Crossed iron core type controlled reactor

A reactor and iron core technology, applied in the field of high-voltage equipment manufacturing and iron-core controllable reactors, can solve the problems of not being widely used, restricting development, and high power consumption, reducing the size of the iron core window, reducing insulation requirements, reducing The effect of controlling the volume of the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

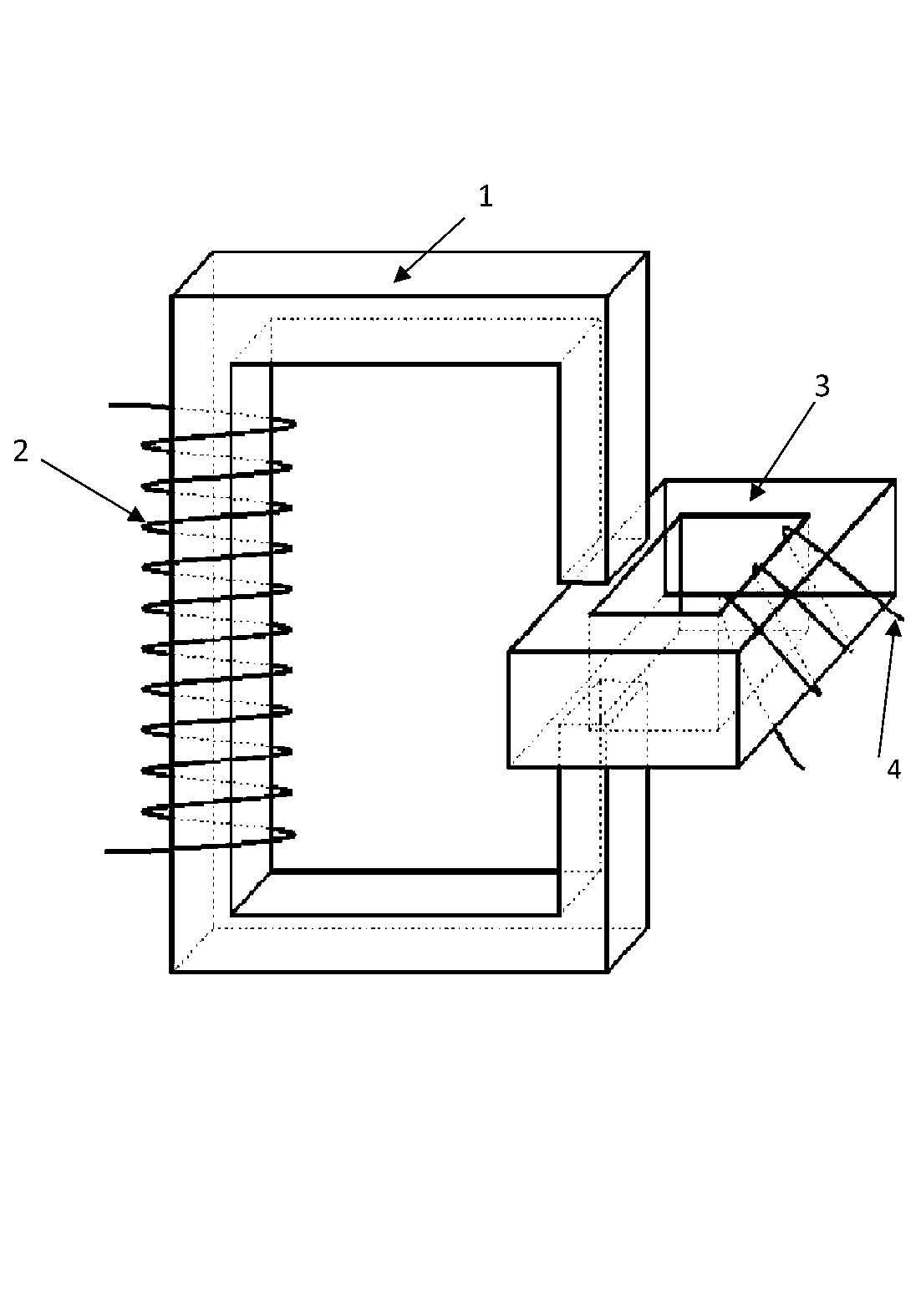

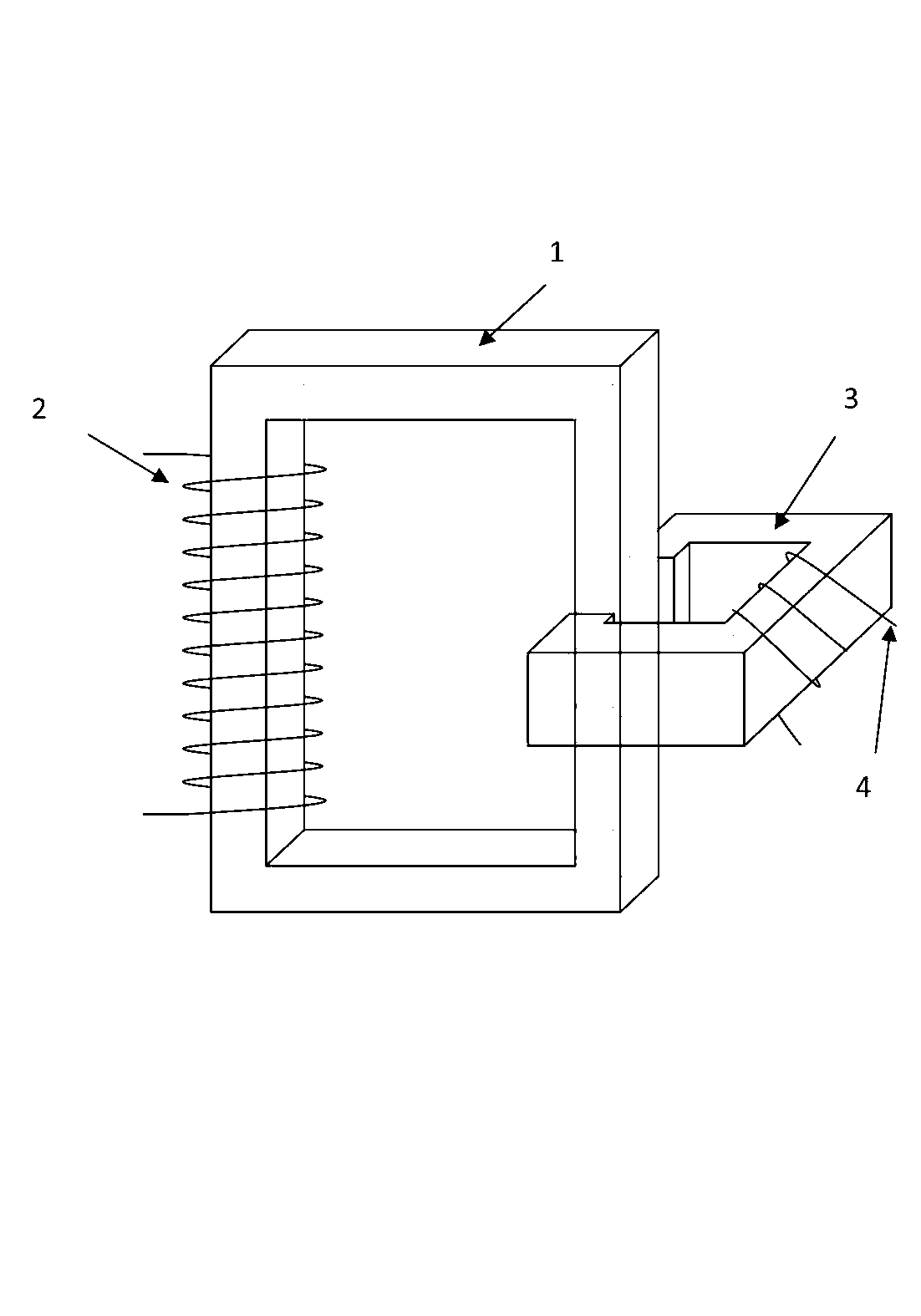

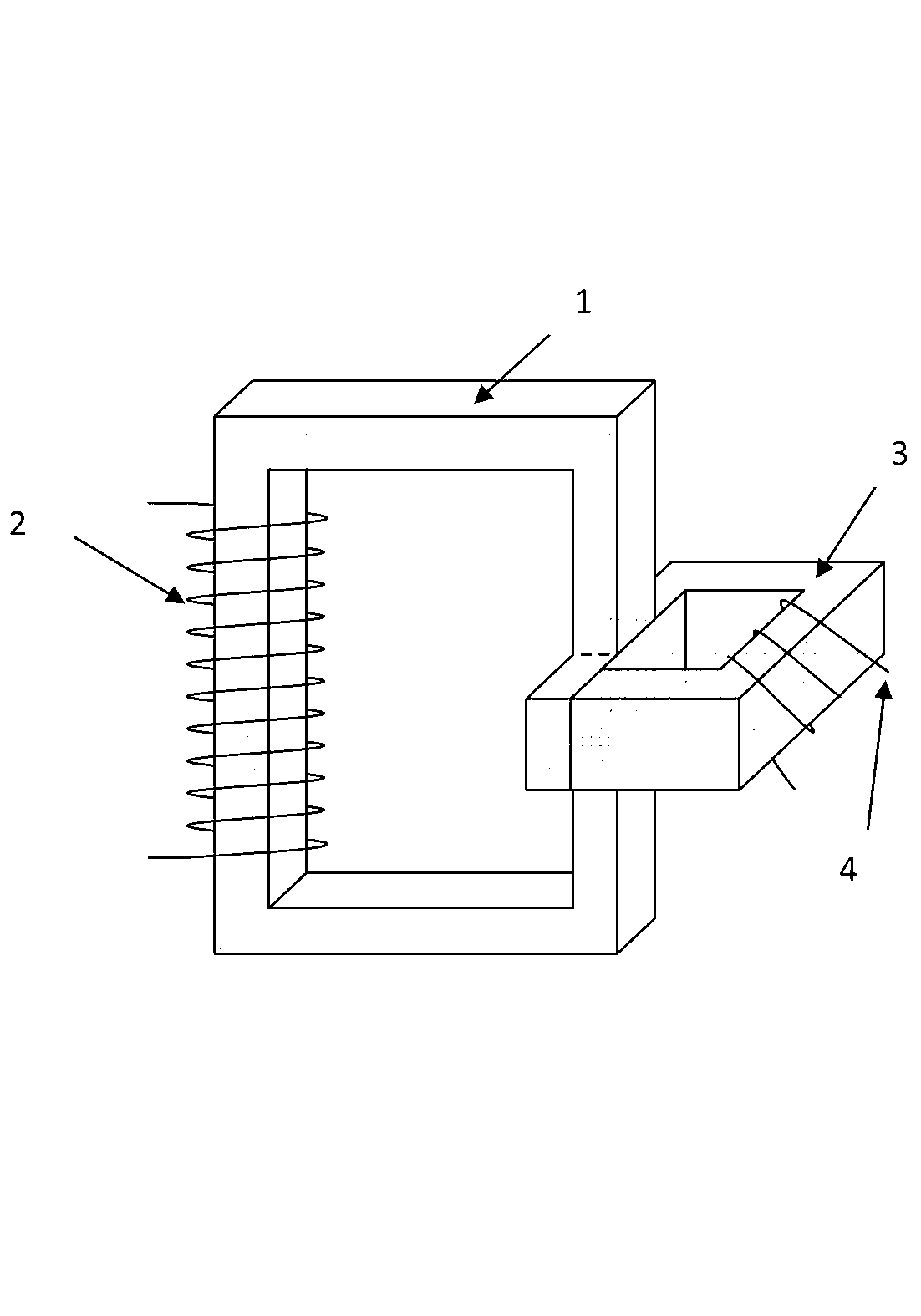

[0026] refer to figure 1 As shown, the main body of the cross-core type controllable reactor of the present invention is composed of a main core 1 , a control core 2 , an AC winding 3 and a DC winding 4 . Among them, the AC winding 3 is wound on the main side column of the main core 1 ; the DC winding 4 is wound on the control core 2 .

[0027] The main innovation of the present invention is that compared with the conventional reactor, a control core 2 is added to the reactor, and the added control core 2 shares part of the core columns with the original main core 1 .

[0028] The combination form of the core column shared by the control core 2 and the main core 1 can be one of the following main forms:

[0029] One: A notch is cut on a part of the iron core column of the main core 1, and a part of the iron core column of the control core is inserted into the notch, and the iron core column of the control iron core is orthogonal or oblique to the iron core column of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com