Quick wire clearing device of motor enameled wire

An enameled wire and motor technology, which is applied in the field of quick disconnection device for enameled wire of electric motor, and the field of disconnection device, can solve the problems of easy to pull broken iron core, burnt out stator coil, difficult dismantling, etc., and achieve the effect of uniform dismantling force and reducing working strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

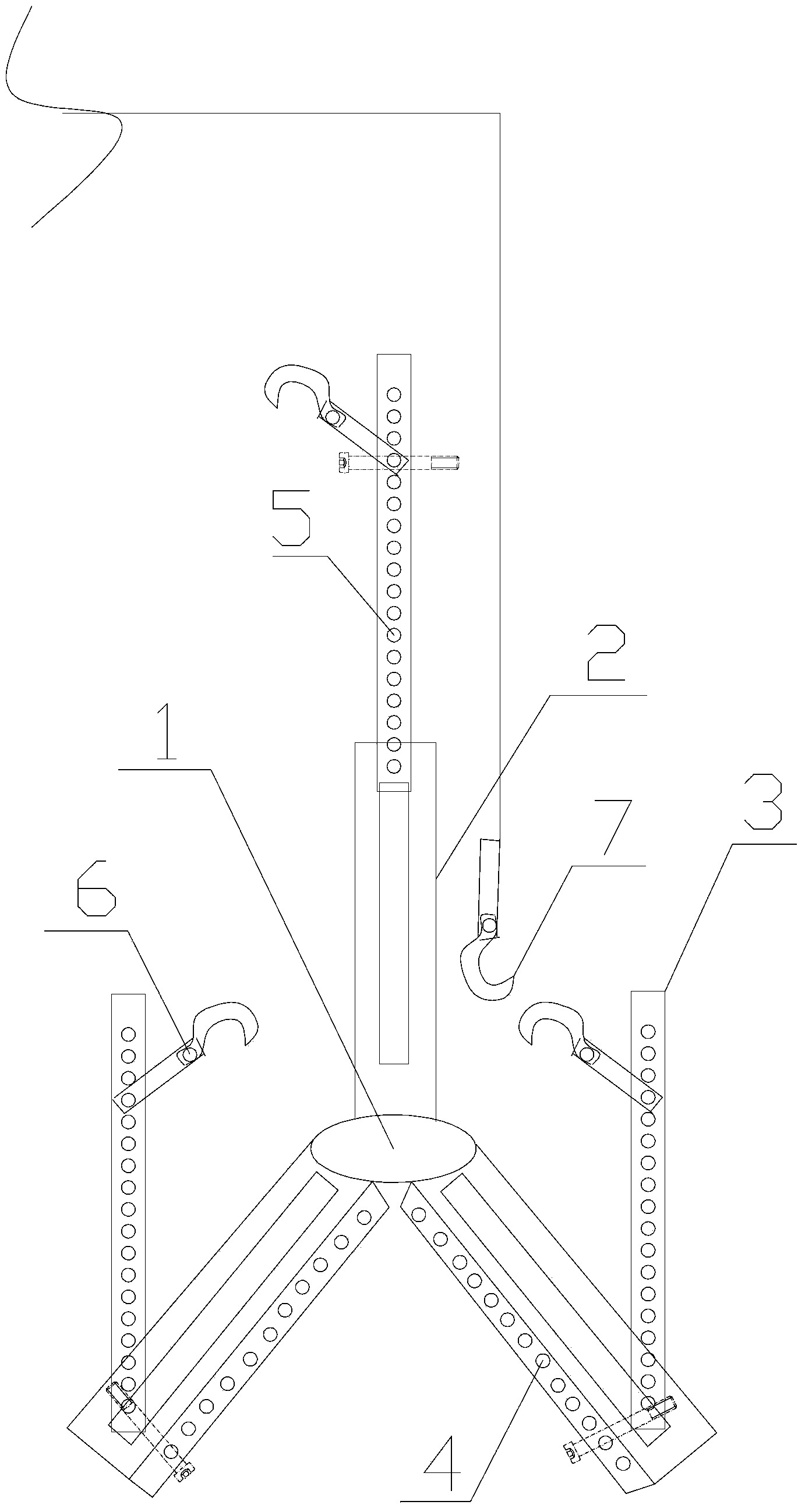

[0011] This embodiment provides a quick disconnecting device for enameled wires of electric motors, such as figure 1 As shown, it includes a central base 1 and an extension arm 2 connected to the central base 1 at one end, a support column 3 is slidably connected to the extension arm 2, and the groove walls on both sides of the chute of the extension arm 2 are provided along the length direction The chute positioning through hole 4, the end of the supporting column 3 connected to the extension arm 2 is provided with a through hole matching the chute positioning through hole 4, and the supporting column 3 is provided with a hook height adjustment hole 5 along the length direction, and the hook The claw 6 is fixed in one of the claw height adjustment holes 5, and a single-beam driving hook 7 for pulling out the enameled wire is fixedly arranged above the center base 1 .

[0012] figure 1 Only three extension arms are shown in the figure, which are evenly distributed with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com