Magnet ring component

A component and magnetic ring technology, applied in the field of magnetic ring components, can solve problems such as winding difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

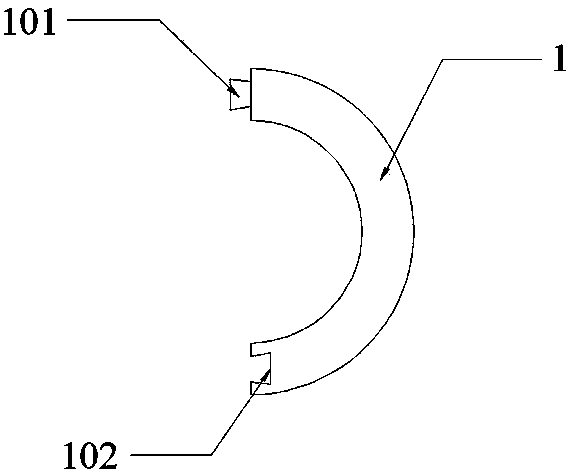

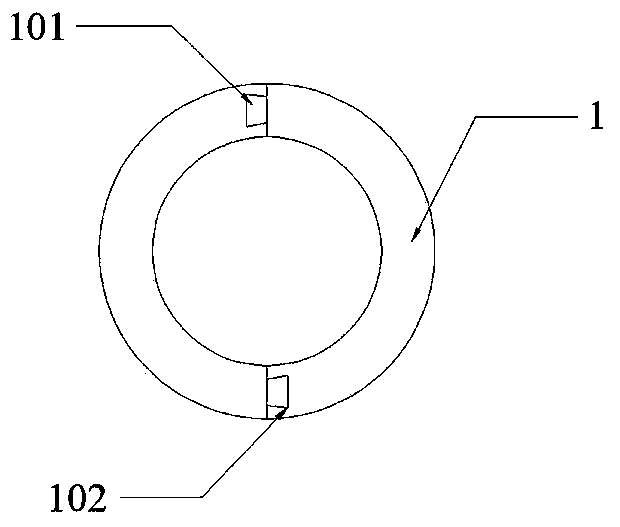

[0016] Such as figure 1 , 2 The magnetic ring assembly shown includes two semi-circular connecting pieces 1, one end of the connecting piece 1 has a raised clamping part 101, and the other end of the connecting piece 1 is provided with a concave interface part matched with the clamping part 101 102. The cross-section of the clamping part 101 in the axial direction of the connector 1 is trapezoidal, and the upper bottom of the trapezoid is connected to the connector 1; edge contact. The locking part 101 and the interface part 102 have the same shape and the same size. It is convenient for batch processing, and can make the clamping part 101 of one connecting part snap into the interface part 102 of another connecting part.

[0017] The axial length of the engaging part 101 and the interface part 102 along the connecting part 1 is equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com