Moving lead wire collecting device capable of feeding back position and actuator

A collection device and actuator technology, which is applied in the direction of measuring devices, household refrigeration devices, instruments, etc., can solve the problem of undescribed connection between the controller and the door switch actuator assembly, high precision of the photoelectric encoder, fast travel speed of the rack, etc. problem, to achieve the effect of solving the problem of lead wire winding, simple component setting, and promotion of lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

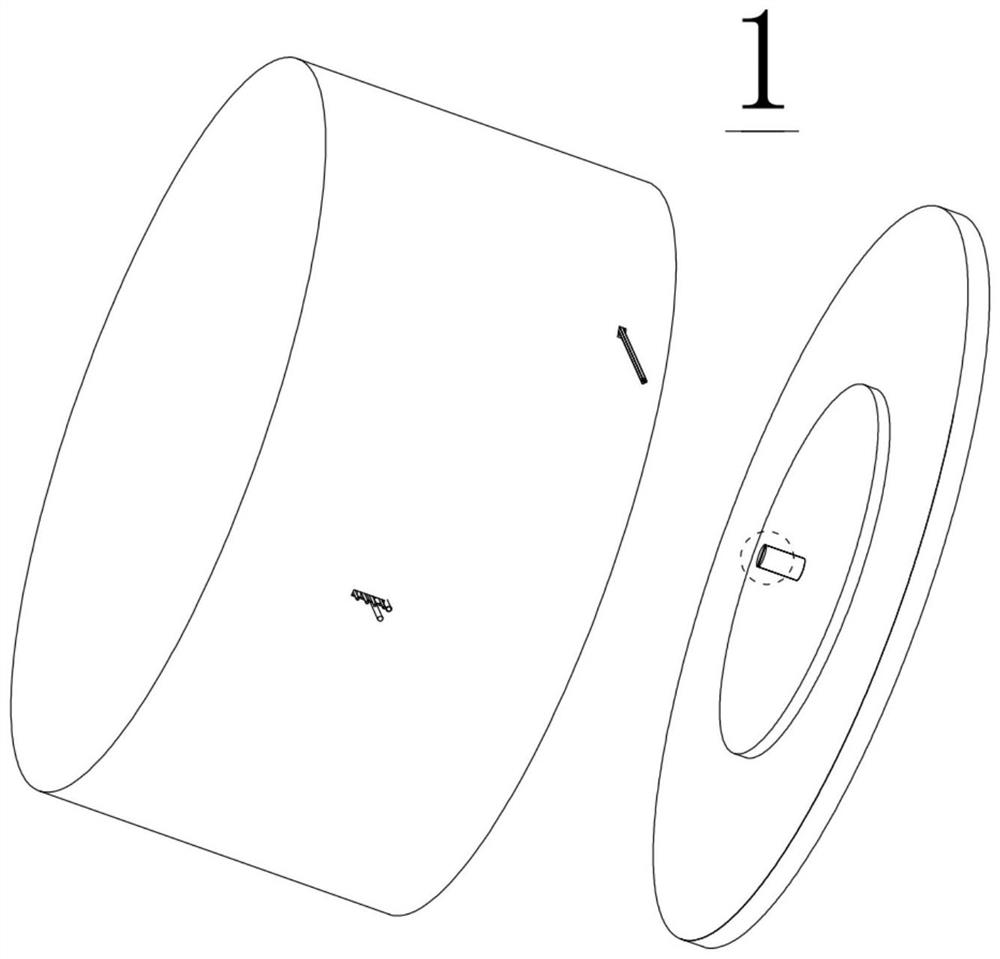

[0037] A motion lead collection device that can feedback position, such as Figures 1 to 9 shown, including:

[0038] A housing 1, the housing 1 is cylindrical, and a housing space is formed in the housing 1;

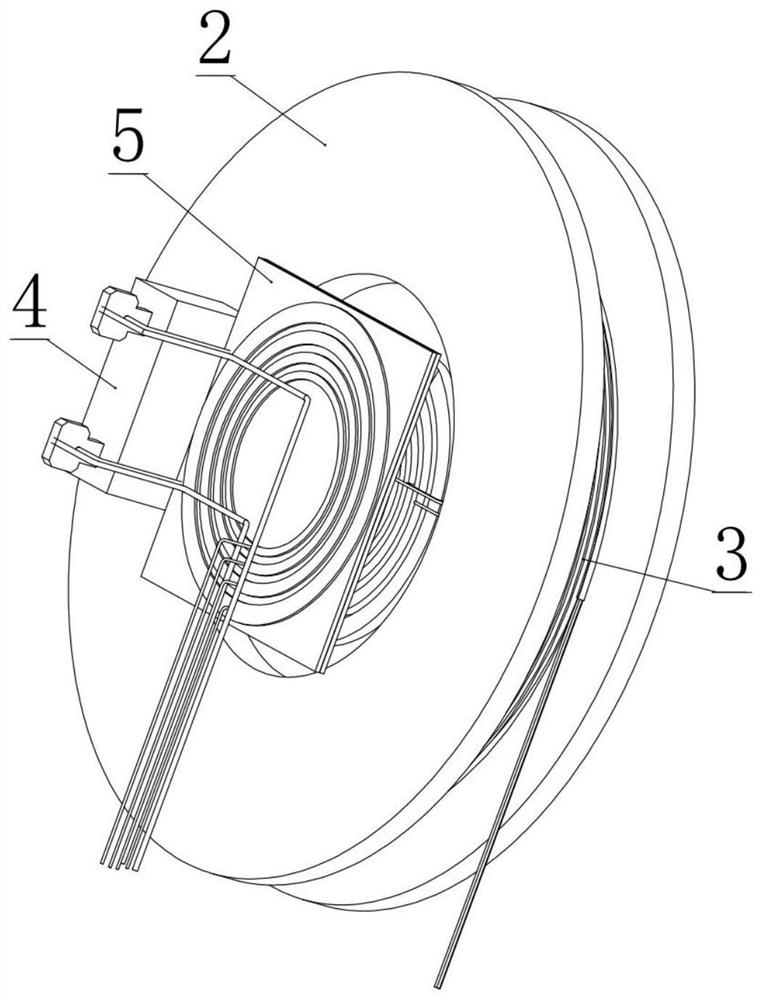

[0039] The wire gathering roller 2, the wire gathering roller 2 is disc-shaped, and is arranged in the accommodation space, the wire gathering roller 2 is elastically rotatable connected with the shell 1, and the wire gathering roller 2 is provided with a wire gathering groove 21;

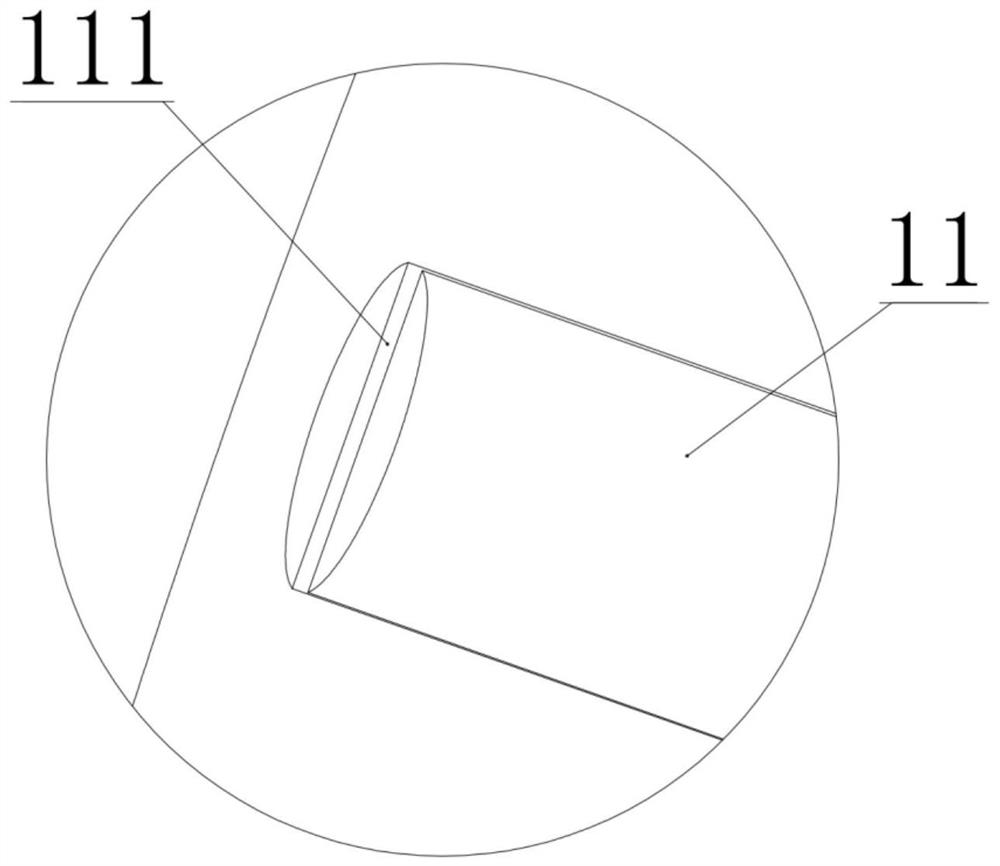

[0040] Lead wire 3, lead wire 3 is wound in the wire collecting groove 21, one end of the lead wire 3 that can be pulled out relative to the wire collecting groove 21 is marked as the movable end 31, and the other end is marked as the fixed end 32, and the movable end 31 passes through the housing 1 The through hole of the housing 1 passes outwards, and the fixed end 32 passes through the through hole on the wire collecting groove 21 to lead out to the center of the wire collecting roller 2...

Embodiment 2

[0048] A motion lead collection device that can feedback position, such as Figures 1 to 10 1. The trigger portion 42 on the surface of the gathering roller 2 in Embodiment 1 is replaced by a plurality of protrusions arranged in an annular array, and the rest of the structure remains unchanged.

Embodiment 3

[0050] A linear motion actuator, including an actuator body and an actuator that moves linearly relative to the actuator body driven by the actuator body, also includes a power supply and a control unit, and also includes the motion lead that can feedback the position provided by Embodiment 1 collection devices (such as Figures 1 to 9 shown); the housing 1 of the executive part and the moving lead collection device is arranged on the fixed carrier, and the actuator body is fixed on the movable carrier that moves linearly relative to the fixed carrier; the movable end 31 is connected to the actuator body as the actuator body The driving force is provided, and the lead wires on the guide ring 51 are connected to the control unit, and the power supply and the detection component 4 are also electrically connected to the control unit; the detection component 4 detects that the wire collection roller 2 is relative to the housing 1 according to the number of times the micro switch 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com