Patents

Literature

62results about How to "Orderly collection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

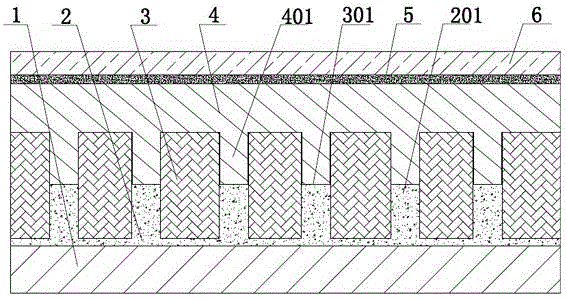

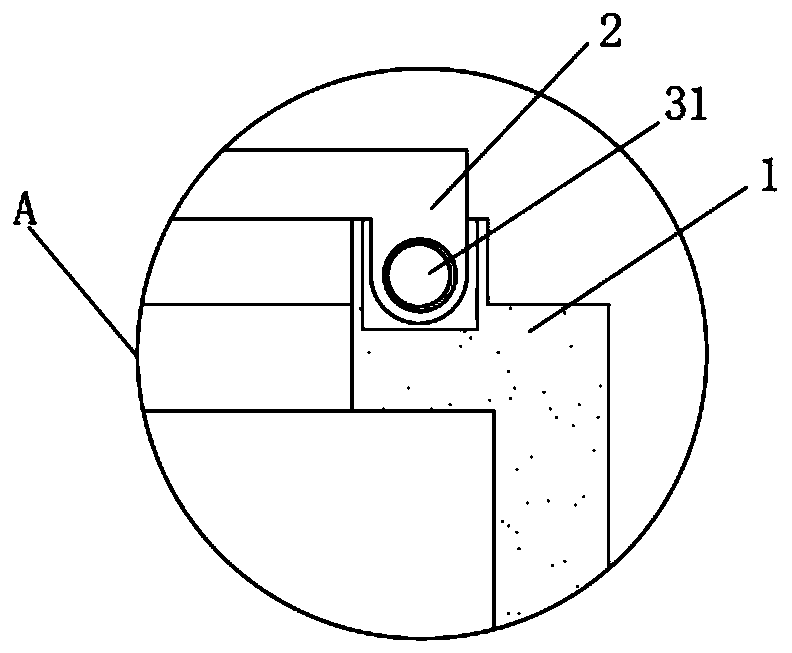

Novel granite facing thermal-insulation integrated plate and construction process thereof

ActiveCN104372908AHave no crackingImprove the decorative effectCovering/liningsLaminationThermal insulationArchitectural engineering

The invention discloses a novel granite facing thermal-insulation integrated plate and a construction process thereof, and belongs to the technical field of construction. The granite facing thermal-insulation integrated plate comprises a baseplate, a polyurethane thermal-insulation plate and the like, wherein the baseplate is connected with the polyurethane insulation plate through an adhesive layer; a cover plate is connected with the polyurethane thermal-insulation plate through inserting a cover plate convex column in a through hole; and an ultrathin granite facing plate is connected with the cover plate through a stone mighty bonding layer. An outer wall decorative material adopts the novel ultrathin granite facing thermal-insulation integrated plate; the plate gap structure and the construction process are precisely adjusted and controlled in a bonding-anchoring combined manner; and the novel granite facing thermal-insulation integrated plate mainly solves the problems of poor appearance quality, poor durability and poor heat-preserving and heat-insulating effects in a traditional outer wall decorative material, greatly improves the construction quality, is short in construction period, is obvious in economic benefit, is specifically suitable for the outer wall outer thermal-insulation decorative construction of various new residential buildings and public buildings, and can satisfy the high-standard requirements of durability of outer walls of the buildings and energy conservation and emission reduction in the use process.

Owner:ZHEJIANG WANDA CONSTR GROUP

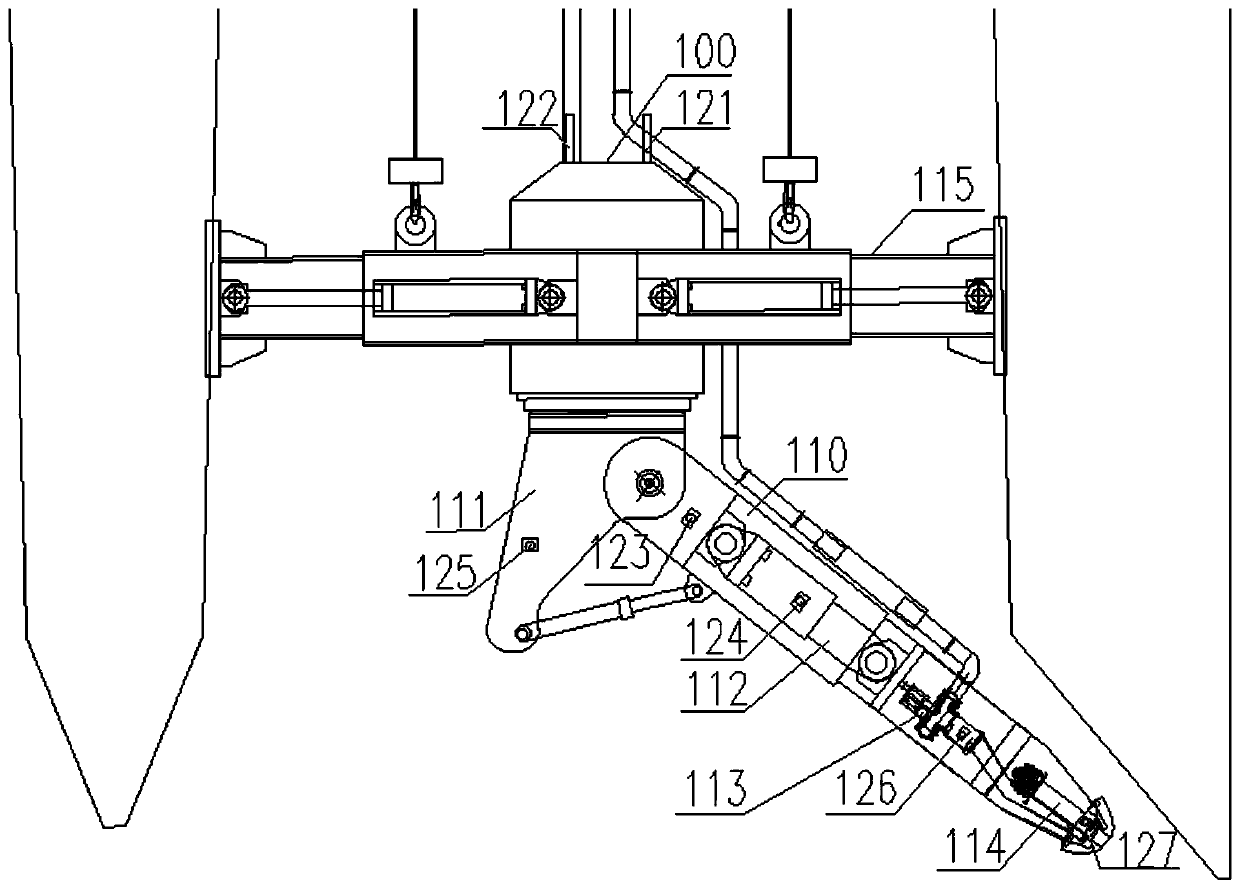

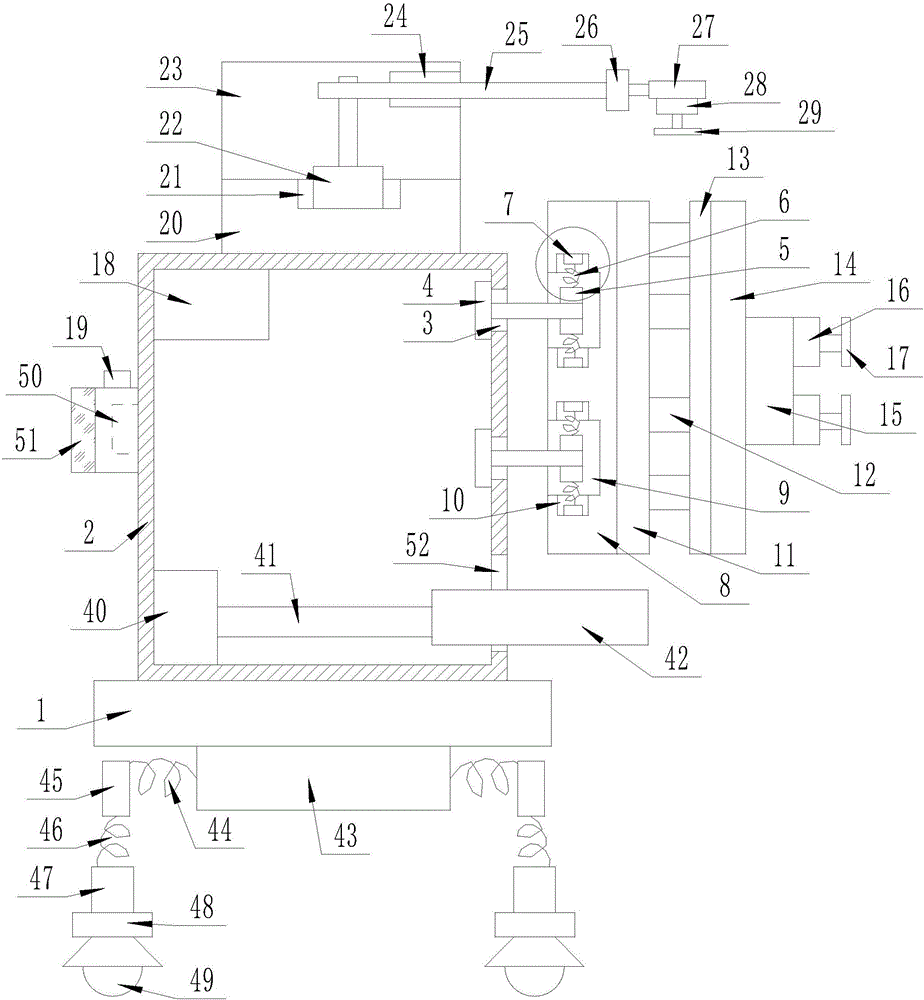

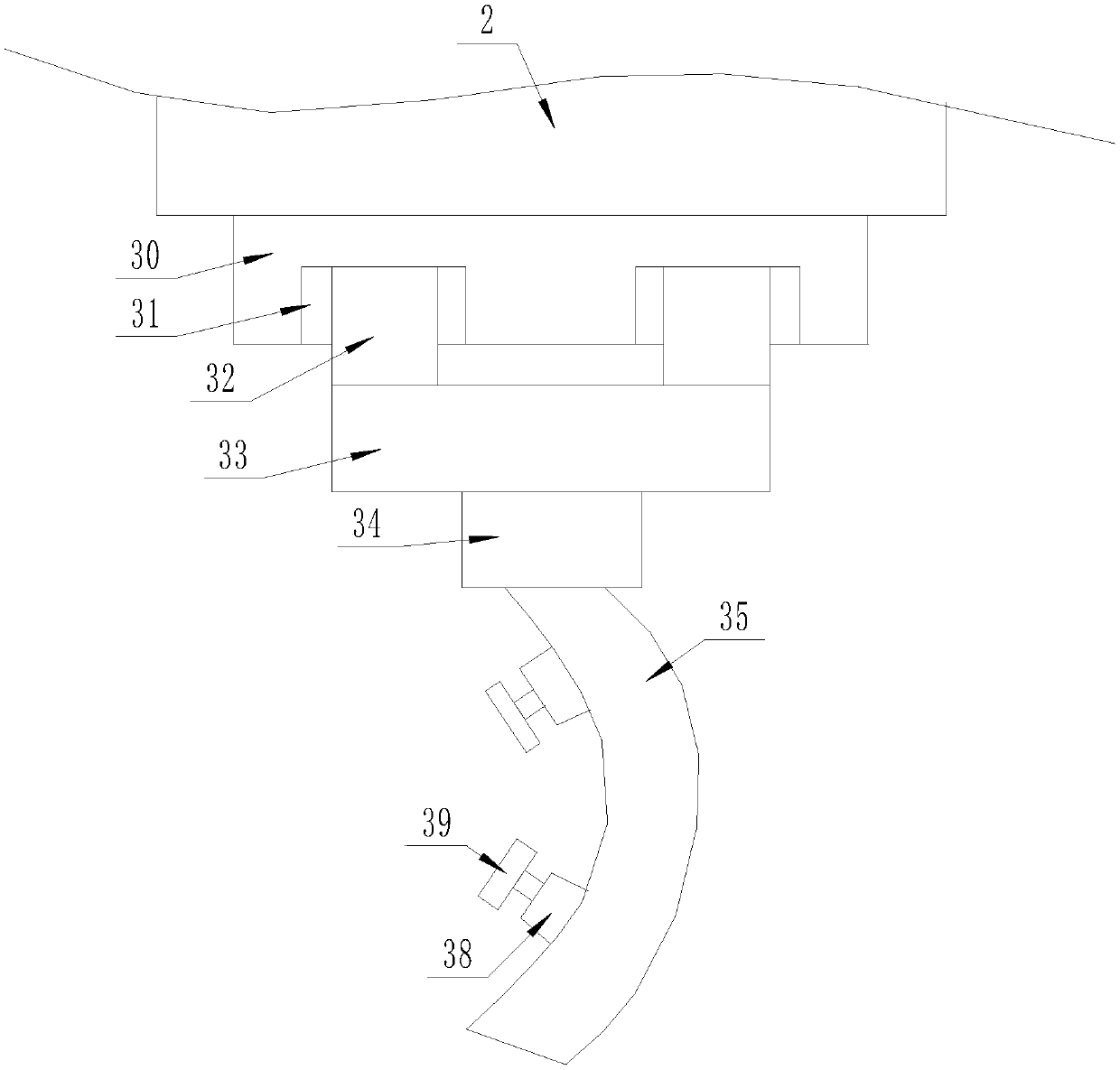

Crushing and slag removing device for hard soil layer at open caisson cutting edge and construction method thereof

InactiveCN110528550AAccurate control of scalingThe coordinates are consistentSoil-shifting machines/dredgersCaissonsSlagEngineering

The invention discloses a crushing and slag removing device for a hard soil layer at an open caisson cutting edge and a construction method of the device. The device comprises a rotating portion, a reamer frame, a hydraulic system, a control unit, various sensors, a detector and a controller. The reamer frame is fixed below the rotating portion, the bottom end of the reamer frame is detachably connected with a reamer head, the hydraulic system drives the rotating portion and the reamer frame to move, the control unit comprises an antenna arranged above the rotating portion, the various sensorsare respectively arranged on the reamer frame, the detector is arranged on the reamer frame, the controller is connected with the antenna, the sensors, the detector and the hydraulic system, and thecontroller analyzes data obtained by the antenna, the sensors and the detector and controls the hydraulic system to operate according to analysis results. The real-time working position of the reamerhead is obtained through the antenna and the various sensors, it is ensured that the real-time working position is always kept the same as a coordinate position preset in an automatic rock breaking construction program, and therefore digging construction operation in the whole open caisson cutting edge is accurately completed.

Owner:CCCC SECOND HARBOR ENG +1

Impermeable material based on flue gas desulfurization byproduct and usage in garbage landfill thereof

InactiveCN101157528AOvercoming the problem of stacking land occupationEnhanced advantageSolid waste managementSodium BentoniteMetallurgy

The invention discloses an impermeable material based on flue gas desulphurization by-product and the usage in trash burying. The impermeable material is compounded evenly according the weight by 60-90 percent of circulating fluidized bed flue gas desulphurization dreg and 10-40 percent of chemical additive under the dried powder ugh condition. The chemical additive is the one kind or two kinds of combination of bentonite and kleit at random proportion, and the impermeable material can be applied to be used as an anti-seepage layer in trash burying, wherein, the anti-seepage layer used as the underlay of the trash burying field has a thickness of 80cm to 120cm; the anti-seepage layer used as the intermediate coating has a thickness of 15cm to 30cm; and the anti-seepage layer used as the full closure field has a thickness of 60cm to 100cm. The impermeable material can not only prevent from polluting the underground water of the trash burying field, reduce the treatment of trash infiltrated liquid and ensure that the trash buried gases are collected orderly, but also make full use of the huge desulphurization dreg and change waste into resources, thereby realizing the win-win benefit.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

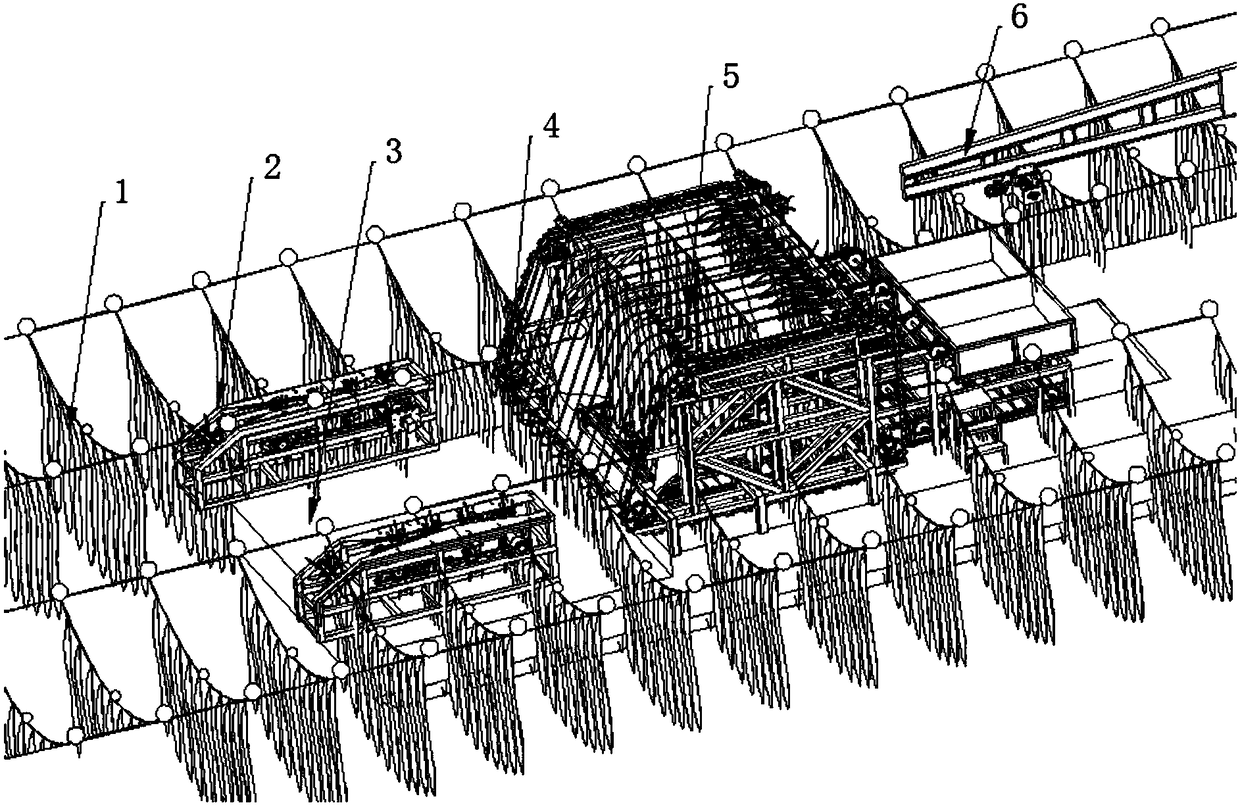

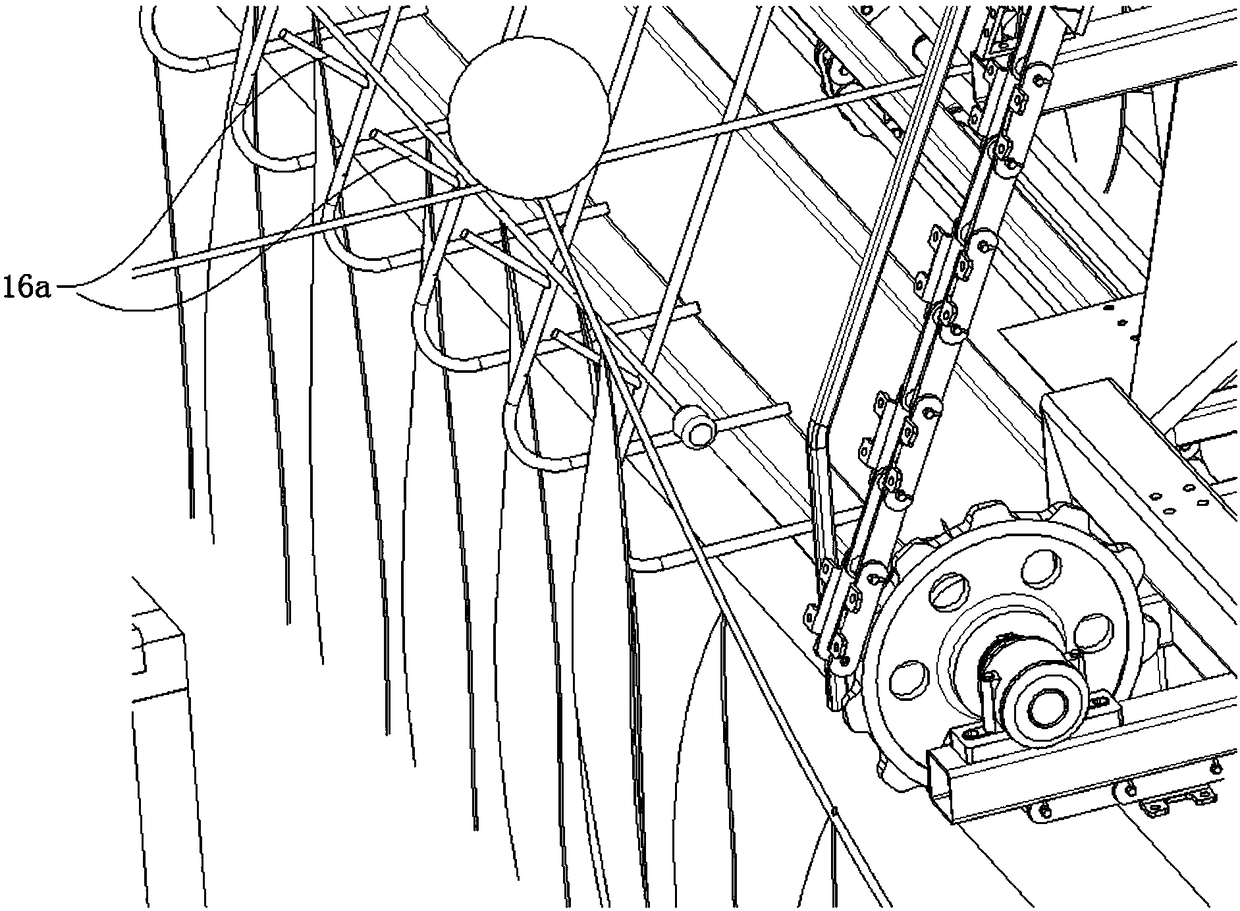

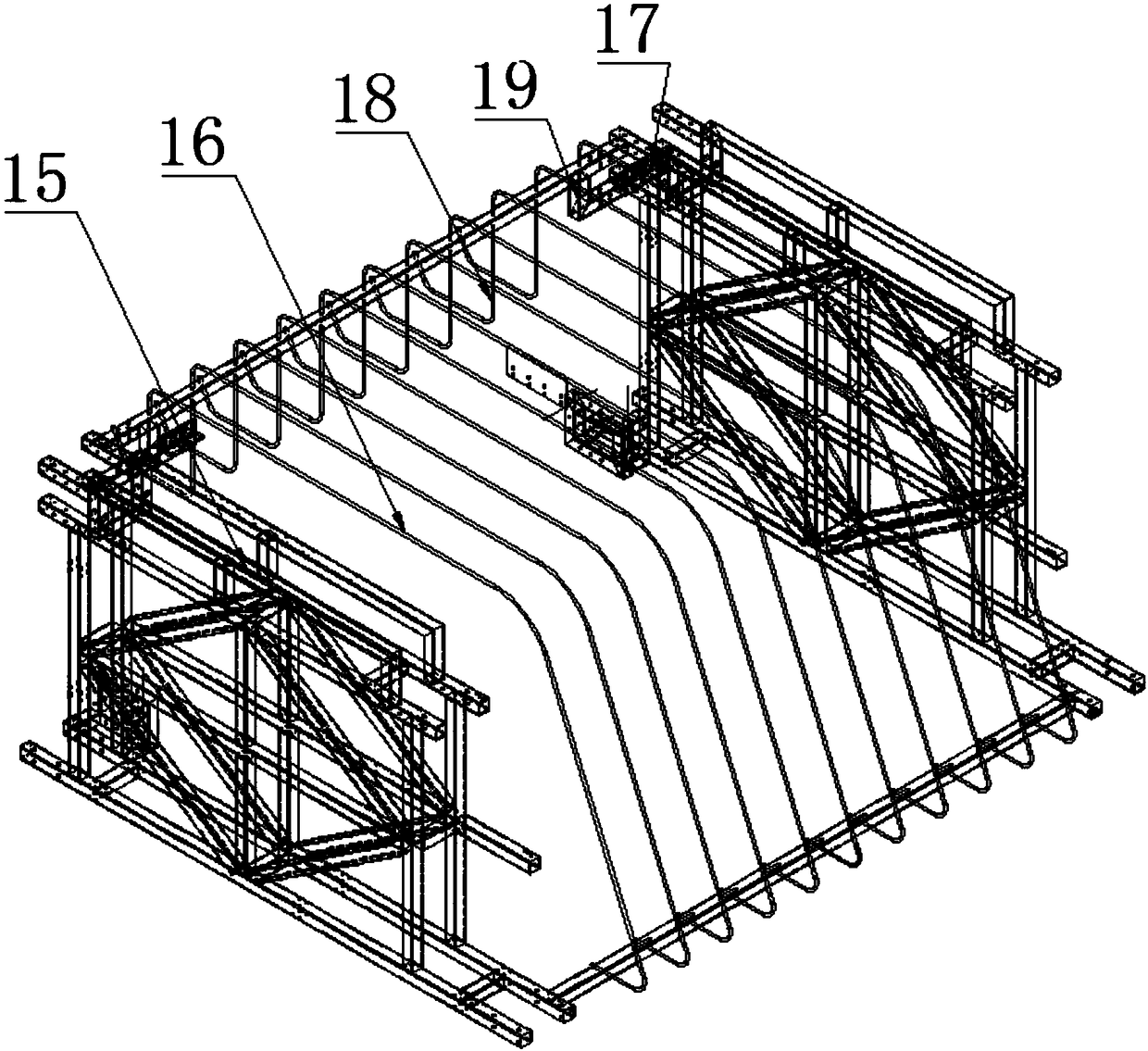

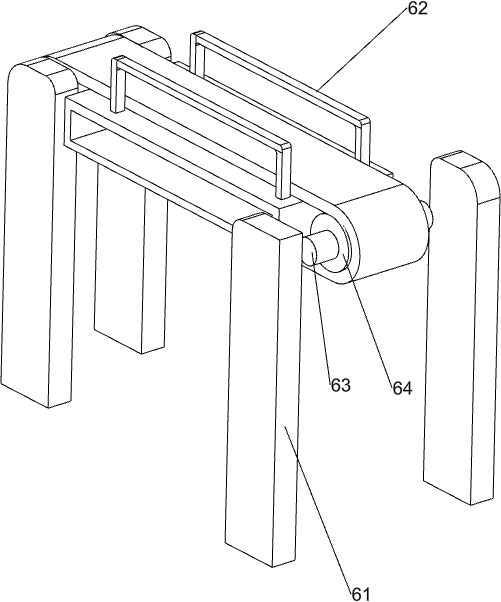

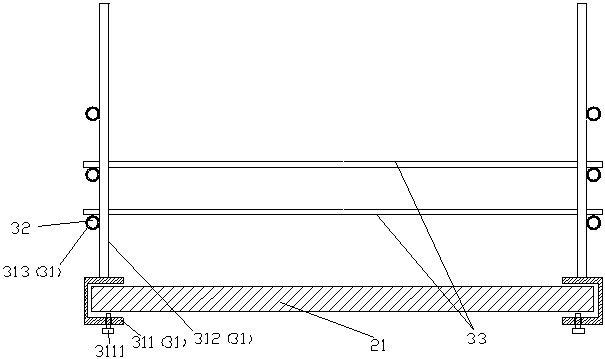

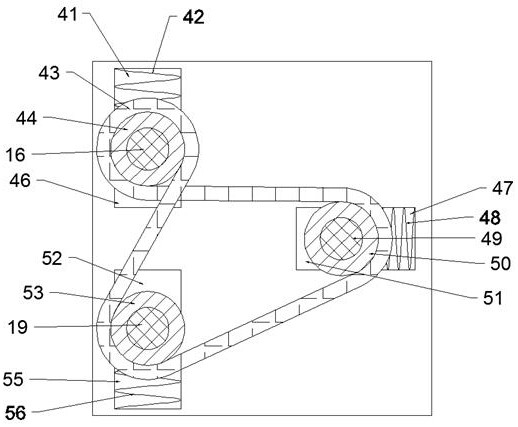

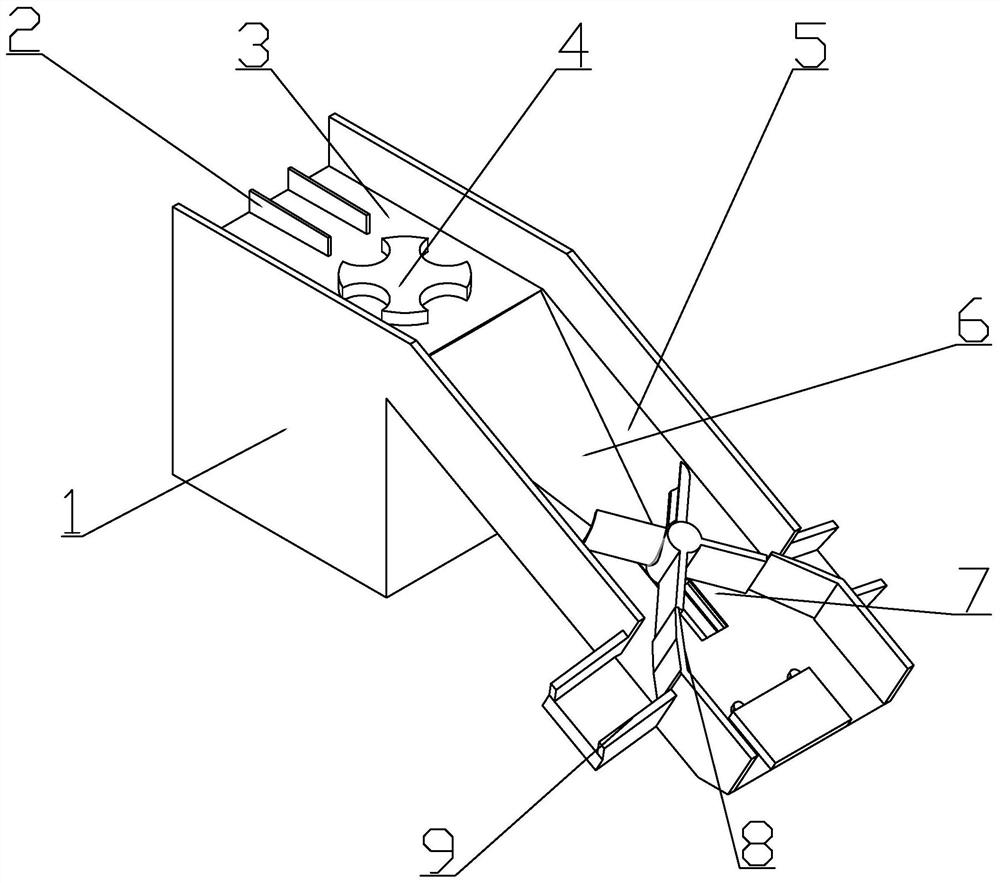

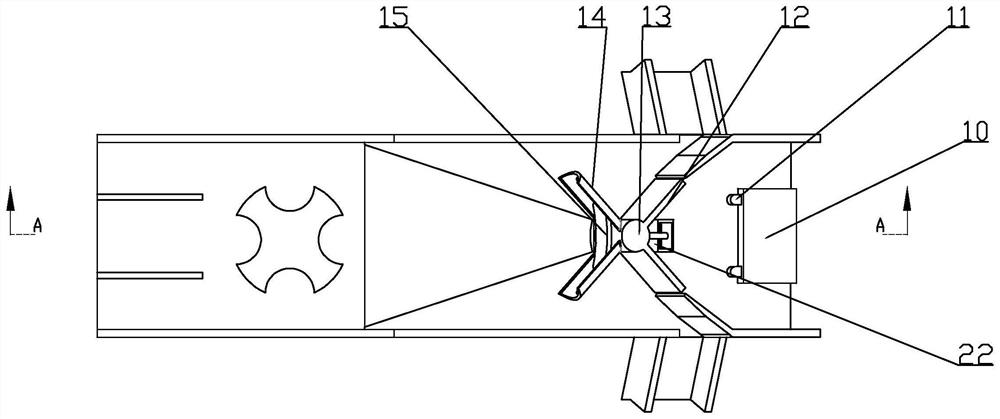

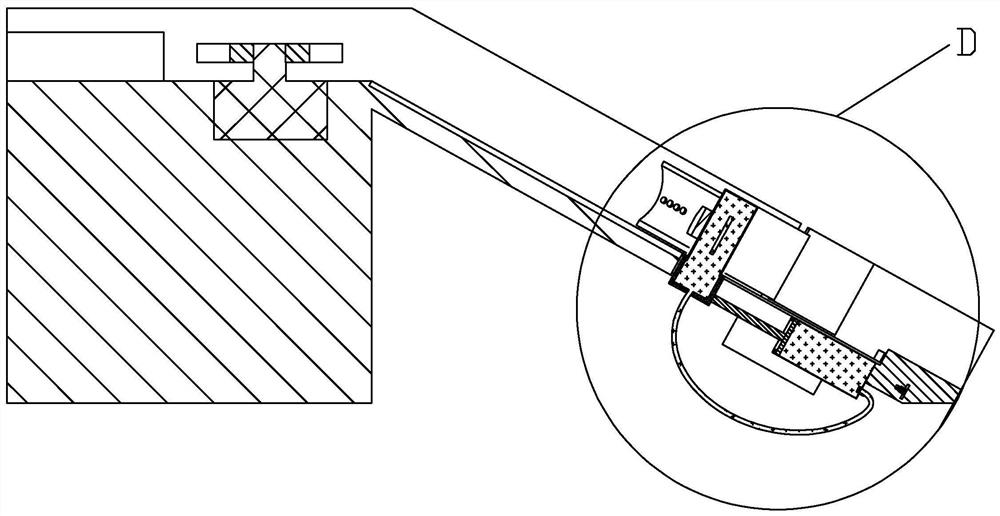

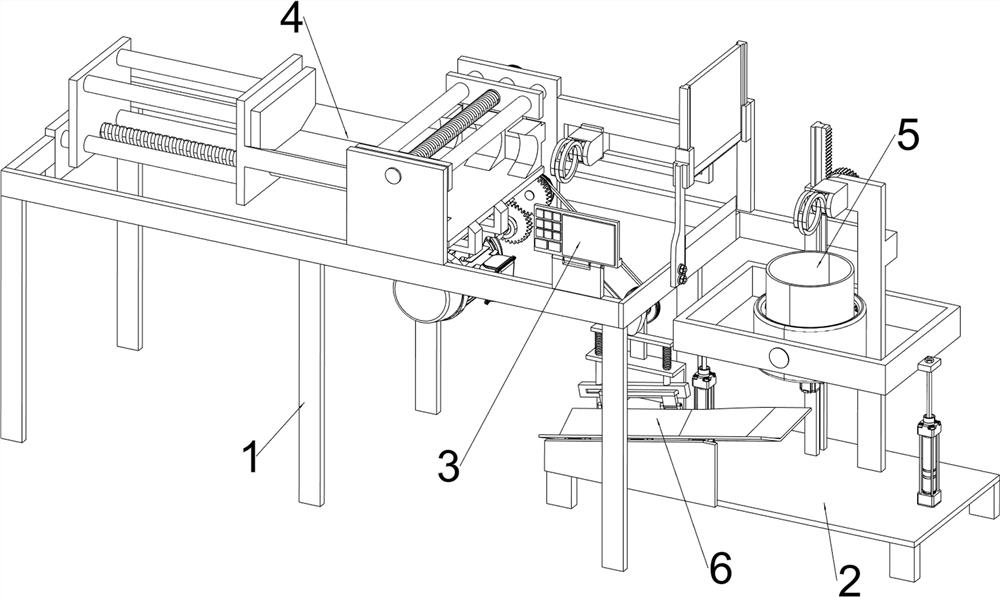

Kelp automatic cutting and rope removing device

PendingCN108377724ASolve the strength problemSolve efficiency problemsHarvestersClimate change adaptationAgricultural engineeringEngineering

The invention relates to a kelp automatic cutting and rope removing device. A plurality of seedling rope guide supporting rods are arranged on a frame body assembly side by side. A hook is arranged atthe bottom of the front end of the seedling rope guide supporting rod. One or more bundles of kelp are located between every two adjacent hooks on seedling ropes. Claw fastening devices are arrangedon the two sides of each seedling rope guide supporting rod and can fasten the corresponding seedling rope towards the two sides. The seedling ropes and the kelp on the seedling ropes are conveyed backwards by the claw fastening devices along the seedling rope guide supporting rods. A plurality of cutting mechanisms for overall cutting the kelp on the seedling ropes are arranged on the frame bodyassembly at different heights according to the cutting sequence from bottom to top. A stirring wheel mechanism is arranged at the tail portion of the frame body assembly and can rotate to stir the seedling ropes on the seedling rope guide supporting rods so that the seedling ropes can fall into collecting grooves on the lower side one by one. By means of the kelp automatic cutting and rope removing device, the problems that in an existing fresh kelp processing process, in the working links of kelp placing, cutting, segmenting and packaging and seeding rope removing, labor intensity is large, and efficiency is low are solved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

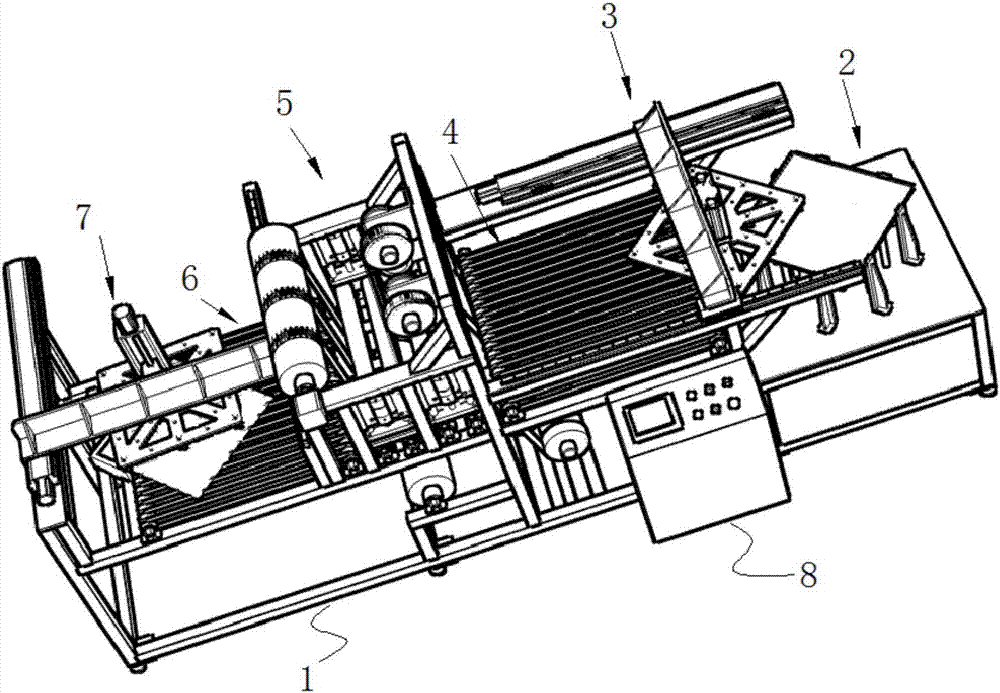

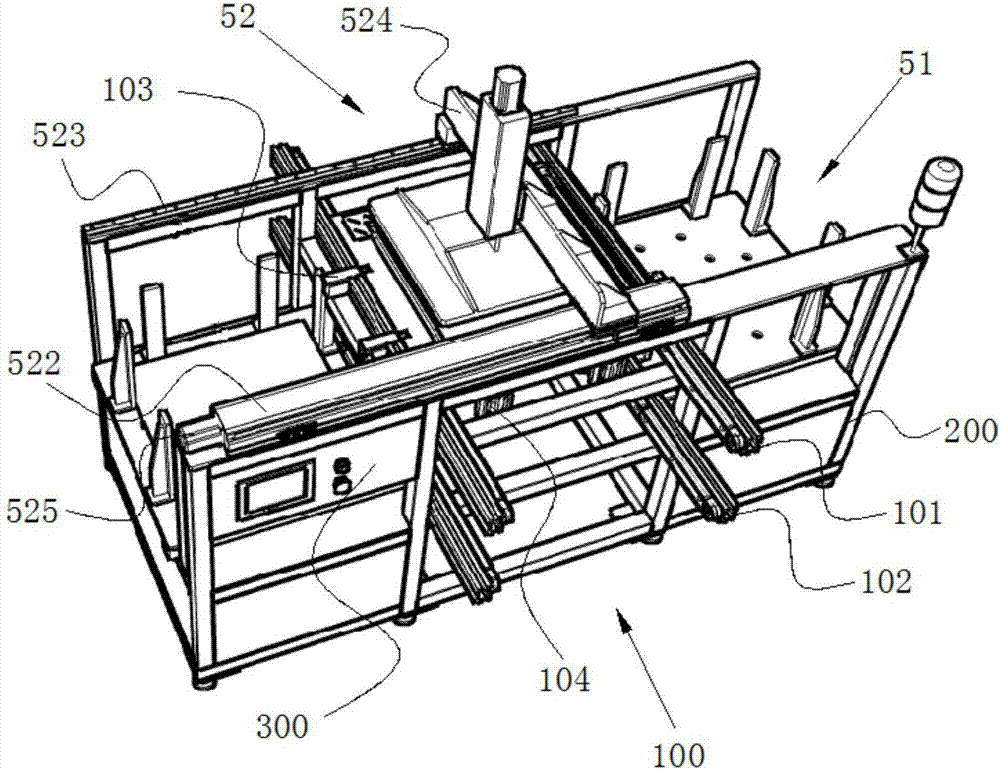

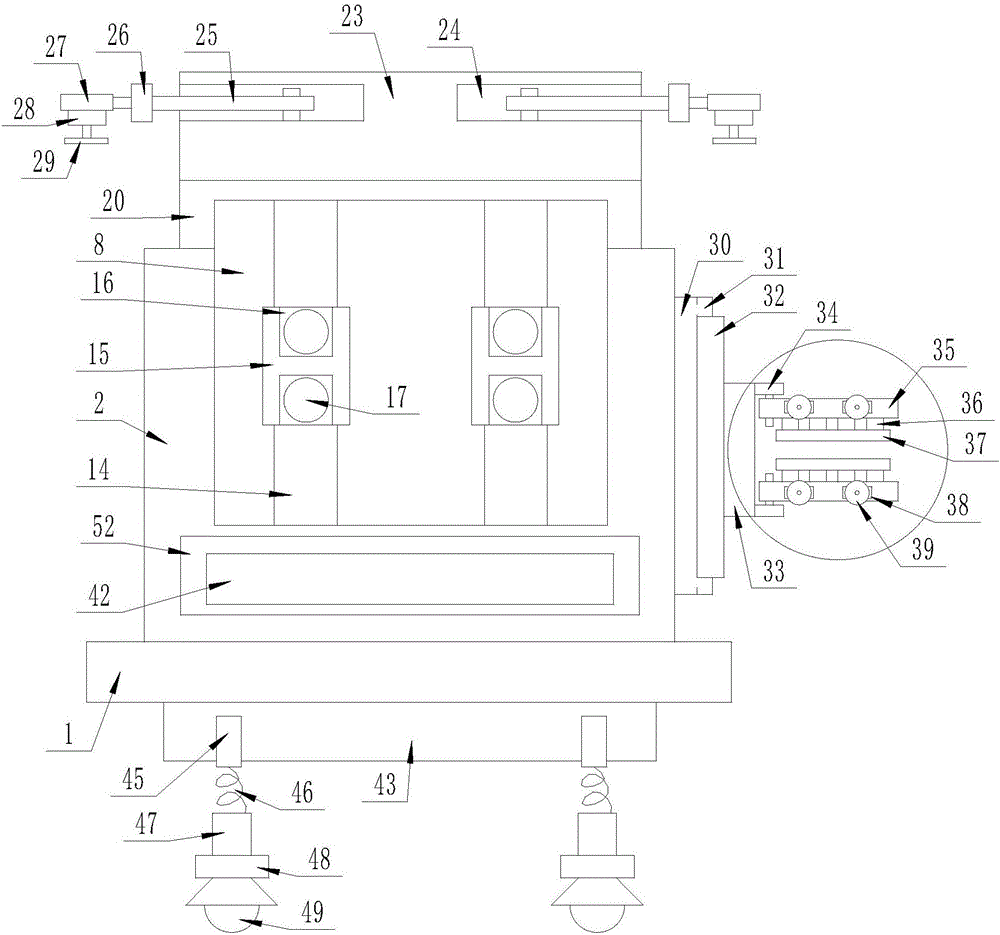

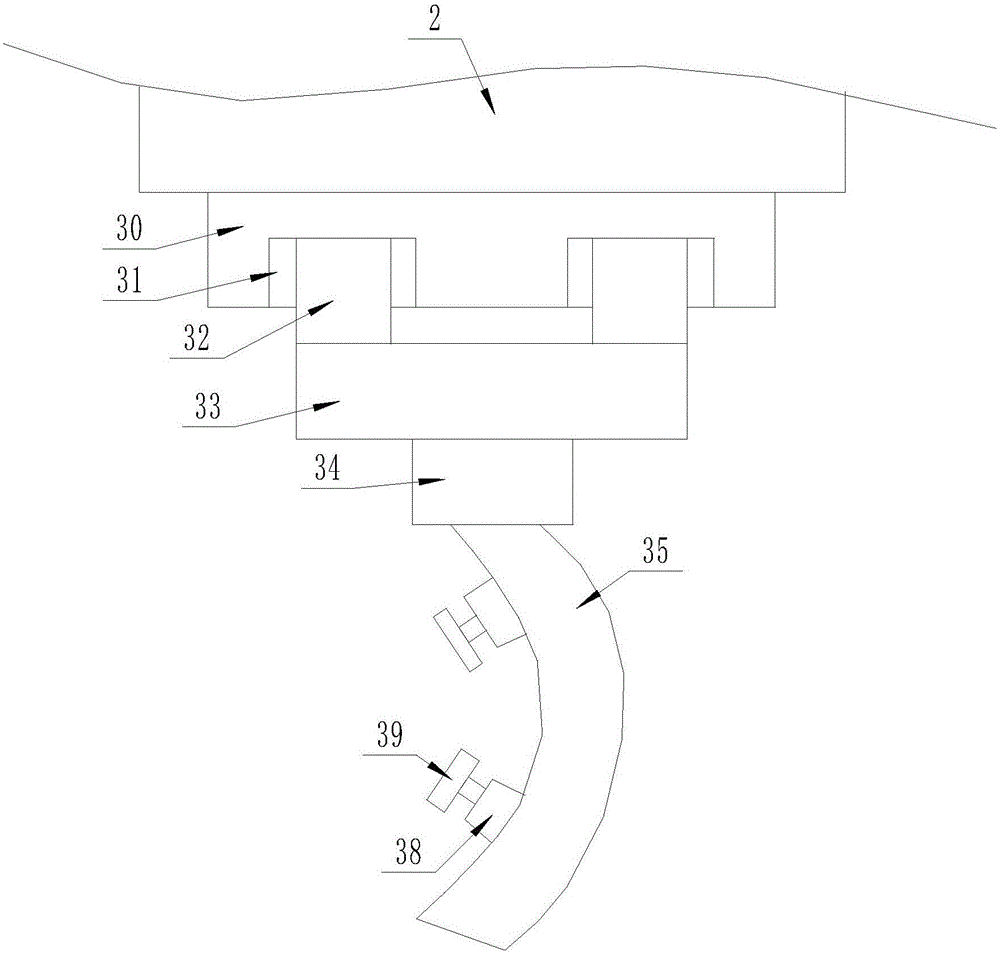

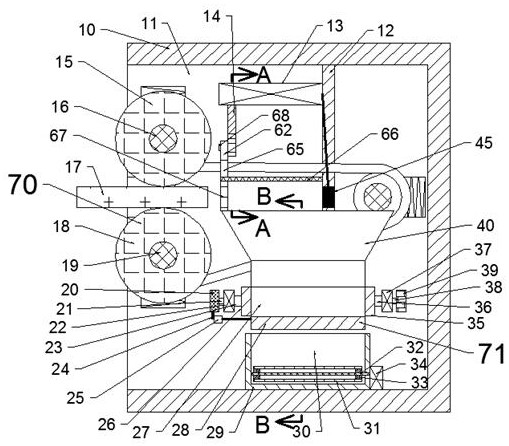

Automatic film stripping equipment

PendingCN107399144ACompact and reasonable structure designReduce scrap rateLamination ancillary operationsLaminationMechanical engineeringPollution

The invention discloses automatic film stripping equipment. The automatic film stripping equipment comprises a feeding mechanism, a first taking mechanism, a first delivery mechanism, a film stripping mechanism, a second delivery mechanism and a second taking mechanism, wherein the film stripping mechanism comprises a first film stripping mechanism and a second film stripping mechanism; the first film stripping mechanism comprises at least one first viscous coil unwinding mechanism and at least one first film collecting wheel; and the second film stripping mechanism comprises at least one second viscous coil unwinding mechanism and at least one second film collecting wheel. The automatic film stripping equipment further comprises a controller, and the feeding mechanism, the first taking mechanism, the first delivery mechanism, the first viscous coil unwinding mechanisms, the first film collecting wheels, the second viscous coil unwinding mechanisms, the second film collecting wheels, the second delivery mechanism and the second taking mechanism are electrically connected with the controller. The automatic film stripping equipment can automatically strip protective films on the upper surface and the lower surface of a product and orderly collect the stripped protective films to reduce environmental pollution; and the whole film stripping process is mechanically controlled fully automatically, the product rejection rate is low, and the automatic film stripping equipment is suitable for wide popularization.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

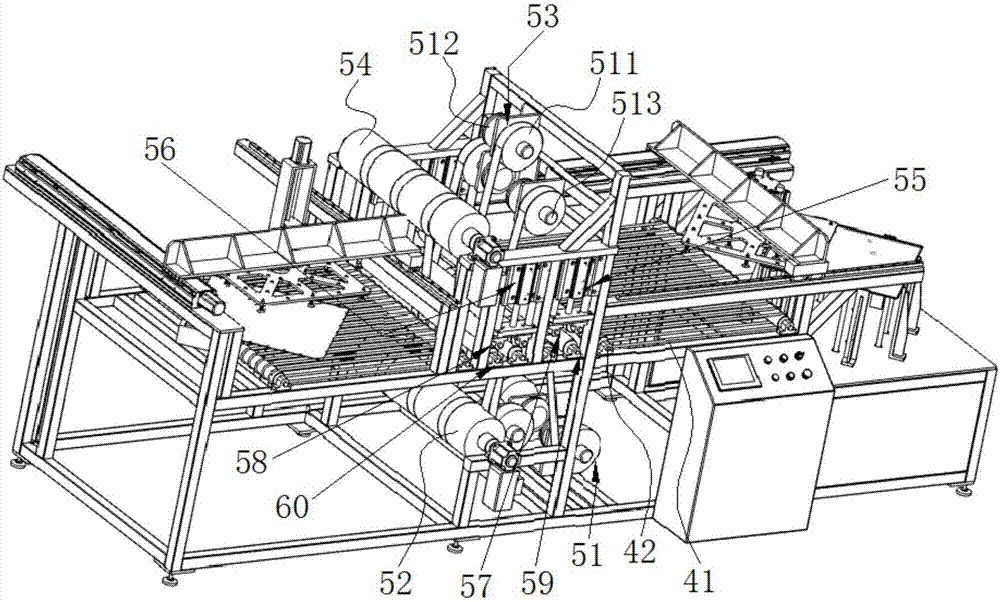

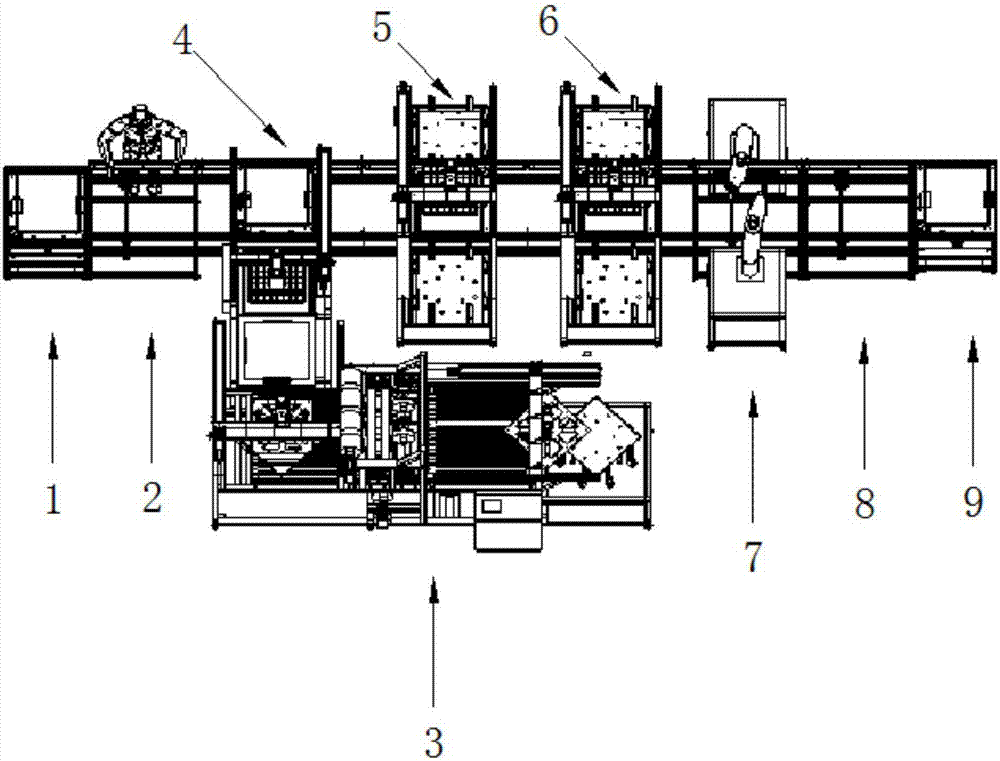

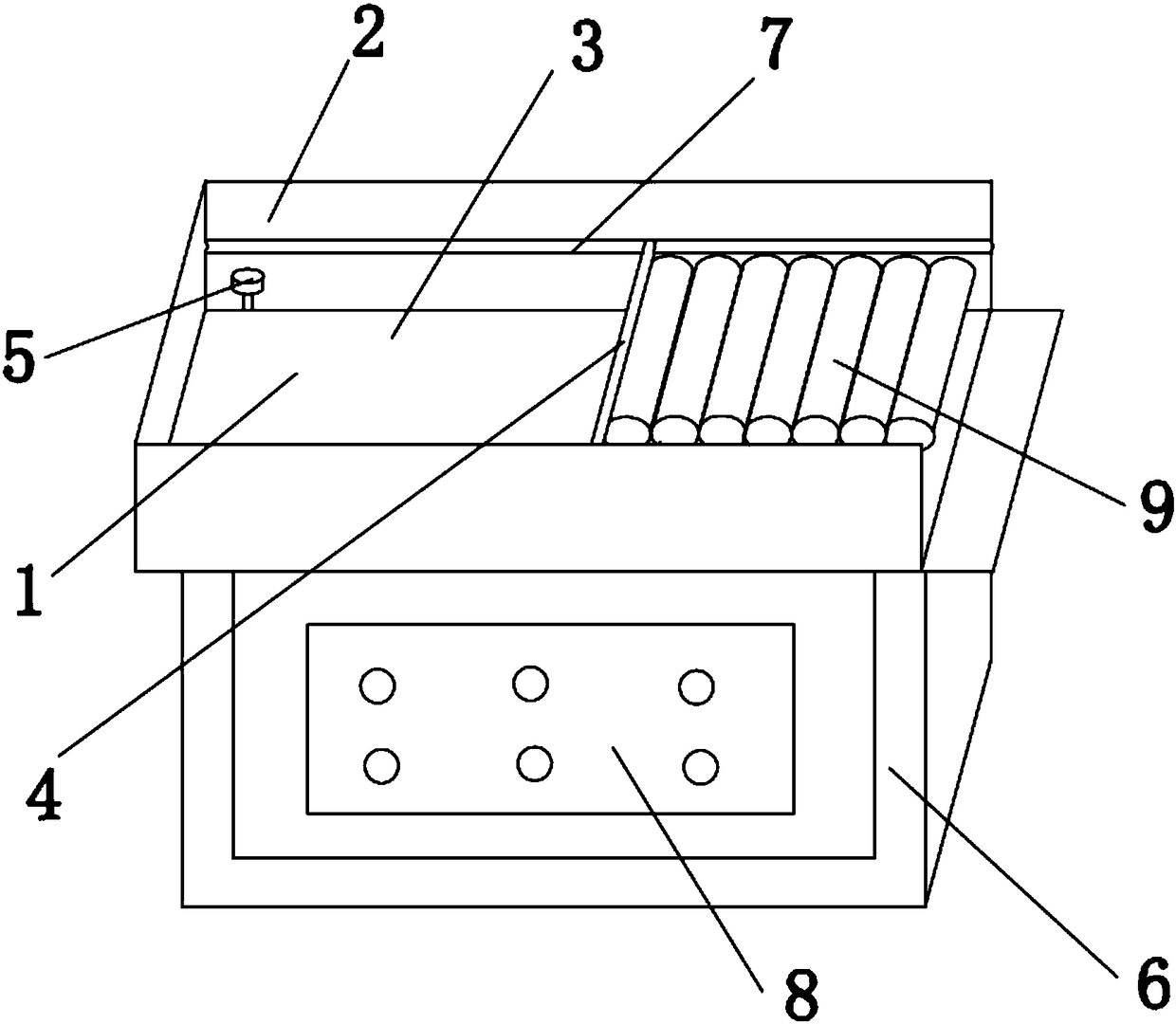

Automatic assembly production line for panel lights

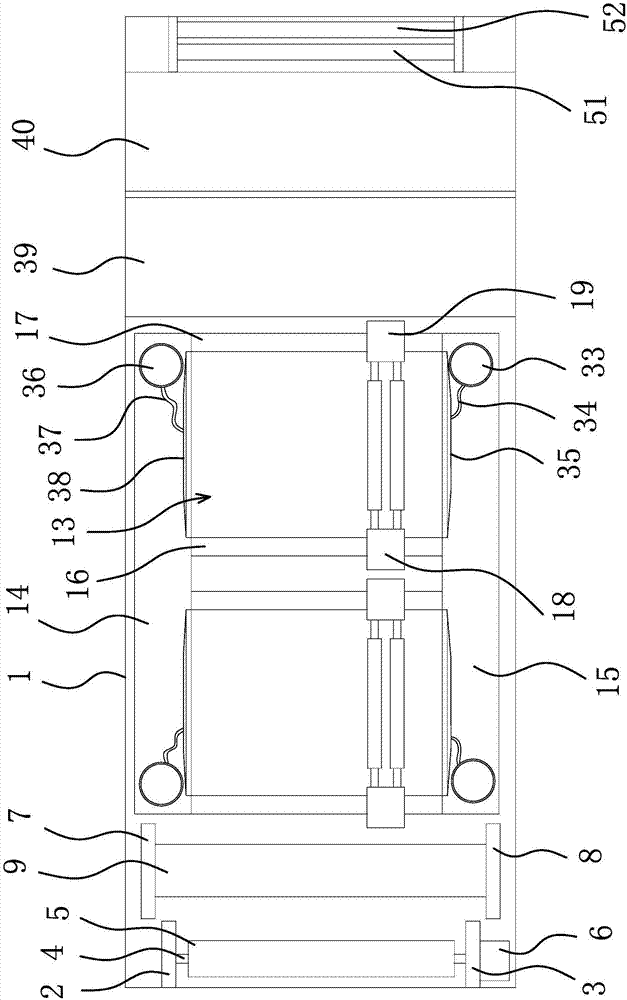

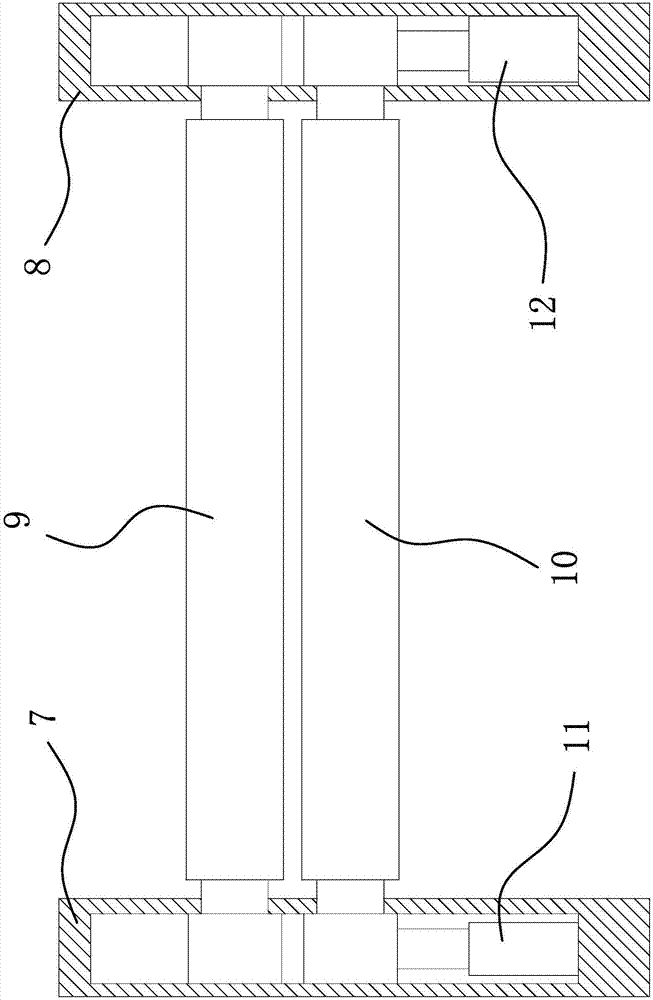

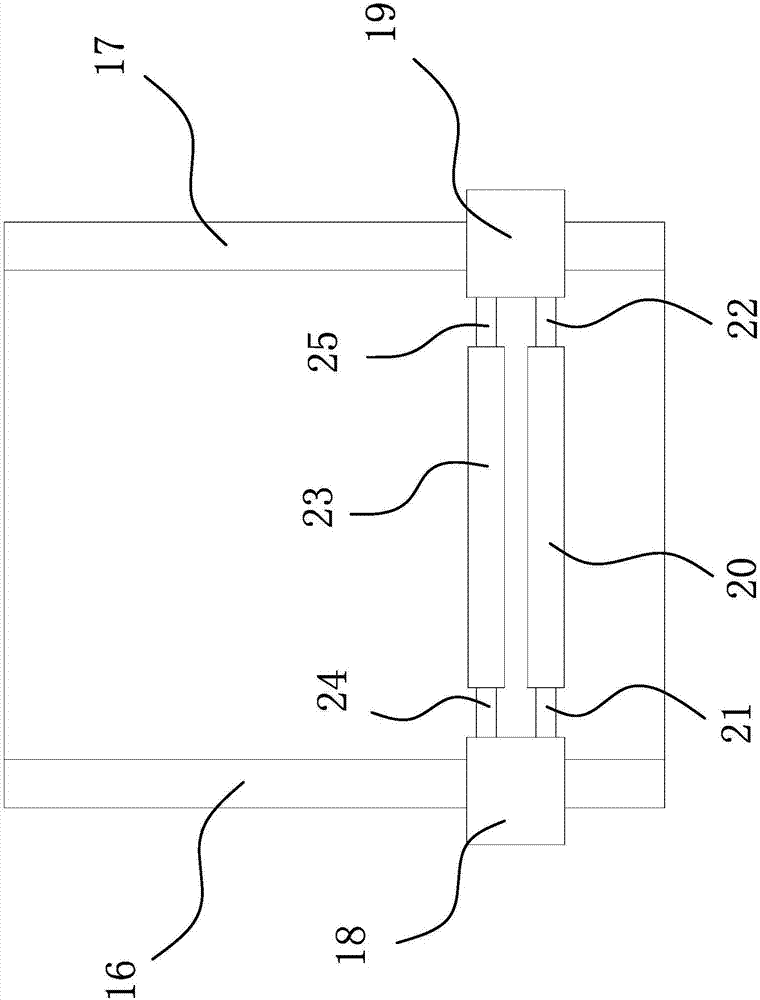

PendingCN107378482AHigh degree of automationImprove assembly accuracyAssembly machinesProduction lineSheet film

The invention discloses an automatic assembly production line for panel lights. The assembly line comprises a carrier jacking station, a light frame feeding station, an optical sheet film-tearing station, a optical sheet assembly station, a reflective plate assembly station, a back plate assembly station, a screw locking station, a finished product collecting station and a carrier return station; the light frame feeding station is located on the downstream portion of the carrier jacking station, the optical sheet assembly station is located on the downstream portion of the light frame feeding station, and the optical sheet film-tearing station is located on the upstream portion of the optical sheet assembly station; the reflective plate assembly station is located on the downstream portion of the optical sheet assembly station, the back plate assembly station is located on the downstream portion of the reflective plate assembly station, the screw locking station is located on the downstream portion of the back plate assembly station, the finished product collecting station is located on the downstream portion of the screw locking station, and the carrier return station is located on the downstream portion of the finished product collecting station. The automatic assembly line for the panel lights has the advantages of being high in automation degree and assembly precision, achieving quick, high-efficiency and high-quality production, reducing labor intensity, and decreasing the scrap rate of the products.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

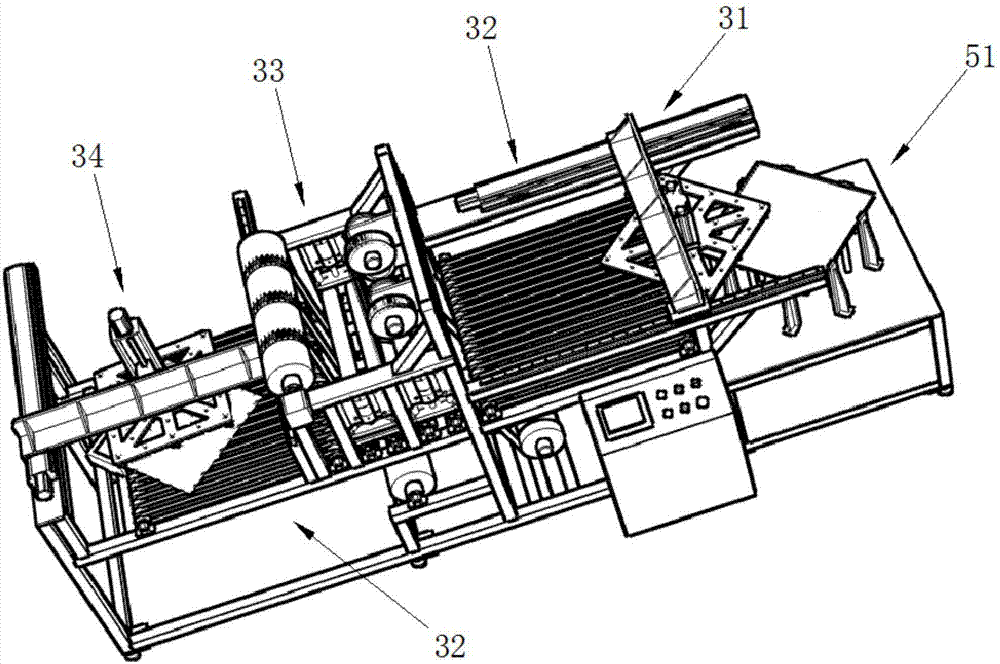

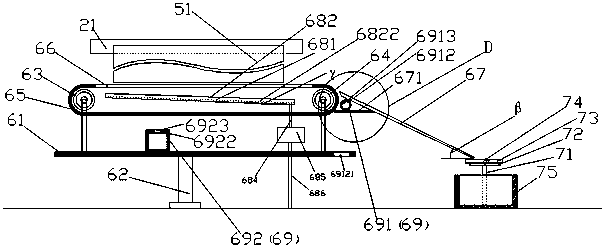

Fabric printing production line

InactiveCN107139583AGuaranteed flatnessConveying orderlyRotary pressesPrinting press partsProduction lineDrive motor

The invention provides a fabric printing production line, and belongs to the technical field of machines. The fabric printing production line comprises a rack, a fabric unreeling device for releasing fabric is arranged at one end of the rack, and comprises a first mounting plate and a second mounting plate which are fixed to the rack, an unreeling shaft is arranged between the first mounting plate and the second mounting plate, one end of the unreeling shaft penetrates the first mounting plate, an unreeling roller cylinder is detachably fixed to the unreeling shaft, and a drive motor used for driving the unreeling shaft to rotate is further fixed to the rack; the production line is characterized in that a conveying mechanism for traction conveying of fabric, multiple printing devices for different-dye printing on fabric, a drying device for drying the printed fabric and a neatening device for neatening the dried fabric are arranged on the rack in sequence. The production line has the beneficial effect that the fabric can be subject to assembly printing, and the printing efficiency of the fabric can be improved.

Owner:ZHEJIANG XIANYU FIBER WEAVING & DYEING GARMENT CO LTD

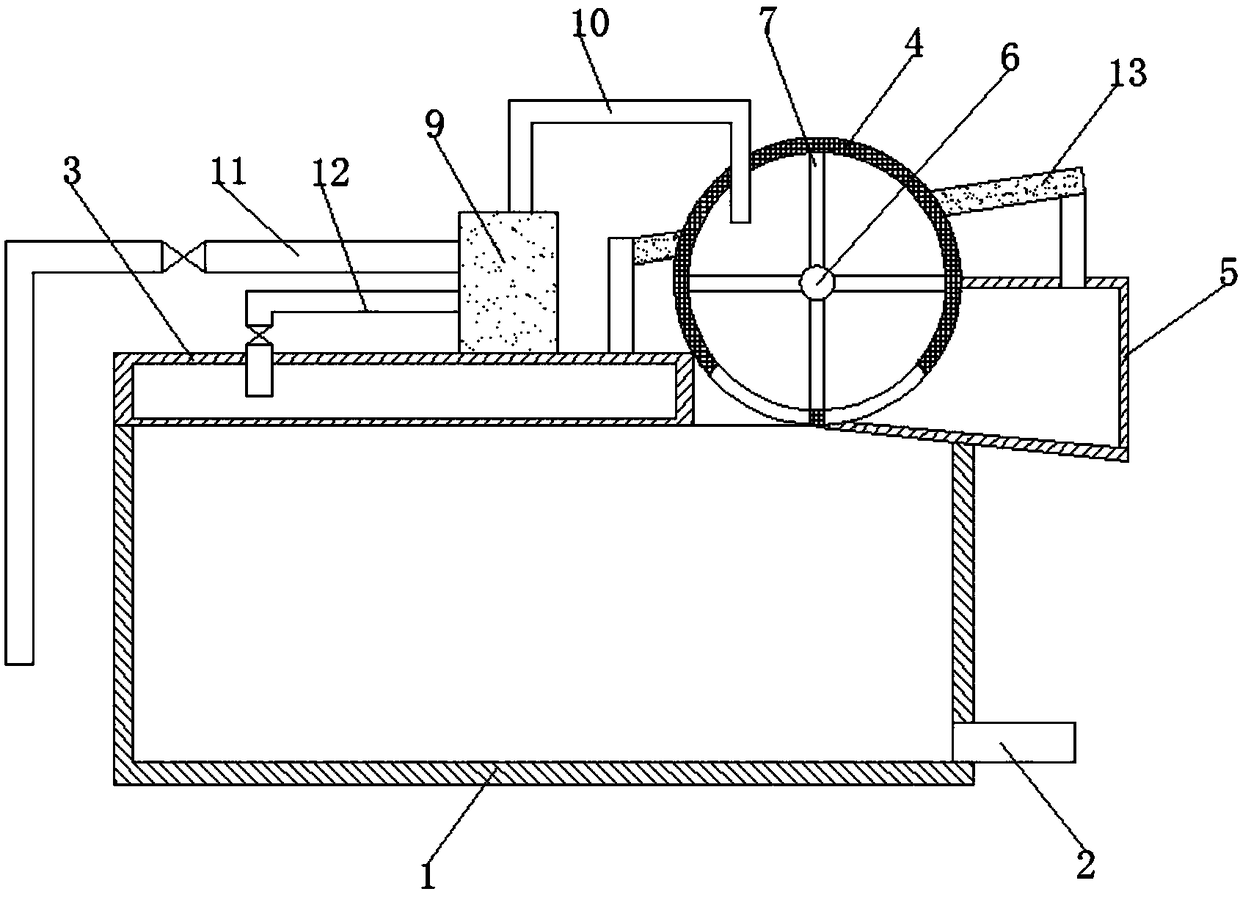

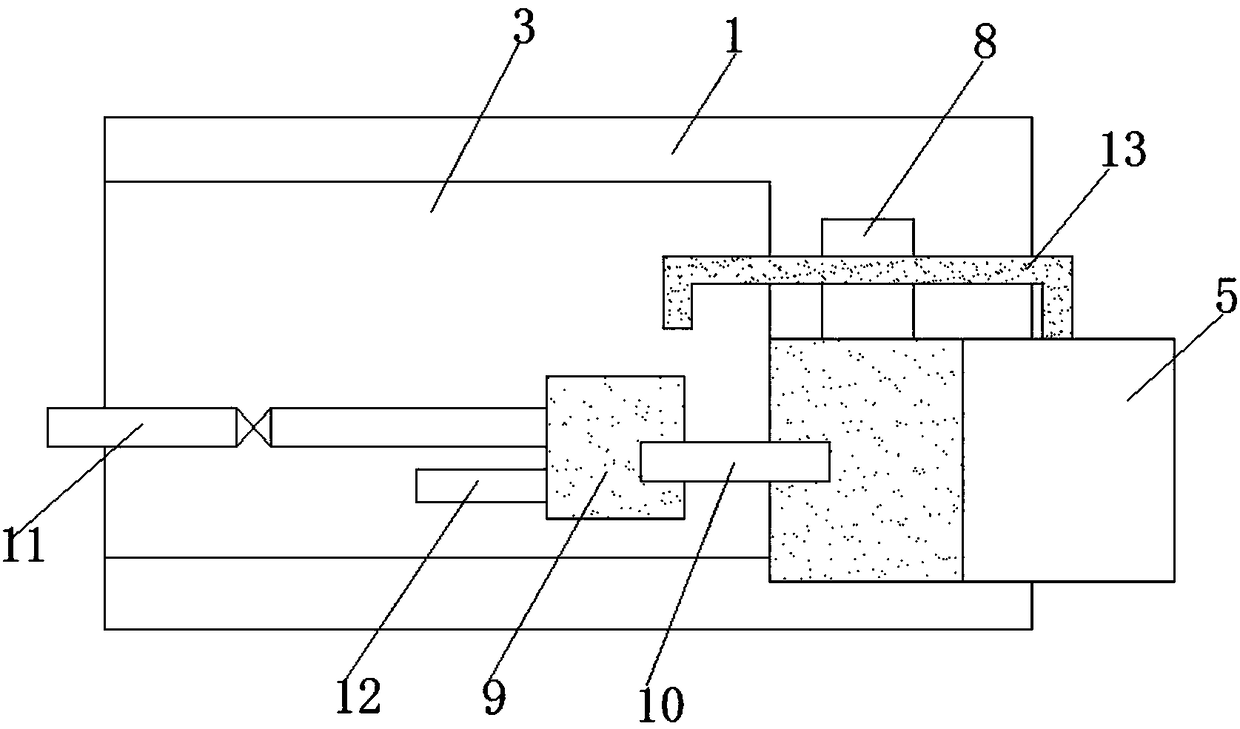

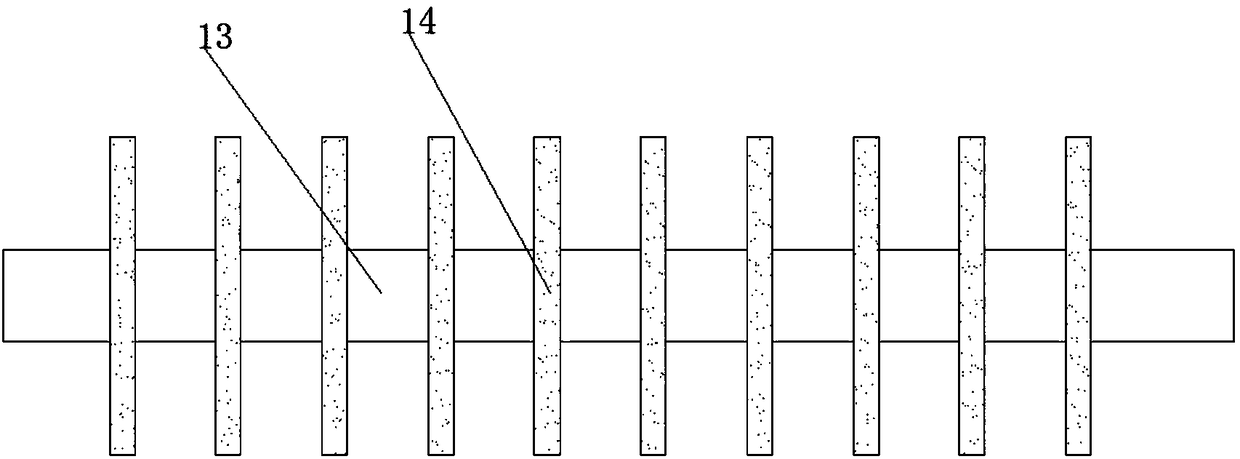

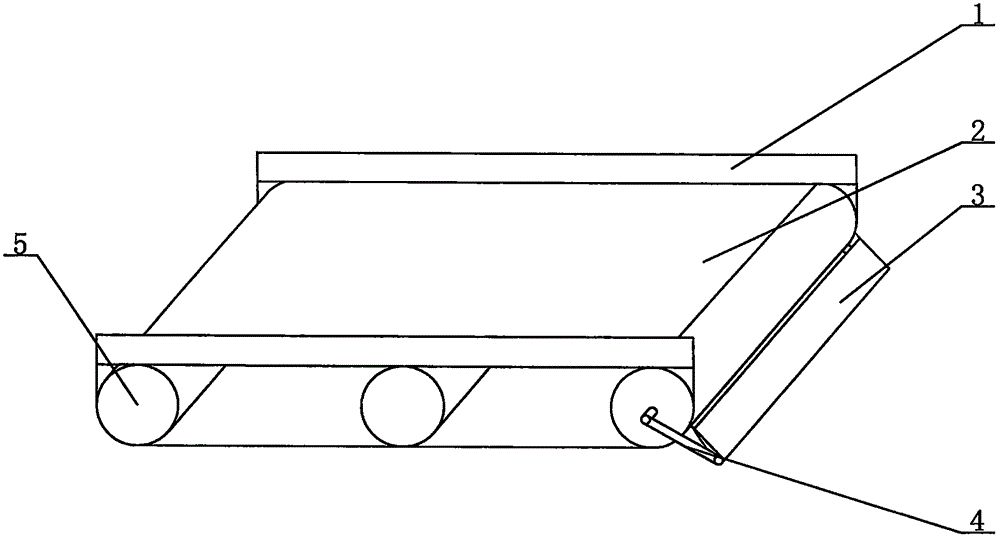

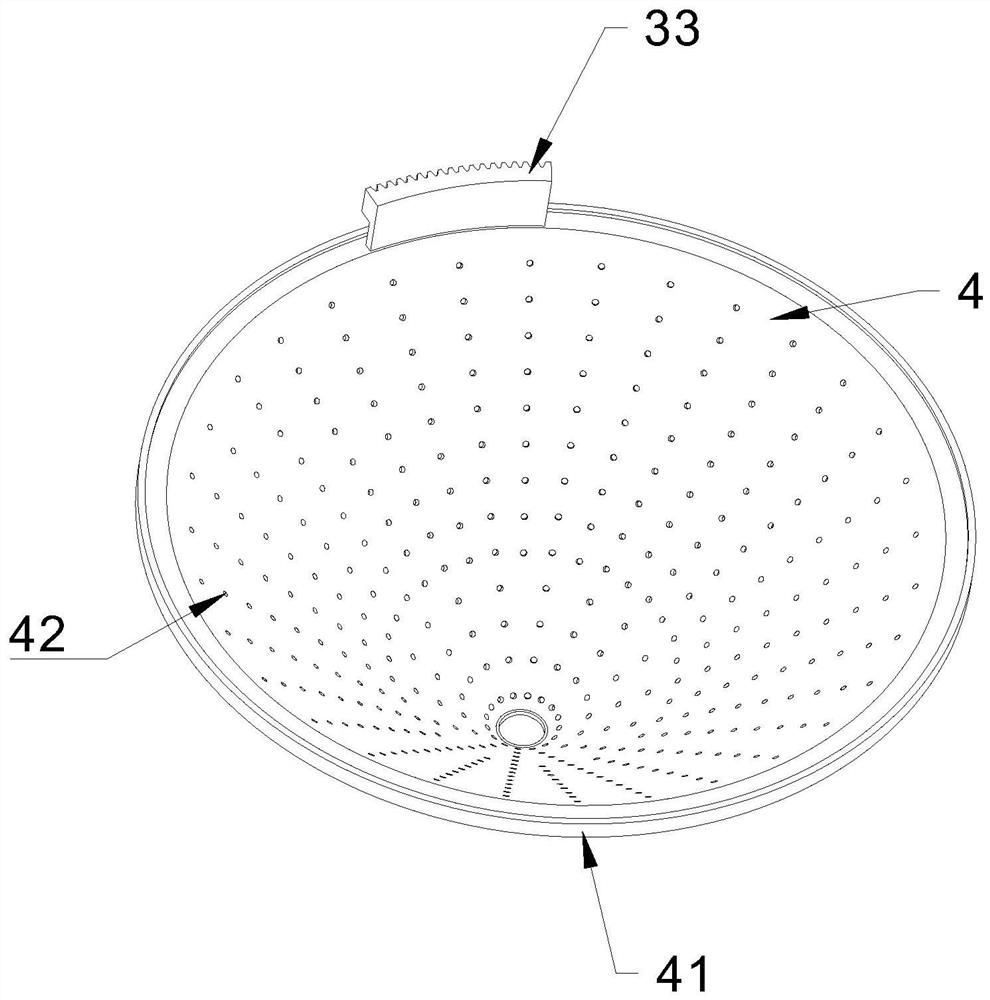

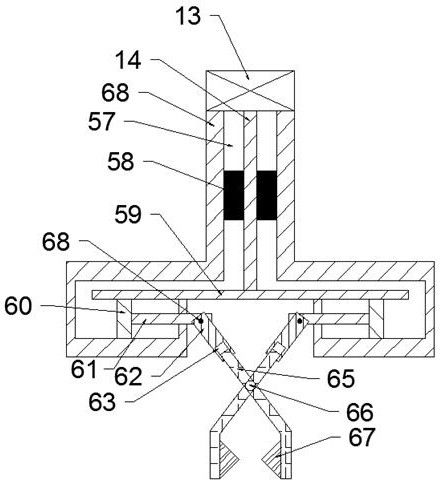

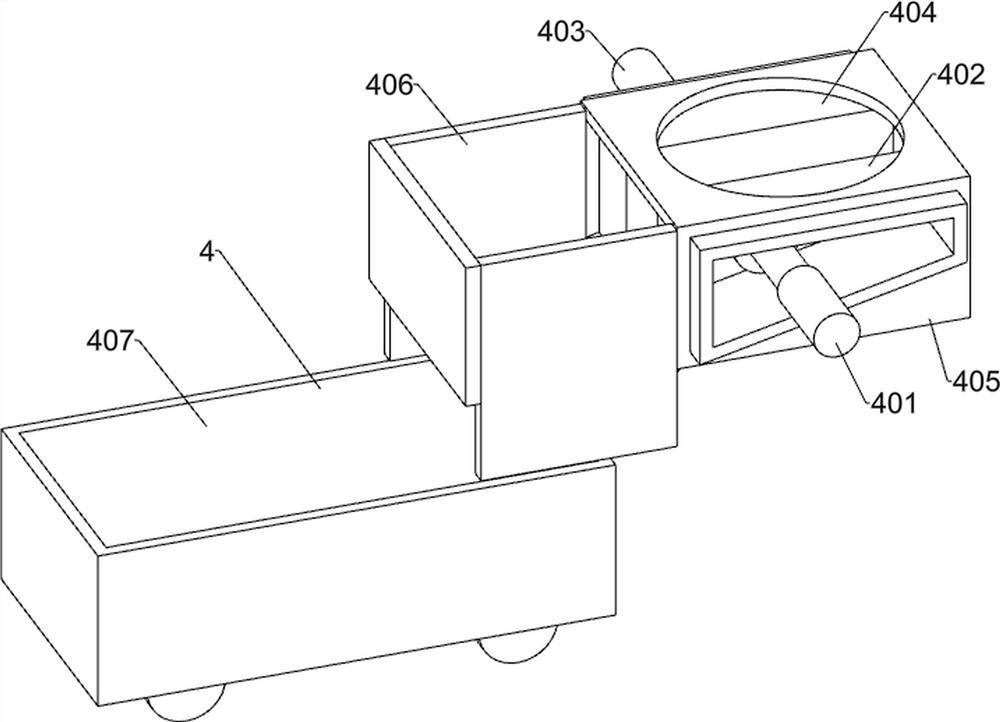

Mask recycling device for public health

InactiveCN111517033APromote energy conservation and environmental protectionPrevent spillageWaste collection and transferRefuse receptaclesMotor drivePublic health

The invention discloses a mask recycling device for public health. The mask recycling device comprises a recycling box. A feed port is formed in the top end of the recycling box, a box cover is mounted on the wall of the feed port, a first mounting frame is fixedly mounted on the inner box wall of the recycling box, a guide opening is formed in the first mounting frame, a rotary shaft is rotationally connected to the inner opening wall of the guide opening, the rotary shaft is fixedly sleeved with a rotary plate, and a motor is fixedly mounted on the outer box wall of the recycling box. Masksentering the box fall on the rotary plate, an infrared sensor can sense the situation when the masks fall in, a controller controls an ultraviolet disinfecting lamp to carry out disinfection, after disinfection is completed, the motor drives the rotary plate to auto-rotate, the disinfected masks are collected in a collecting box under the conveying effect of a conveying belt under the effect of mutual extrusion of the conveying belt and a guide roller, thus, the masks are collected in order, and the masks can be efficiently recycled; and the device is provided with a solar photovoltaic plate,solar energy is converted into electric energy, power is supplied to equipment in the recycling box, and energy saving and environmental friendliness are facilitated.

Owner:张文景

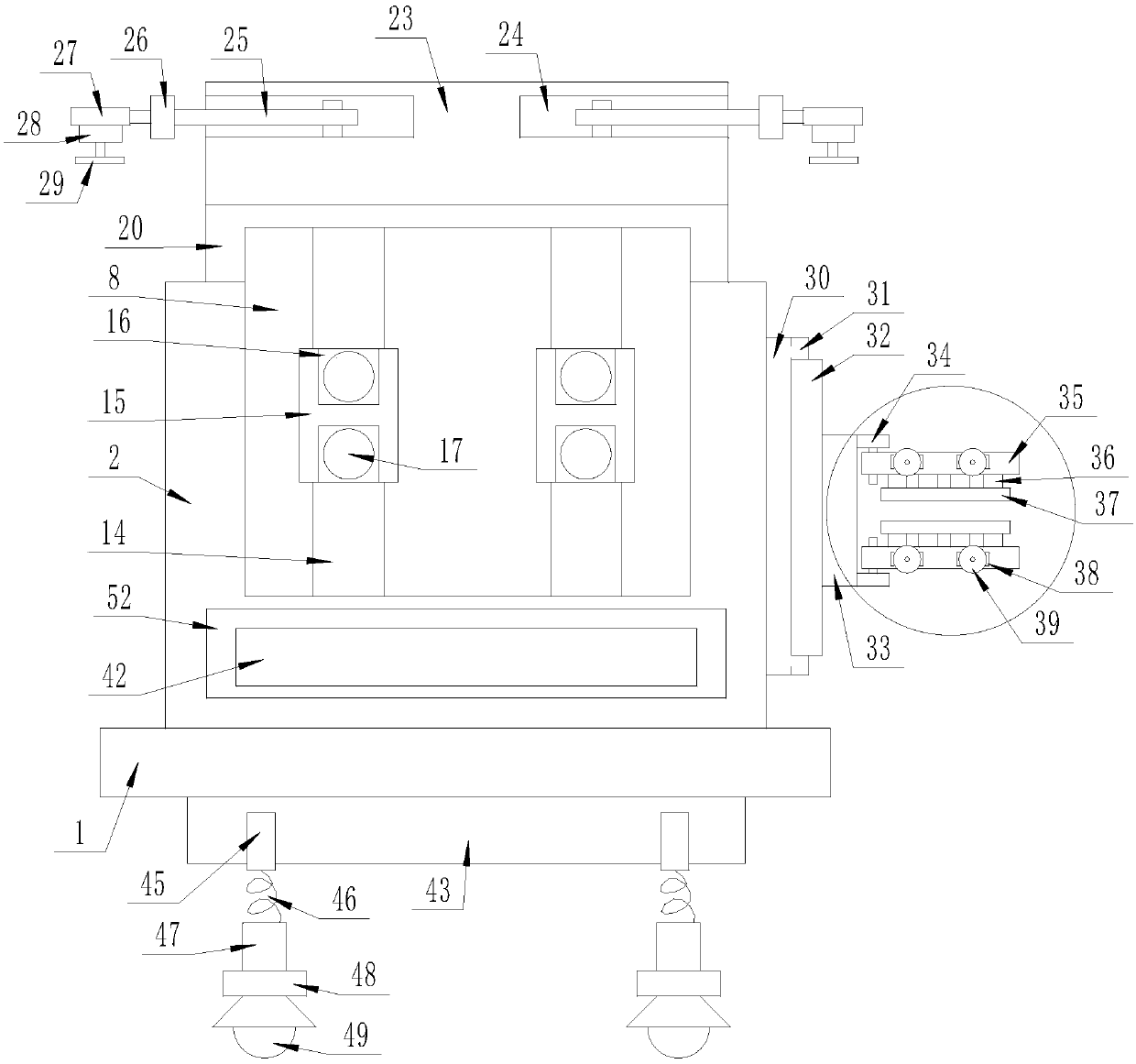

Tree trimming device

ActiveCN106538255ASimple structureEasy to useCuttersCutting implementsEngineeringMechanical engineering

The invention discloses a tree trimming device which comprises a rectangular base, wherein a rectangular bearing box is firmly connected to the upper surface of the rectangular base; a rotary trimming mechanism is disposed on the side surface of the rectangular bearing box; a stretchable carrying mechanism is disposed on the lower surface inside the rectangular bearing box; a supporting movable mechanism is disposed on the lower surface of the rectangular base; a scanning cutting mechanism is disposed on the upper surface of the rectangular bearing box; an edge cleaning mechanism is disposed on the front surface of the rectangular bearing box; a storage battery is disposed on the upper surface inside the rectangular bearing box; a controller is disposed on the side surface of the rectangular bearing box; and an input end of the controller is electrically connected to the storage battery via a wire. The device disclosed by the invention has the beneficial effects of a simple structure and high practicability.

Owner:常州泓麟智能科技有限公司

Environment-friendly vehicle sewage collecting device

InactiveCN108382756AIncrease profitOrderly collectionRefuse receptaclesStationary filtering element filtersScrapWater pipe

The invention discloses an environment-friendly vehicle sewage collecting device. The environment-friendly vehicle sewage collecting device comprises a waste water box; a water outlet is formed in thelower end of the waste water box; a housing and a waste bunker are welded at the upper end of the waste water box; a rotating shaft is arranged on the inner side of the housing through a bearing; a filter plate is arranged at the upper end of the rotating shaft; one end of the rotating shaft extends to the outer side of the housing and is connected with a motor; the motor is connected with the outer wall of the housing through screws; the output end of the motor is connected with the rotating shaft through a coupler; a feed pipe is inserted into the upper end of the housing; the other end ofthe feed pipe is in screwed connection with the outlet end of a water pump; and the water pump is arranged at the upper end of a water storage tank. When the environment-friendly vehicle sewage collecting device is in use, waste water is collected through the water pump and a waste water pipe; the waste water enters into the housing through the water pump and is filtered by the filter plate, filter residues are intercepted by the filter plate, the motor is started when the amount of the filter residues on the filter plate is large, and the filter residues are poured into the waste bunker.

Owner:佛山杰致信息科技有限公司

Collecting box for refuse bags

InactiveCN101284574AOrderly collectionSmall footprintContainers for flexible articlesFlat article dispensingAsymmetric distributionEngineering

Owner:DAJING HIGH SCHOOL AFFILIATED TO SHANGHAI INT STUDIES UNIV

Special excreta disposal device for rabbit keeping

Owner:XINAN ERLONG PLANTING FARMERS SPECIALIZED COOP

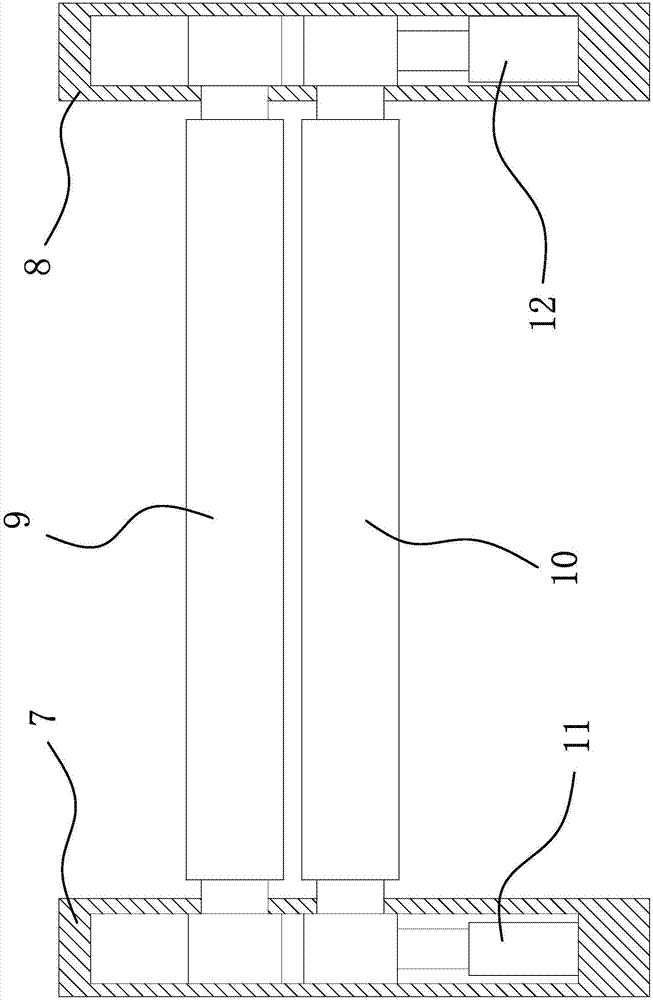

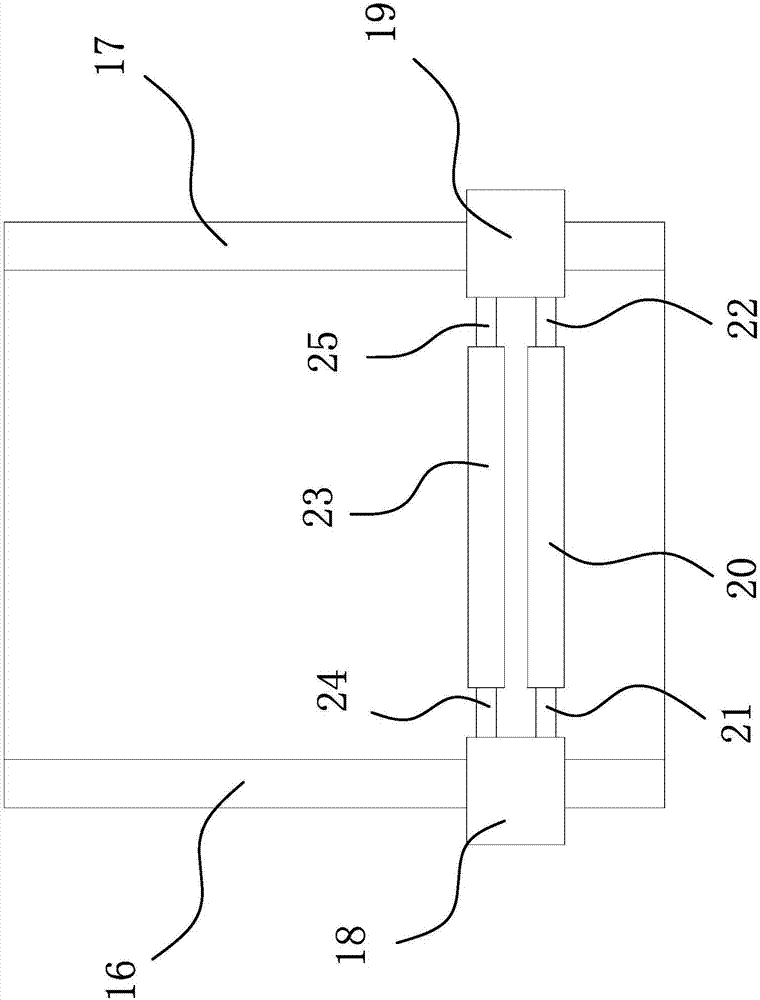

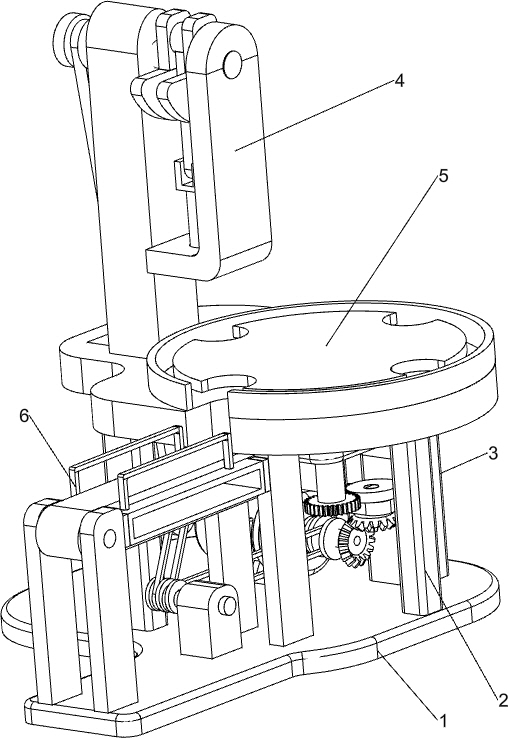

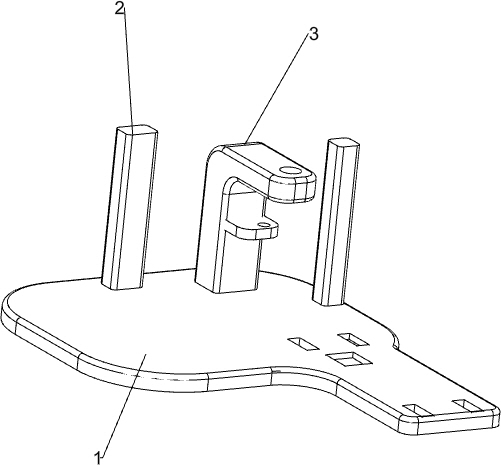

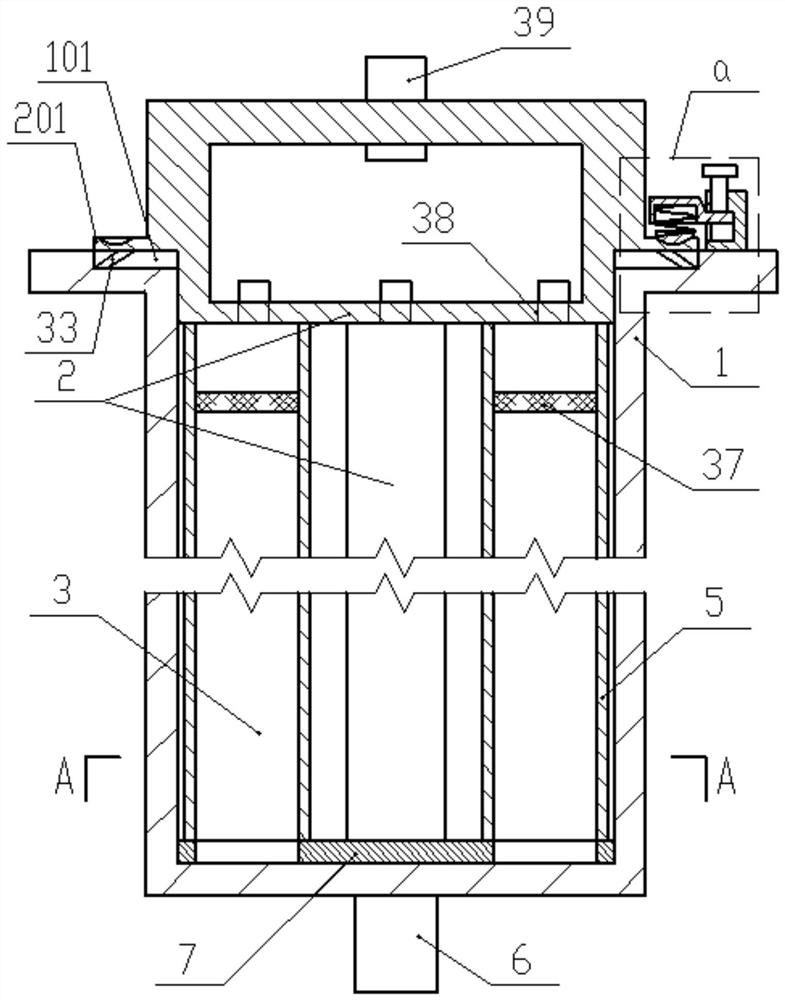

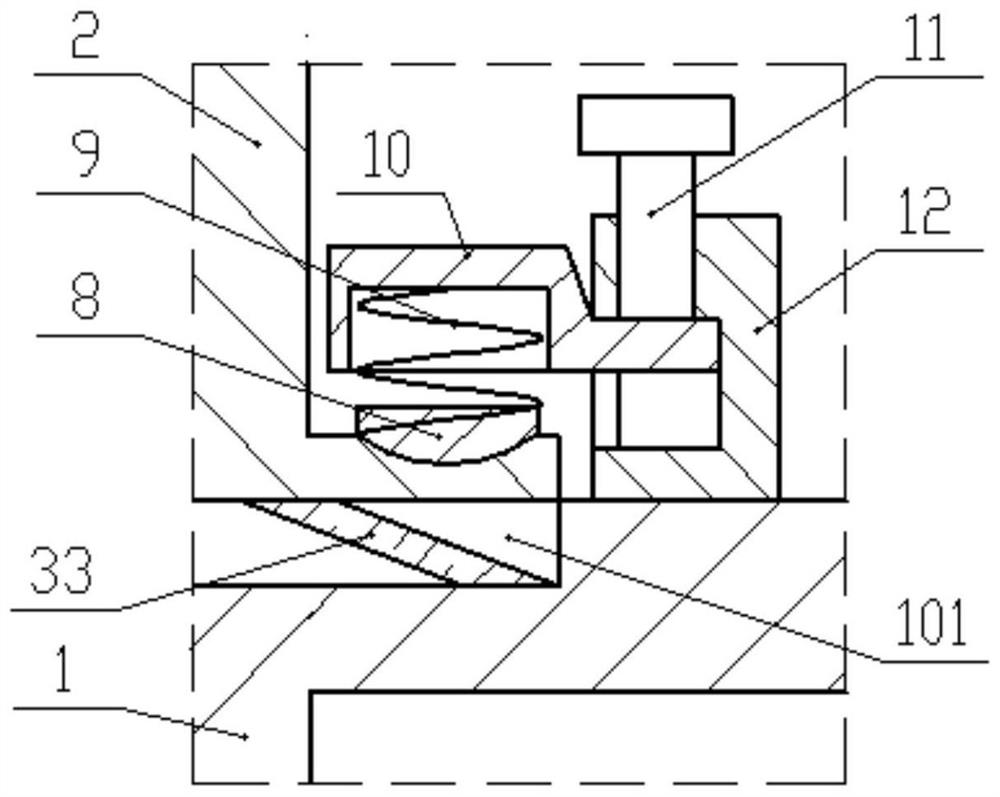

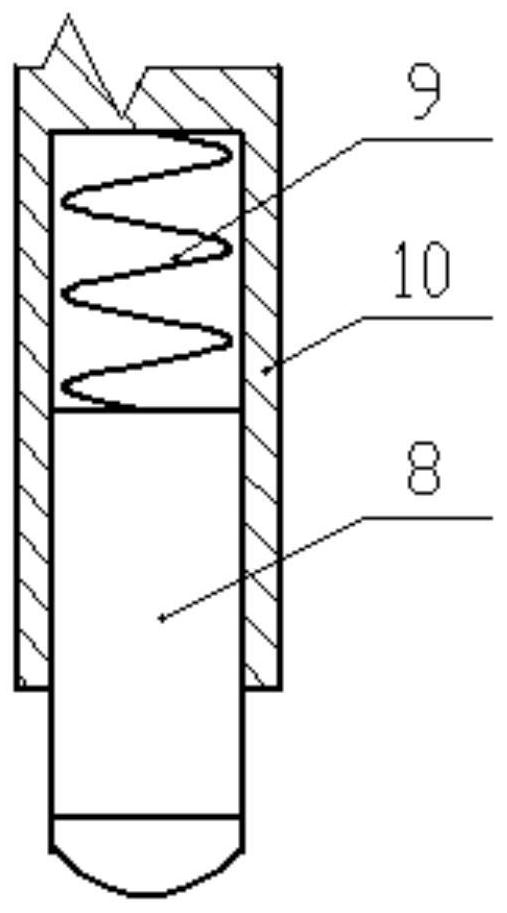

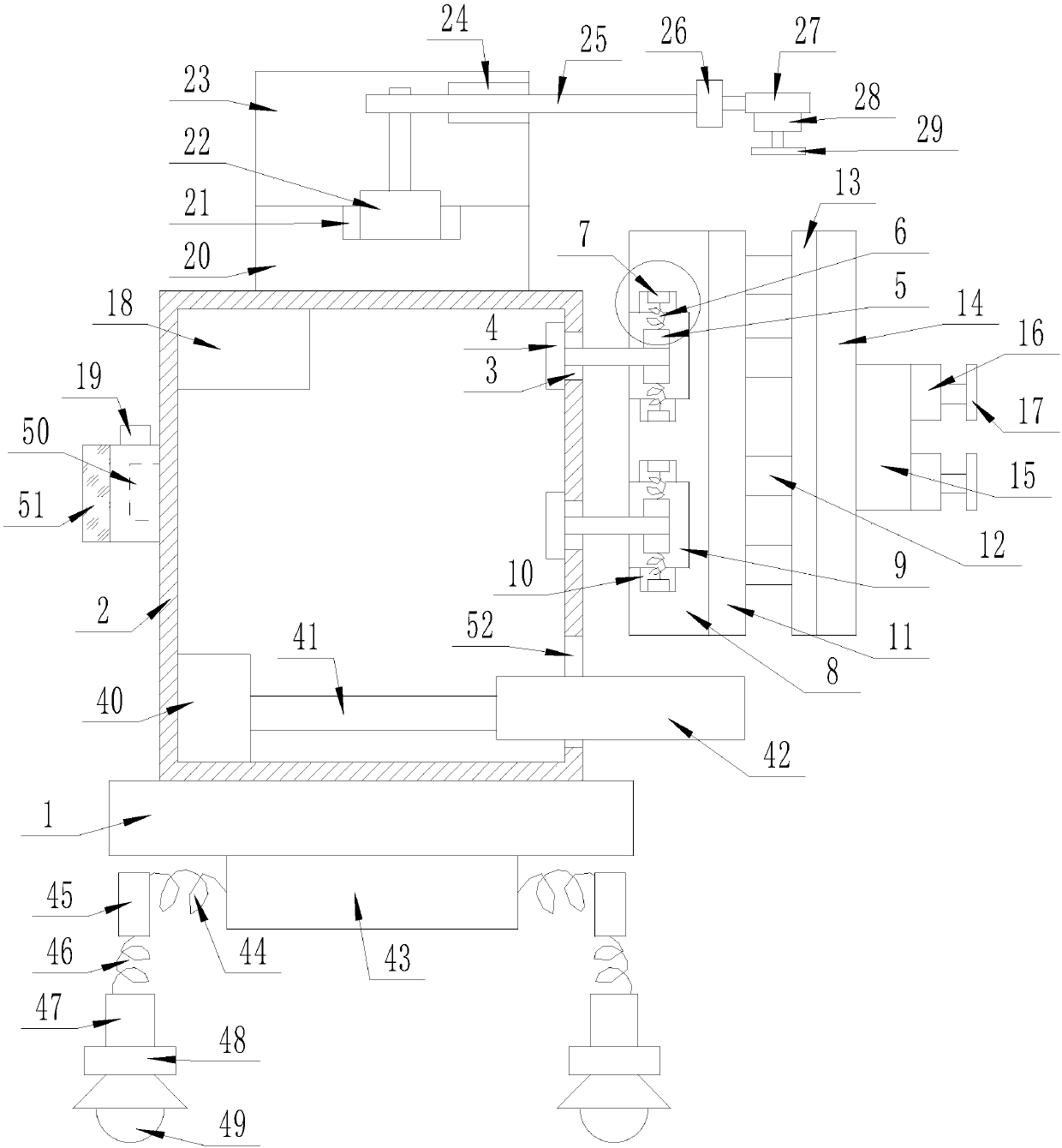

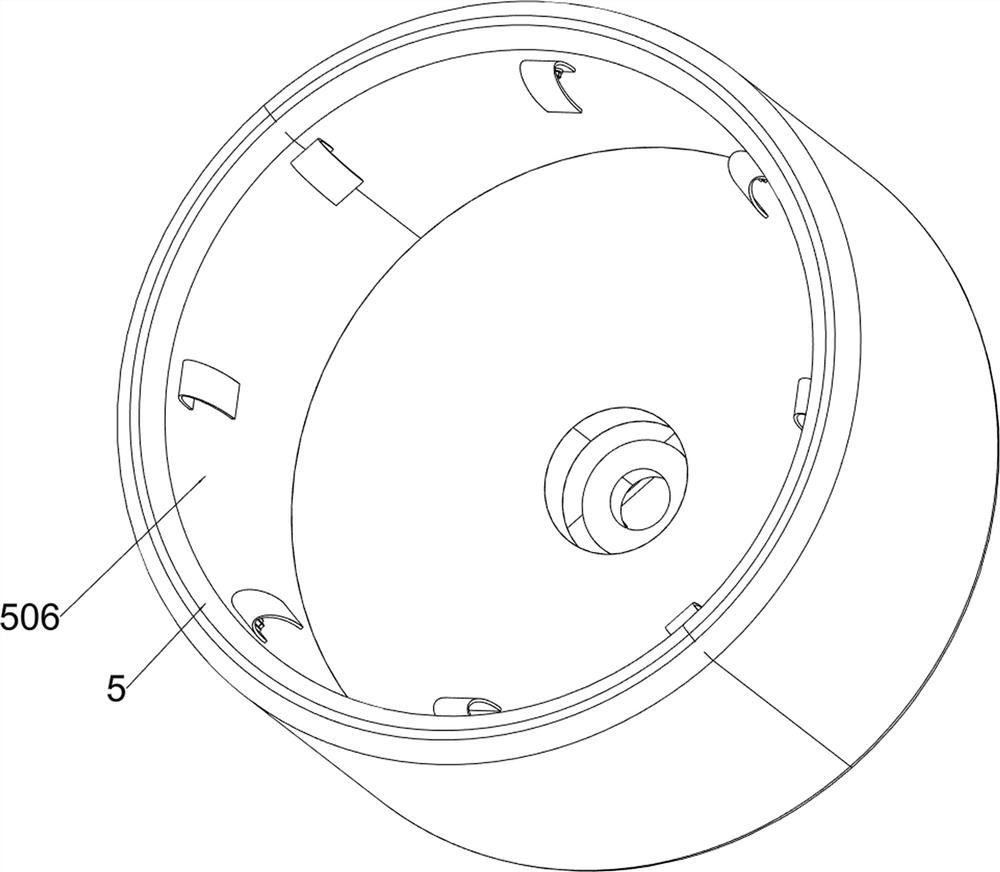

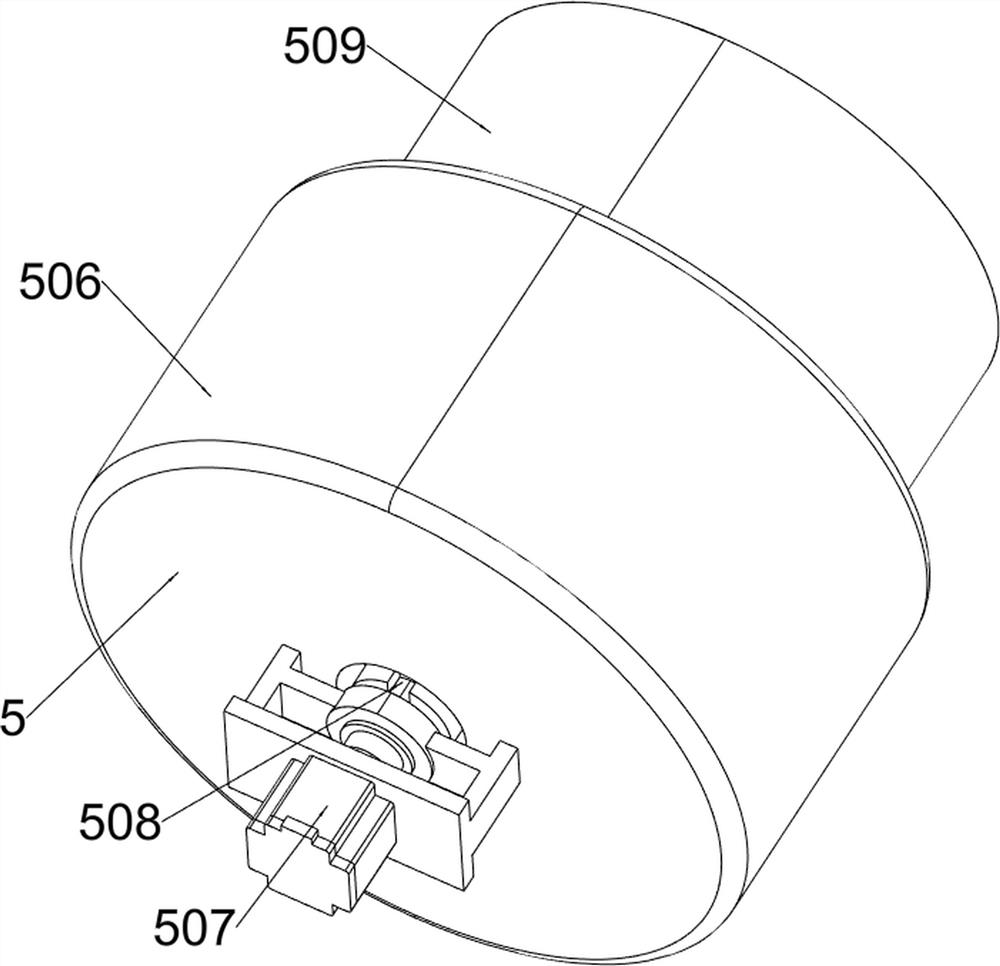

Bearing pressing machine

InactiveCN111702442AAchieve rotationRealize automatic pressingMetal working apparatusEngineeringMachine

The invention relates to a pressing machine, in particular to a bearing pressing machine. According to the bearing pressing machine, workpieces and bearings can be fixed, the bearings can be automatically pressed, the time and labor are saved, and operation is easy. The bearing pressing machine comprises a base, supporting columns, a first supporting frame, a pressing mechanism, a rotating mechanism and a discharging mechanism; the supporting columns are arranged in the middles of the front side and the rear side and the middle of the right side of the top of the base correspondingly; the first supporting frame is arranged on the rear part of the right side of the top of the base; the pressing mechanism is connected between the tops of the supporting columns and the top of the base; and the rotating mechanism is connected between the first supporting frame and the pressing mechanism, and the discharging mechanism is arranged on the front right side of the base. When needing to press the bearings, people place the bearings needing to be pressed into a part of the rotating mechanism, the pressing mechanism is started, under cooperation of the rotating mechanism, the bearings are pressed by the pressing mechanism, when pressing of the bearings is completed, the bearings fall into the discharging mechanism, and people can take out the bearings orderly.

Owner:刘茂椿

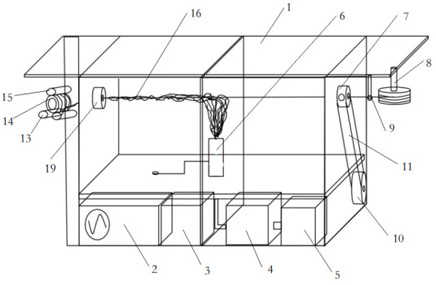

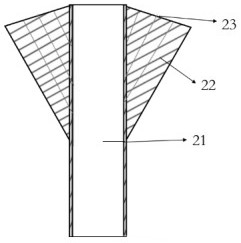

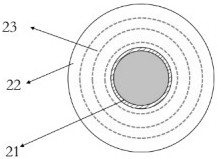

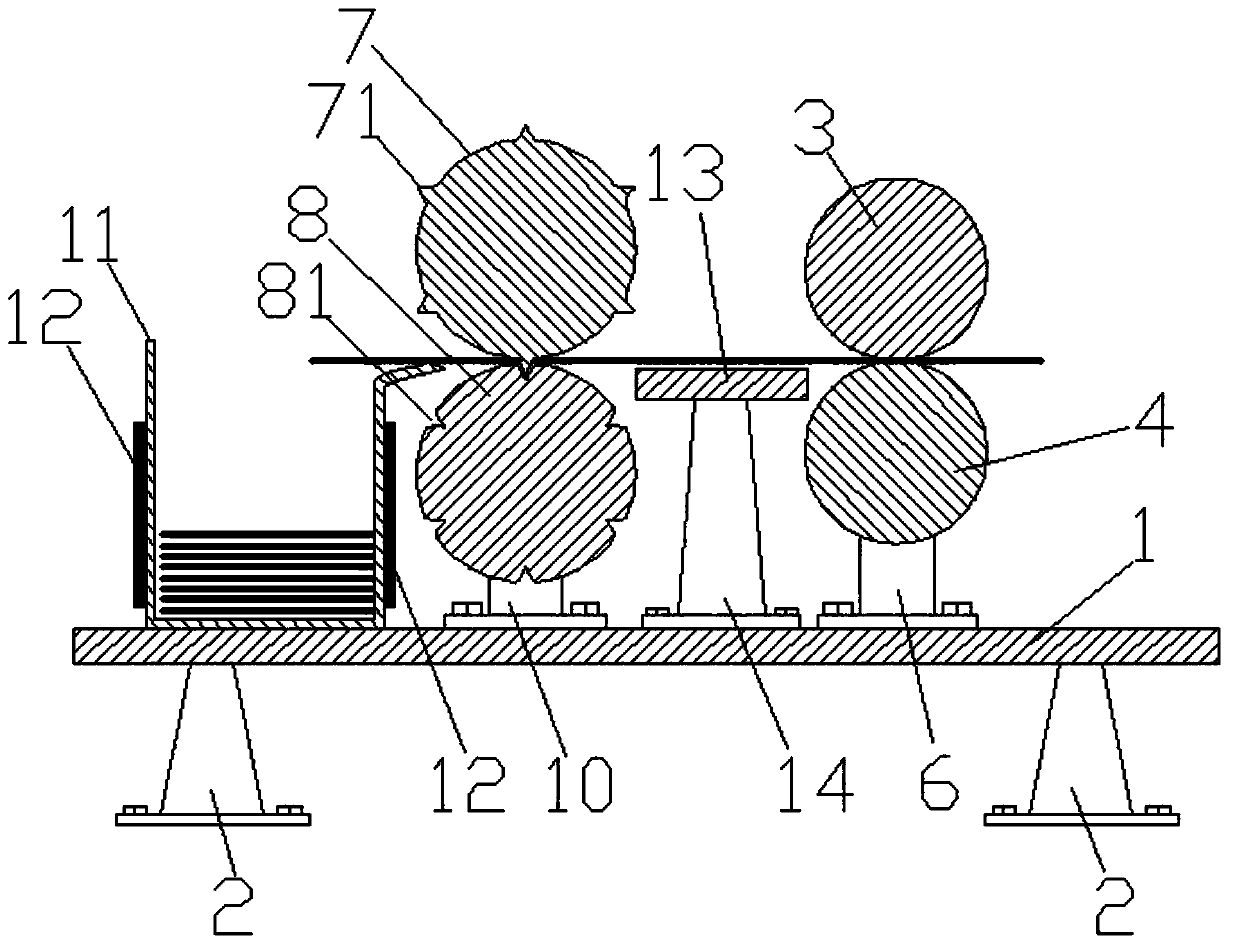

Device and method for continuously preparing nanofiber covering yarn

InactiveCN112251868AEasy to collectEfficient collectionFilament/thread formingYarnElectrospinningYarn

The invention relates to a device and a method for continuously preparing nanofiber covering yarn. The device comprises a frame, and a high-voltage alternating electric field spinning system and a covering yarn forming system which are mounted on the frame, wherein the high-voltage alternating electric field spinning system is mounted on the lower portion of the covering yarn forming system; the high-voltage alternating electric field spinning system is used for forming a nanofiber bundle and spraying the nanofiber bundle to core yarn; the covering yarn forming system is used for inputting, twisting and outputting the core yarn; and the high-voltage alternating electric field spinning system and the covering yarn forming system are both connected into a control box. The device and method have the advantages that a high-voltage alternating electric field is adopted, and through the design of a spinning nozzle, nanofiber bundles can be generated, the yield of electrospinning is greatly increased, and collection of nanofiber is facilitated. The covering yarn is formed by collecting the nanofiber bundles through a core yarn balloon wrapping technology, and efficient and orderly collection of the nanofiber is facilitated.

Owner:IANGSU COLLEGE OF ENG & TECH

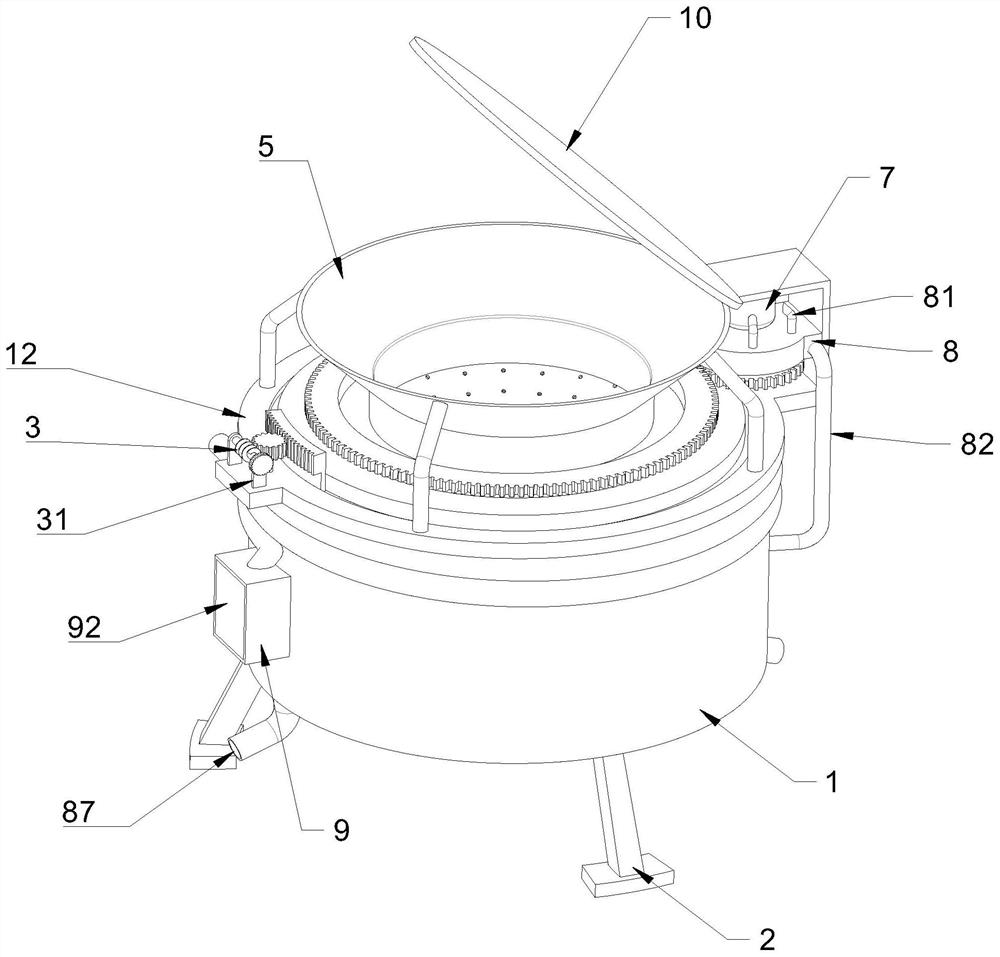

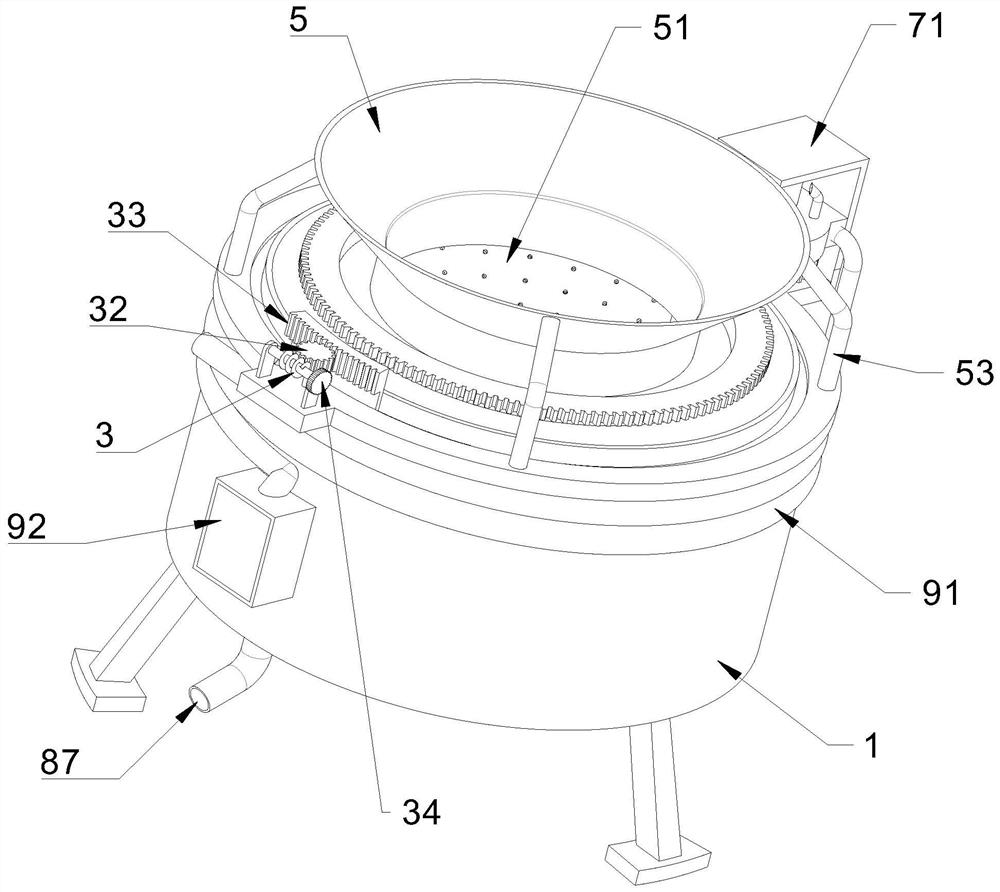

Rapeseed drying equipment

PendingCN114136064ARealize the filtration and screening requirements of particle sizeRealize filtering and sieving needsSievingScreeningEngineeringRapeseed

The invention relates to the technical field of rapeseed processing, in particular to rapeseed drying equipment which comprises a drying box body, an outer cylinder, an inner cylinder and supporting legs, the supporting legs are fixedly installed on the outer wall of the bottom of the drying box body, an adjusting mechanism is arranged at the top of the outer cylinder, and a stirring component is arranged on the inner wall of the inner cylinder. A driving part is arranged at the top of one side of the drying box body, and a drying mechanism is arranged in the space between the inner wall of the drying box body and the outer wall of the outer cylinder. Finally, through meshing of the gear and the arc-shaped toothed plate, the size of the overlapped filtering holes of the first sieve holes and the second sieve holes is driven to be adjusted, the filtering and screening requirements for different rapeseed particle sizes can be met, the applicability is improved, the arc-shaped toothed plate can be locked through the worm, the situation that the size of the overlapped filtering holes of the first sieve holes and the second sieve holes is changed is avoided, and the practicability is high. And the filtering and screening process can be continuously carried out, and the device runs stably and reliably.

Owner:九江市彭泽县宏兴油脂有限公司

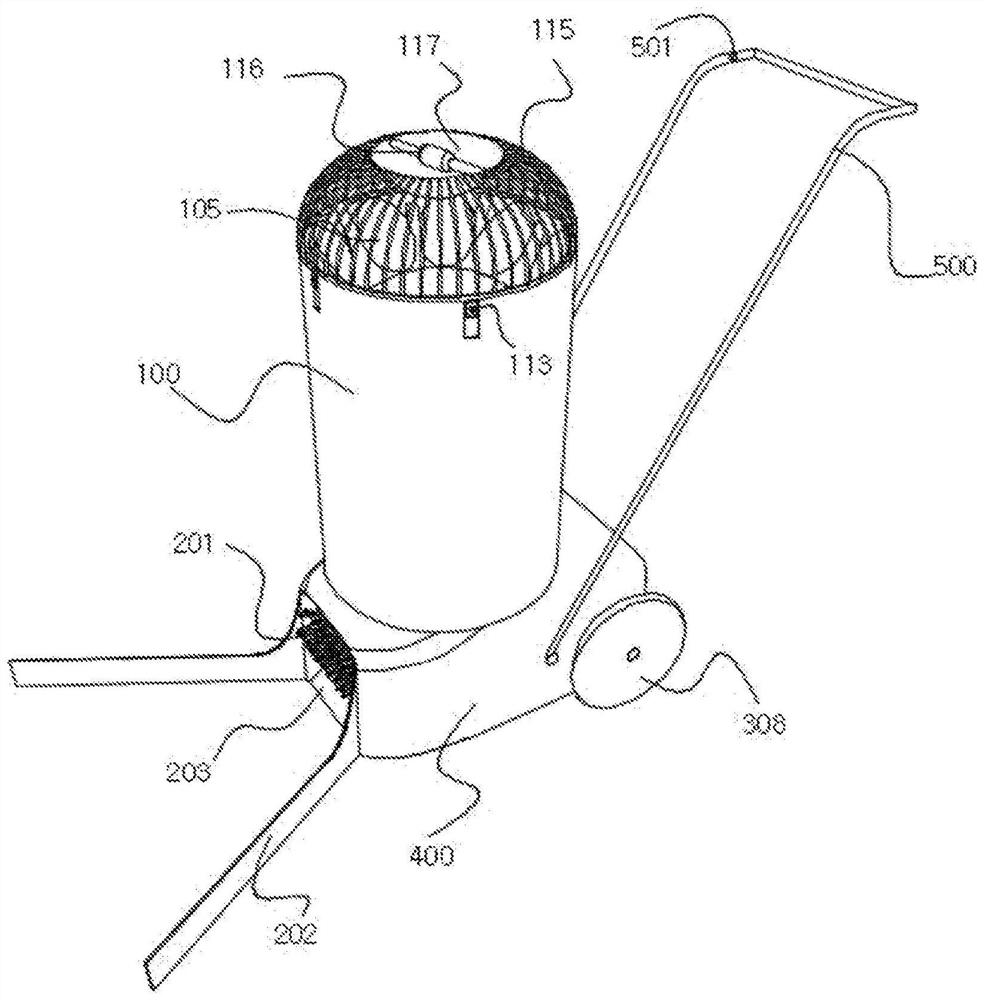

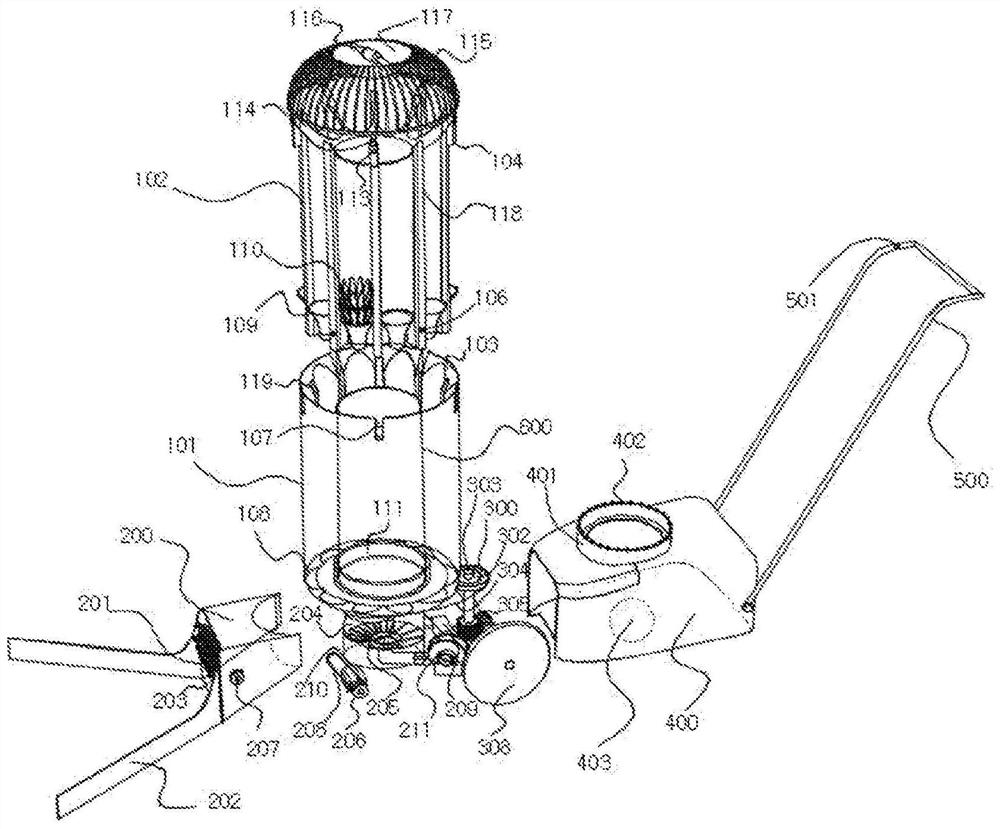

Novel metabolic cage for livestock animals and using method thereof

The invention relates to the field of metabolic cages, in particular to a novel metabolic cage for livestock animals and a using method thereof. The cage comprises a front section support portion, a middle section collection portion, limit devices, a partial urine collection device, a rear section collection portion, a urine and feces separation device and a feces storage device, the front sectionsupport portion is connected with the middle section collection portion, the limit devices are disposed on the front section support portion and the middle section collection portion, the middle section collection portion is provided with the urine collection device, the rear portion of the middle section collection portion is provided with the rear section collection portion, the rear section collection portion is arranged corresponding to the urine and feces separation device, and the feces storage device is arranged on one side of the outlet of the urine and feces separation device; the cage has reasonable structure and saves manpower, the using method is simple, and the feces collection process is convenient and orderly. The cage can be applied not only to the feces collection of a bull, but also to the feces collection of a cow, the separate collection of the feces and urine of the cow does not have a mutual affecting situation, and the feces and urine of the bull can also be separated.

Owner:内蒙古犇粤生态养殖有限公司

Equipment for steel bar straightening, notch flat-grinding and collecting after cutting-off

InactiveCN112024770AOrderly collectionIncrease the welding areaEdge grinding machinesOther manufacturing equipments/toolsPlanishingRebar

The invention discloses equipment for steel bar straightening, and notch flat-grinding and collecting after cutting-off. The equipment comprises a placement block, wherein a placement cavity with a leftward opening is formed in the placement block, a straightening mechanism is arranged in the placement cavity, the straightening mechanism comprises a length baffle fixedly connected with the inner wall of the upper side of the placement cavity, a cutting-off induction block which is fixedly connected is arranged on the lower side of the length baffle, the shearing-off hydraulic block which is fixedly connected is arranged on the left end surface of the length baffle, and the cutting-off induction block can be turned on through the length baffle. According to the equipment, steel bars with different diameters can be straightened, the straightened steel bars can be cut on the basis of the same length, the cut steel bars are fixed through magnets, notches in the two sides are ground to be flat, it is guaranteed that the welding area for welding for the following use is maximum, the problem that the steel bars are broken after welding is solved, and the steel bars with the flat-ground notches are collected in order.

Owner:福州晋安丁舒基电子科技有限公司

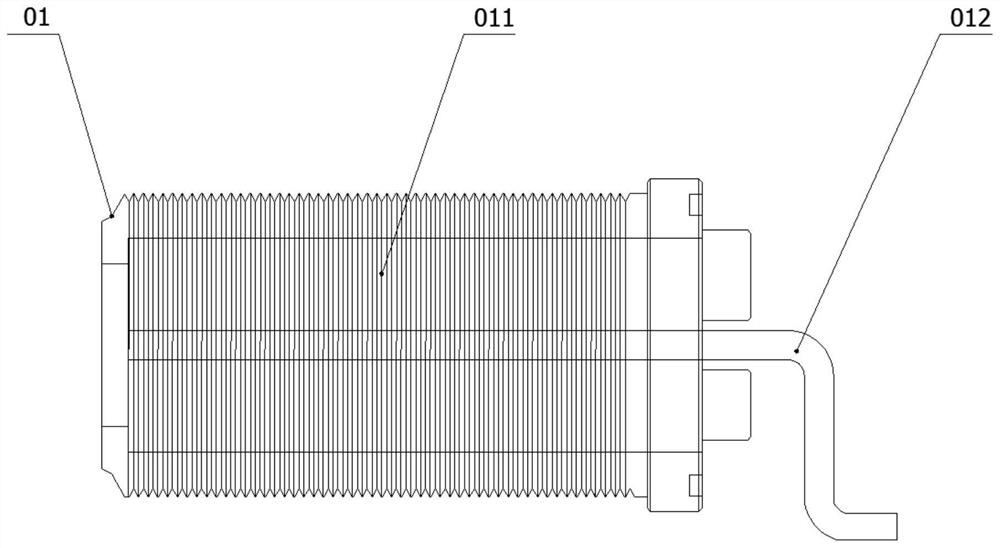

Collecting device for capacitor product

The invention discloses a collecting device for a capacitor product. The device comprises a tray, a baffle plate, an alarming device and a PLC, wherein the tray is of a box structure of which the sideedge is opened; the tray is encircled by sidewalls and a bottom plate, and the bottom plate can be movably arranged relative to the sidewalls; the sidewalls are provided with grooves in the length direction; the baffle plate is arranged in the tray and is in fitting connection with the grooves; the alarming device is fixedly arranged on the sidewall; the bottom plate and the alarming device are electrically connected to the PLC. According to the collecting device for the capacitor product, the alarming device is arranged in the tray; when the tray is full of capacitors, an operator is reminded to collect, and thus the capacitors are effectively prevented from extrusion.

Owner:NANTONG HICON ELECTRONICS

Self-sealing fluid collector

InactiveCN111879571ASuccessful connectionConnected orderlyWithdrawing sample devicesEngineeringPhysics

The invention provides a self-sealing fluid collector. The self-sealing fluid collector comprises an outer barrel and a core body, the top of the outer barrel is opened for integrally inserting the core body, and an air inlet for fluid to flow in is formed in the bottom end; the core body can be installed in the outer barrel in a pluggable mode and freely rotates with the central axis of the outerbarrel as a rotating shaft, and an air inlet nozzle is installed in the air inlet pipeline in an axial sliding mode, always stretches into the inner bottom of the outer barrel under the action of elastic force and makes extrusion contact with the bottom end of the core body. An air inlet nozzle is inserted into the lower section of a middle hole in an embedded plug in an air inlet in the bottom of the air storage bin, and a sealing plug matched with the conical hole in a bell-and-spigot joint mode is hung above the conical hole and arranged on a guide rod hung in the air inlet pipe in a sleeving and sliding fit mode. The reset spring enables the sealing plug to block the conical hole in the state that the sealing plug is not connected with the air inlet nozzle, and when the air inlet nozzle is connectd, flowing-in fluid is ejected away from the interior of the conical hole. The self-sealing fluid collector is good in maneuverability, high in adaptability and convenient for daily management and use.

Owner:查常财

Lead ball collecting channel

ActiveCN112121378ASimple structureOrderly collectionBall sportsSports equipmentStructural engineering

A shot collecting channel belongs to the field of sports equipment and comprises a bottom box, a transverse roller path is arranged at the upper end of the bottom box, two bilaterally symmetrical retaining plates are arranged in the middle of the transverse roller path, a feeding grooved pulley is arranged at the rear section of the middle of the transverse roller path, and an inclined slideway isarranged at the lower portion of the transverse roller path; and a buffering allocating assembly which absorbs and converts potential energy generated when the shot slides down, and then allocates the shot left and right. Collision in the transfer process after shot production can be prevented, and impurities on the surface of a shot after machining can be removed while the shot is decelerated.

Owner:BINZHOU UNIV

tree trimming device

ActiveCN106538255BSimple structureEasy to useCuttersCutting implementsEngineeringMechanical engineering

The invention discloses a tree trimming device which comprises a rectangular base, wherein a rectangular bearing box is firmly connected to the upper surface of the rectangular base; a rotary trimming mechanism is disposed on the side surface of the rectangular bearing box; a stretchable carrying mechanism is disposed on the lower surface inside the rectangular bearing box; a supporting movable mechanism is disposed on the lower surface of the rectangular base; a scanning cutting mechanism is disposed on the upper surface of the rectangular bearing box; an edge cleaning mechanism is disposed on the front surface of the rectangular bearing box; a storage battery is disposed on the upper surface inside the rectangular bearing box; a controller is disposed on the side surface of the rectangular bearing box; and an input end of the controller is electrically connected to the storage battery via a wire. The device disclosed by the invention has the beneficial effects of a simple structure and high practicability.

Owner:常州泓麟智能科技有限公司

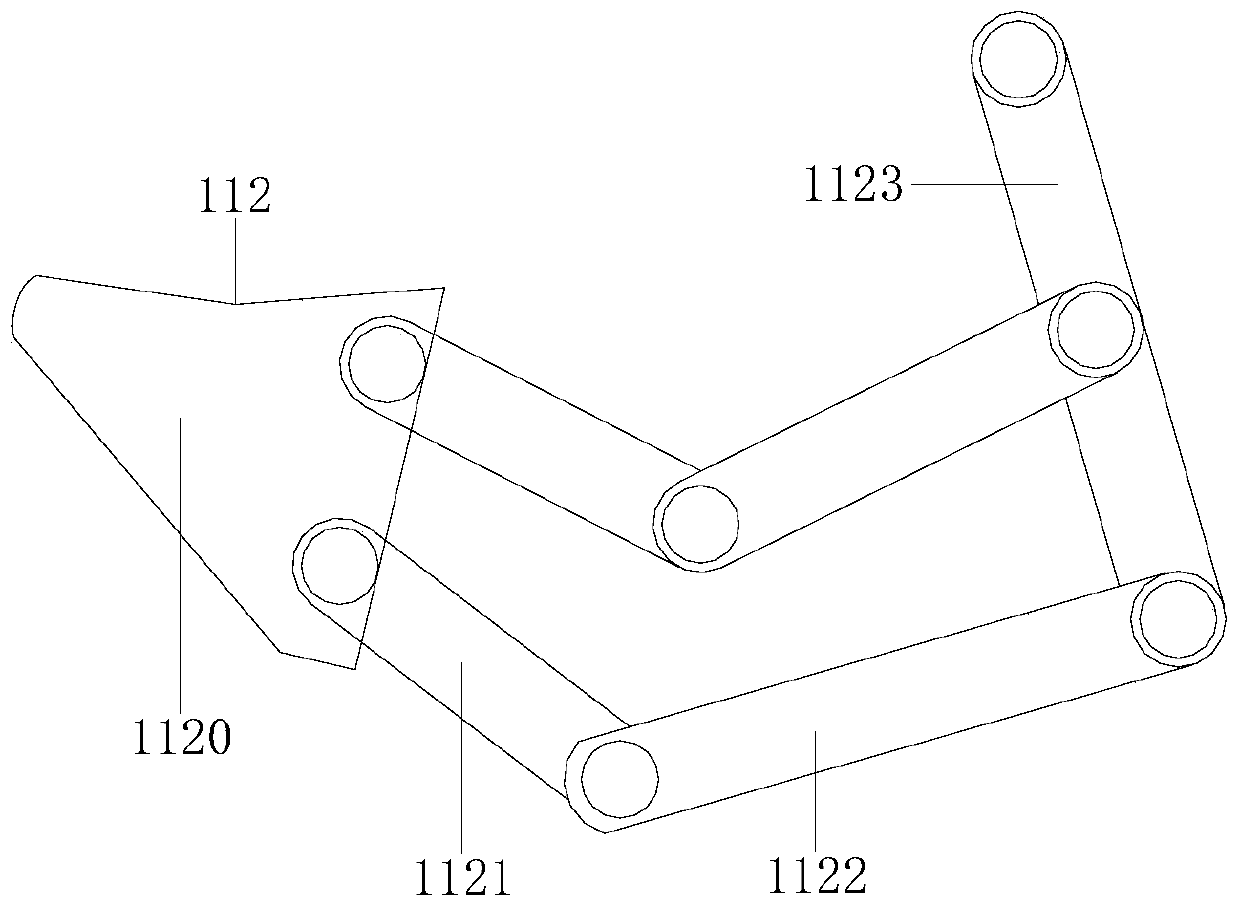

Automatic watermelon picking device capable of conducting judgment, classification and arrangement during transferring

The invention discloses an automatic watermelon picking device capable of conducting judgment, classification and arrangement during transferring. A structure of the automatic watermelon picking device capable of conducting judgment, classification and arrangement during transferring comprises picking clamping arms, a centrally-arranged motor, a shaft disk and a cord cover machine, wherein the picking clamping arms and the centrally-arranged motor are connected, the centrally-arranged motor and the cord cover machine are in shaft connection through the shaft disk, and the picking clamping armsare composed of clamping finger boards, middle clamping boards and installation arm boards. According to the automatic watermelon picking device capable of conducting judgment, classification and arrangement during transferring, the cord cover machine moves on a rail rope, and rotates in cooperation with the shaft disk to drive the picking clamping arms to rotate, the picking clamping arms clampwatermelons and transfer the watermelons, inner arm boards have inner end support effects, while inner telescoping rods conduct slight knocking, sounds are made so that whether or not the watermelonsare mature can be judged, inner middle boards have main bearing effects, and scanning inner finger boards can conduct large-amplitude overturning to tightly clamp tail ends so that the watermelons canbe covered and transferred, and also conduct scanning so that whether or not the watermelons are mature can be judged by observing surface layers; and when the cord cover machine moves, through transmission of a lock, the watermelons are orderly collected and classified according to the qualities, so that subsequent receiving, packaging and selling are facilitated.

Owner:天辰兰德(山东)科技服务有限公司

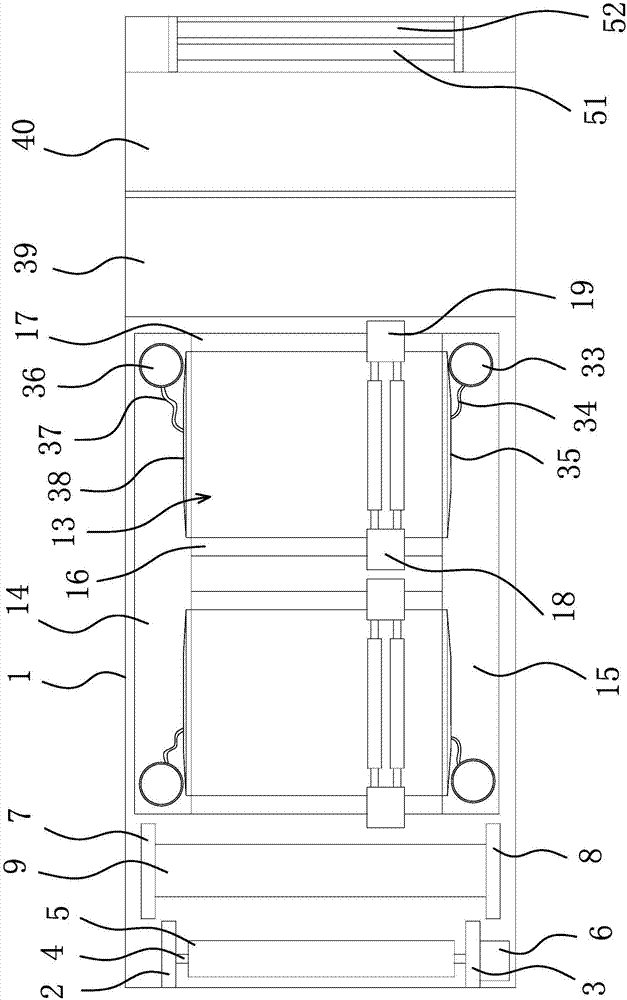

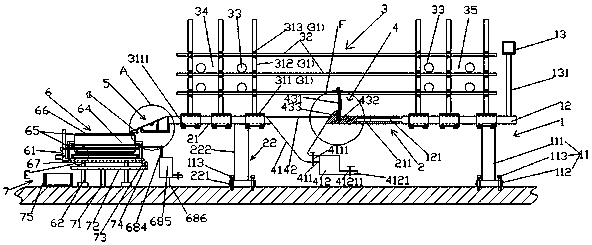

Improved fabric printing production line

InactiveCN107139580AGuaranteed flatnessConveying orderlyTransfer printingPrinting press partsProduction lineDrive motor

The invention provides a fabric printing production line, and belongs to the technical field of machines. The fabric printing production line comprises a rack, a fabric unreeling device for releasing fabric is arranged at one end of the rack, and comprises a first mounting plate and a second mounting plate which are fixed to the rack, an unreeling shaft is arranged between the first mounting plate and the second mounting plate, one end of the unreeling shaft penetrates the first mounting plate, an unreeling roller cylinder is detachably fixed to the unreeling shaft, and a drive motor used for driving the unreeling shaft to rotate is further fixed to the rack; the production line is characterized in that a conveying mechanism for traction conveying of fabric, multiple printing devices for different-dye printing on fabric, a drying device for drying the printed fabric and a neatening device for neatening the dried fabric are arranged on the rack in sequence. The production line has the beneficial effect that the fabric can be subject to assembly printing, and meanwhile, automatic dye supply and recycling is achieved.

Owner:ZHEJIANG XIANYU FIBER WEAVING & DYEING GARMENT CO LTD

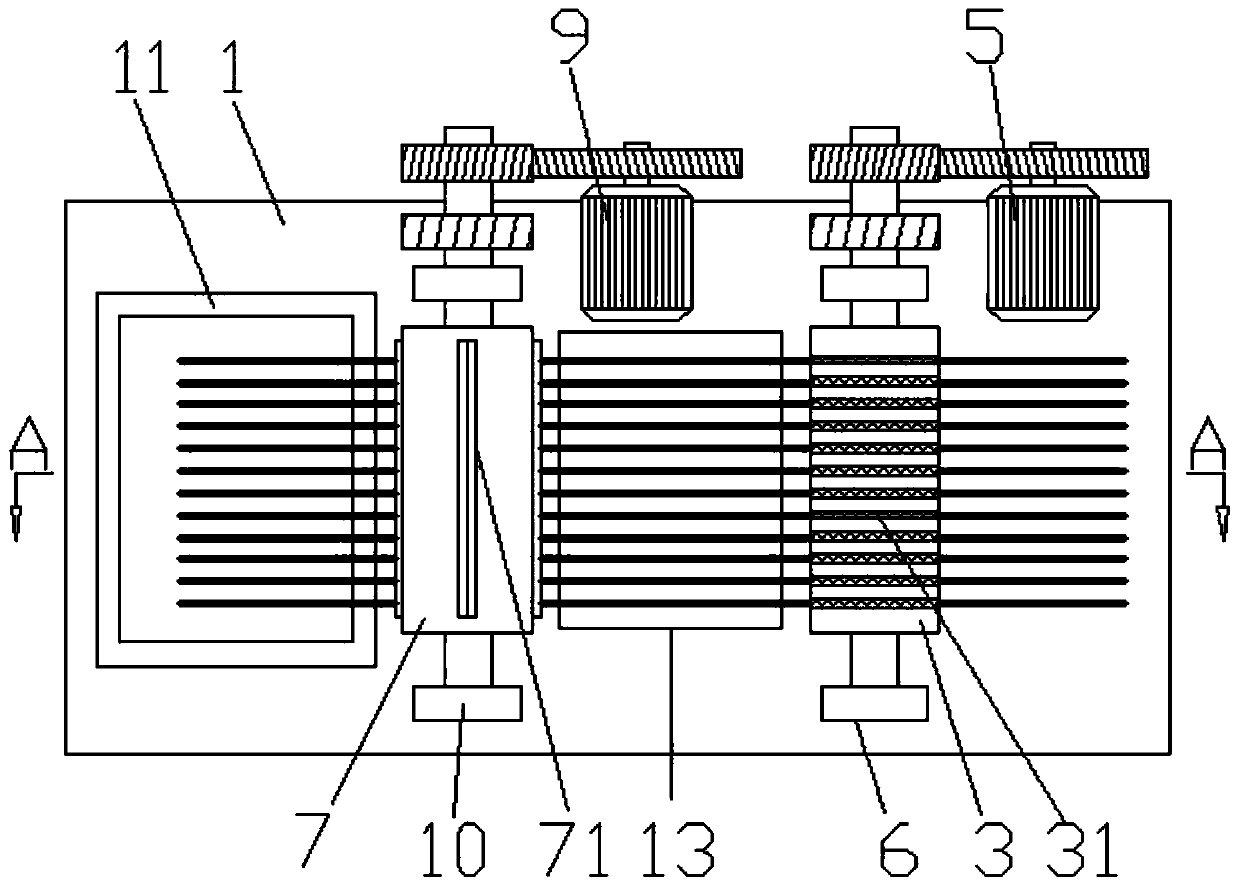

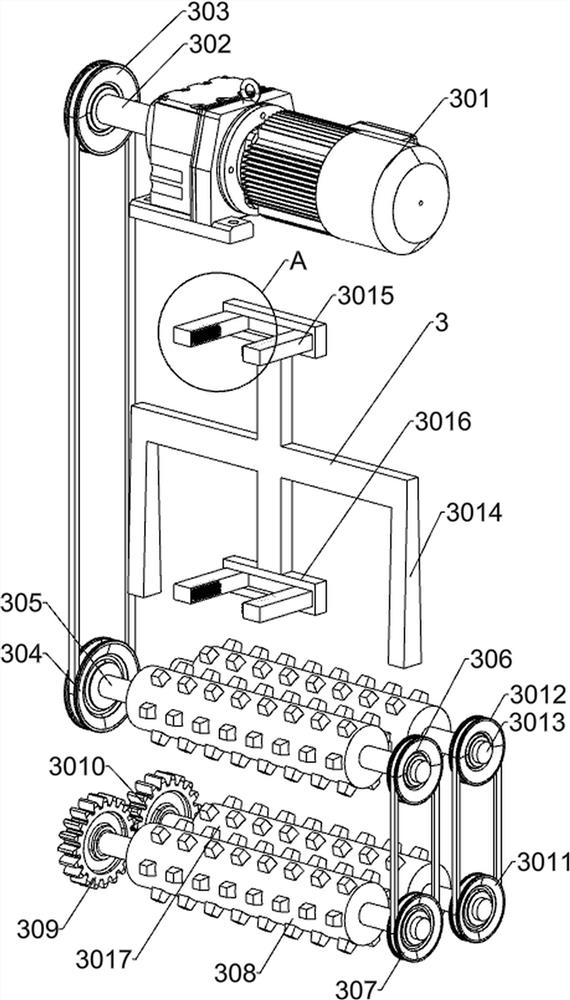

Novel high-efficiency steel wire brush hair shearing equipment

The invention discloses novel high-efficiency steel wire brush hair shearing equipment, and belongs to the field of hairbrush production equipment. The shearing equipment comprises a bottom plate, a conveying mechanism, a shearing mechanism and a storage bin. The conveying mechanism comprises an upper pressing roller, a lower pressing roller and a conveying motor. The upper pressing roller and thelower pressing roller are linked through a synchronous gear or a synchronous belt; a plurality of circumferential protrusions which are evenly distributed in the axial direction are arranged on the upper pressing roller; circumferential grooves are correspondingly formed in the lower pressing roller; antiskid lines are arranged on the surfaces of the circumferential protrusions and the surfaces of the circumferential grooves; and the shearing mechanism comprises a cutter roller, a grooving roller and a shearing motor, wherein the cutter roller and the grooving roller are linked through a synchronous gear or a synchronous belt; a plurality of axial cutters which are uniformly distributed in the circumferential direction are arranged on the cutter roller, and axial grooves are correspondingly formed in the grooving roller; and the storage bin is connected to the rear end of the shearing mechanism. The shearing equipment is simple in structure and reasonable in design, not only can effectively prevent steel wires from slipping, but also can improve the steel wire shearing efficiency.

Owner:安徽杉森刷业有限公司

Pre-folded spina gleditsiae taking device

ActiveCN112657628AEasy to recycleBroken and orderlyPharmaceutical product form changeGrain treatmentsEmergency medicineMechanical engineering

The invention relates to the field of traditional Chinese medicine, in particular to a pre-folded spina gleditsiae taking device. The technical problem is to provide the pre-folded spina gleditsiae taking device. According to the technical scheme, the pre-folded spina gleditsiae taking device comprises a bottom frame, a spina gleditsiae taking unit, a crushing unit, a collecting unit, a control screen and a collecting box, wherein the bottom frame is connected with the spina gleditsiae taking unit; the bottom frame is connected with the crushing unit; the bottom frame is connected with the collecting unit; the bottom frame is connected with the control screen; the bottom frame is connected with the collecting box; and the spina gleditsiae taking unit is connected with the crushing unit. According to the device, main spina and small spina of spina gleditsiae branches and trunks are separated, manual treatment is replaced, the efficiency is improved, and the situation that spina splashes and injure workers in the cutting process is avoided.

Owner:ANHUI JIULI MACHINERY EQUIP

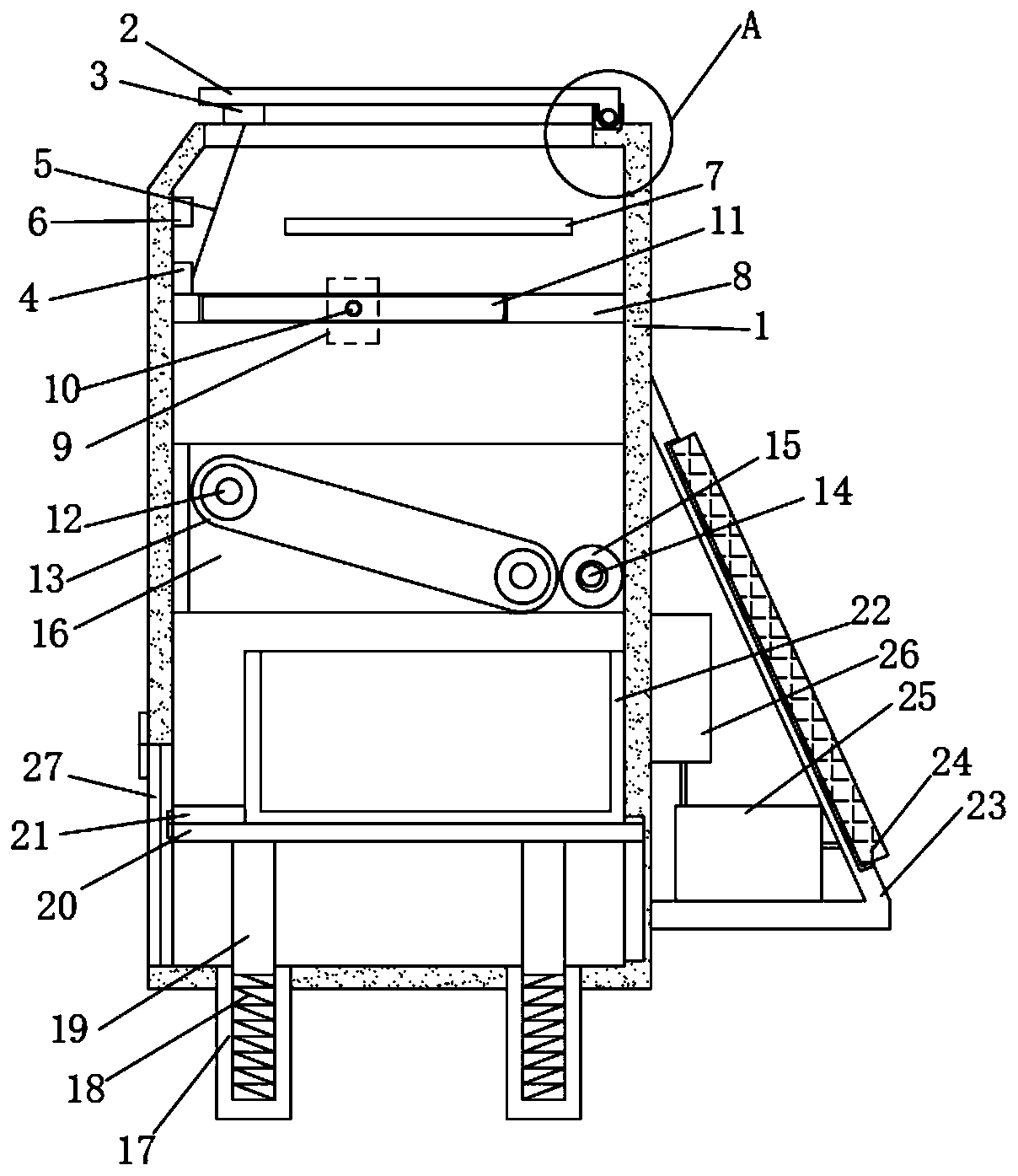

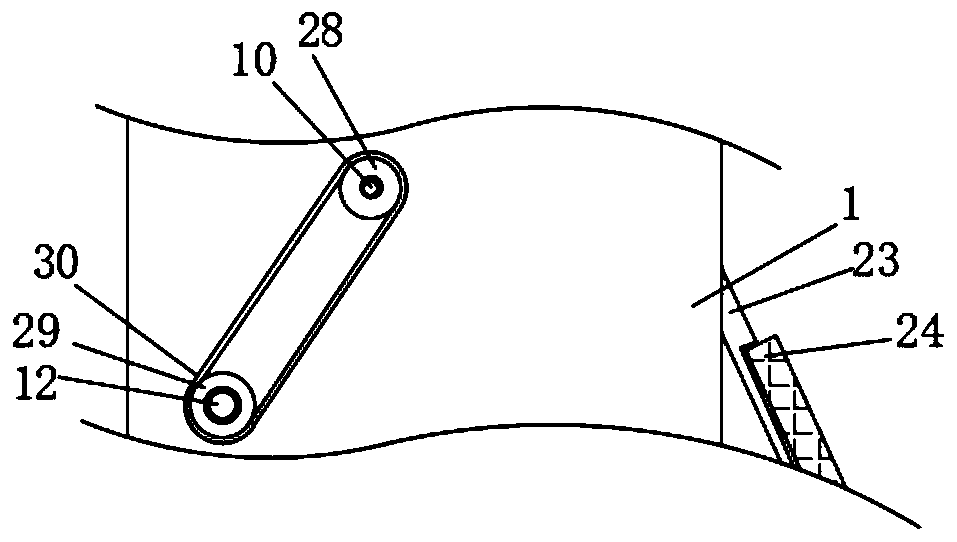

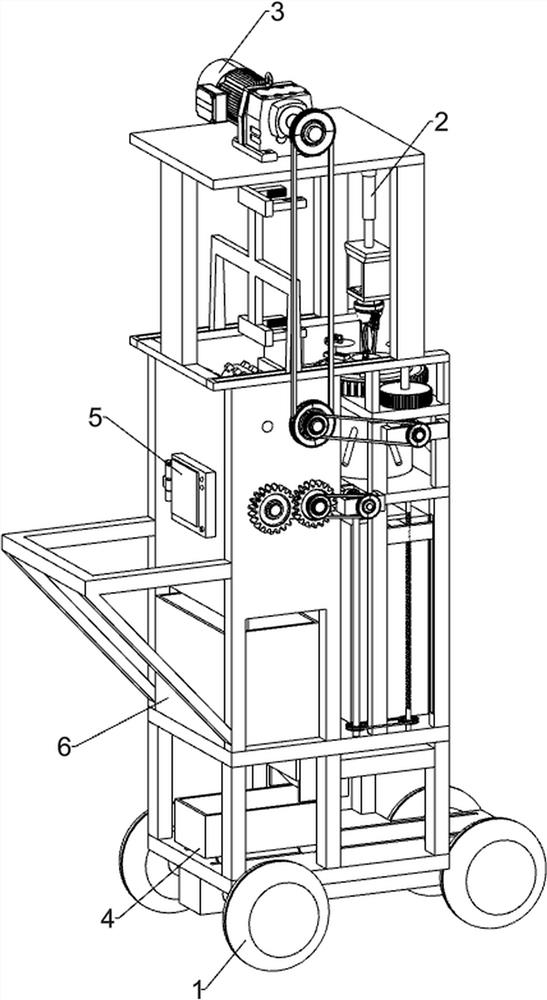

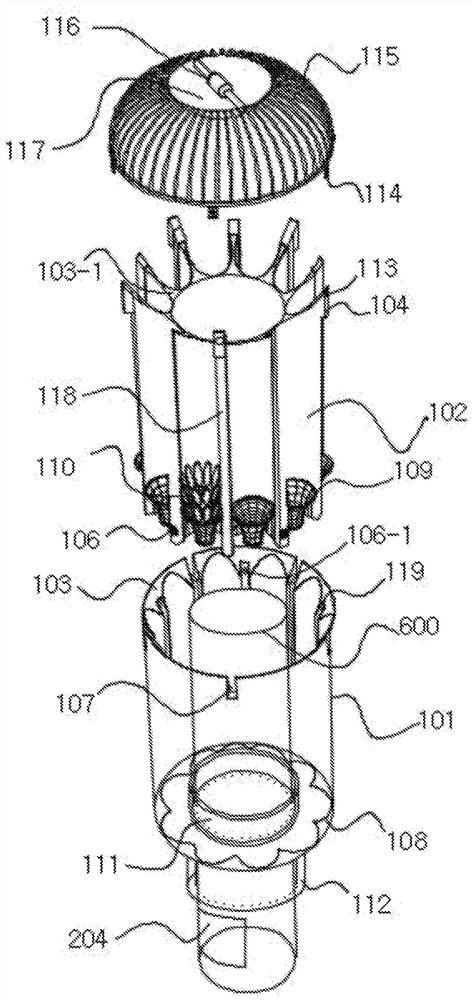

Automatic badminton collecting device

ActiveCN112044035AOrderly collectionThe badminton can be concentrated and orderly in the collection departmentBall sportsRacket sportsStructural engineeringMechanical engineering

Owner:OK ALLCO LTD

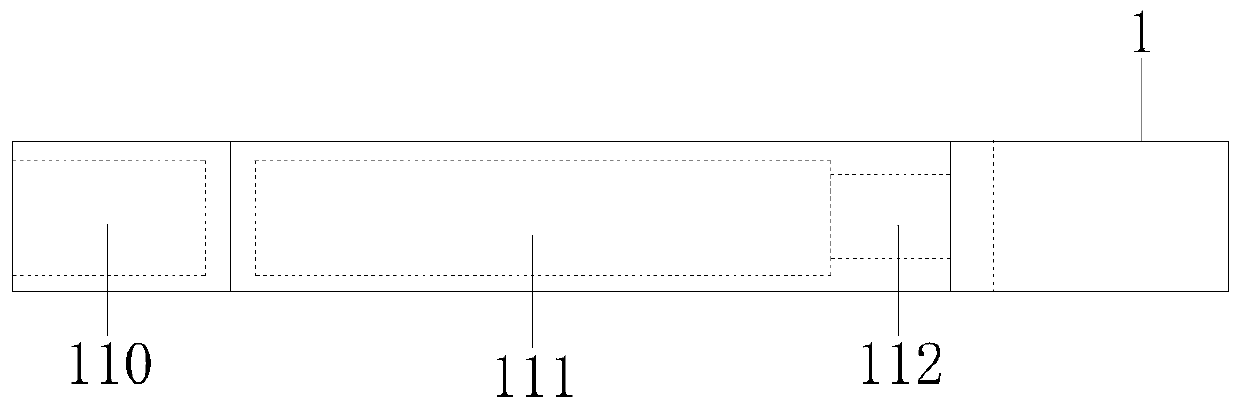

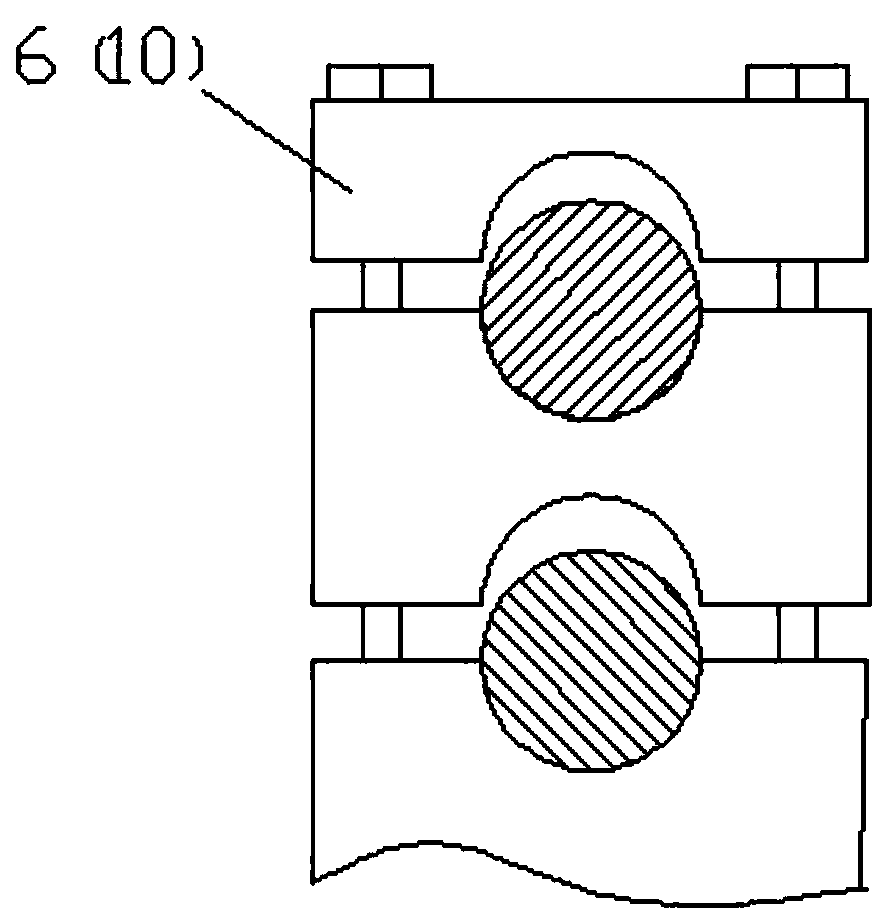

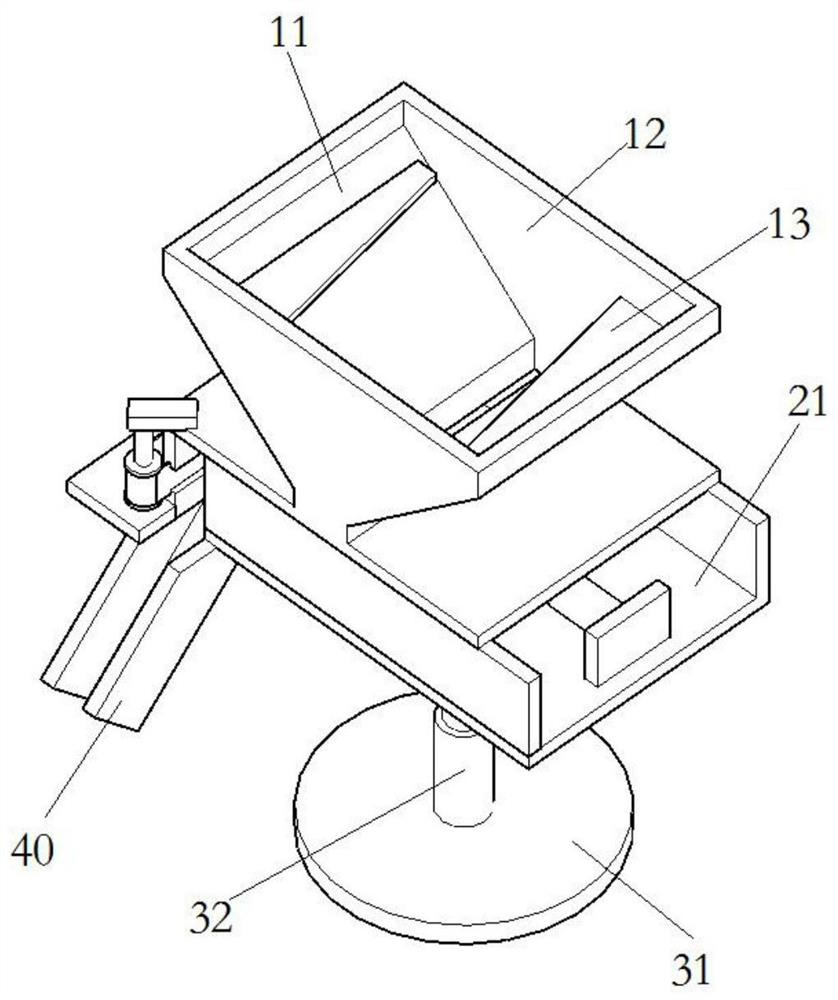

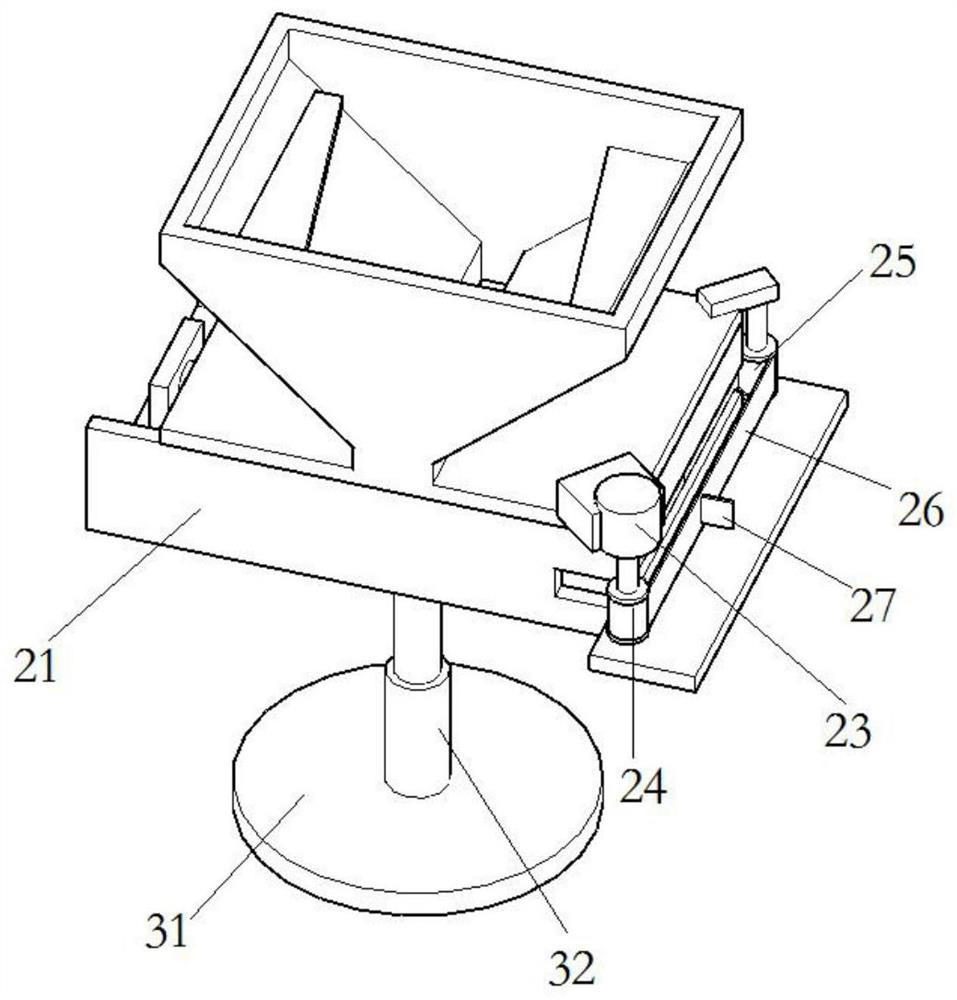

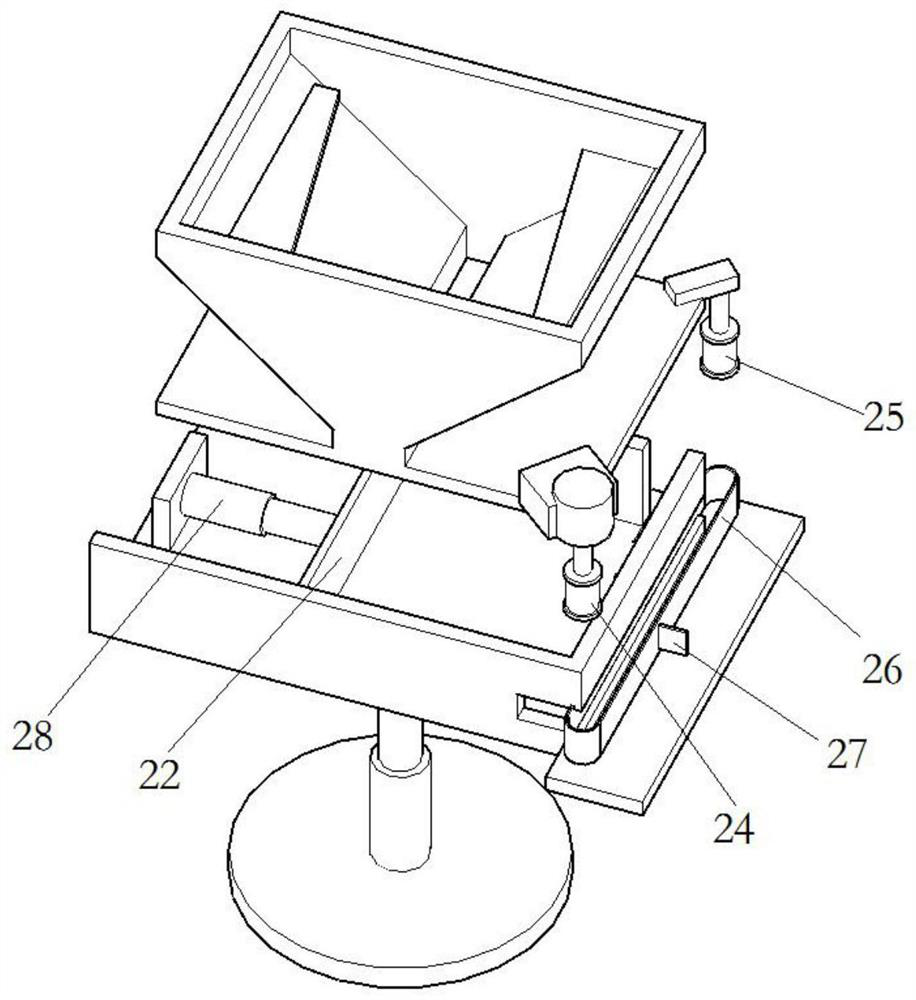

Automatic material collecting device for punch press production line

ActiveCN112338085AOrderly collectionAvoid bending overMetal-working feeding devicesPositioning devicesProduction linePunch press

The invention relates to the field of punch press equipment, in particular to an automatic material collecting device for a punch press production line. The automatic material collecting device comprises a material falling assembly and a correcting and pushing assembly, the material falling assembly comprises a material falling port, the material falling port comprises two symmetrically arranged inclined plates and two oppositely arranged side plates, and the lower parts of the inclined plates are drawn close to each other to form a strip-shaped channel; the correcting and pushing assembly comprises a bearing body, a parallel pushing plate and a discharging driving mechanism, the bearing body is arranged below the strip-shaped channel, and the parallel pushing plate is arranged in the bearing body, is parallel to the strip-shaped channel and is used for pushing materials to be close to the edge of the bearing body; and the discharging driving mechanism is used for pushing the materialspushed to the edge of the bearing body by the parallel pushing plate, a discharging opening is formed in the side edge of the bearing body and used for discharging the materials, the situation that workers need to stoop down for a long time when picking up the scattered materials on the ground is avoided, and the materials can be collected in order.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

Straw equal-length cutting device capable of removing scattered branches and broken segments

InactiveCN113021442AOrderly collectionImprove efficiencyMetal working apparatusPulp and paper industryMechanical engineering

The invention relates to the field of artware production, in particular to a straw equal-length cutting device capable of removing scattered branches and broken segments. The straw equal-length cutting device capable of removing the scattered branches and the broken segments is provided. According to the technical solution, the straw equal-length cutting device capable of removing the scattered branches and the broken segments comprises a connecting frame, a connecting bottom plate, a control screen, a transmission feeding system, a cutting-off and separating system and a reversing system, wherein the cutting-off and separating system is connected to the connecting frame and the connecting bottom plate, and the reversing system is connected to the transmission feeding system. According to the straw equal-length cutting device, the effects that during cutting, fixed-length cutting can be continuously carried out on straws, the uneven scattered branches and the scattered broken segments in the straws are separated out through rotary separation, the straws with the consistent length is obtained, then the straws which do not need to be separated is sent out in order, and efficiency is improved are achieved.

Owner:李冲

An automatic watermelon picking device for judging and sorting during transfer

Owner:天辰兰德(山东)科技服务有限公司

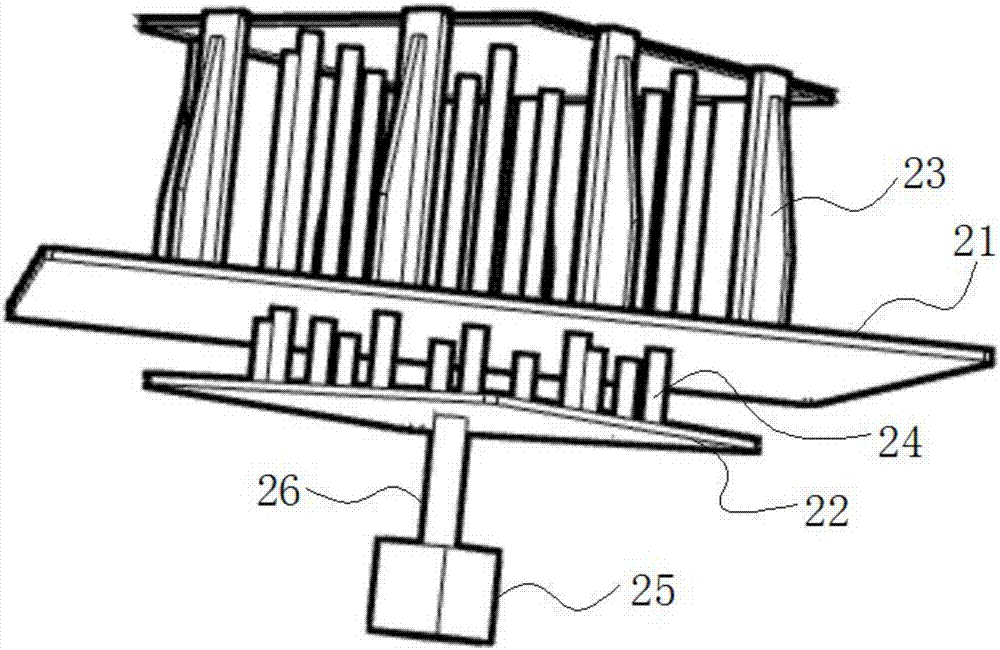

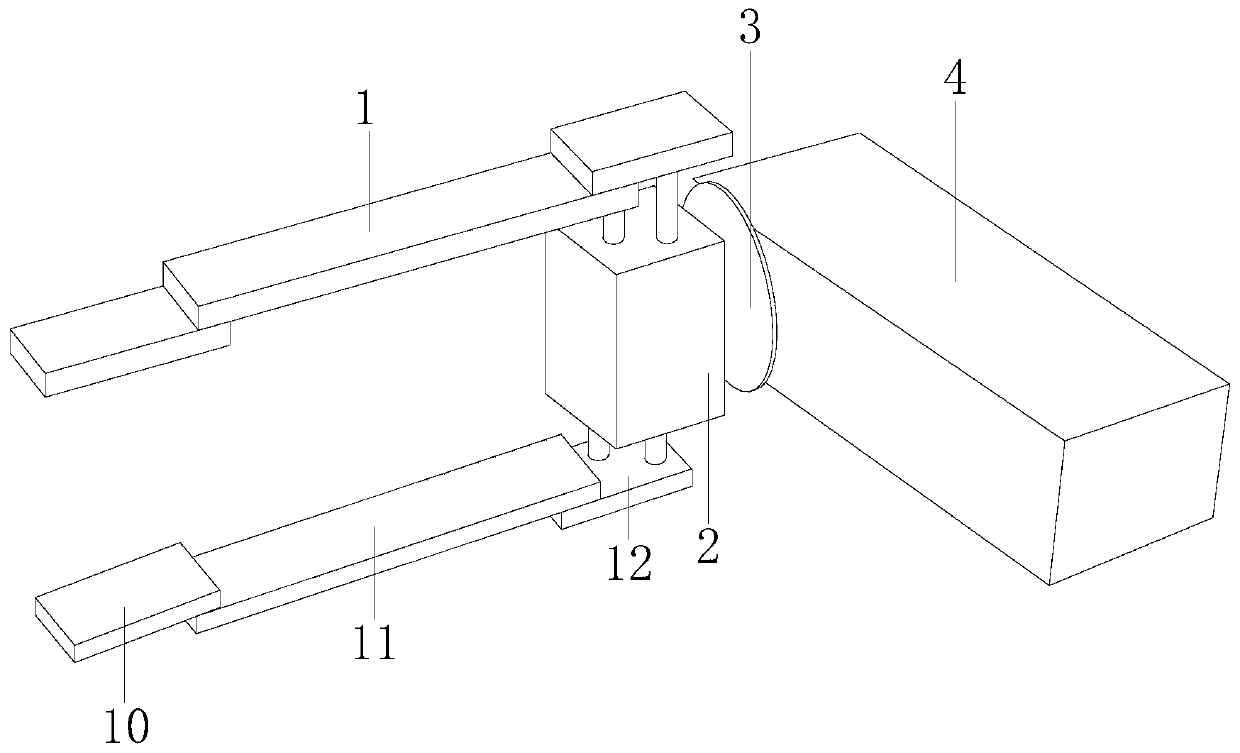

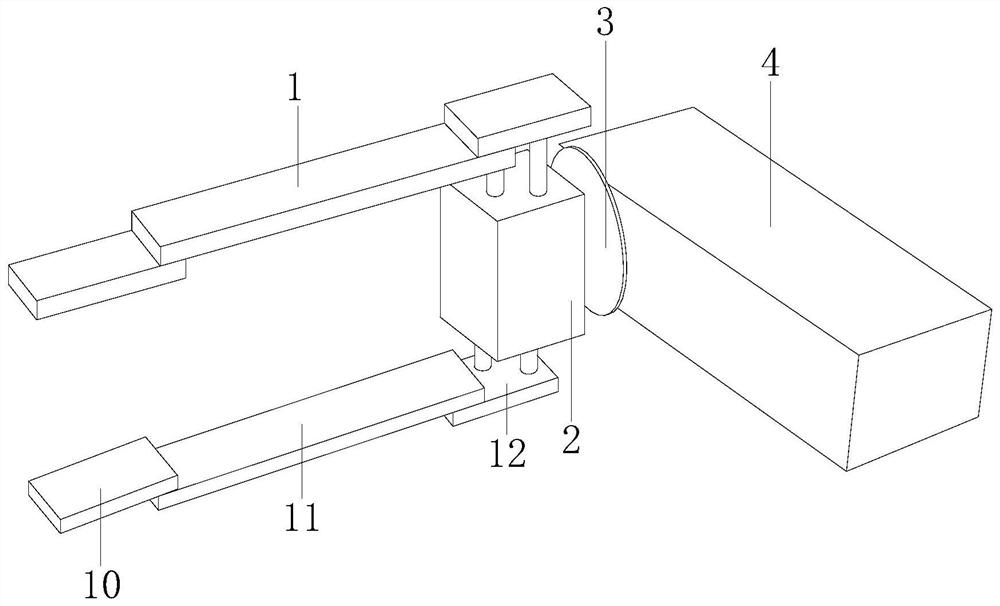

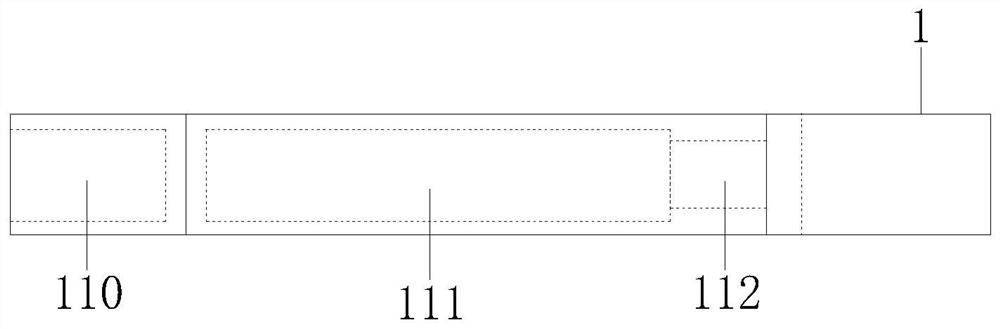

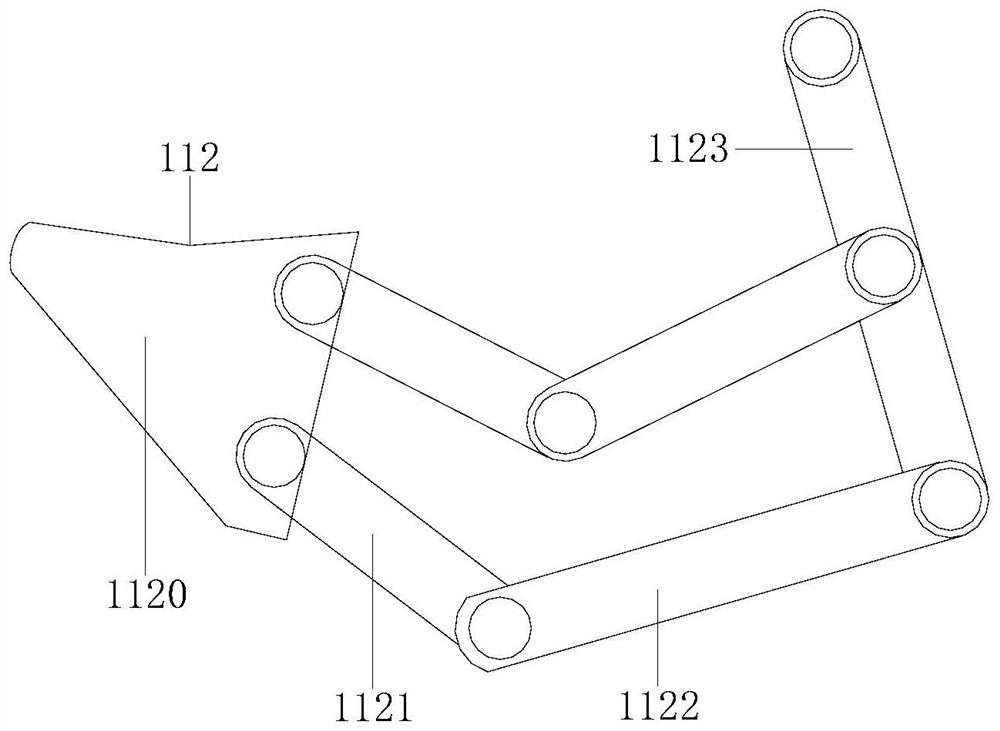

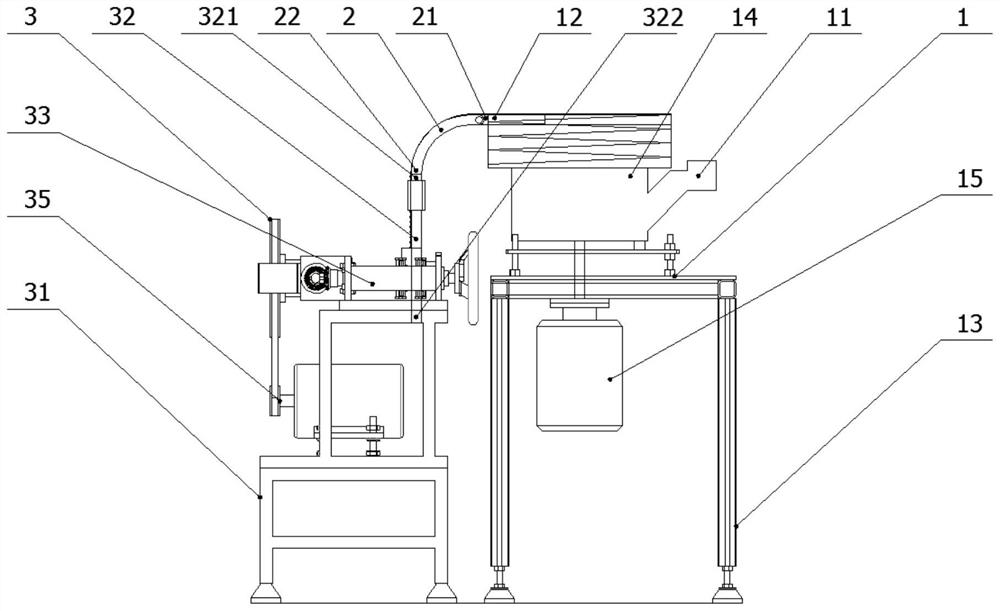

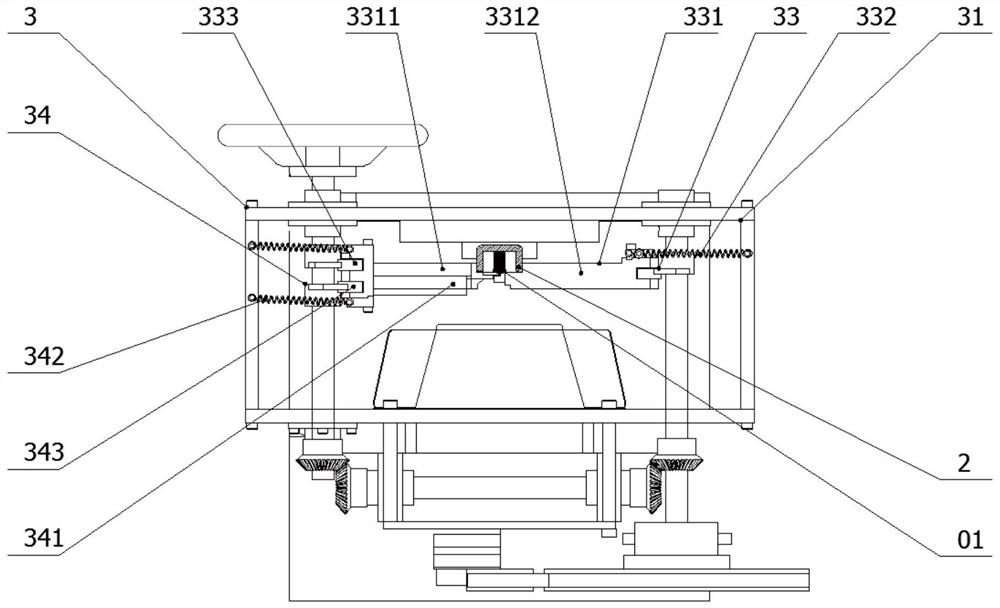

Automatic PIN bending machine and PIN bending method thereof

The invention discloses an automatic PIN bending machine. The automatic PIN bending machine comprises a loading device, a conveying track and a bending and shearing device, wherein the loading deviceorganizes unordered PINs into PINs with the same direction and conveys the PINs to the conveying track; the conveying track is a strip-type track for conveying the PINs; and the bending and shearing device is used for bending PINs to reserved shapes and shearing excess materials, and comprises a bending and shearing frame body, a moving PIN track, a bending mechanism, a shearing mechanism and a driving mechanism. According to the automatic PIN bending machine, the loading device organizes the unordered PINs for automatic loading, the moving PIN track in the bending and shearing device sequentially conveys the received PINs to bending stations, the bending mechanism and the shearing mechanism successively bend and shear the PINs under the driving of the driving mechanism, so that the finalproduct PINs are obtained, the configuration is simple, the production efficiency is high, and the processing cost is economic.

Owner:CHERRY CHIEF PRECISION IND KUNSHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com