Cover tape and method for manufacture

A technology for cover tapes and products, applied in the field of manufacturing cover tapes, which can solve problems such as roll instability, reduced aesthetic value, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

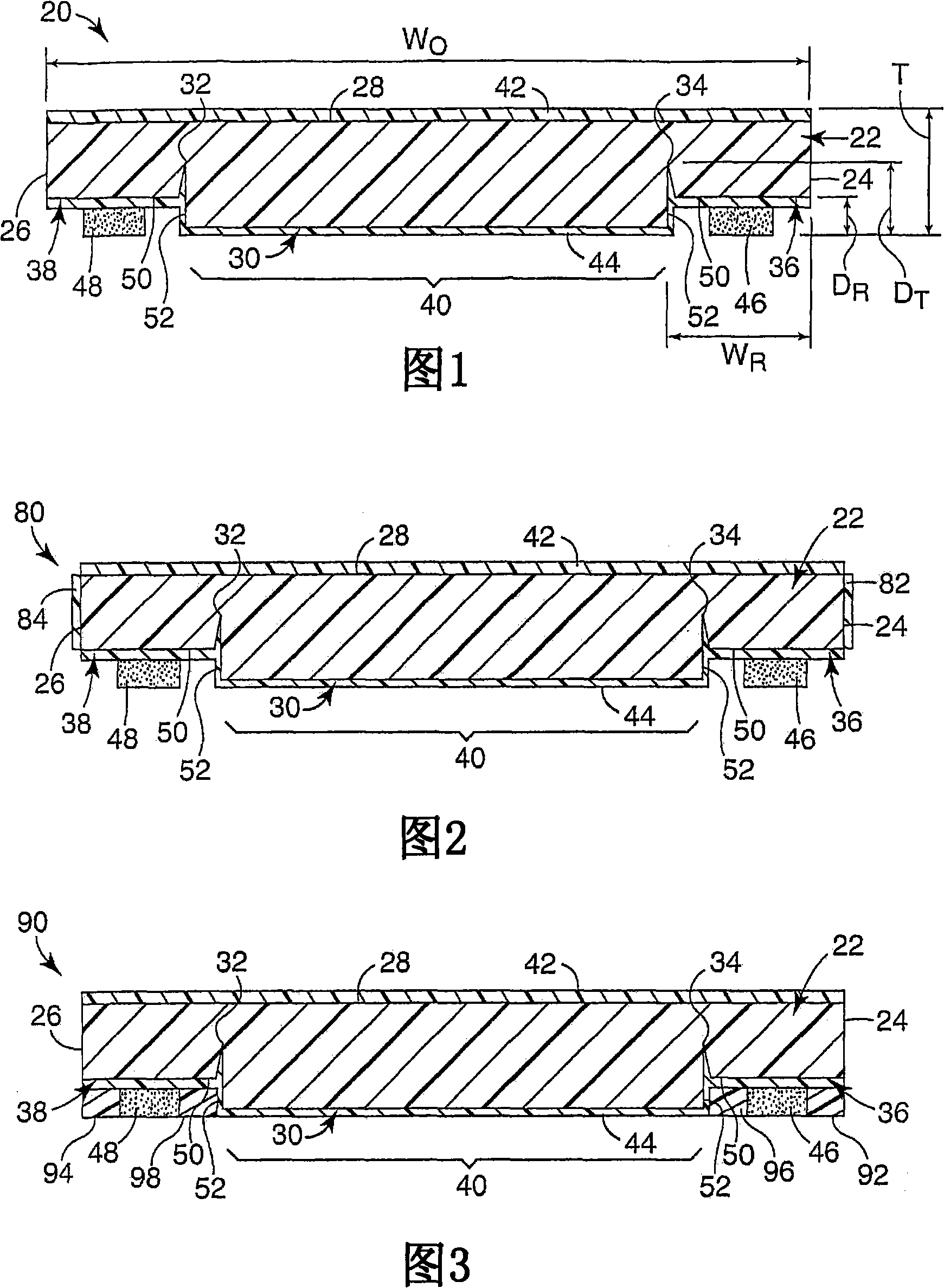

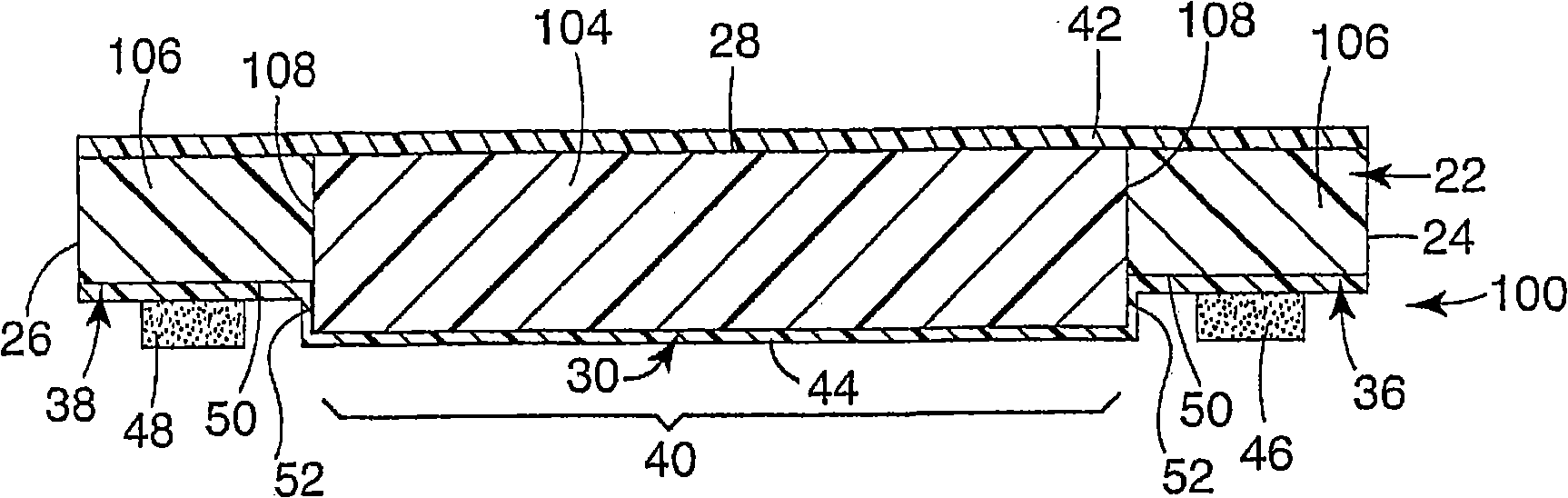

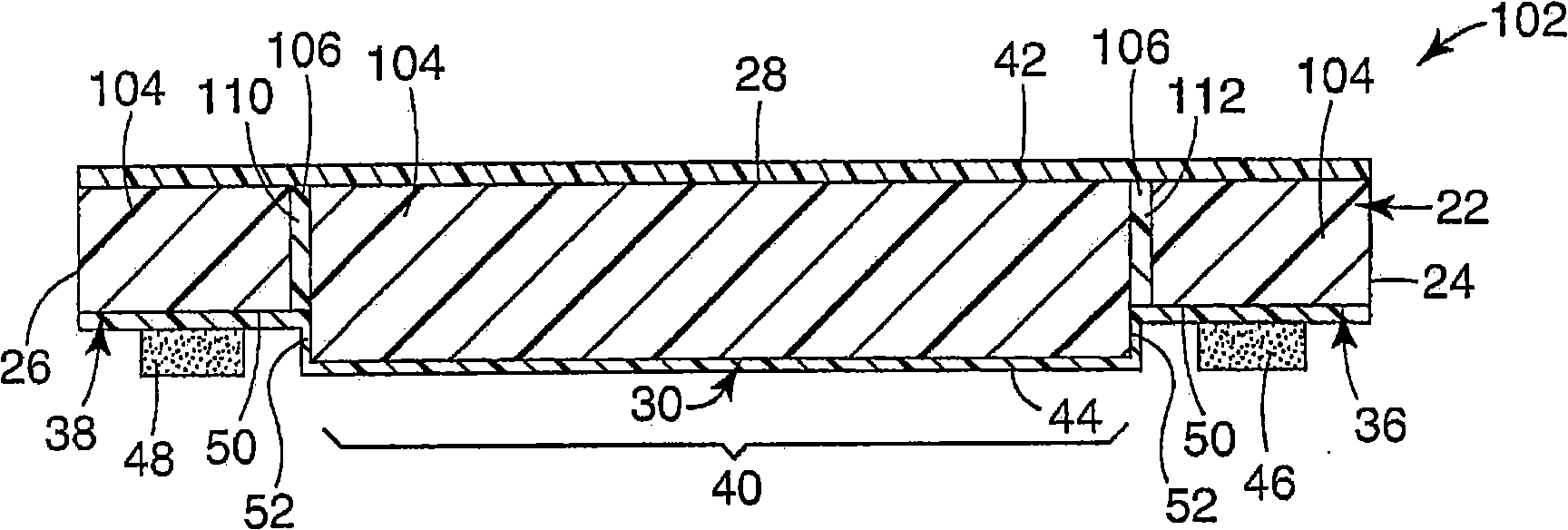

[0024] Aspects of the invention relate to cover tapes, carrier tape / cover tape systems, and methods and apparatus for making cover tapes. The cover tape according to the invention can be adhered to a carrier tape which can hold elements for storage and transport. The cover tape can cover the pockets on the carrier tape for holding components, and a part can be detached from the system to expose the pockets in the carrier tape. The tearable feature on the cover tape allows a portion of the cover tape to be separated from other portions of the cover tape (and the carrier tape to which the cover tape is attached) with a substantially consistent and uniform separation force that reduces the The possibility of unwanted movement of components held by the carrier tape during the process. As used herein, the term "tear" generally refers to the controlled separation of parts of an assembly. Additionally, the cover tape according to the present invention provides grooves along the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com