Spinning bobbin

A bobbin and tube body technology, applied in the field of textile bobbins, can solve the problems of easy loosening of yarn, inconvenient yarn transportation, easy staggered winding of yarn, etc., and achieve the effects of convenient use, convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

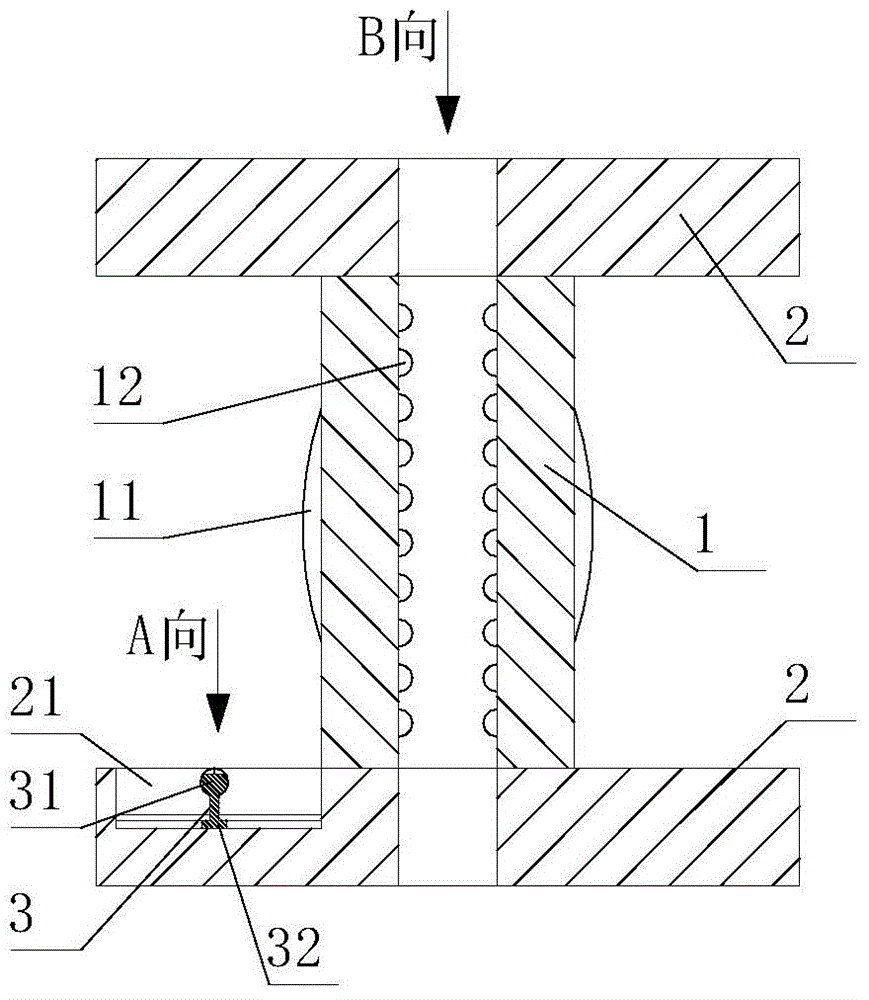

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

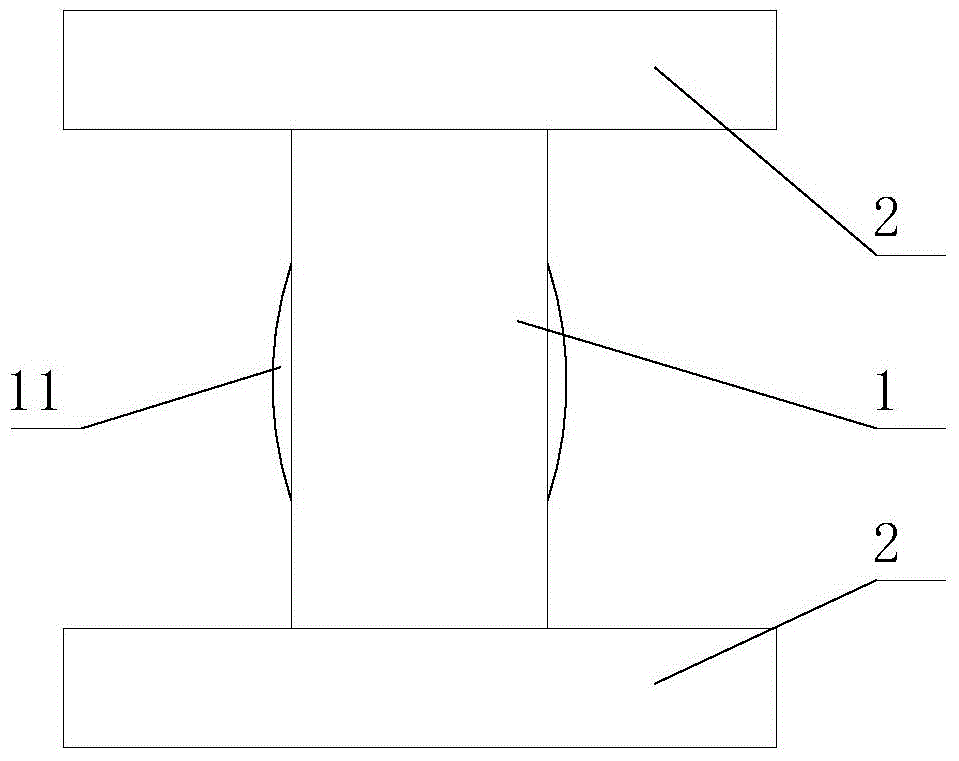

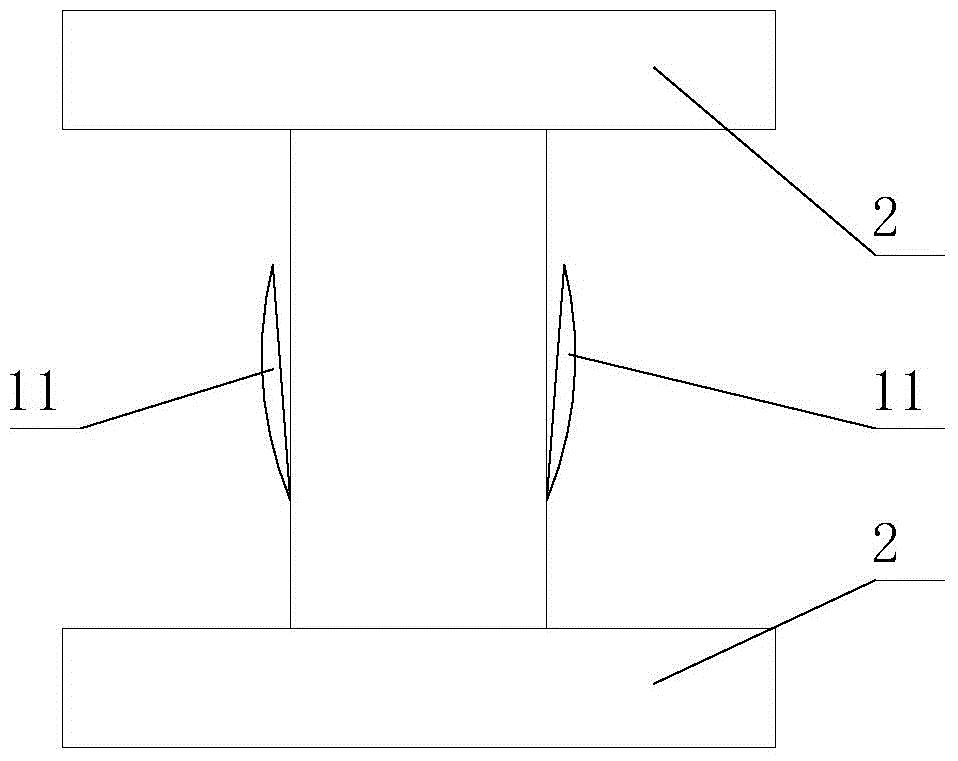

[0025] like Figures 1 to 6 As shown, a bobbin for textiles includes a tube body 1 and tube caps 2 arranged at both ends of the tube body 1. A pressing piece 11 tightly fitted to the outside of the tube body 1 is provided on the outside of the tube body 1. The pressing piece One end of 11 is connected with the tube body 1, and the other end of the pressing piece 11 is movable. There is a fixed column 3 that can slide radially along the pipe body 1, and the end thread of the spinning thread can be fixed on the fixed column 3.

[0026] In the textile bobbin of the present invention, a pressing sheet 11 tightly fitted with the outer side of the tubular body 1 is arranged on the outside of the tubular body 1, one end of the pressing sheet 11 is connected to the tubular body 1, and the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com