Automatic assembly production line for panel lights

An automatic assembly and production line technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of easy fatigue of assembly workers, reduced assembly efficiency, low assembly efficiency, etc., to improve the degree of automation and assembly accuracy, tear film The effect of high efficiency and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

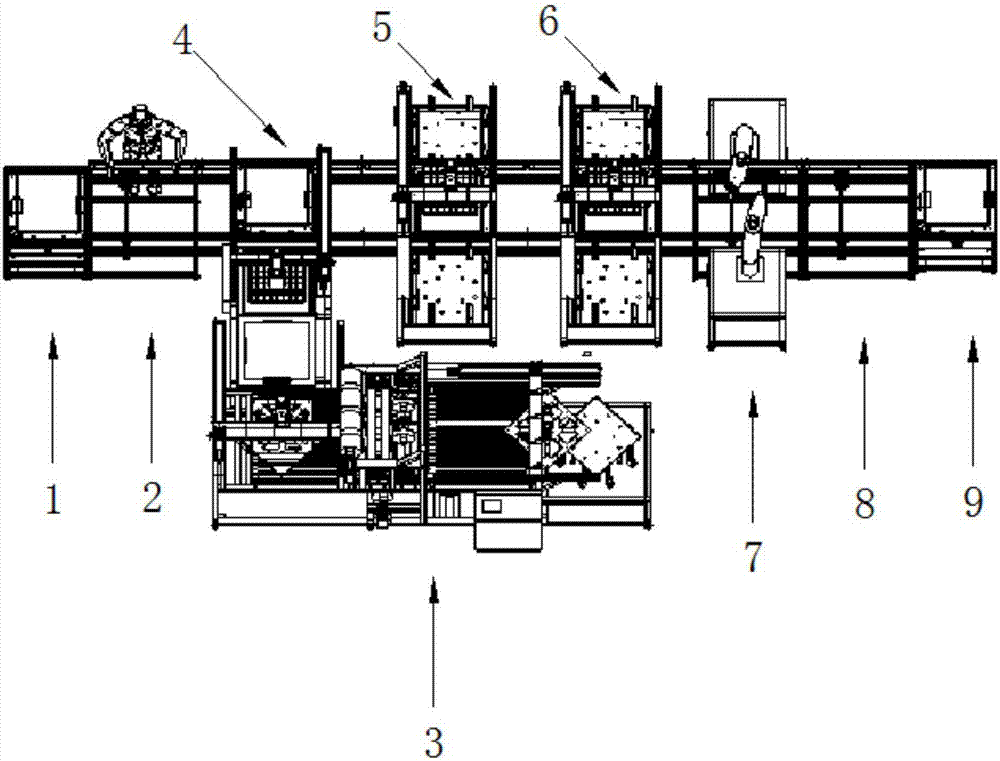

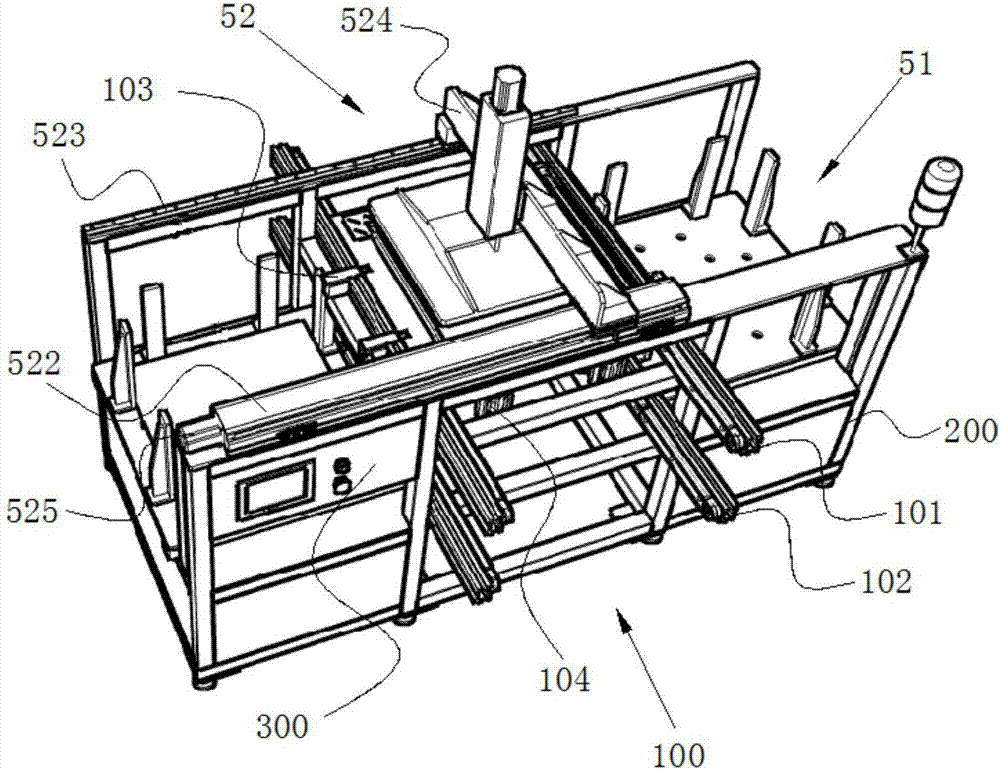

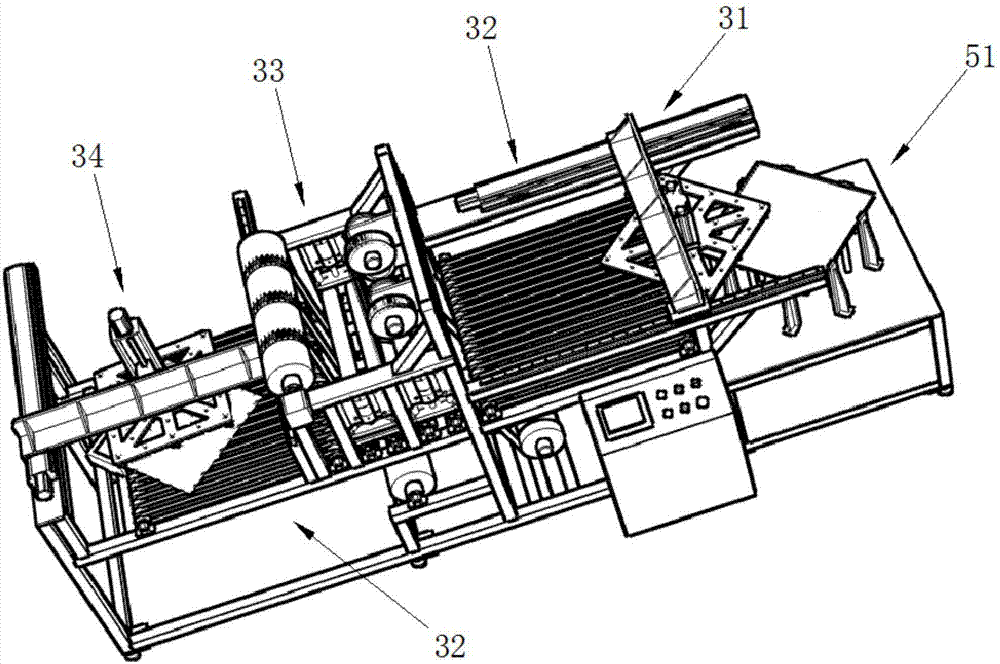

[0040] Embodiment: A kind of flat lamp automatic assembly production line, such as Figure 1-Figure 8 As shown, it includes carrier jacking station 1, lamp frame discharging station 2, optical sheet tearing station 3, optical sheet assembly station 4, reflector assembly station 5, and backplane assembly station 6 , screw lock paying station 7, finished product receiving station 8 and carrier return station 9;

[0041] The lamp frame discharging station 2 is located downstream of the carrier jacking station 1, the optical sheet assembly station 4 is located downstream of the lamp frame discharging station 2, and the optical sheet tearing The film station 3 is located upstream of the optical sheet assembly station 4, the reflector assembly station 5 is located downstream of the optical sheet assembly station 4, and the backplane assembly station 6 is located at the reflector assembly station. The downstream of the chip assembly station, the screw lock payment station 7 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com