Synchronous die filling mechanism of winding machine

A synchronous winding machine technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of high labor intensity, large space size of multi-strand wires, old and worn knuckles of workers, etc., to achieve winding High manufacturing efficiency, convenient winding and fully mechanized, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

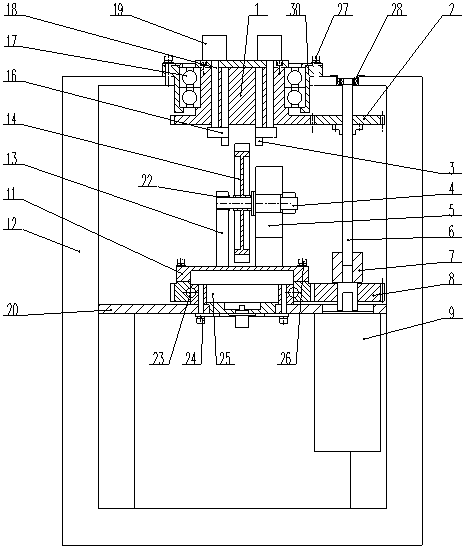

[0026] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

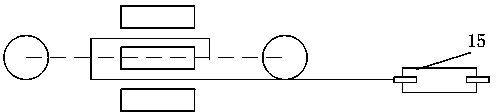

[0027] like figure 1 As shown, a synchronous mold loading mechanism of a winding machine of the present invention includes a driven gear 1, a second driving gear 2, a fixed shaft 4, a fixed shaft rotation controller 5, a synchronous shaft 6, and a first driving gear 8 , Main drive motor 9, winding turntable 11, frame 12, armature support frame 13, motor armature 14, wire arrangement mechanism 15, middle plate 20, inner turntable 25 and crimping base 30.

[0028] The middle board 20 is fixedly connected to the frame 12 . The main drive motor 9 is fixedly connected to the bottom surface of the middle plate 20 , and the output shaft of the main drive motor 9 passes through the top surface of the middle plate 20 . The output shaft of the main drive motor 9 is fixedly connected with the synchronous shaft 6 through a shaft coupling 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com