Stator modular double-rotor doubly salient permanent magnet motor

A double-rotor, double-convex technology, applied in electrical components, electromechanical devices, etc., to achieve the effect of facilitating heat dissipation, reducing winding difficulty, improving utilization rate and motor torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

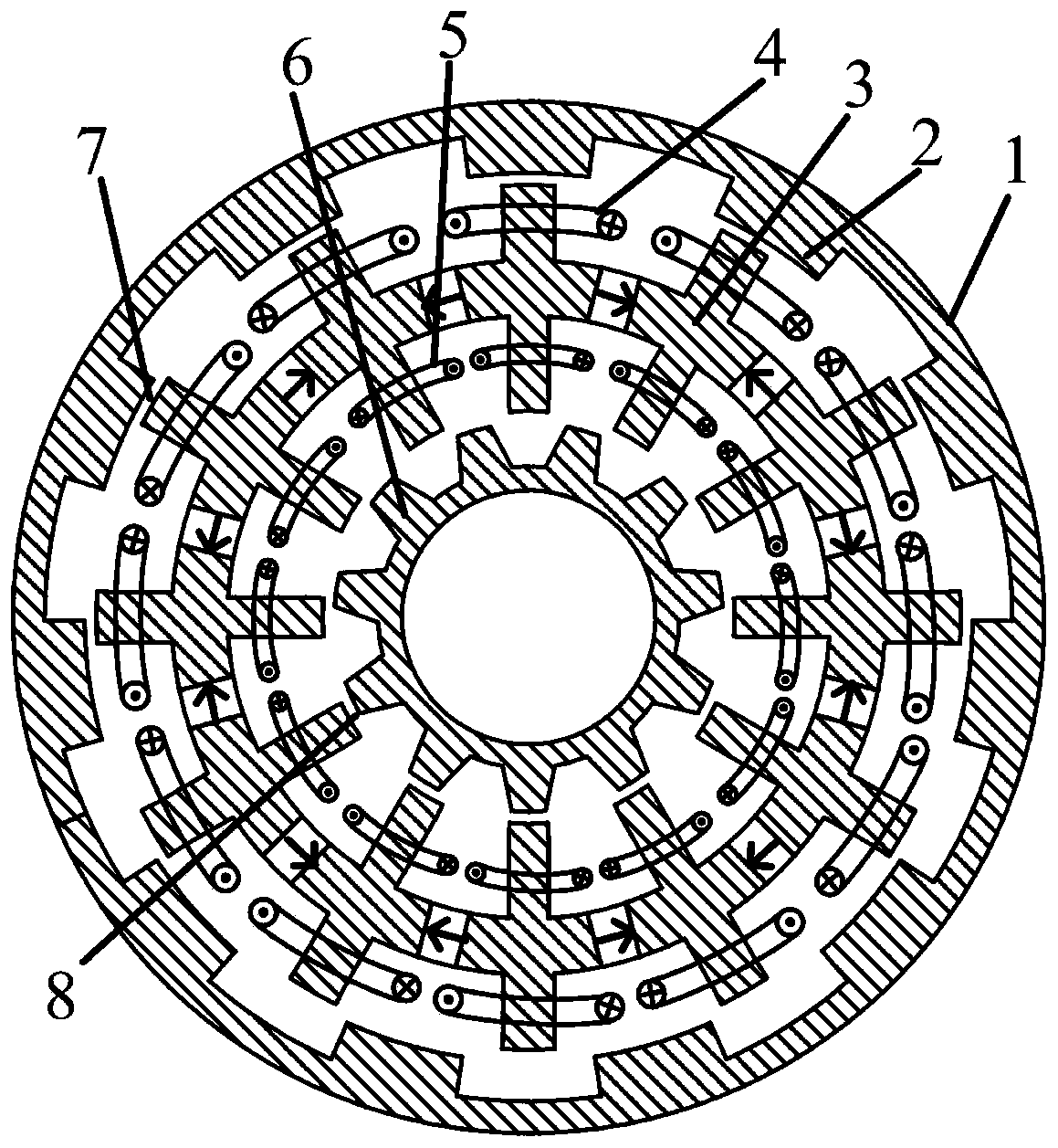

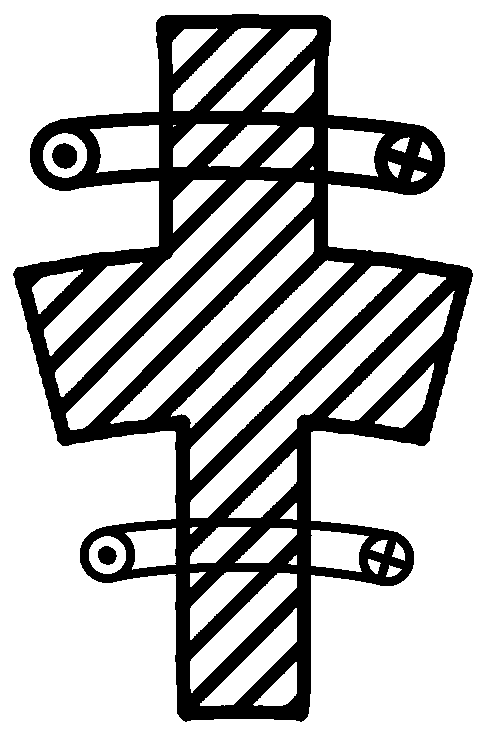

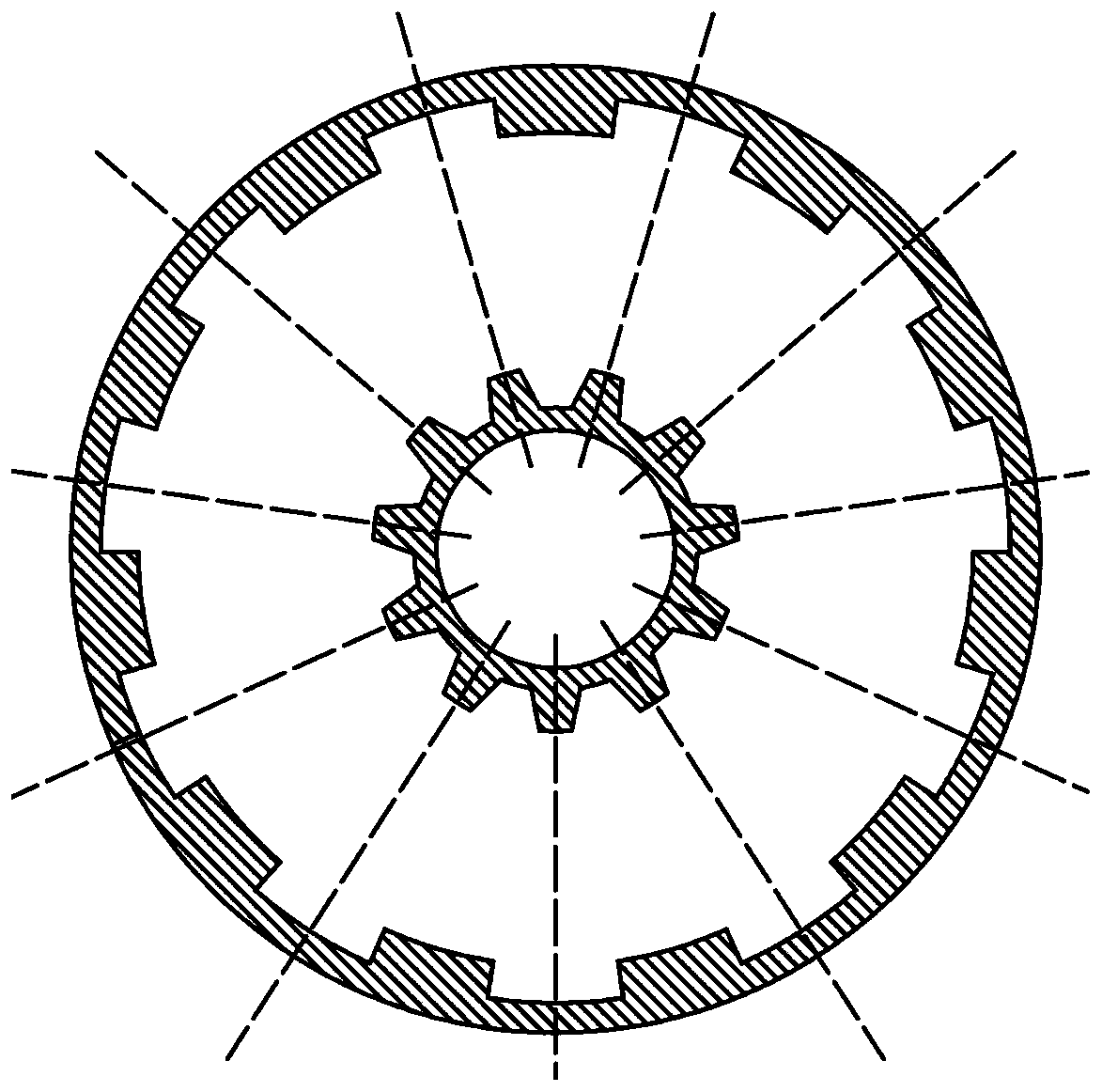

[0025] Such as figure 1 As shown, a stator modular double-rotor double-convex permanent magnet motor includes an inner salient pole rotor 6, an outer salient pole rotor 1 and a stator between the two, the inner salient pole rotor 6 and the outer salient pole rotor 1 Separate air gaps 8 and 7 are formed with the stator respectively. The stator includes several stator modules 3, such as figure 2 As shown, each stator module 3 includes a stator yoke and outer stator teeth and inner stator teeth respectively connected to the outside and inside of the middle position of the stator yoke, and the stator yokes of each stator module are connected by permanent magnets to form a complete stator . Armature windings 5 and 4 are wound on the outer and inner stator teeth of each stator module. Such as image 3 As shown, the number of pole pairs of the inner salient pole rotor and the outer salient pole rotor is the same (that is, the two rotors have the same number of teeth), and the ...

Embodiment 2

[0031] In order to simplify the processing and assembly process and improve the torque density and fault tolerance performance of the motor, the stator module in this embodiment adopts Image 6 The structure shown, the structure of the inner and outer salient pole rotor of the motor and the corresponding way of inner and outer cogging are the same as image 3 be consistent. The armature winding connection mode of the inner and outer stator of the motor is as follows: Figure 7 shown, with Figure 4 The only difference is that the armature windings are no longer wound on the inner and outer stator teeth at the junction of each stator module, and the winding direction and sequence of the coils on the other inner and outer stator teeth are the same as Figure 4 no difference. The winding connection method can realize the physical isolation between the winding phases and improve the reliability of the motor operation. In addition, the stator teeth wound with armature windings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com