driving gear, the wire arranging mechanism is fixedly connected with the frame, and a wire at an outlet of the wire arranging mechanism is wound on a wire press unit. The synchronous die filling mechanism solves the problem in the prior art that a multi-strand winding small-slot motor rotor is difficult in winding.

Owner:SOUTHEAST UNIV

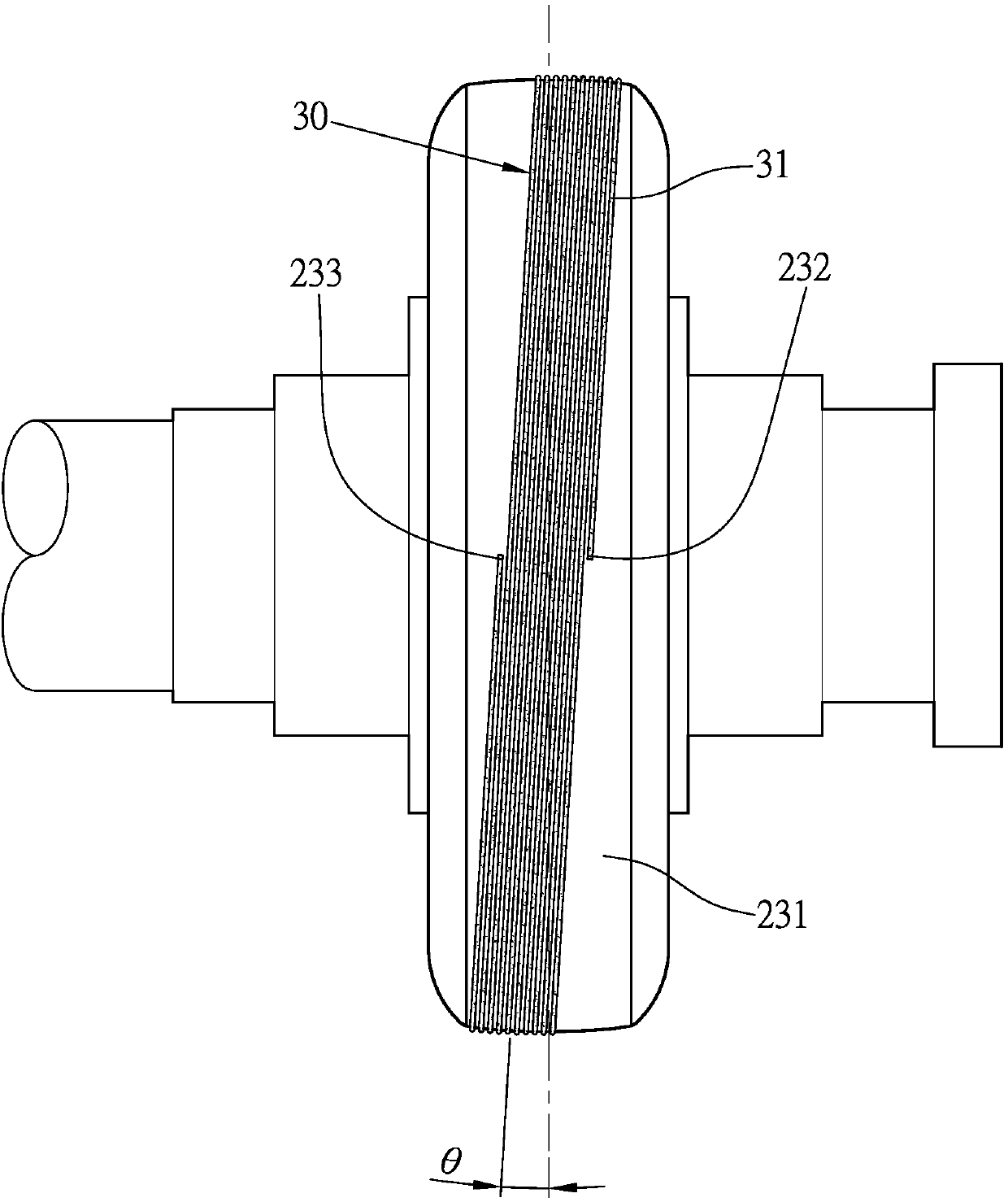

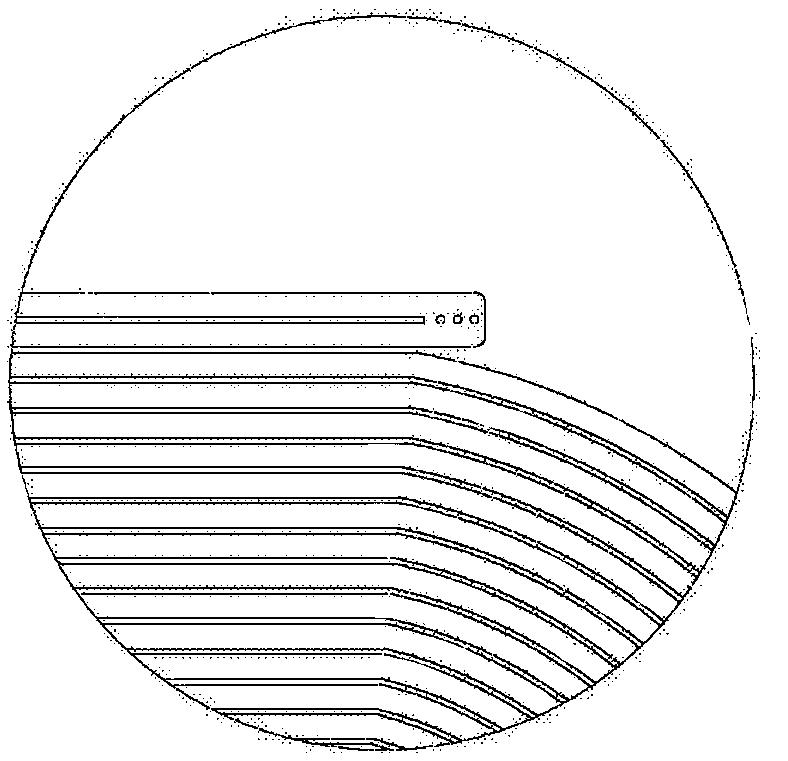

Tire of winding type steel wire girdle structure

InactiveCN109866556AImprove performanceTroubleshoot issues with cut jointsPneumatic tyre reinforcementsTire beadEngineering

The invention mainly provides a tire of a winding type steel wire girdle structure. A main tire body is composed of a tire tread, a tire bead, a tire shoulder and a tire lip, a steel wire girdle layerand a winding steel wire layer in the tire body are sequentially stacked on a tire body steel wire layer, and then a tire tread outer layer annularly wraps the steel wire girdle layer; the winding steel wire layer is provided with a winding steel wire strip which is wound on a winding part in a single wire continuous winding manner, a winding starting point conducts continuous winding with a preset winding inclined angle until a winding end point is reached, a preset angle is formed between the winding inclined angle and a tire equator line, the numerical range is -5 degree to +5 degree, in this way, the winding steel wire strip using single continuous winding is used, the formed steel wire girdle layer and the steel wire girdle layer are laminated to form a reinforcing structure, local wear can be reduced, the service life of the tire is prolonged, the rigidity, strength and buffering capacity are improved, meanwhile, the distance of the winding steel wire strip can be adjusted, andthe effect of elastic adjustment of the tread reinforcement is achieved.

Owner:CHENG SHIN RUBBER

Negative pressure adsorption wall-climbing robot and its system

Disclosed are a negative-pressure adsorption type wall-climbing robot and a system thereof. Through the negative-pressure adsorption type wall-climbing robot and the system thereof, the technical problems of many limits to the usage range and usage environment, poor universality, difficult maintenance, high function extension and technology upgrading difficulty and the like of an existing wall-climbing robot are mainly solved. According to the main points of the technical scheme, the negative-pressure adsorption type wall-climbing robot comprises a power negative-pressure adsorption type wall-climbing robot body (1), an unpowered negative-pressure adsorption type wall-climbing robot body (2) and a system control device. The negative-pressure adsorption type wall-climbing robot and the system thereof are mainly applied to robot work in various complex environments.

Owner:湖南千智机器人科技发展有限公司

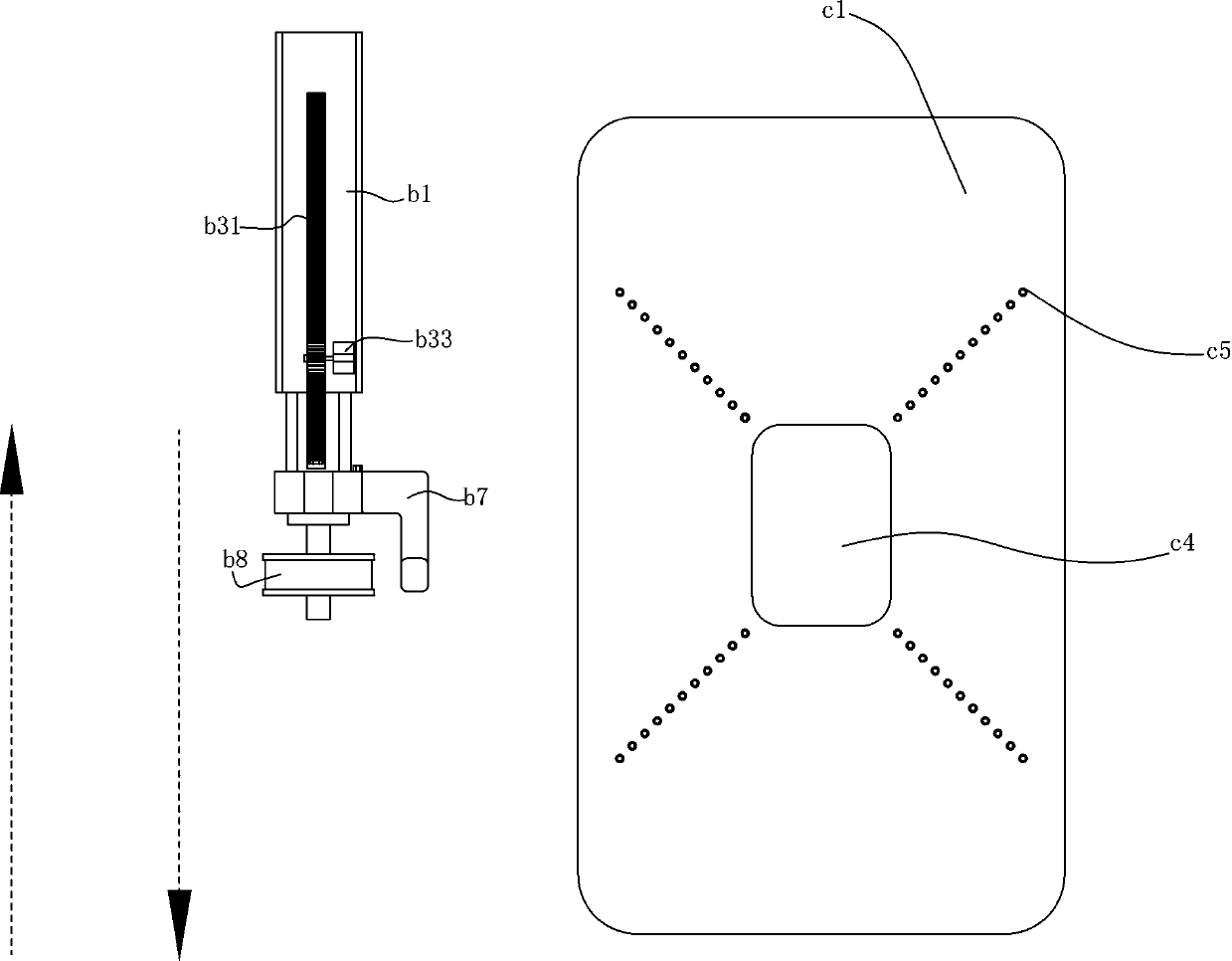

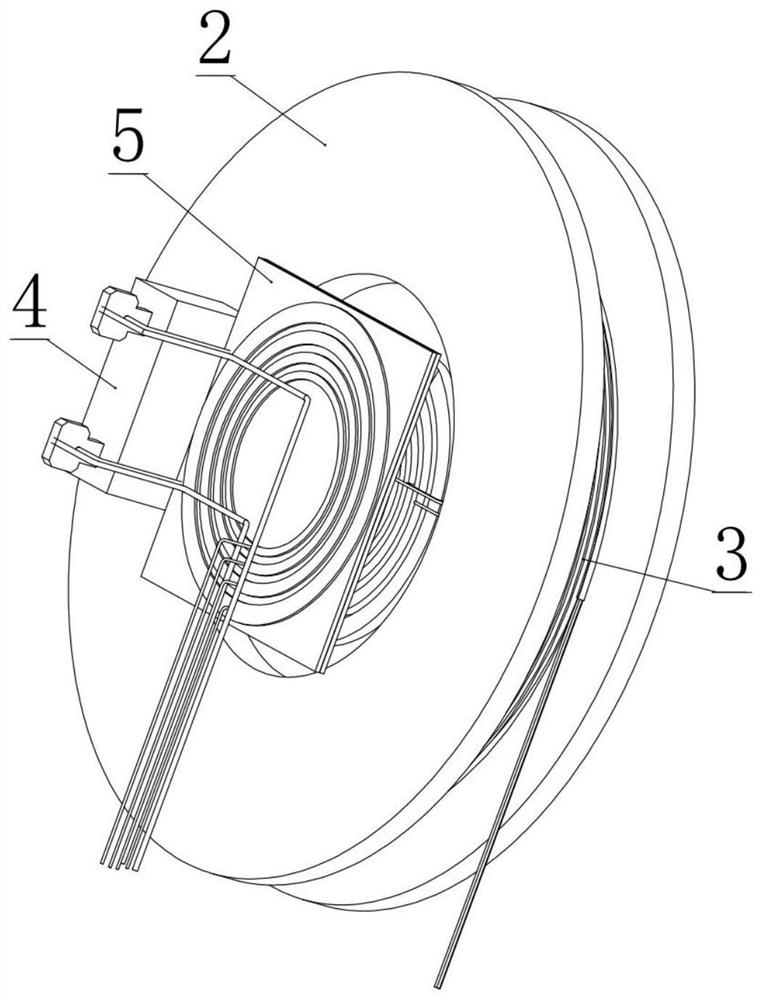

Charge coil winding device

ActiveCN107680797AImprove yield rateSolve the winding problemInductances/transformers/magnets manufactureEngineeringConductor Coil

The invention discloses a charge coil winding device. The charge coil winding device comprises a swinging mechanism and a rotating mechanism, wherein the swinging mechanism comprises a fixed bar and afixed block; a guide bar is arranged on the back of the fixed block, the fixed bar is internally provided with a guide tube corresponding to the guide bar, and the guide bar of the fixed block is insliding connection with the guide tube of the fixed bar. The charge coil winding device also comprises a rack, and one end of the rack is fixed on the back of the fixed block. The charge coil windingdevice also comprises a first motor arranged on the top surface of the fixed bar. The charge coil winding device solves the problem that the clearance becomes smaller during winding internally, and the winding problem is also solved while the yield is greatly improved.

Owner:NANJING ANSEN ELECTRONICS CO LTD

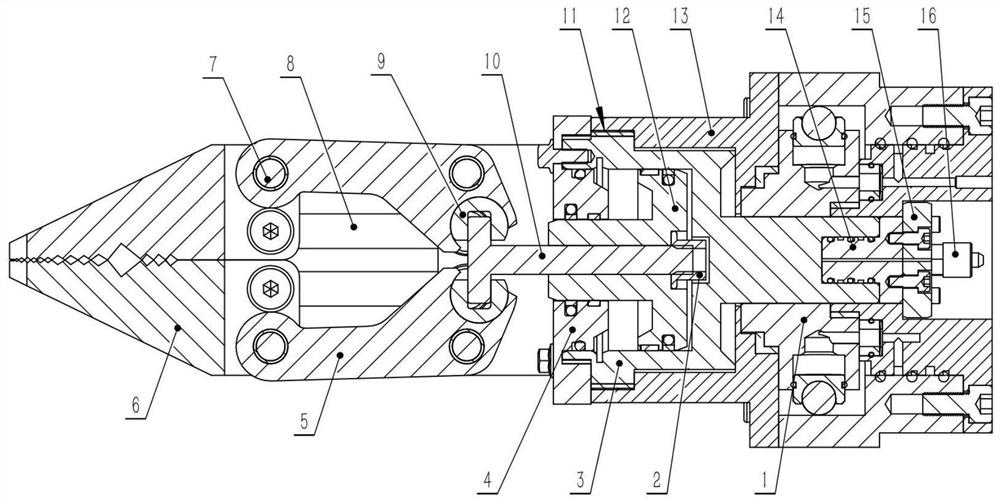

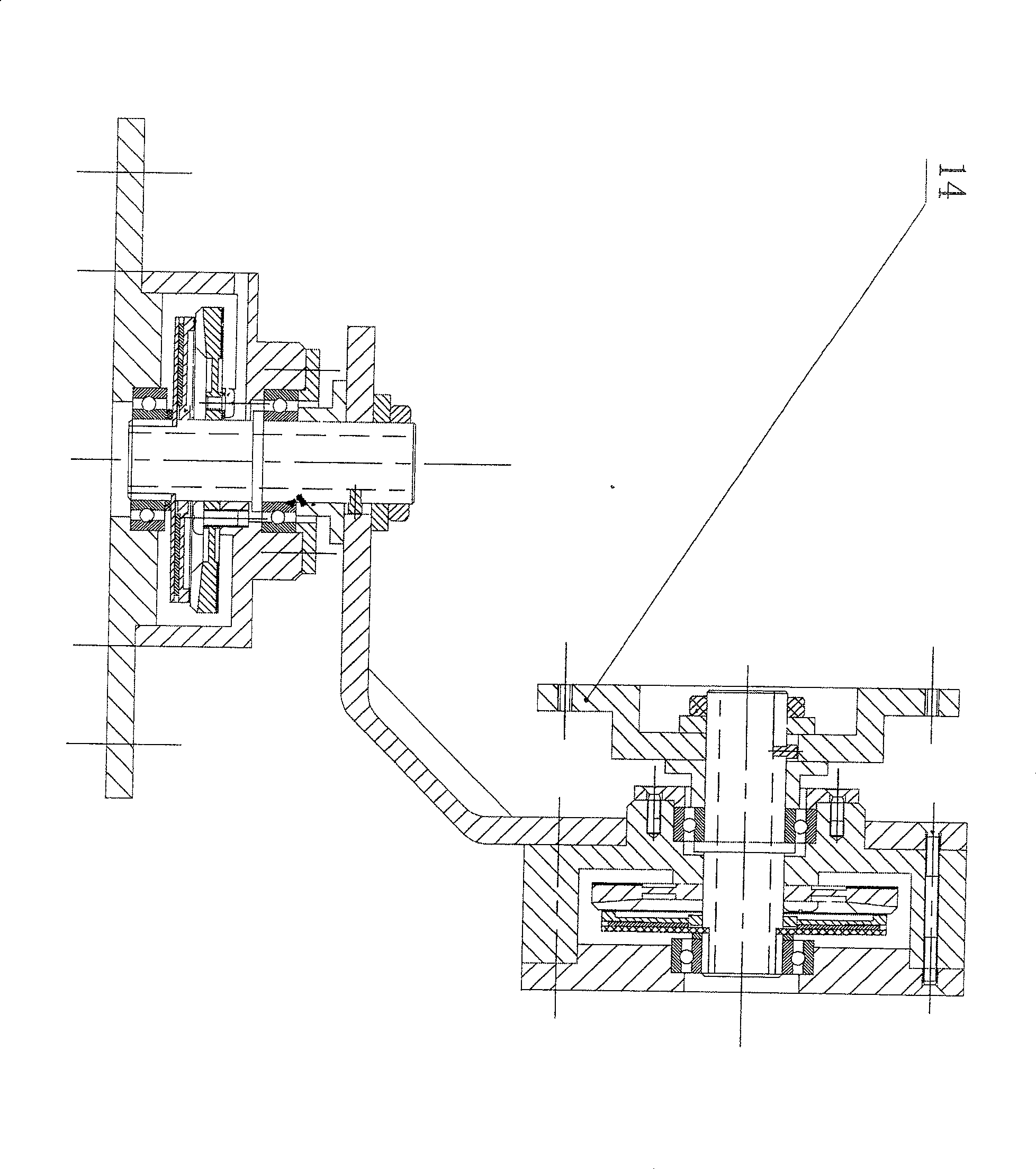

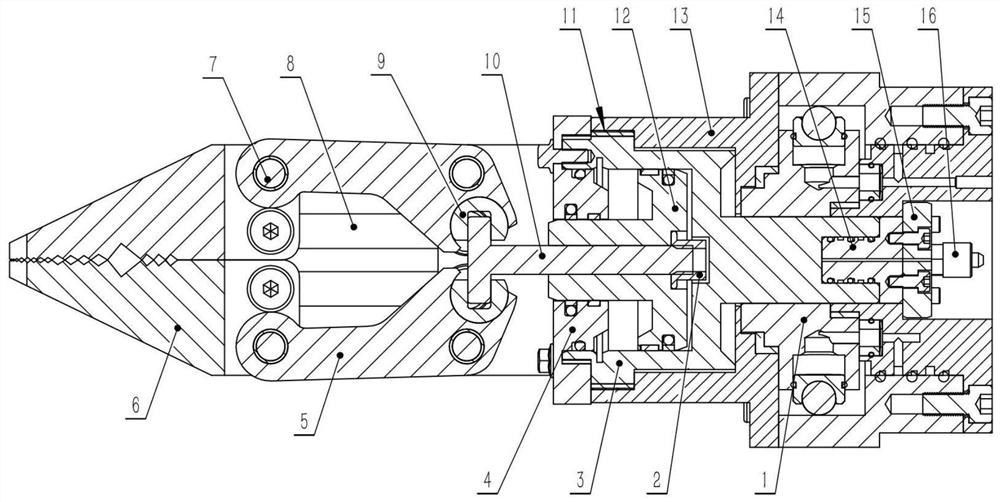

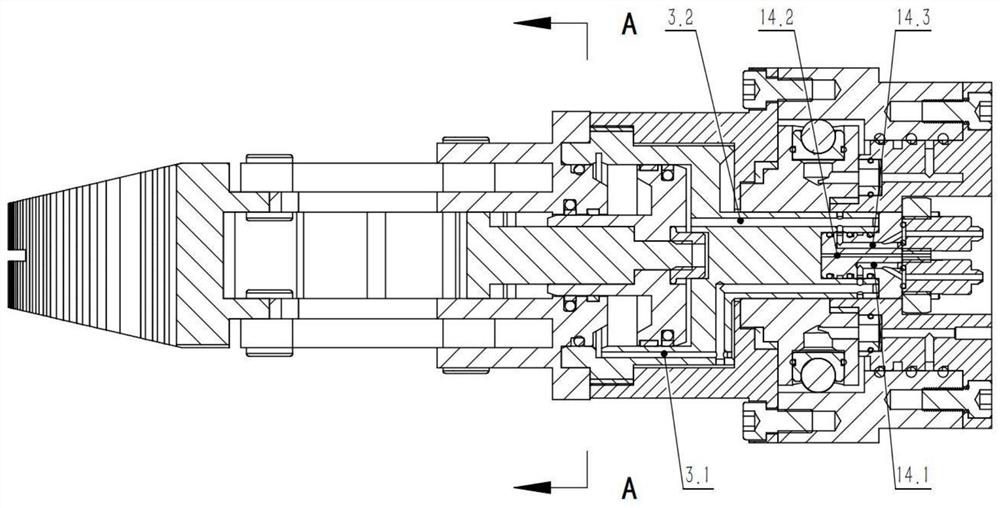

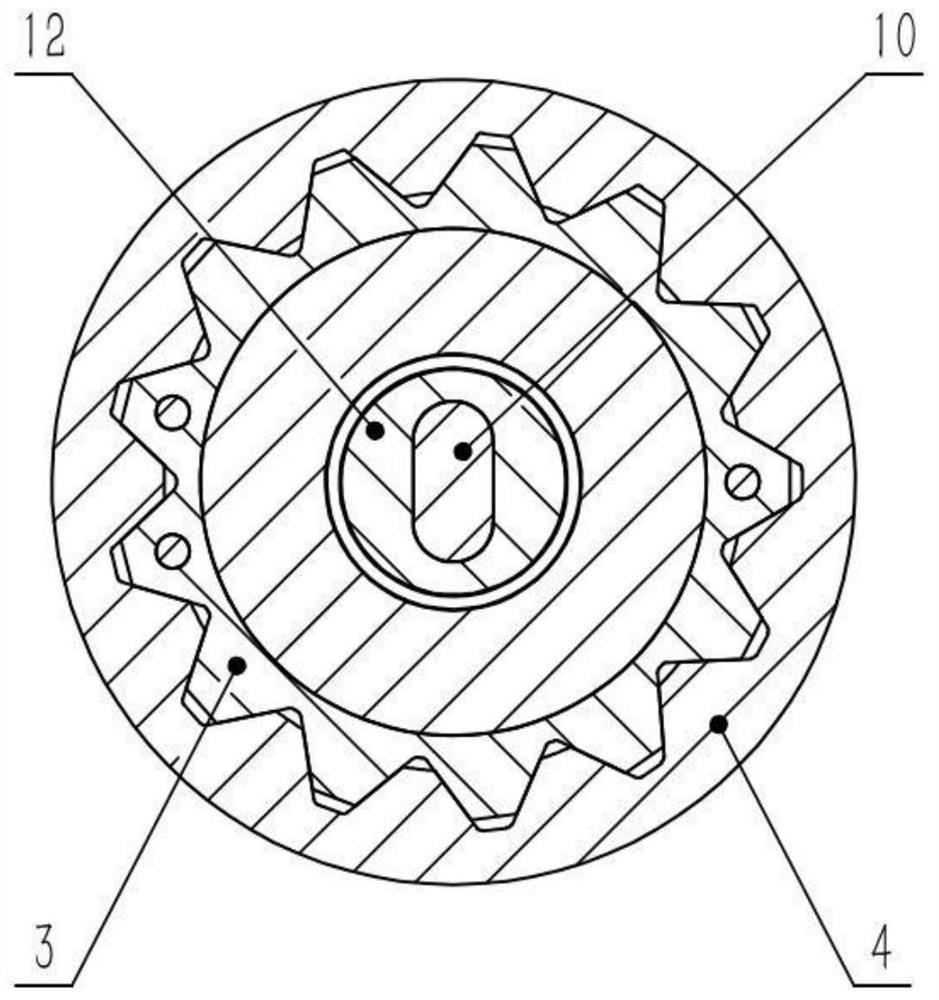

A hydraulically driven integrated manipulator end effector

ActiveCN112809717BReduce end loadReduce complex connection structuresGripping headsHydraulic cylinderUnderwater manipulator

The invention belongs to the technical field related to underwater manipulators, and discloses a hydraulically driven integrated manipulator end effector. The end effector has an integrated structure, which includes an end clamp mechanism and a special-shaped hydraulic cylinder mechanism connected in sequence. , a rotary joint mechanism and a rotary drive mechanism; the end clamp mechanism and the special-shaped hydraulic cylinder mechanism share an end effector base; the special-shaped hydraulic cylinder mechanism and the rotary drive mechanism share a special-shaped hydraulic cylinder cylinder and an end effector a housing; the rotary joint mechanism is partially embedded in the rotary drive mechanism. The end effector adopts hydraulic drive and high-strength corrosion-resistant structure to ensure full-sea deep operation without pressure compensator. The improved kinematic pair improves the working life and reliability of the end effector. The integrated The unique design solves the complex connection structure, reduces its own weight, and at the same time solves the problem of complex pipeline layout and easy winding.

Owner:HUAZHONG UNIV OF SCI & TECH

a dental flosser

ActiveCN110403723BEasy to fix and tightSolve the winding problemDental flossDental flossingDentistry

The invention relates to a dental flosser, which comprises a dental flosser hand-held part, a dental floss fixing part, a support rod and dental floss. The dental floss fixing part is fixed on the front end of the housing through a support rod, the housing is provided with a dental floss unwinding mechanism, and one end of the dental floss is connected to the dental floss unwinding mechanism and is unwound by it. , the top of the housing is provided with an outlet hole, the other end of the dental floss protrudes from the outlet hole and is fixed on the floss fixing part, and the floss length fixing mechanism is also arranged on the support rod, The top of the housing is also provided with a cutting knife. The design has the advantages of simple structure, easy manufacture, practicality and high efficiency.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

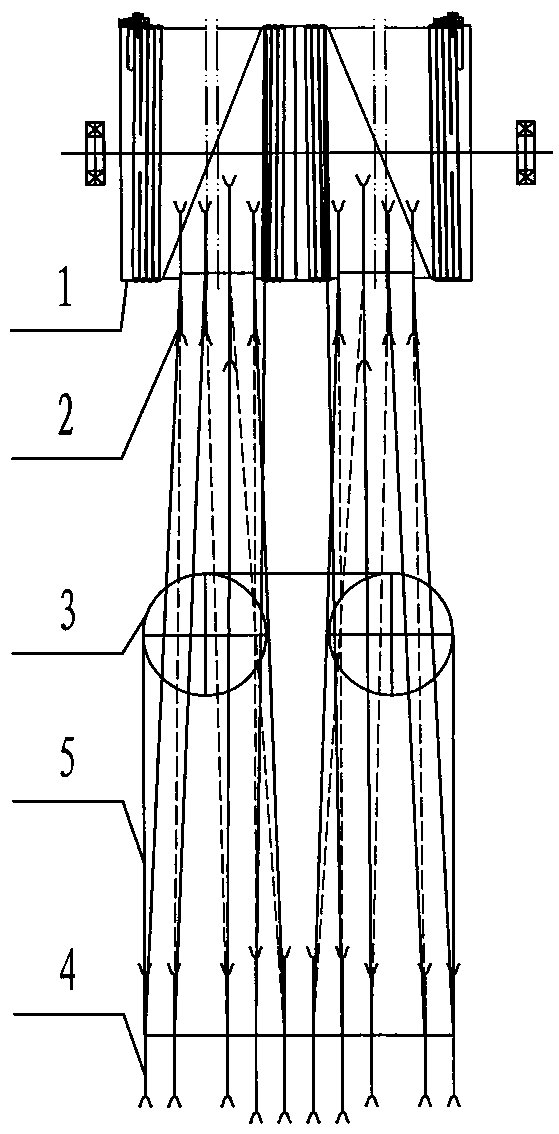

Winding device and winding method of motor armature of electric motor vehicle

InactiveCN101860145BSolve the winding problemEasy winding and fully mechanizedElectric machinesManufacturing dynamo-electric machinesEngineeringElectric vehicle

The invention discloses a winding device and a winding method of a motor armature of an electric motor vehicle. The winding device comprises a winding stand, a wire coil and an iron core fixed shaft which are arranged on the wire coil, the wire coil rotates around a winding shaft of the stand; two winding suspension mechanisms are respectively arranged on two sides of the stand; each winding suspension mechanism comprises a suspension part and a power component which is connected with the suspension part to control the suspension part to rotate; and each suspension part is provided with two stations, i.e. a first station for the upper end of the suspension part positioned in a paying-off plane of the wire coil to wind the winding and a second station for the upper end of the suspending mechanism of the winding to swing to the inner side of the stand and release the winding. Compared with the prior art, in the method, the winding to be wound is firstly wound on the suspension part of the suspending mechanism, the suspension part is swung by swinging the suspending mechanism to release the winding on the suspension part from the suspension part, the winding can be automatically furled into a wire trough under the action of the tension of the wire coil, the winding is convenient and fully automatic, the labor force is saved and the winding efficiency is high.

Owner:崔建伟

Moving lead wire collecting device capable of feeding back position and actuator

PendingCN113120703AOrderly collectionAvoid destructionMeasurement devicesLighting and heating apparatusStructural engineeringActuator

The invention belongs to the technical field of smart homes, and relates to a moving lead wire collecting device capable of feeding back a position and an actuator. The lead wire collecting device comprises a shell, a wire collecting roller, a lead wire and a detection assembly, wherein a holding space is formed in the shell; the wire collecting roller is arranged in the holding space, the wire collecting roller and the shell are elastically and rotatably connected, and a wire collecting groove is formed in the surface of the wire collecting roller; the lead wire is wound in the wire collecting groove, the end, capable of being pulled out relative to the wire collecting groove, of the lead wire is marked as a movable end, the other end of the lead wire is marked as a fixed end, the movable end penetrates out of the shell, and the fixed end penetrates through the wire collecting groove; and the detection assembly detects the angle of rotation of the wire collecting roller relative to the shell so as to judge the movement distance of the movable end. According to the moving lead wire collecting device, orderly winding of the lead wire and position detection are integrated, the problem of winding of the lead wire is solved, the lead wire is prevented against the damage such as extrusion and scraping in the moving process, and the cost of additionally arranging a position detection device is saved. In addition, the moving lead wire collecting device can be used in cooperation with the actuator.

Owner:OECHSLER PLASTIC PROD TAICANG

A method for testing real-time dynamic stress of disc-type tie-rod combined rotors

ActiveCN108387331BReal-time monitoringAvoid inaccuraciesForce measurementElectrical resistance and conductanceFatigue fractures

Owner:XI AN JIAOTONG UNIV

A mobile charging pile

ActiveCN106274541BImprove protectionSolve the winding problemCharging stationsElectric vehicle charging technologyEngineeringConductor Coil

Owner:重庆荣渝创新信息技术有限责任公司

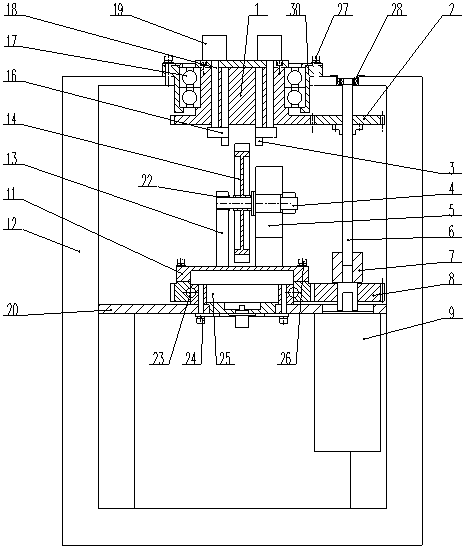

Ultrasonic motor for monitor cradle

InactiveCN100511958CSolve the winding problemSmooth support movementPiezoelectric/electrostriction/magnetostriction machinesLow speedPhase difference

An ultrasonic motor for a monitor pan-tilt. The motor is composed of a rotor (5), a stator (4), a leaf spring (11), a hollow shaft (13), a piezoelectric ceramic sheet (12) and the like. The stator (4) is fixed on the casing (3) by screws (6), the rotor (5) relies on the deformation of the spring sheet (11) to generate pre-pressure to press on the stator, and the thickness of the adjusting washer (9) determines the deformation of the spring The amount also determines the size of the pre-pressure. The rotor and the leaf spring, as well as the spring leaf and the shaft are transmitted through a keyway connection, and the shaft (13) is fixedly supported by bearings (2 and 7) at both ends. When the piezoelectric ceramic sheet (12) on the stator of the motor is fed with a sinusoidal excitation signal with a two-phase phase difference of 90 degrees, the particles on the surface of the stator make an elliptical motion to push the rotor to rotate. With low speed, no noise, simple structure, hollow, good start and stop characteristics, it is especially suitable as the driving part of the monitor pan / tilt.

Owner:JIANGSU FENGKE ULTRASONIC MOTORS TECH

Water drive integrated manipulator end effector

ActiveCN112809717AReduce end loadReduce complex connection structuresGripping headsKinematic pairCorrosion resistant

The invention belongs to the related technical field of underwater manipulators, and discloses a water drive integrated manipulator end effector. The effector is of an integrated structure and comprises an end clamp mechanism, a special-shaped hydraulic cylinder mechanism, a rotary joint mechanism and a rotary drive mechanism which are connected in sequence. The end clamp mechanism and the special-shaped hydraulic cylinder mechanism share an end effector base. The special-shaped hydraulic cylinder mechanism and the rotary drive mechanism share a special-shaped hydraulic cylinder barrel and an end effector shell; and the rotary joint mechanism is partially embedded in the rotary driving mechanism. The end effector adopts water drive and a high-strength corrosion-resistant structure to ensure that full-sea-depth operation can be realized without a pressure compensator, the service life of the end effector is prolonged and the reliability of the end effector is improved by an improved kinematic pair form, a complicated connecting structure is solved by adopting integrated design, the weight of the end effector is reduced, and meanwhile, the problems of complex pipeline arrangement and easy winding are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com