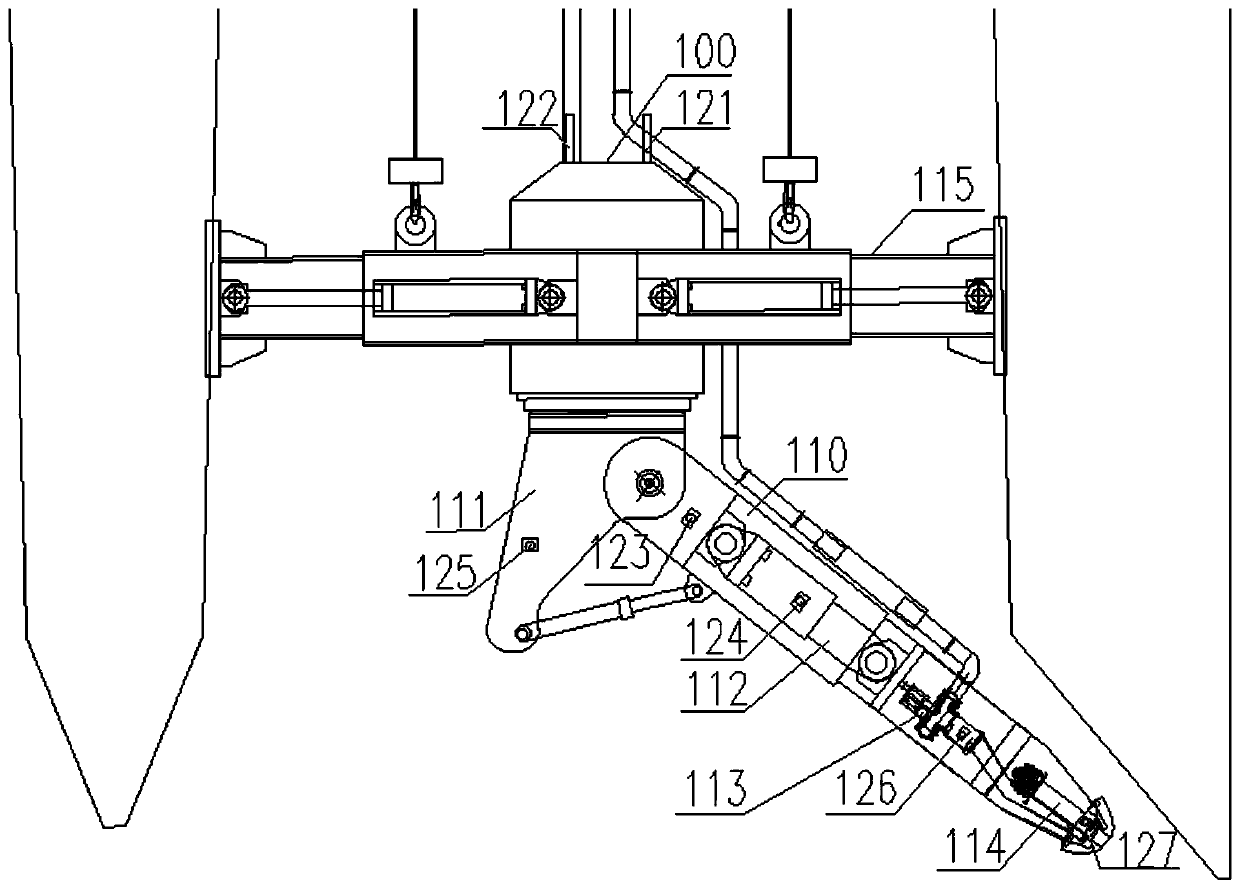

Crushing and slag removing device for hard soil layer at open caisson cutting edge and construction method thereof

A technology for parts and caissons, which is applied in the field of hard soil layer crushing and slag removal devices at the blade foot of caissons, which can solve the problems of potential safety hazards, difficulty in achieving results in hard soil layers, and inability to accurately control the sinking depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The construction method of the hard soil layer crushing and slag cleaning device at the blade foot part of the caisson comprises the following steps:

[0074] Step 1: According to the geological conditions of the construction site, select the corresponding reamer head and install it on the reamer.

[0075] Step 2: Fix the rotary part on the inner support frame, then fix the inner support frame at the construction position in a caisson compartment, position the reamer on the inner wall of the caisson through the inner support frame, and start the construction of a station Excavation work.

[0076] Step 3: After selecting the automatic rock breaking mode on the control interface and pressing the initial coordinate positioning button, select the initial excavation target point, and obtain the three-dimensional coordinate information and deflection angle of the winch in the 3D guidance system through the positioning antenna and the directional antenna respectively informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com