Stator stamping and motor

A stator punching and stator core technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, winding conductor shape/style/structure, etc., can solve the unfavorable inner coil 25 and outer coil 26 winding Manufacturing, insulation treatment process is complicated, coil winding is difficult, etc., to achieve the effect of reducing winding difficulty, reducing production cost, and reducing insulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

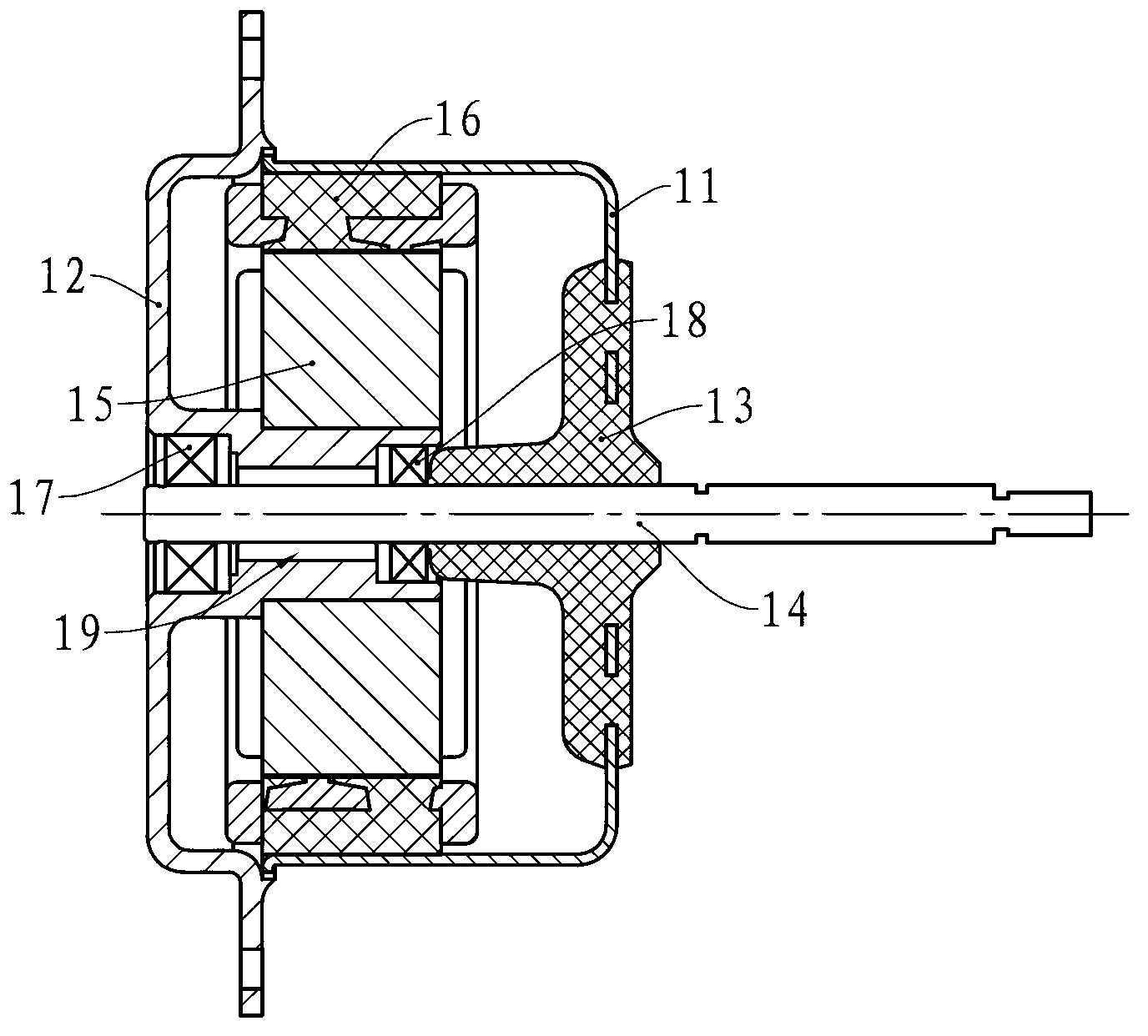

[0030] The motor of the present invention has a housing and end covers located on both sides of the housing. The housing and the end covers form a cavity, and a stator and a rotor are installed in the cavity. The motor in this embodiment is an external rotor motor, that is, the stator is located in the middle of the motor, the rotor is sleeved outside the stator, and the middle of the stator is provided with a shaft hole. The rotor shaft is installed in the middle of the rotor, and the rotor shaft can pass through the shaft hole to output power outward.

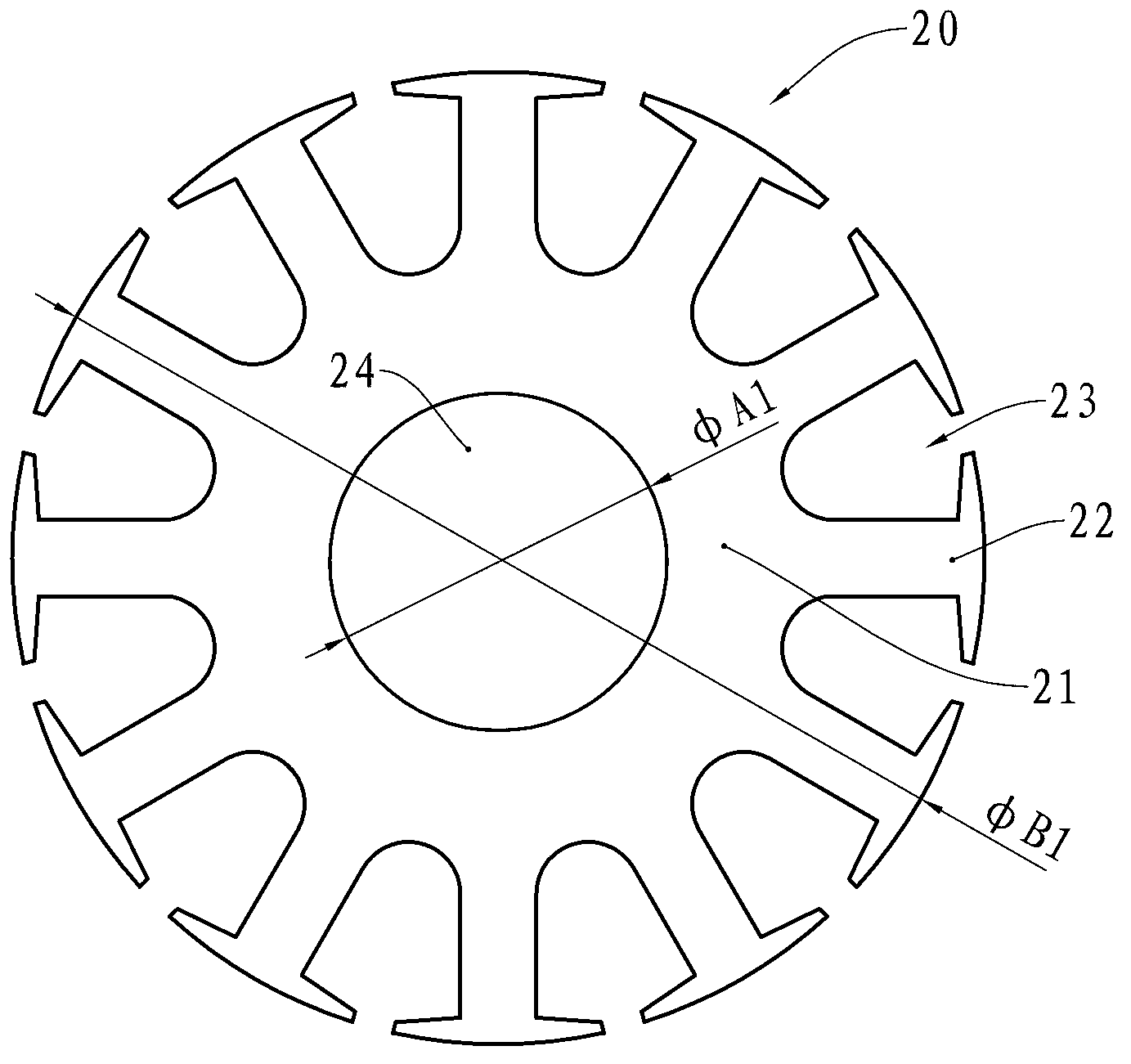

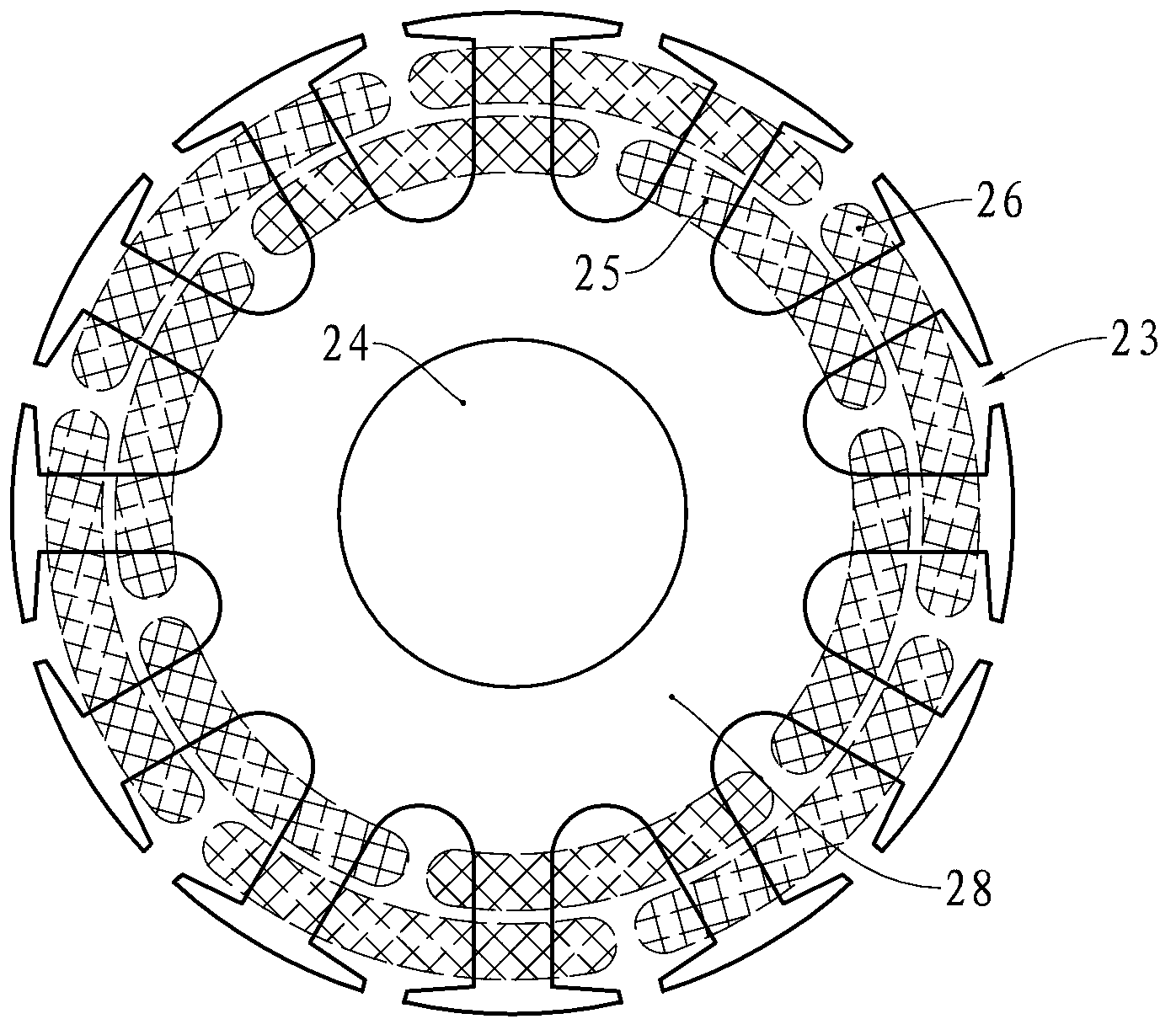

[0031] The stator has a stator core and a coil wound on the stator core, and the stator core is formed by laminating a plurality of stator punches with the same shape. see Figure 4 , the stator punching sheet 30 of the present embodiment is formed by stamping silicon steel sheets, which is roughly annular, and is provided with an annular yoke 31, the middle part of the yoke 31 is provided with an inner circular hole 35, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com