Threaded block disassembling device

A technology for dismantling devices and threaded blocks, which is applied in the field of plastic production equipment, can solve the problems of high equipment cost and complex structure, and achieve the effect of low equipment cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

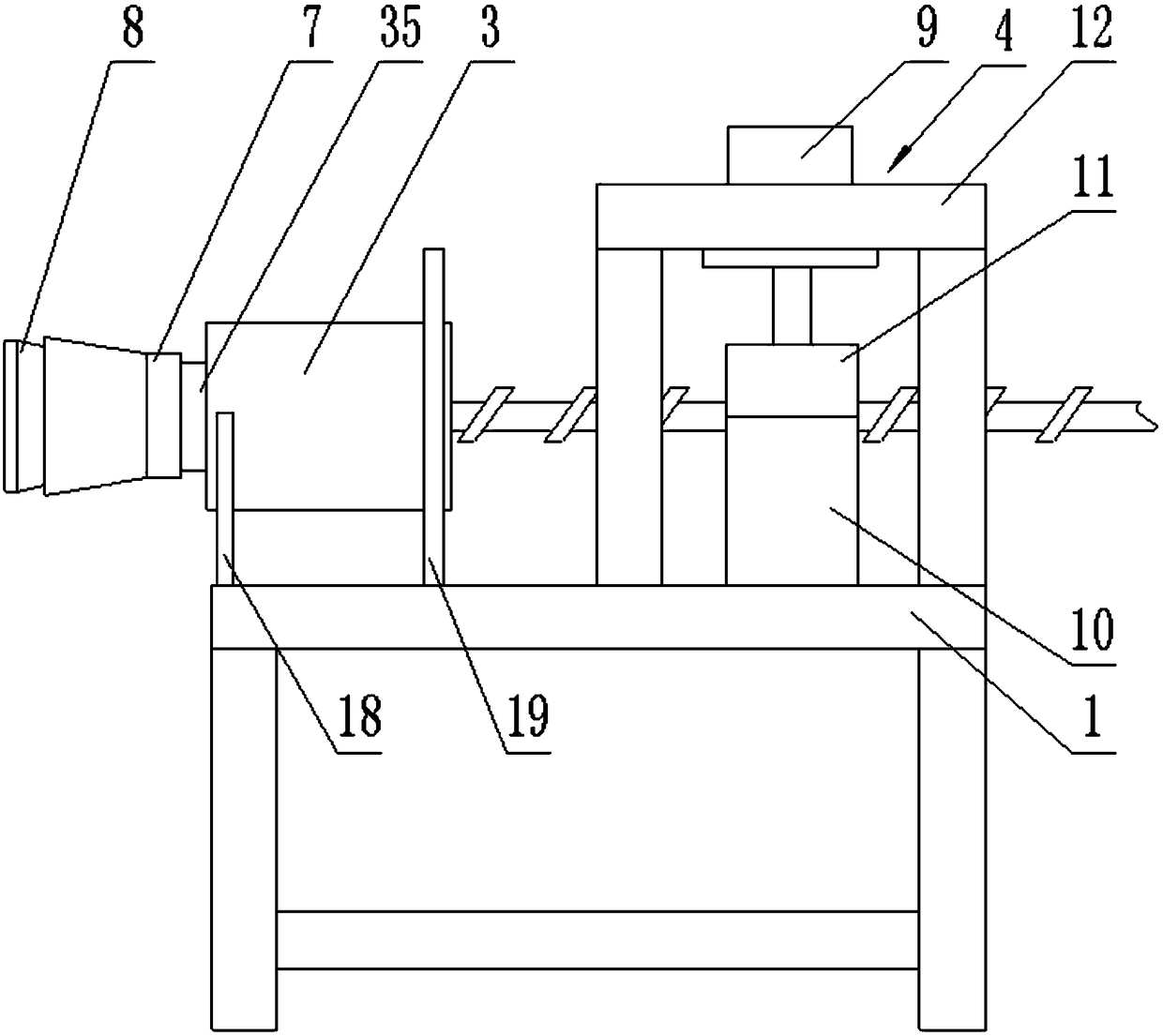

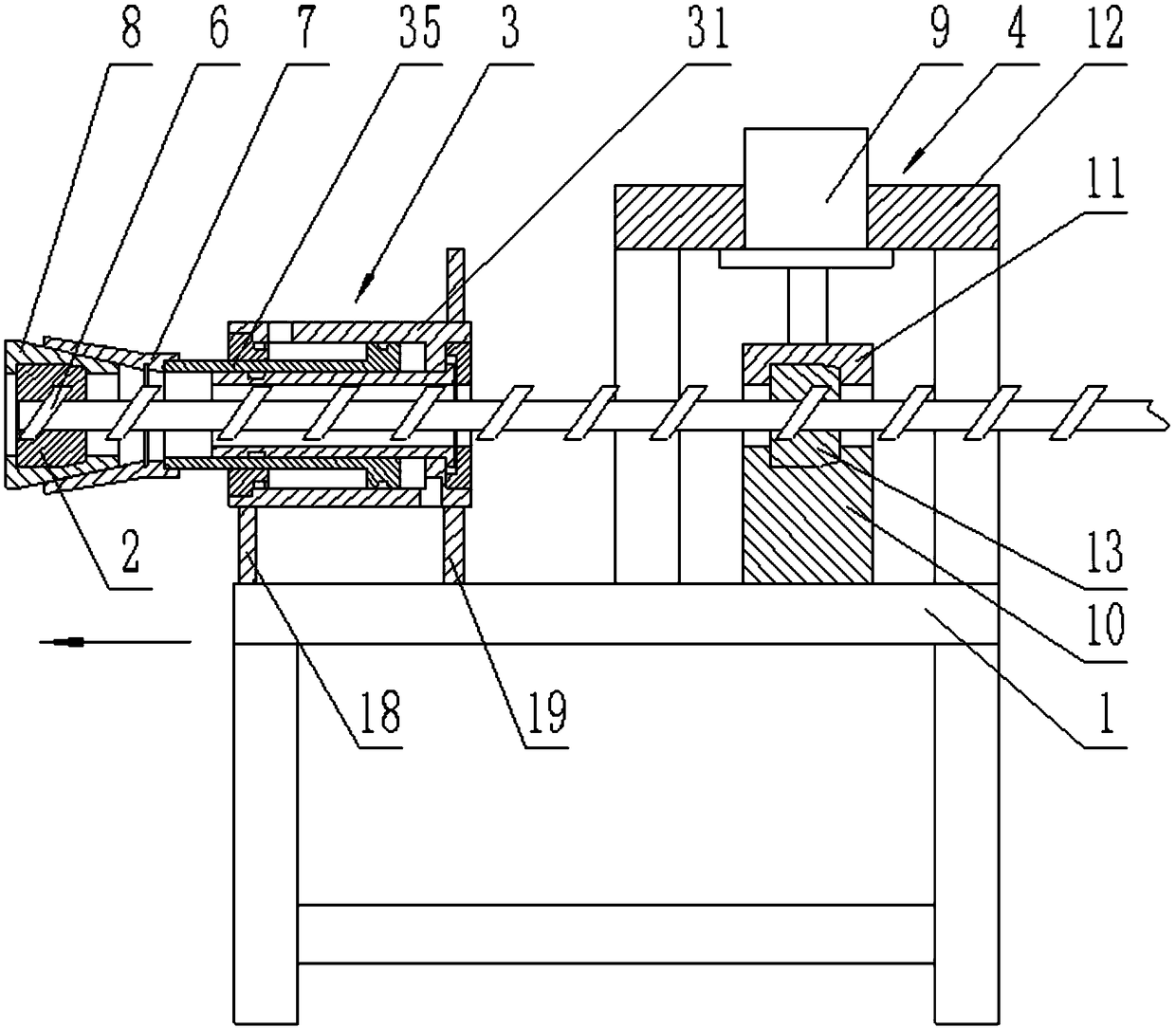

[0044] like Figure 1-4 A threaded block removal device shown includes a support base 1, a hollow hydraulic cylinder 3 and a mandrel clamping mechanism 4. On the upper surface of the support base 1, a first support frame 18, a second support frame 18, and a second Support frame 19 and hydraulic cylinder support frame 12. The upper end of the first support frame 18 is provided with semicircular groove, and this semicircular groove is used for installing hollow hydraulic cylinder 3, offers the hole that is used to install hollow hydraulic cylinder 3 in the middle part of second support frame 19, and hollow hydraulic cylinder 3 The left end is installed on the semicircular groove (the hollow hydraulic cylinder 3 can also be welded on the semicircular groove), and the right end of the hollow hydraulic cylinder 3 passes through the hole on the second support frame 19 and is welded on the second support frame 19 . The hollow hydraulic cylinder 3 is an existing technology, such as ...

Embodiment 2

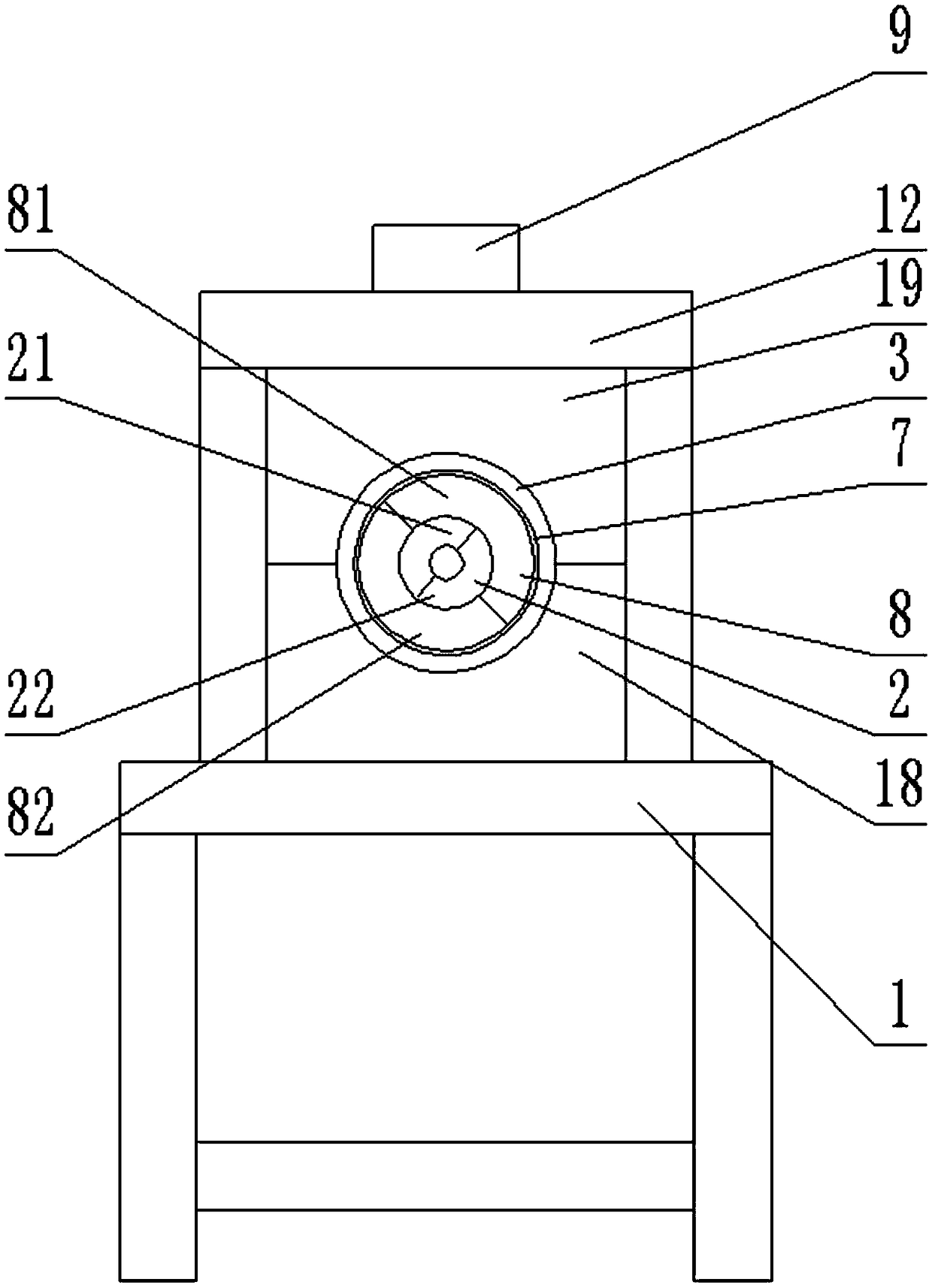

[0049] like Figure 11 Shown, embodiment 2 is improved on the basis of embodiment 1. The outer tapered sleeve 8 in Embodiment 2 has an integral structure (that is, the upper outer tapered sleeve 81 and the lower outer tapered sleeve 82 in Embodiment 1 are fixedly connected to each other). With such a structure, after putting the outer tapered sleeve 8 on the first screw ferrule 2, it can prevent the first upper threaded clip 21 from being separated from the first lower threaded clip 22, but it is inconvenient to install.

[0050] The rest of the structure and working principle of embodiment 2 are the same as embodiment 1.

Embodiment 3

[0052] like Figure 12-13 As shown, Embodiment 3 is changed on the basis of the structure of the thread block removal device in Embodiment 1. The large end of the outer tapered sleeve 8 in embodiment 3 is threadedly connected to the left end of the piston cylinder 35, and the mandrel clamping member is replaced by the first V-shaped block 16 and the second V-shaped block 17 in the embodiment 3. The V-shaped surfaces of a V-shaped block 16 and the second V-shaped block 17 are all towards the mandrel 5, and the first V-shaped block 16 is fixedly connected on the second clamping seat 11, and the second V-shaped block 17 is fixedly connected on the first On the clamping seat 10.

[0053] In Embodiment 1, the threaded block removal device disassembles the threaded block 6 from one end of the mandrel 5. When the last few threaded blocks 6 are disassembled, because the length of the last few threaded blocks 6 is not enough to be clamped by the first hydraulic cylinder 9, that is, U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com