Polyurethane flexible foam material for railway curing ballast bed and preparation method thereof

A polyurethane soft foam and ballast bed technology, which is applied in the field of solidified ballast bed materials, can solve the problems of wasting fatigue resistance, high cost, and difficult maintenance of foundation arches, etc., and achieve superior fatigue resistance, benefit health, and reduce toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A polyurethane flexible foam material for railway solidified ballast bed, composed of 100 parts of material A and 86 to 91 parts of material B in parts by mass; wherein,

[0050] Described A material is made up of following material by mass parts:

[0051] 100 parts of polyether polyol, 30-40 parts of castor oil and its derivative polyol, 20-30 parts of expanded graphite, 4-8 parts of 1,4-butanediol, 1.75-2.75 parts of water, 0.6-1.2 parts of catalyst , the catalyst is made up of triethylenediamine solution (solution concentration is 33%) and dibutyltin dilaurate;

[0052] The B material is composed of the following materials in parts by mass:

[0053] 57-63 parts of 4,4-diphenylmethane diisocyanate, 37-43 parts of polyether polyol;

[0054] Wherein, in the A material, the polyether polyol is composed of the following materials in parts by mass:

[0055] Polyoxypropylene and oxyethylene copolymer polyol with a number average molecular weight of 4800 24-32 parts

[0...

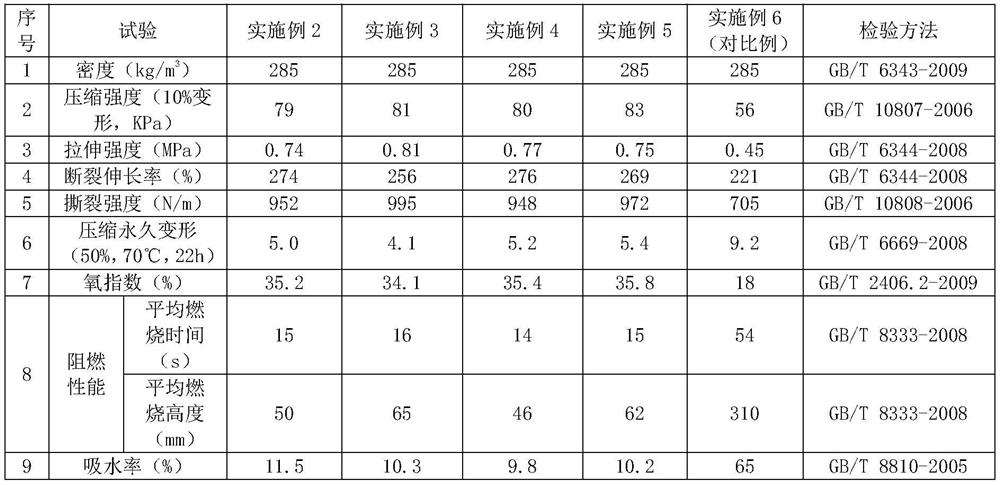

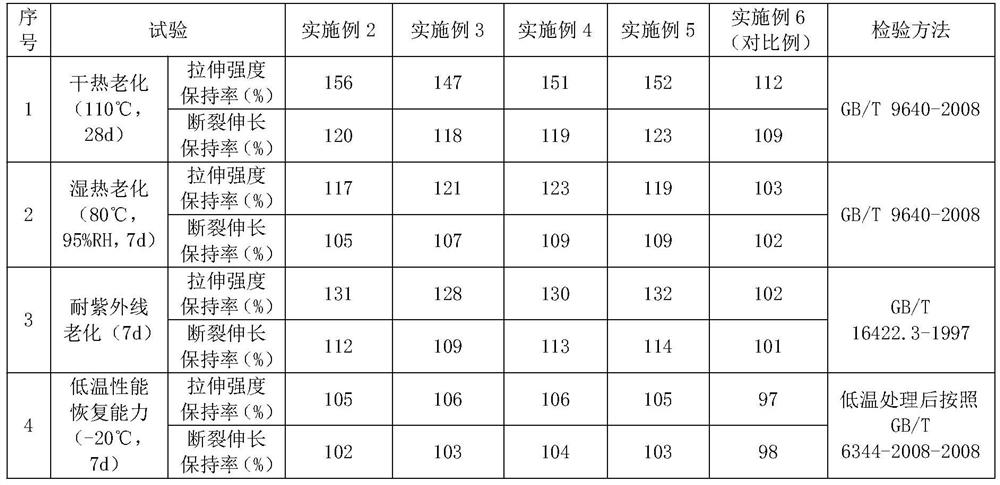

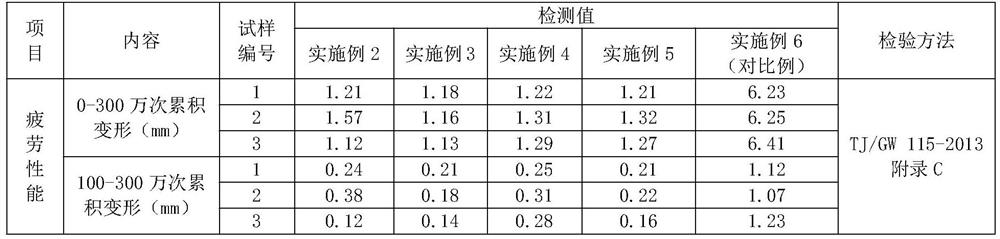

Embodiment 2

[0077] A kind of polyurethane flexible foam material for railway solidified ballast bed, is made up of 100 parts of A material and 86 parts of B material by mass parts; Wherein,

[0078] Described A material is made up of following material by mass parts:

[0079] Polyoxypropylene and oxyethylene copolymer polyol with a number average molecular weight of 4800... 28 parts

[0080] Polytetrahydrofuran diol with a number average molecular weight of 1000…………………… 32 parts

[0081] Polytetrahydrofuran diol with a number average molecular weight of 2000………………… 40 parts

[0082] Castor oil and its derivatives polyols…………………………………… 30 parts

[0083] Expanded graphite ……………………………………………………… 25 servings

[0084] 1,4-Butanediol………………………………………………………………… 8 parts

[0085] Water ……………………………………………………………… 1.75 parts

[0086] Triethylenediamine solution (concentration of solution is 33%)……………………… 0.3 parts

[0087] Dibutyltin Dilaurate……………………………………………………………………………………………………………………………………………………...

Embodiment 3

[0098] A kind of polyurethane flexible foam material for railway solidified ballast bed, is made up of 100 parts of A material and 91 parts of B material by mass parts; Wherein,

[0099] Described A material is made up of following material by mass parts:

[0100] Polyoxypropylene and oxyethylene copolymer polyol with a number average molecular weight of 4800... 32 parts

[0101] Polytetrahydrofuran diol with a number average molecular weight of 1000…………………… 36 parts

[0102] Polytetrahydrofuran diol with a number average molecular weight of 2000…………………… 32 parts

[0103] Castor oil and its derivatives polyols…………………………………… 35 parts

[0104] Expanded graphite……………………………………………………………………………… 20 servings

[0105] 1,4-Butanediol…………………………………………………………………………………………………………………………………………………………………………………………………………………………

[0106] Water …………………………………………………………………… 2.25 parts

[0107] Triethylenediamine solution (concentration of solution is 33%)……………………… 0.4 parts

[0108] Dibutyltin Dilau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com