Horizontal roller aerobic composting reactor for ecological toilet

An aerobic composting and reactor technology, applied in the application, organic fertilizer, fertilization device and other directions, can solve the problems of high local temperature, high local humidity, high labor cost, and achieve enhanced disturbance, enhanced stirring, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

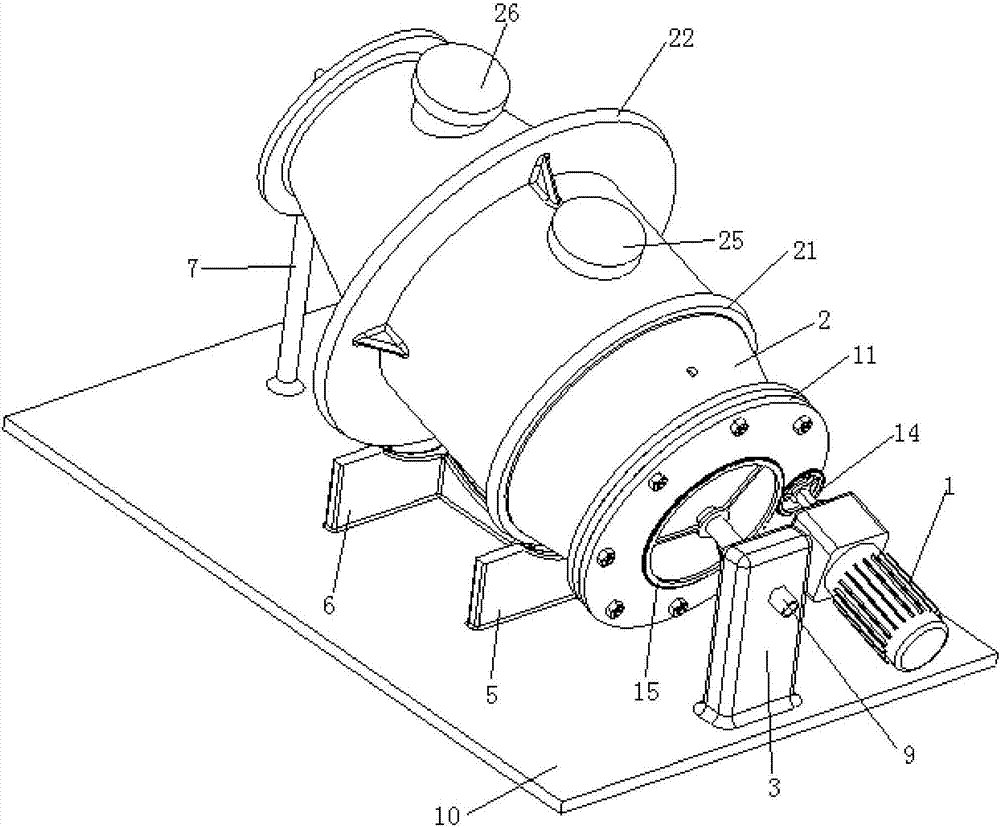

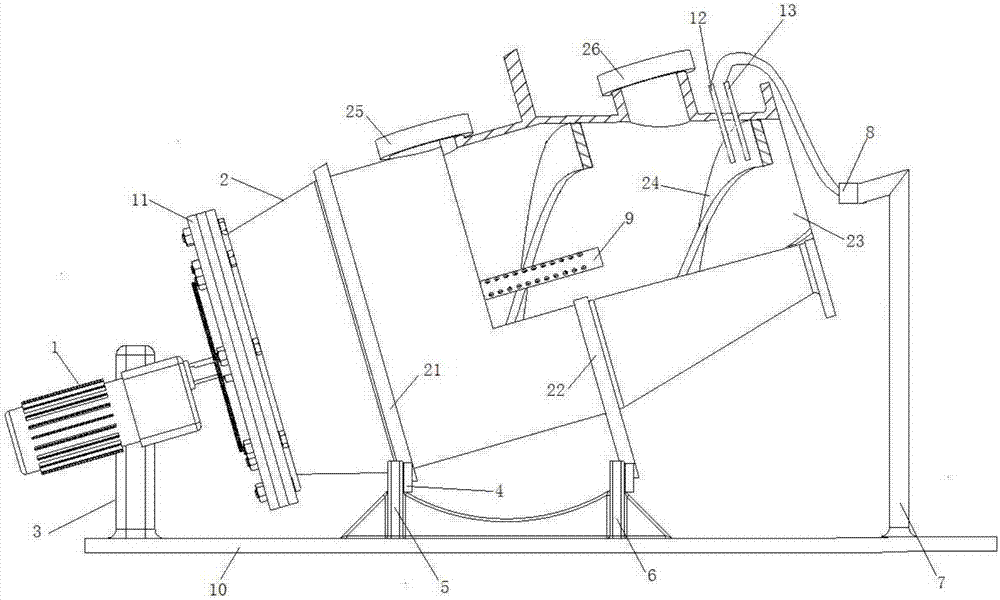

[0024] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, this embodiment is used for the horizontal drum aerobic composting reactor of ecological toilet, and this reactor is made up of motor 1, drum 2, motor bracket 3, supporting wheel 4, first supporting wheel bracket 5, the second supporting wheel Wheel bracket 6, threading pipe 7, slip ring 8, aeration pipe 9, base 10, drum sealing cover 11, temperature sensor 12 and humidity sensor 13;

[0025] The motor bracket 3, the first roller bracket 5, the second roller bracket 6 and the threading pipe 7 are sequentially arranged on the upper surface of the base 10, and the first roller bracket 5 and the second roller bracket 6 are respectively provided with two The supporting wheel 4 and the cylinder circumference of the drum 2 are provided with a first raceway 21 and a second raceway 22, the radius of the first raceway 21 is smaller than the radius of the second raceway 22, and the end of...

specific Embodiment approach 2

[0037] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the middle part of the cylinder wall of the drum 2 is also provided with a first sampling port 25, and the cylinder wall of the drum 2 is also provided with a first sampling port 25 on the side close to the threading pipe 7. Two sampling ports 26. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the sealing cover 11 is connected to the end of the drum 2 by bolts. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com