Combined type fiber loop framework for fiber-optic gyroscope

A technology of fiber optic ring skeleton and fiber optic gyroscope, which is applied in Sagnac effect gyroscopes, gyroscopes/steering sensing equipment, measuring devices, etc., and can solve the problem of increasing the radial temperature gradient effect of fiber optic rings and affecting the temperature performance of fiber optic gyroscopes , lower pass rate of optical fiber ring, etc., to achieve the effect of reduced radial temperature gradient effect, simple structure, and reduced number of layers of optical fiber winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

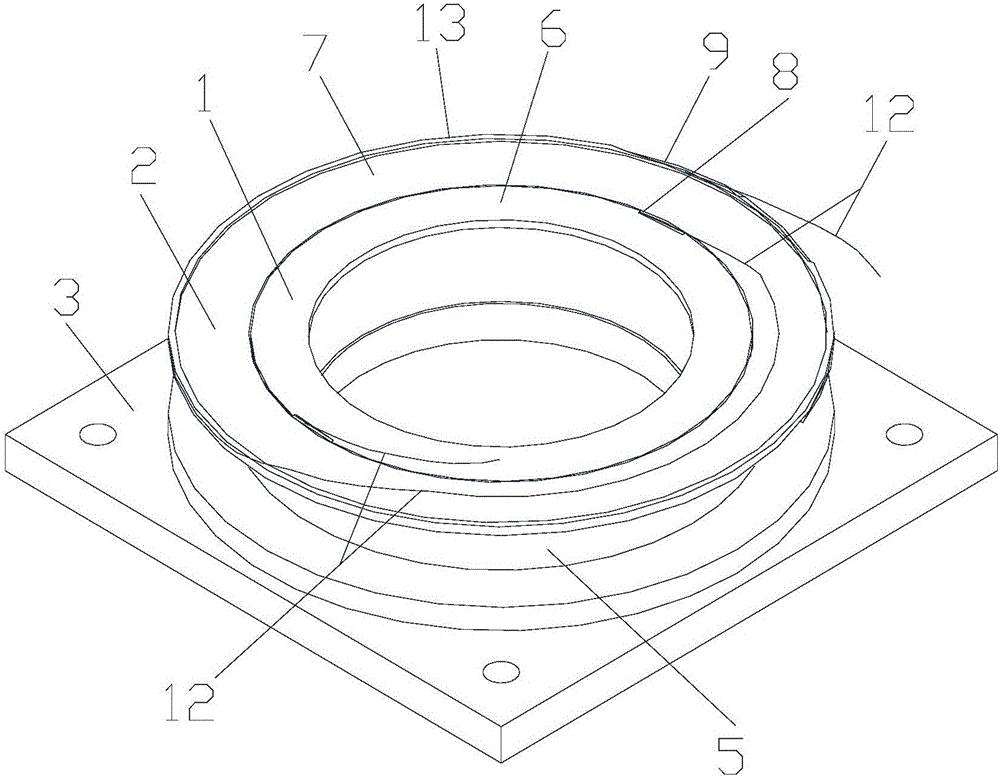

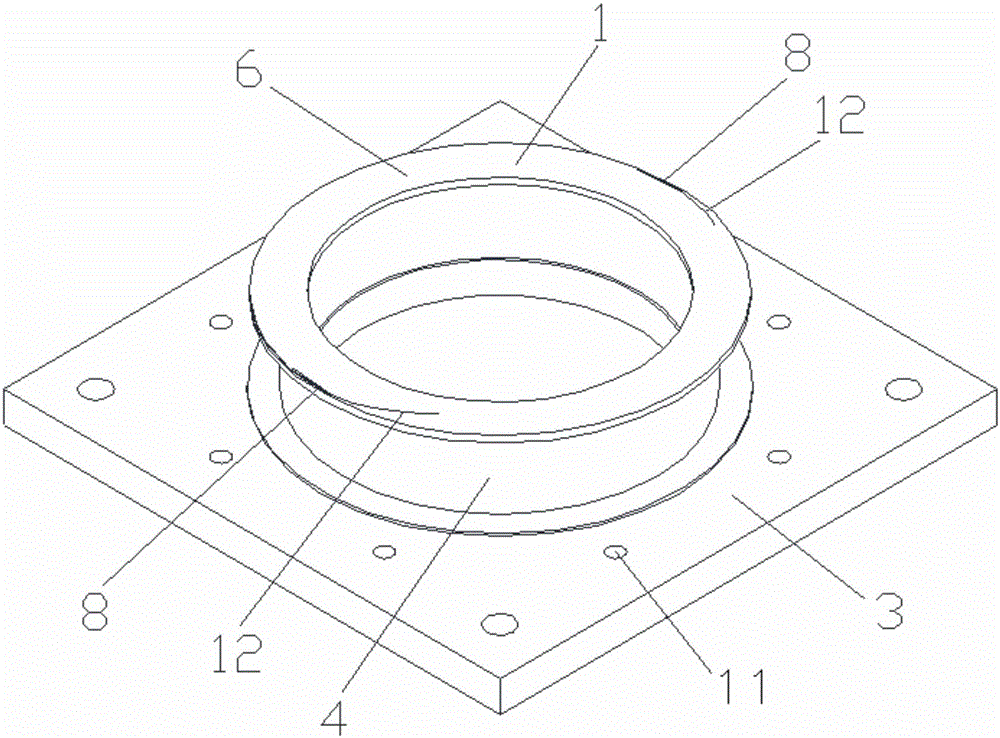

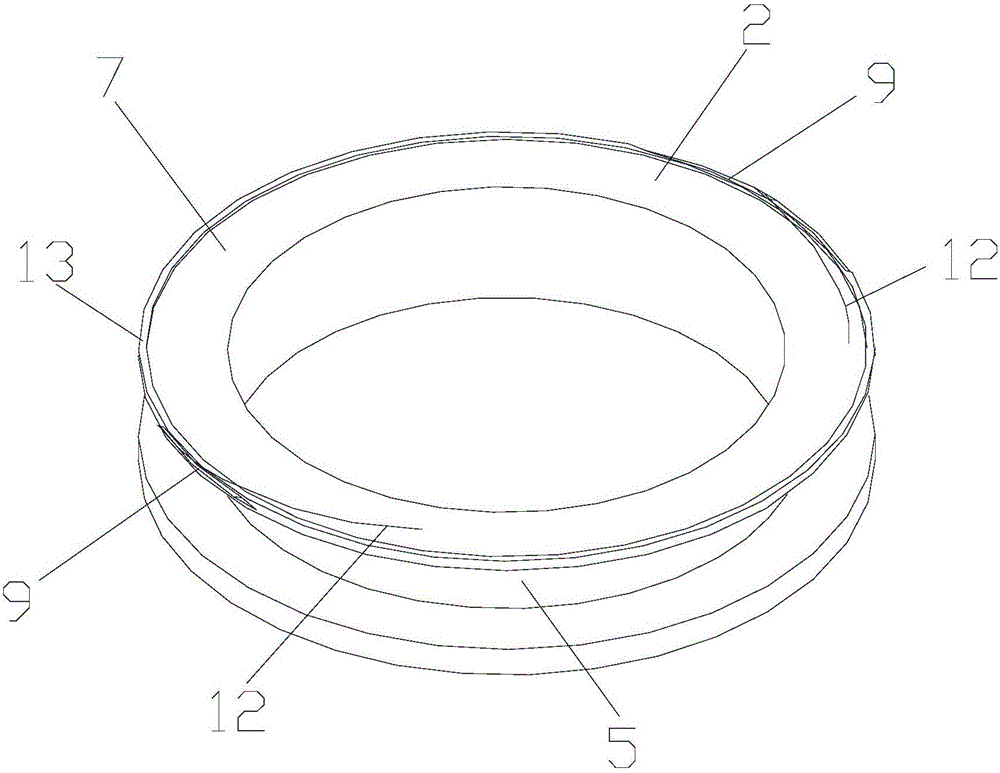

[0018] Attached below Figure 1-5 An embodiment of the present invention is described.

[0019] A combined fiber optic ring skeleton for a fiber optic gyroscope, comprising an inner fiber optic ring skeleton 1, an outer fiber optic ring skeleton 2 and a mounting plate 3, the inner fiber optic ring skeleton 1 and the outer fiber optic ring skeleton 2 both having an I-shaped ring structure and The lower end surface of the inner fiber ring frame 1 is fixed on the mounting plate 3, and the upper end faces of the inner fiber ring frame 1 and the outer fiber ring frame 2 are respectively the fiber optic disk installation surface I6 and the fiber optic disk installation surface II7, and the inner fiber optic ring skeleton 1 The outer ring wall between the upper and lower end faces of the outer fiber ring skeleton 2 is the fiber winding torus I4 and the fiber winding torus II5 respectively, and the fiber winding torus I4 and the fiber winding torus II5 are equipped with four The opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com