Inner screen continuous type coil adopting fractional turn integer winding method and winding method thereof

A winding method and fractional turn technology, applied to the field of inner screen continuous coil and its winding, can solve the problems of low filling rate of few turns, thick insulation of screen turns, increase winding difficulty, etc., and achieve obvious improvement effect. , Small insulation thickness, the effect of reducing the cost of the coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

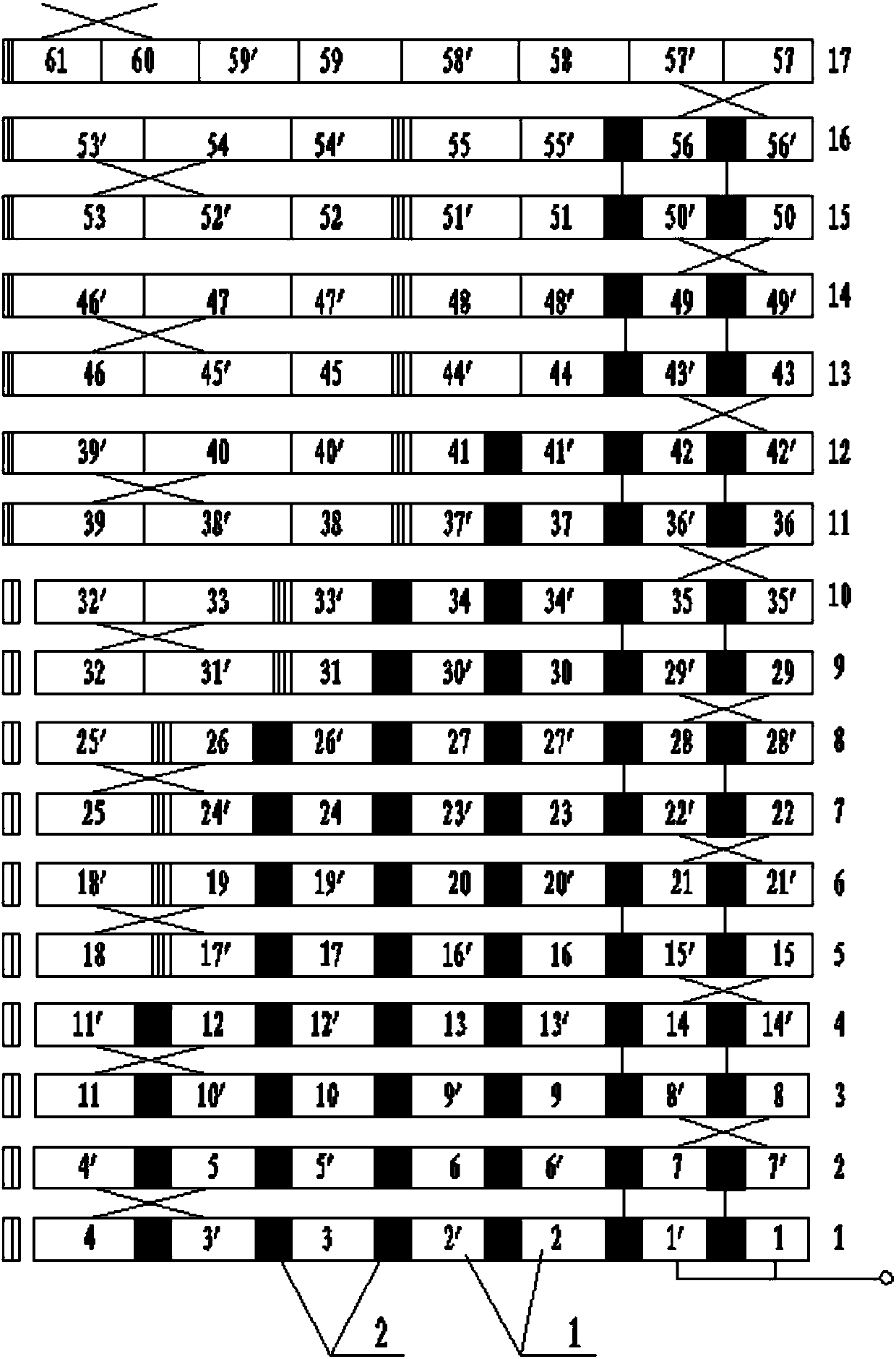

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0018] The present invention is an inner screen continuous coil adopting the fractional-turn integer winding method, which has a working wire 1 and a screen wire 2, the working wire 1 is two wires wound in parallel, and the screen wire 2 is arranged between the turns and the wires of the working wire .

[0019] At the line-changing section of working line 1, one of the two parallel-wound working lines winds one more turn and then rises to the next section, and the other directly rises to the next section, forming a structure of integer plus half-turn.

[0020] The above-mentioned winding method of the inner screen continuous coil using the fractional-turn integer winding method has a working wire 1 and a screen wire 2. The working wire 1 is wound in parallel by two wires, and the screen wire 2 is wound by two parallel wires, that is, the screen wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com