Bead-like porous PLA (Poly Lactic Acid) nano fiber as well as preparation method and application thereof

A nanofiber and bead-like technology, which is applied in the field of beaded porous PLA nanofiber and its preparation, to achieve the effects of facilitating circulation, reducing filling rate, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

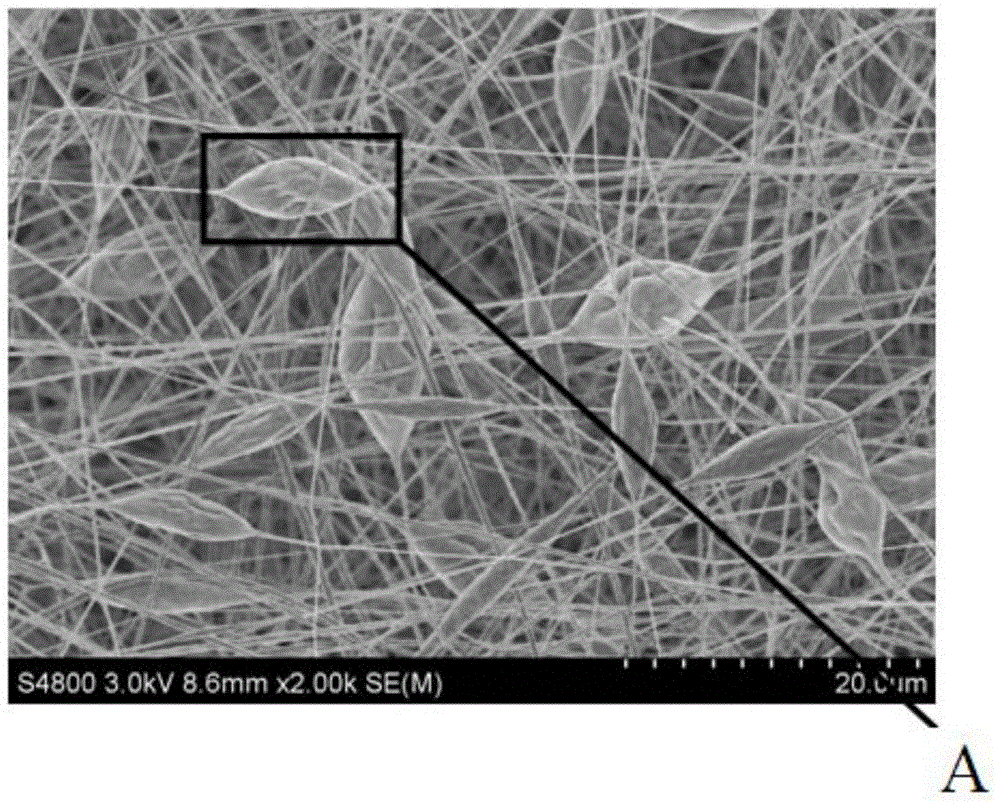

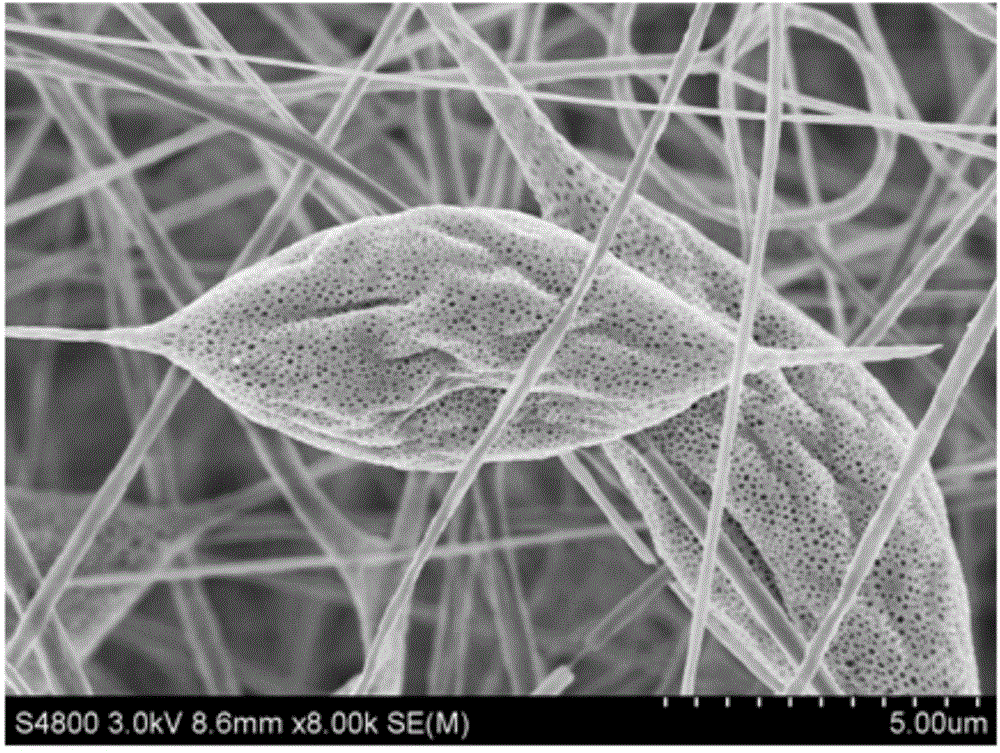

[0037] Embodiment 1: a kind of preparation method of beaded porous PLA nanofiber, its steps are as follows:

[0038] 1) Preparation of spinning solution

[0039] Mix dichloromethane and N,N-dimethylacetamide in a mass ratio of 10:1 as a mixed solvent, weigh 0.5 g of PLA polymer particles and dissolve them in 9.5 g of the above mixed solvent, and then Under stirring with a magnetic stirrer, a uniformly mixed transparent solution (spinning solution) with a mass fraction of 5% was prepared.

[0040] 2) Preparation of beaded porous PLA nanofiber air filtration membrane

[0041] The spinning solution prepared in step 1) is subjected to electrospinning, and the process conditions of electrospinning are as follows:

[0042] Electrospinning was carried out under the conditions of spinning voltage of 15kV, spinning liquid flow rate of 1ml / h, collection roller speed of 5.5m / min, and spinning distance of 12cm.

[0043] The conventional horizontal electrospinning method is adopted, and t...

Embodiment 2

[0047] Embodiment 2: a kind of preparation method of beaded porous PLA nanofiber, its steps are as follows:

[0048] 1) Preparation of spinning solution

[0049] Dichloromethane and N,N-dimethylacetamide are mixed in a mass ratio of 10:1 as a mixed solvent, and 0.45g of PLA polymer particles are weighed, dissolved in 9.55g of the mixed solvent, and then A homogeneously mixed transparent solution (spinning solution) with a mass fraction of 4.5% was prepared by stirring with a magnetic stirrer at room temperature.

[0050] 2) Preparation of beaded porous PLA nanofiber air filtration membrane

[0051] The spinning solution prepared in step 1) is subjected to electrospinning, and the process conditions of electrospinning are as follows:

[0052] Electrospinning was carried out under the conditions of a spinning voltage of 15kV, a spinning solution flow rate of 1ml / h, a collection roller speed of 5.5m / min, and a spinning distance of 12cm.

[0053] The conventional horizontal ele...

Embodiment 3

[0056] Embodiment 3: a kind of preparation method of beaded porous PLA nanofiber, its steps are as follows:

[0057] 1) Preparation of spinning solution

[0058] Mix dichloromethane and N,N-dimethylacetamide in a mass ratio of 10:1 as a mixed solvent, weigh 0.55g of PLA polymer particles and dissolve them in 9.45g of mixed solvent, and then pass through Stirring with a magnetic stirrer prepared a homogeneously mixed transparent solution (spinning solution) with a mass fraction of 5.5%.

[0059] 2) Preparation of beaded porous PLA nanofiber air filtration membrane

[0060] The spinning solution prepared in step 1) is subjected to electrospinning, and the process conditions of electrospinning are as follows:

[0061] Electrospinning was carried out under the conditions of spinning voltage 15kV, spinning solution flow rate 1ml / h, collection roller speed 5.5m / min, and spinning distance 12cm.

[0062] The conventional horizontal electrospinning method is adopted, and the convent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com