Tire of winding type steel wire girdle structure

A steel ring and belt structure technology, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as abnormal jitter, affecting tire structure, shortening tire service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

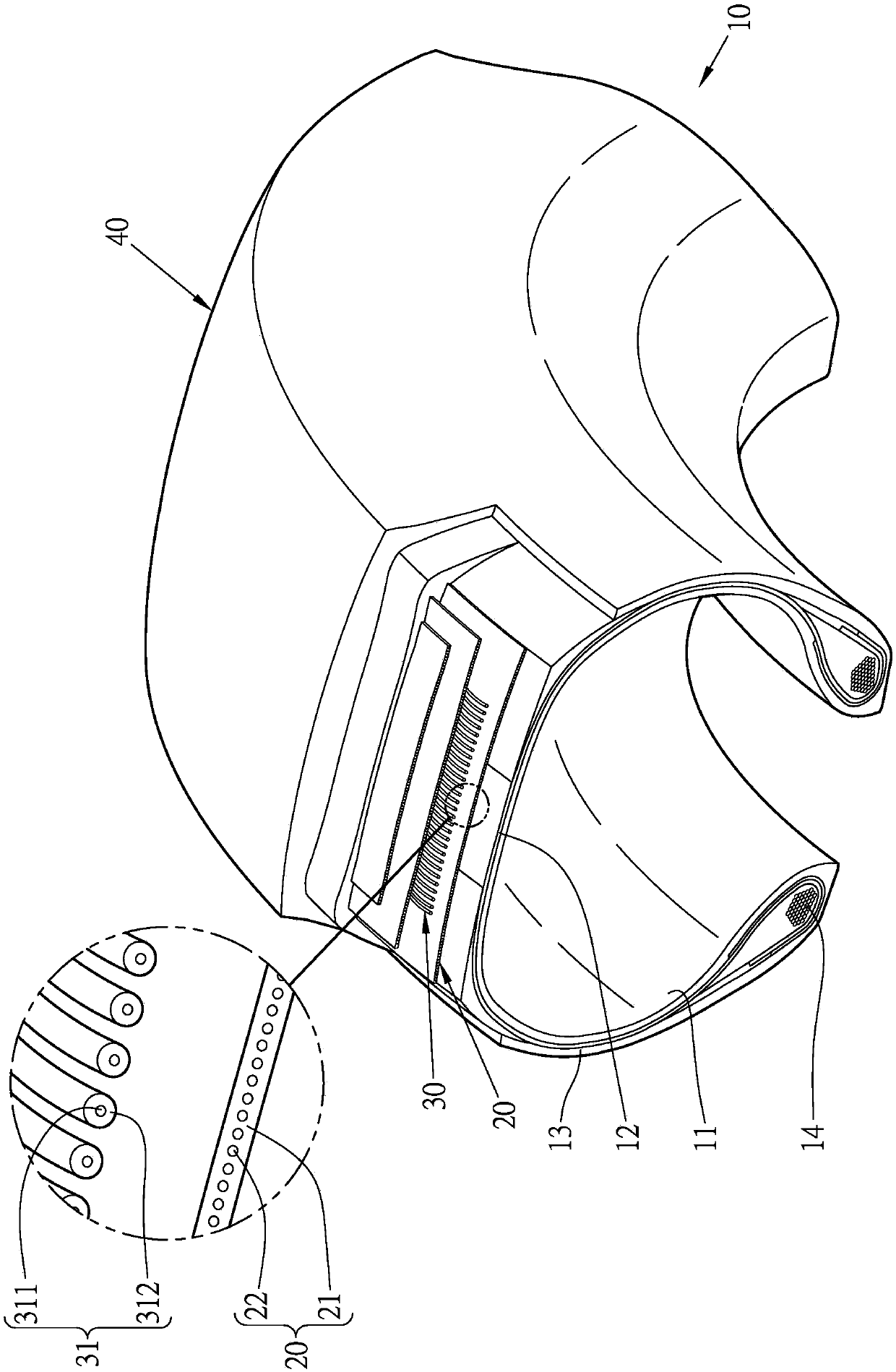

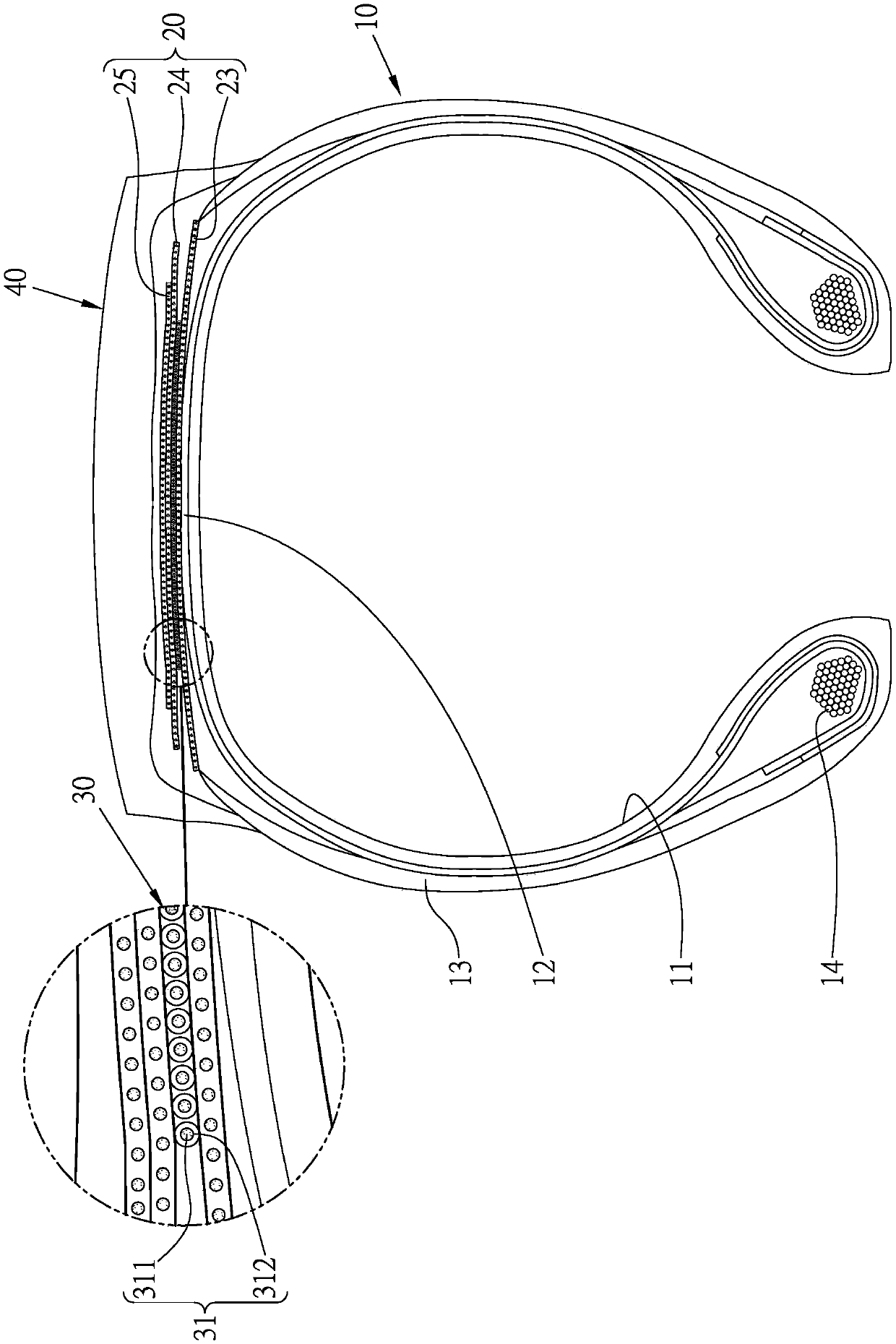

[0032] First please refer to Figure 1 to Figure 5 , a kind of winding tire steel wire ring belt structure provided by the present invention, the main tire carcass is composed of tread, bead, tire shoulder and bead lip, firstly three layers of steel wire ring belt layer and one layer of winding steel wire The layer is an illustration of the implementation, which includes: a tire carcass 10 , and three steel wire ring belt layers 20 , a wound steel wire layer 30 and a tread outer layer 40 arranged on the tire carcass 10 .

[0033] The tire carcass 10 is in the shape of a U-shaped ring, and has an inner rubber layer 11 that is open inward and a carcass steel wire layer 12 that is closed outward; the two sides of the tire carcass 10 are respectively It is jointly formed by at least one bead rubber layer 13 and at least one bead traveler 14 .

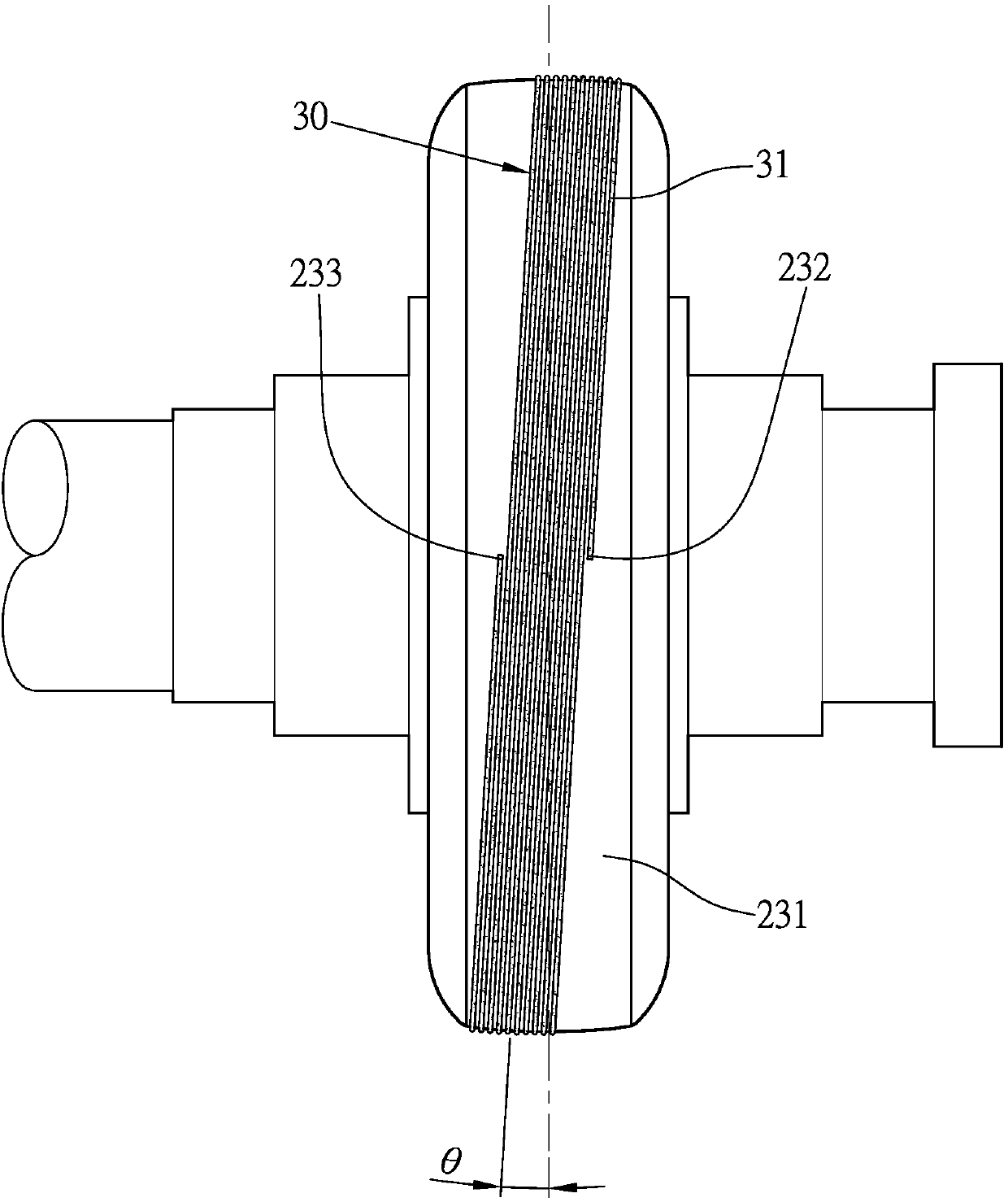

[0034] Each steel wire hoop layer 20 is pasted on the outer diameter edge of the carcass steel wire layer (12) with a first steel wire ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com