Symmetrical all-fiber Fabry-Perot sensor and manufacturing method thereof

The technology of a Fab sensor and its manufacturing method is applied in the direction of using optical devices to transmit sensing components, etc., which can solve the problems of high manufacturing cost and achieve the effects of low stripe fineness, small structure, and symmetrical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

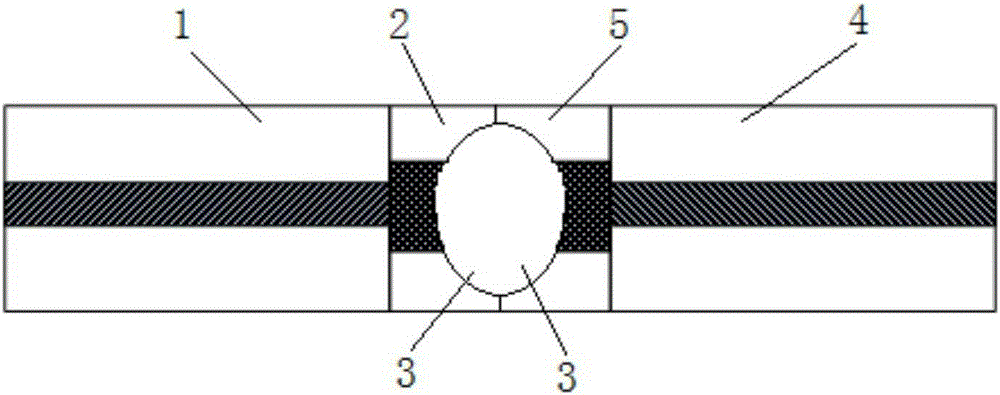

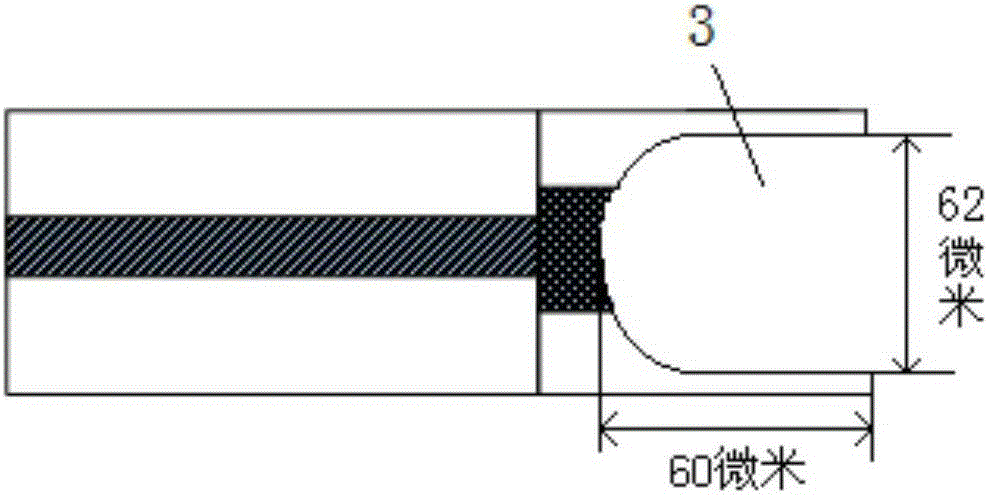

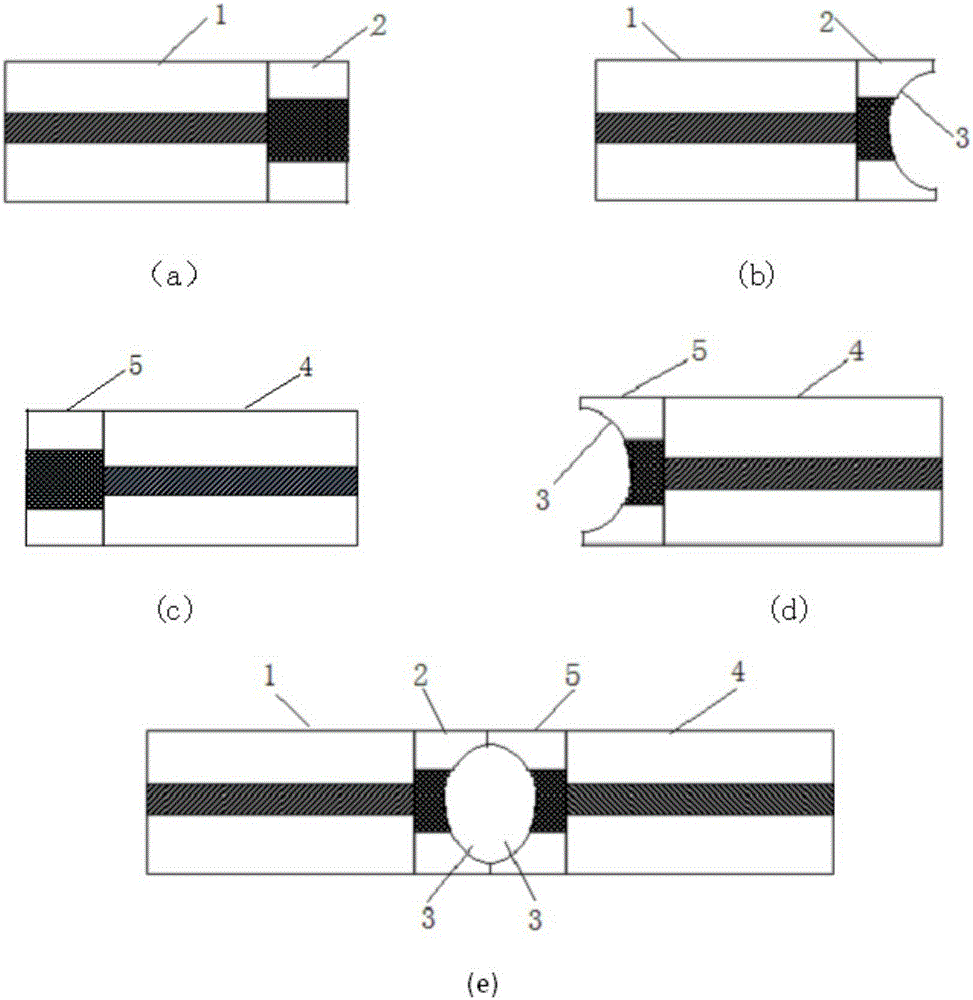

[0026] Such as figure 1 , figure 2 As shown, a symmetrical all-fiber Fab sensor includes: a first single-mode fiber 1, a first multimode fiber 2, a second single-mode fiber 4 and a second multimode fiber 5, and the first single-mode fiber 1 and the first multimode optical fiber 2 are welded by an optical fiber fusion splicer, and the end face of the first multimode optical fiber 2 is corroded with a concave cavity 3, and the second single-mode optical fiber 4 is also fused with the second multimode optical fiber 5, and the A cavity 3 is corroded on the end face of the second multimode optical fiber 5; the length of the cavity 3 is set to 60 microns, the end face of the cavity 3 is set to a circular structure, and the diameter of the end face is set to 62 microns. The first multimode optical fiber 2 and the second multimode optical fiber 5 are butt-connected together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com