Ultrasonic motor for monitor cradle

An ultrasonic motor and monitor technology, applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve problems such as winding, and achieve reliable transmission and stable support movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

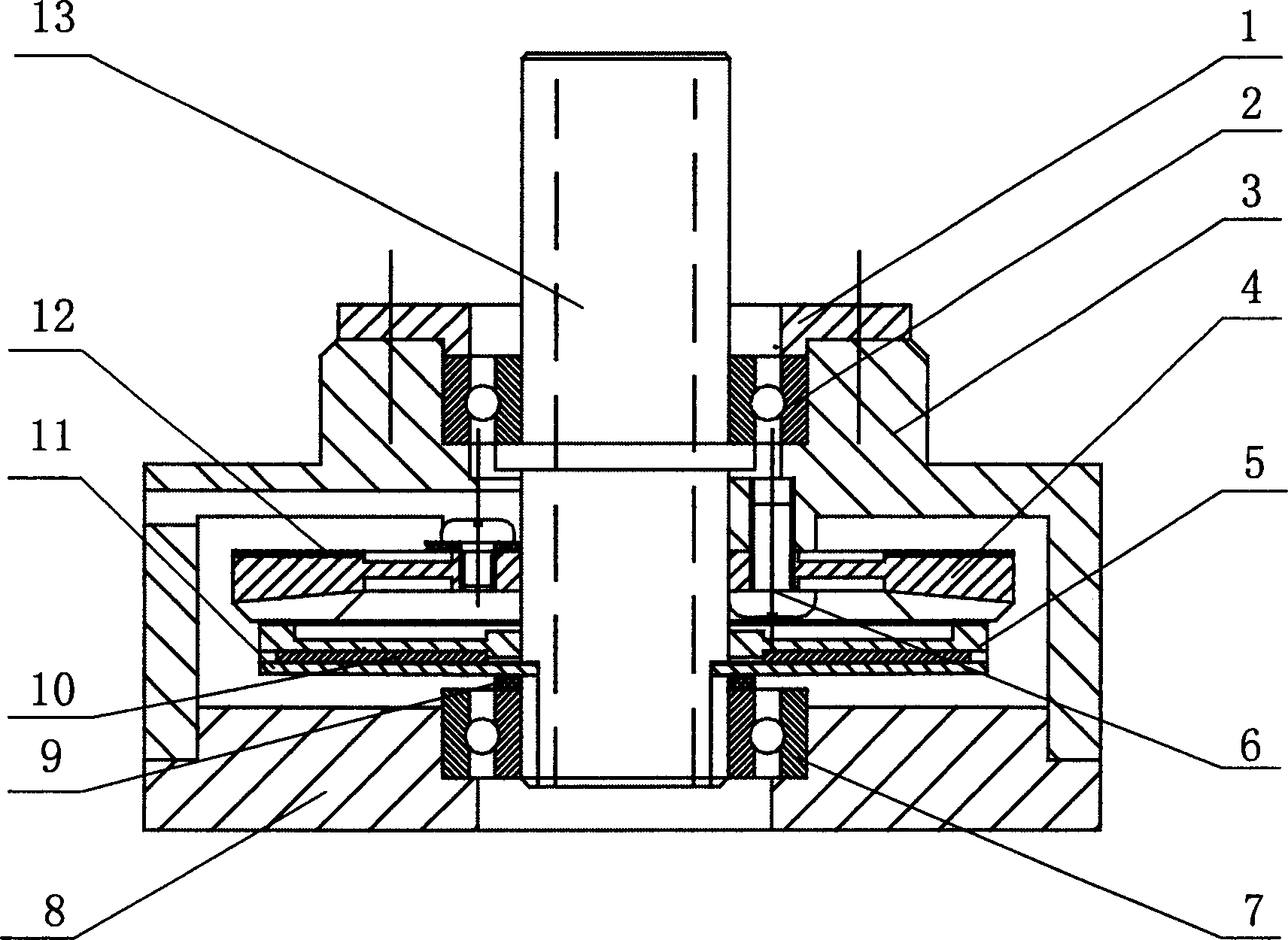

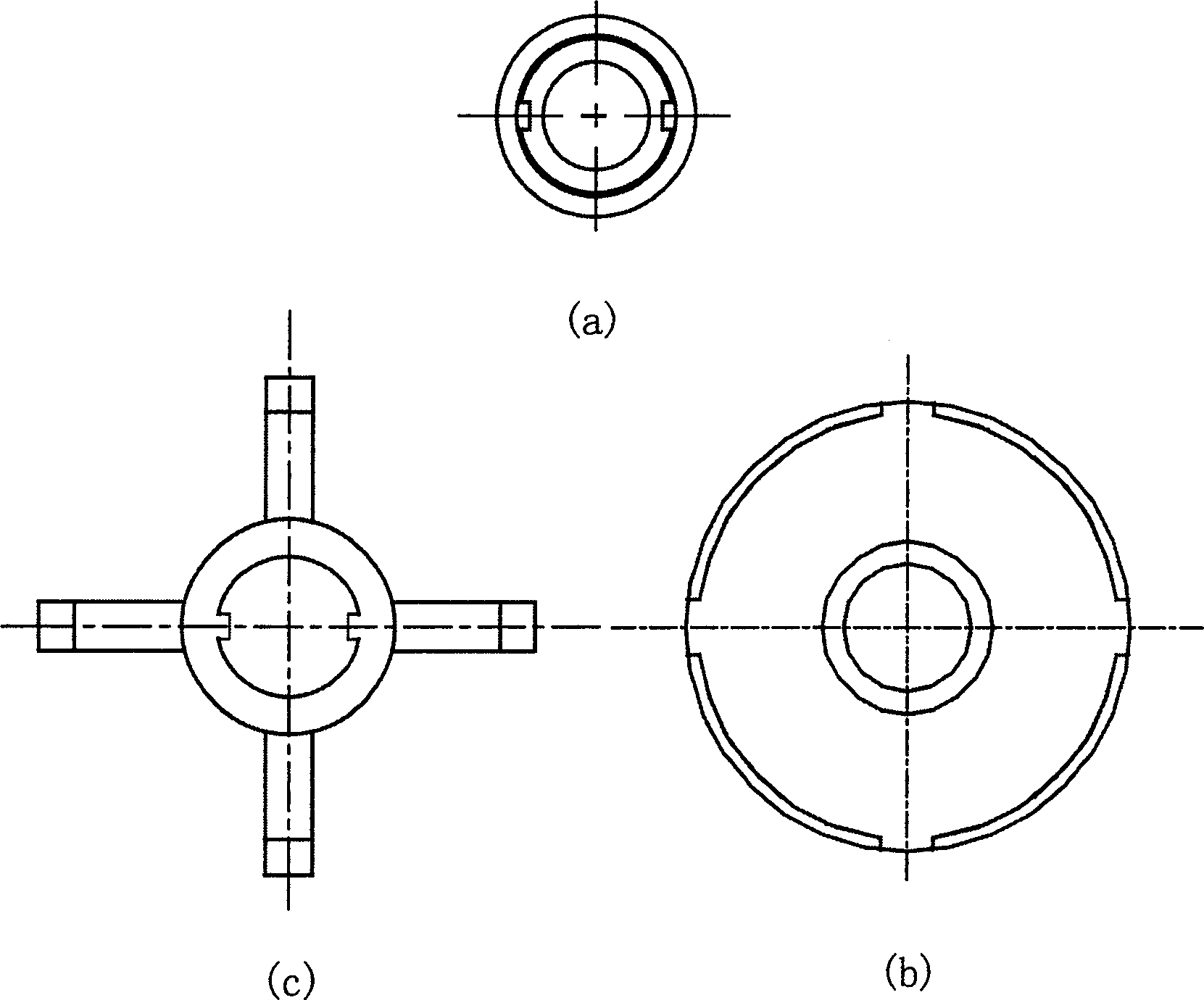

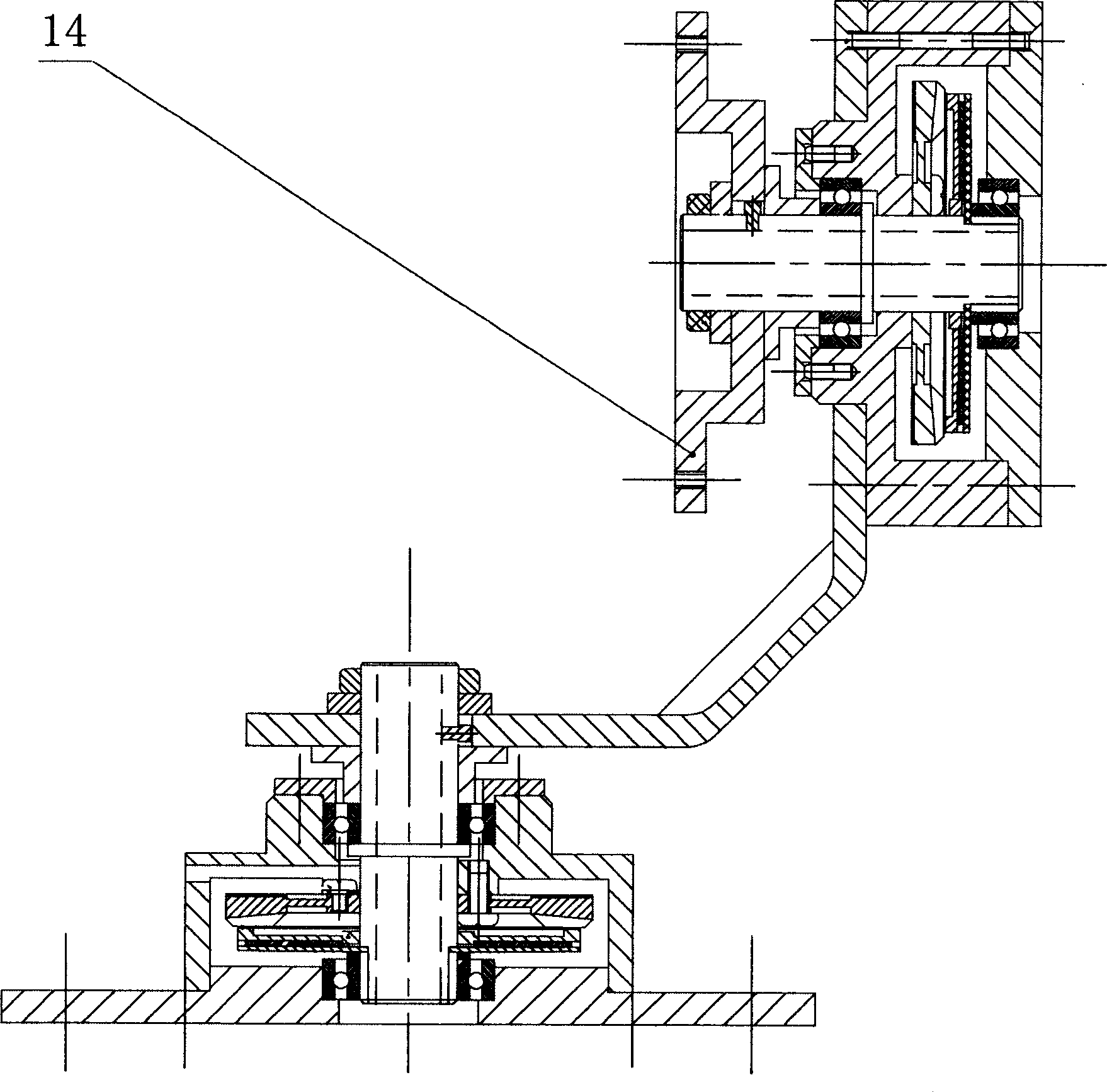

[0009] As can be seen from Figure 1, the structure of the ultrasonic motor used for a single monitor pan / tilt is that the bearing cap 1 is connected to the upper end surface of the housing 3 by screws, the piezoelectric ceramic sheet 12 is pasted on the upper surface of the stator 4, and the stator 4 is placed in the housing. The body is installed on the boss in the middle of the upper end of the housing 3 through screws, the rotor placed under the stator 4 is fixed on the output shaft 13, and the spring leaf 11 installed on the output shaft is placed between the rotor 5 and the gasket 10, The upper and lower ends of the output shaft 13 are respectively supported by bearings on the bearing 1 and the base 8 to make the movement more stable and reliable. The output shaft 13 is hollow and can pass through wires, which solves the problem of winding when the pan / tilt rotates. The outer diameter of the shaft has a pair Symmetrical keyway, as shown in figure (a) in Figure 2. There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com