Collecting device for capacitor product

A technology for collecting finished products and capacitors, applied in packaging and other directions, can solve the problems of capacitor collision and extrusion, irregular placement of capacitors, and inability to collect capacitors, and achieve the effect of avoiding extrusion, collision and extrusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

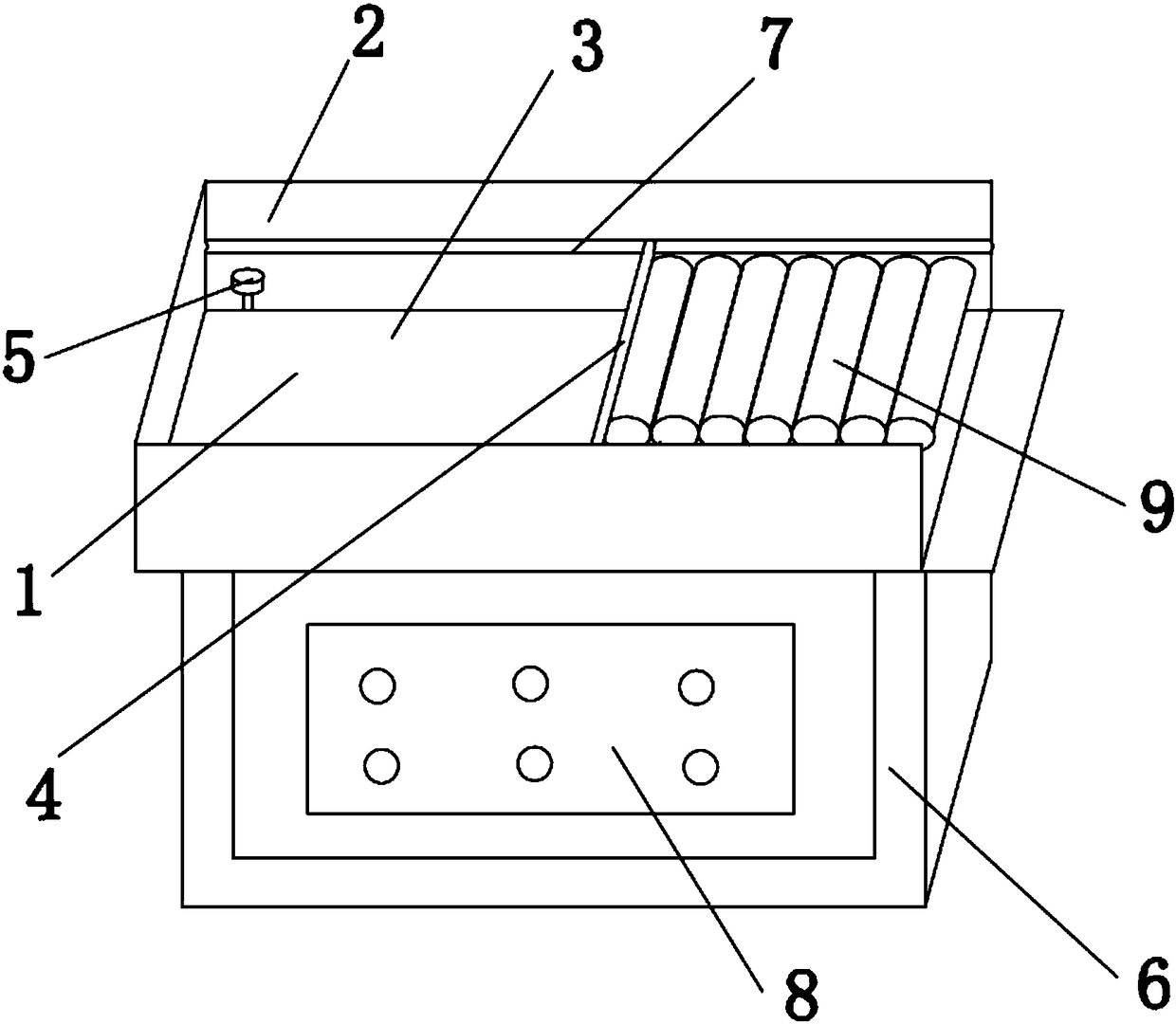

[0030] see Figure 1-2 . As shown in the figure, the present invention discloses a capacitor product collection device, including a tray 1, a baffle 4, an alarm device 5 and a PLC controller 8, the tray 1 is a box structure with side openings, and the tray 1 It is surrounded by a side wall 2 and a bottom plate 3, the bottom plate 3 is movable relative to the side wall 2, the side wall 2 is provided with a groove 7 along its length, and the baffle plate 4 is arranged on the The interior of the tray 1 is matched and connected with the groove 7, the alarm device 5 is fixedly arranged on the side wall 2, and the bottom plate 3 and the alarm device 5 are electrically connected to the PLC controller 8 .

[0031] One short side of the tray 1 is open, and the lower side of the bottom plate 3 is provided with pulleys. The tray 1 is arranged on the supporting device 6 . The supporting device 6 is a hollow structure, and the PLC controller 8 is arranged inside the supporting device 6...

Embodiment 2

[0034] The invention discloses a capacitor finished product collection device, comprising a tray 1, a baffle plate 4, an alarm device 5 and a PLC controller 8, the tray 1 is a box structure with side openings, and the tray 1 is composed of side walls 2 and The bottom plate 3 is surrounded by the bottom plate 3, which is movable relative to the side wall 2. The side wall 2 is provided with a groove 7 along its length direction. The baffle plate 4 is arranged inside the tray 1 and Matched with the groove 7 , the alarm device 5 is fixed on the side wall 2 , and the bottom plate 3 and the alarm device 5 are electrically connected to the PLC controller 8 .

[0035] One short side of the tray 1 is open, and the bottom plate 3 is replaced by a conveyor belt. The tray 1 is arranged on the supporting device 6 . The supporting device 6 is a hollow structure, and the PLC controller 8 is arranged inside the supporting device 6, which effectively saves space. The alarm device 5 is dispos...

Embodiment 3

[0037] The invention discloses a capacitor finished product collection device, comprising a tray 1, a baffle plate 4, an alarm device 5 and a PLC controller 8, the tray 1 is a box structure with side openings, and the tray 1 is composed of side walls 2 and The bottom plate 3 is surrounded by the bottom plate 3, which is movable relative to the side wall 2. The side wall 2 is provided with a groove 7 along its length direction. The baffle plate 4 is arranged inside the tray 1 and Matched with the groove 7 , the alarm device 5 is fixed on the side wall 2 , and the bottom plate 3 and the alarm device 5 are electrically connected to the PLC controller 8 .

[0038] One short side of the tray 1 is open, and the lower side of the bottom plate 3 is provided with pulleys. The tray 1 is arranged on the supporting device 6 . The alarm device 5 is disposed away from the open end of the tray 1 . Grooves 7 are provided on two opposite side walls 2 of the tray 1 .

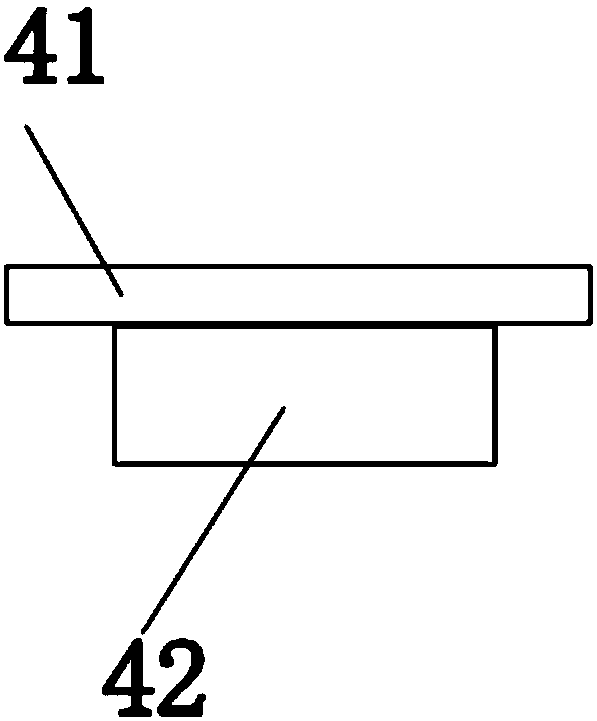

[0039] The baffle plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com