Magnetorheological elastomer thrust bearing base dynamic vibration absorber and use method

A magneto-rheological elastomer and dynamic shock absorber technology, applied in the functional characteristics of spring/shock absorber, shock absorber, spring/shock absorber, etc., can solve unbalanced interference force, temperature rise, insufficient magnetic field strength, etc. problems, to achieve the effect of lengthening the heat dissipation path, increasing the heat dissipation area, and reducing radiation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The dynamic vibration absorber in the present invention is different from the way that the existing dynamic vibration absorber is fixed on the shaft system, and the dynamic vibration absorber is directly arranged on the thrust bearing base. Of course, the connection mode between the dynamic vibration absorber and the thrust bearing base is not the same It is not limited, and can be designed according to different styles of bearing bases. Therefore, the fixed connection between the dynamic vibration absorber and the thrust bearing base will not be repeated here. The dynamic vibration absorber and its components are further described in detail below.

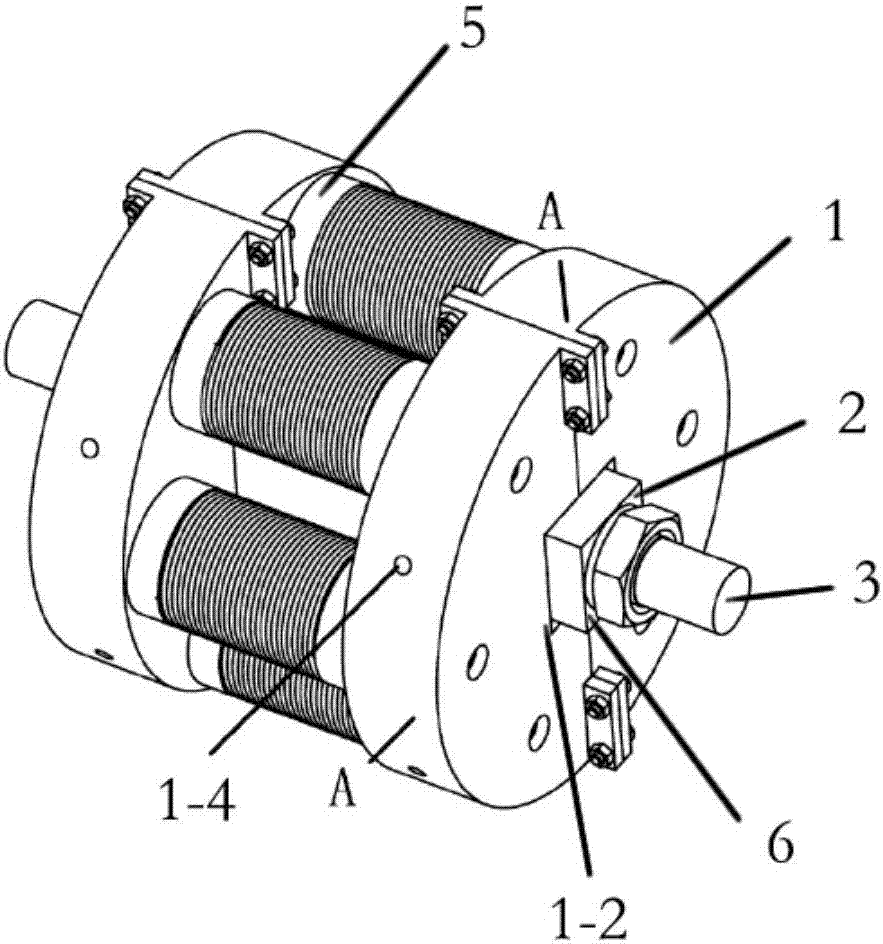

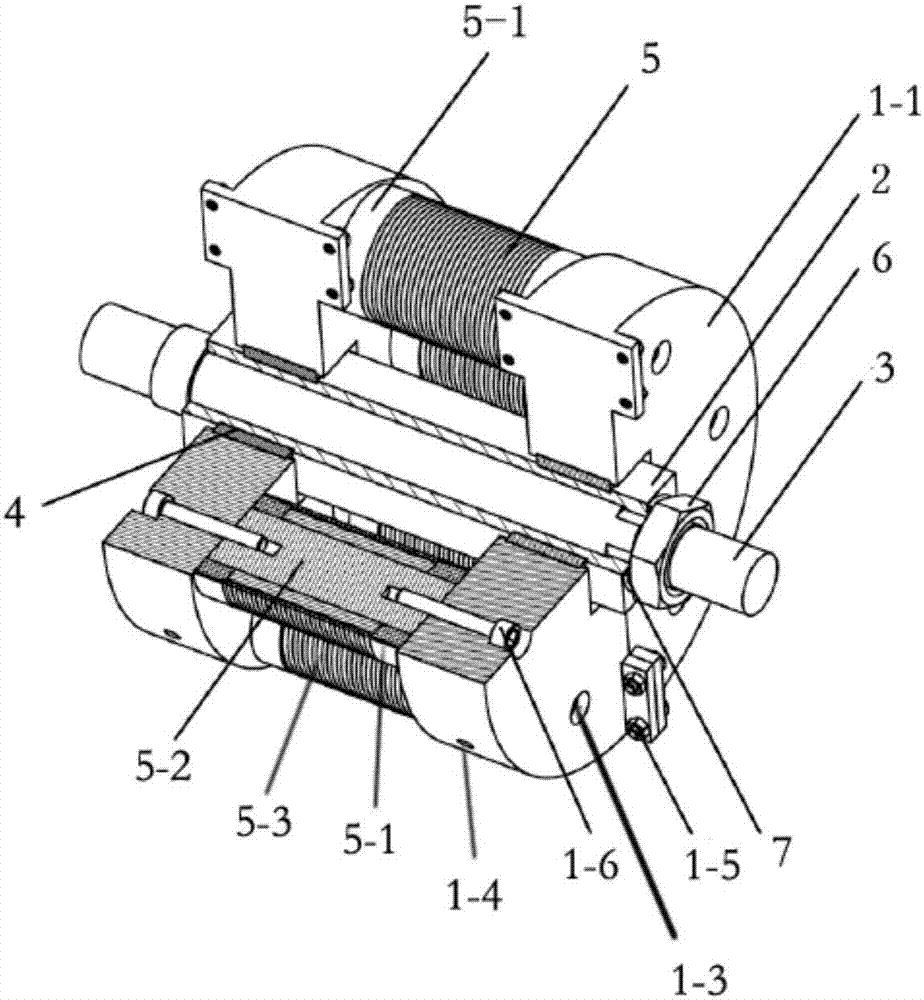

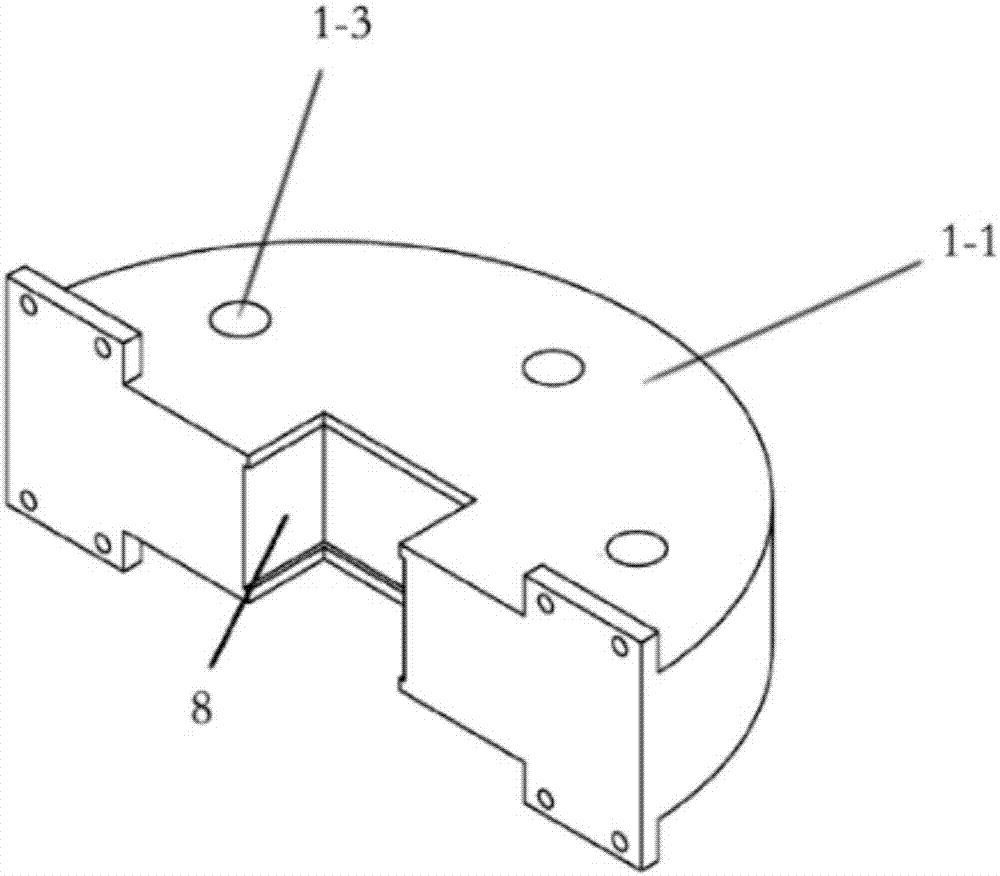

[0044] see figure 1 and figure 2 , the dynamic vibration absorber includes a yoke group 1, a magnetically isolated support shaft 3, a magnetically conductive sleeve 2, a magnetorheological elastomer 4, and an electromagnetic assembly 5, and the outer layer of the magnetically isolated support shaft 3 is provided with a ma...

Embodiment 2

[0053] The present invention also provides a method for using the dynamic vibration absorber of the magnetorheological elastomer thrust bearing base, which adopts the dynamic vibration absorber for the magnetorheological elastomer thrust bearing base in Embodiment 1, and the usage method includes the following steps:

[0054] a. Fix the dynamic vibration absorber on the horizontal vibration table, and connect the electromagnetic components 5 of the dynamic vibration absorber to the power supply to form a closed circuit;

[0055] b. The signal generator generates a vibration signal to excite the vibration of the horizontal vibration table, continuously changes the magnitude of the input current, detects the natural frequency of the dynamic vibration absorber under different currents, and draws the frequency shift characteristic curve of the dynamic vibration absorber;

[0056] c. Fix the dynamic vibration absorber on the thrust bearing base, keep the connection between the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com