Patents

Literature

210results about How to "Solve high precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SoC power management ensuring real-time processing

InactiveUS20080022140A1Accurate calculationLeak power can notEnergy efficient ICTVolume/mass flow measurementResource managementTime processing

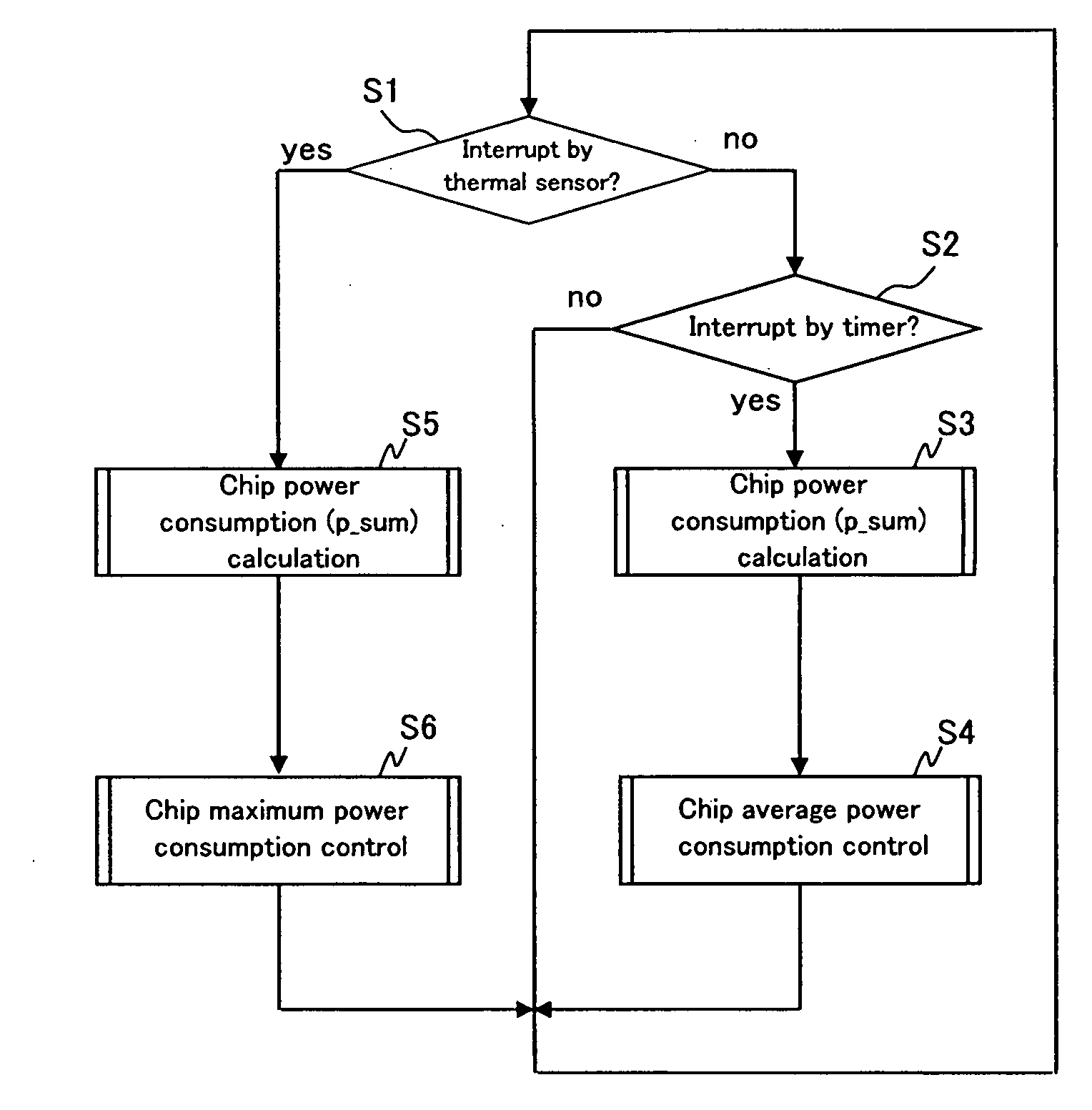

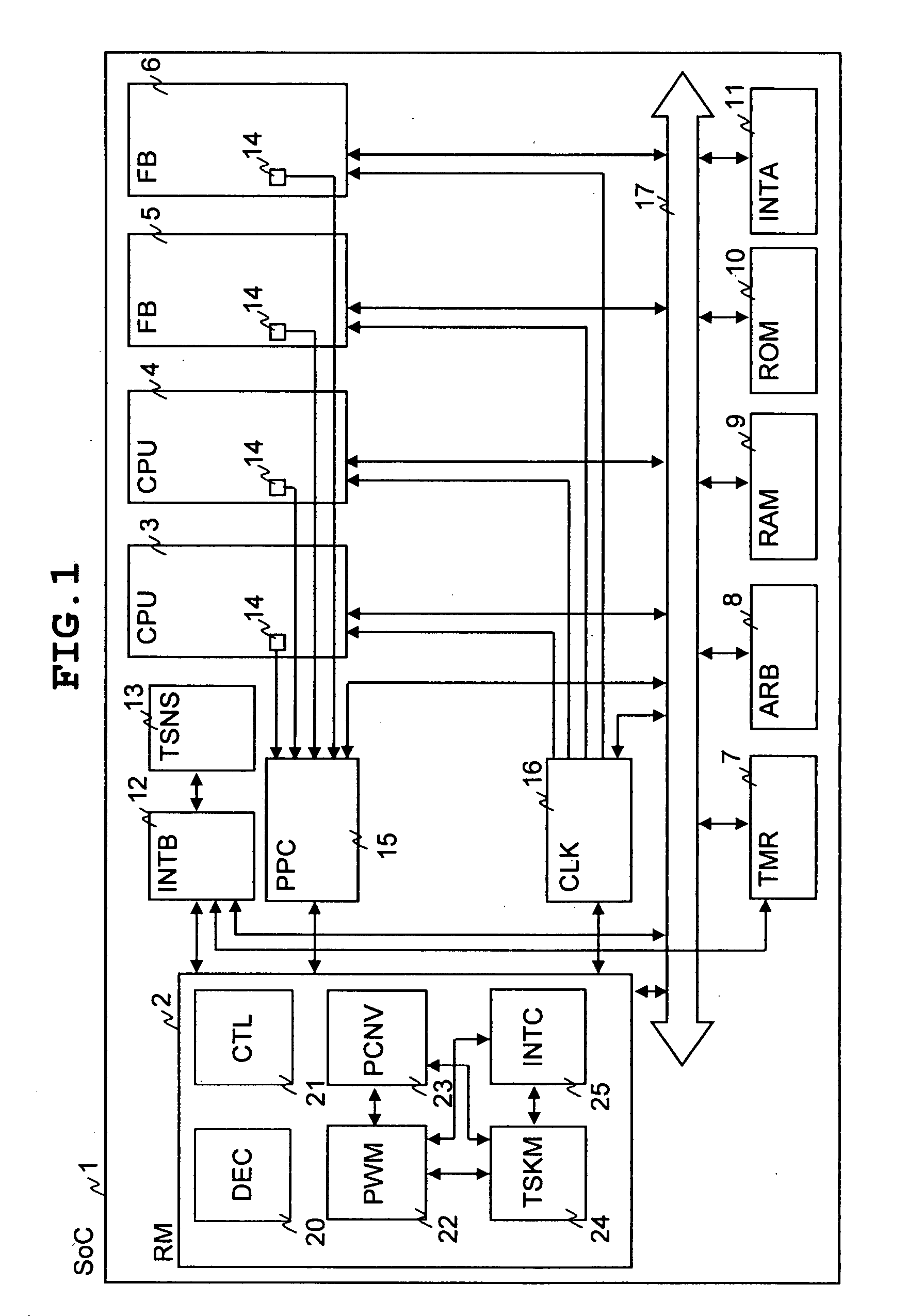

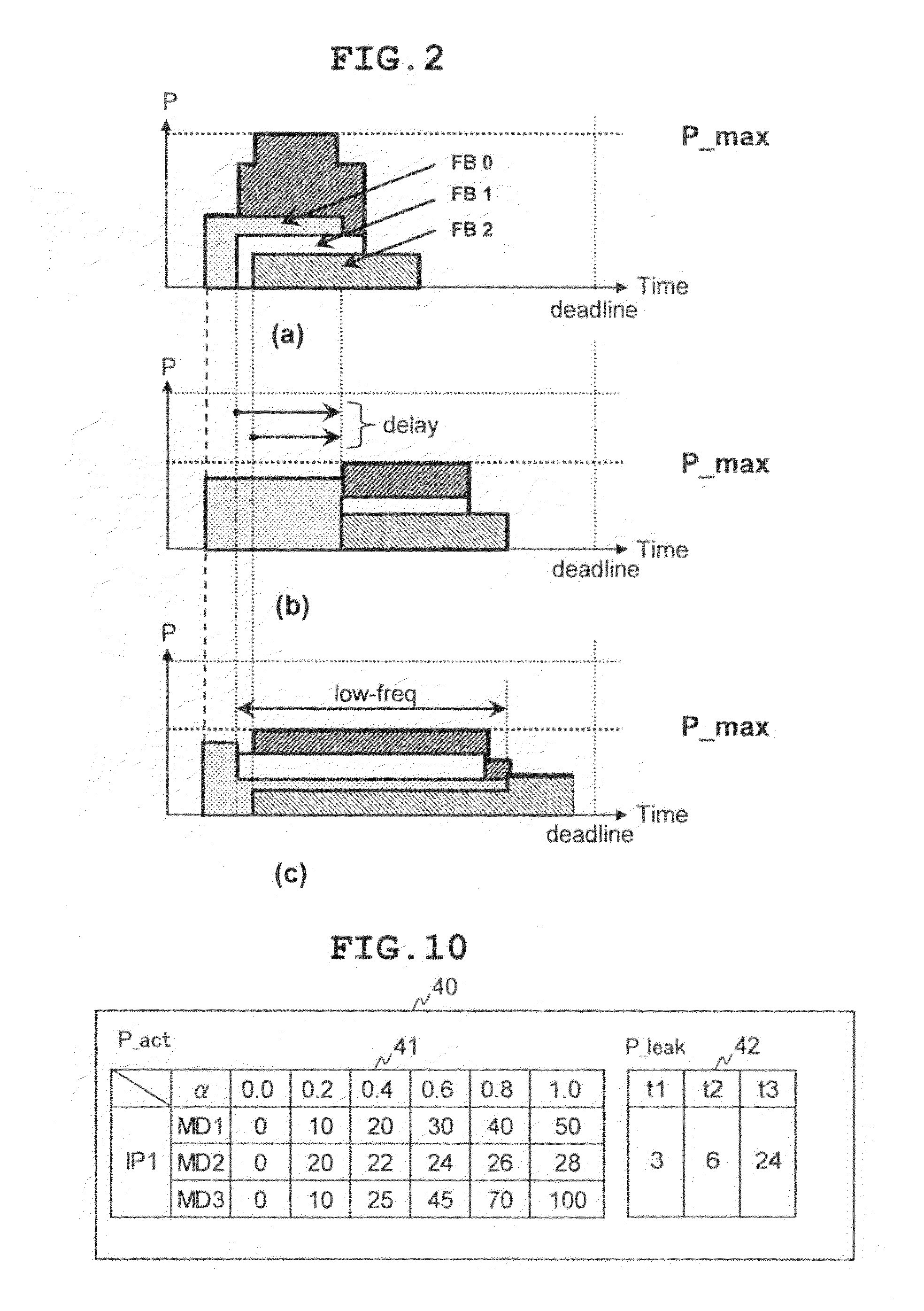

A chip (1) includes: a resource manager (2); various kinds of functional blocks (3-6); a thermal sensor (13); and a performance counter (15). The resource manager manages tasks that the functional blocks execute, and determines a task progress (38) for each task from an activated ratio (α) provided from the performance counter and a deadline (39) contained in task information (33) and decides priority of each task. When the temperature detected by the thermal sensor during execution of a task is not less than a threshold (T_max), the resource manager reads out a power consumption budget (P_max) from a memory (9) which has been set to make the temperature below the threshold, and stops the clock fed to the functional block executing a task having a lower priority or lowers the frequency of the clock until a chip power consumption value (p_sum) becomes smaller than the power consumption budget.

Owner:RENESAS ELECTRONICS CORP

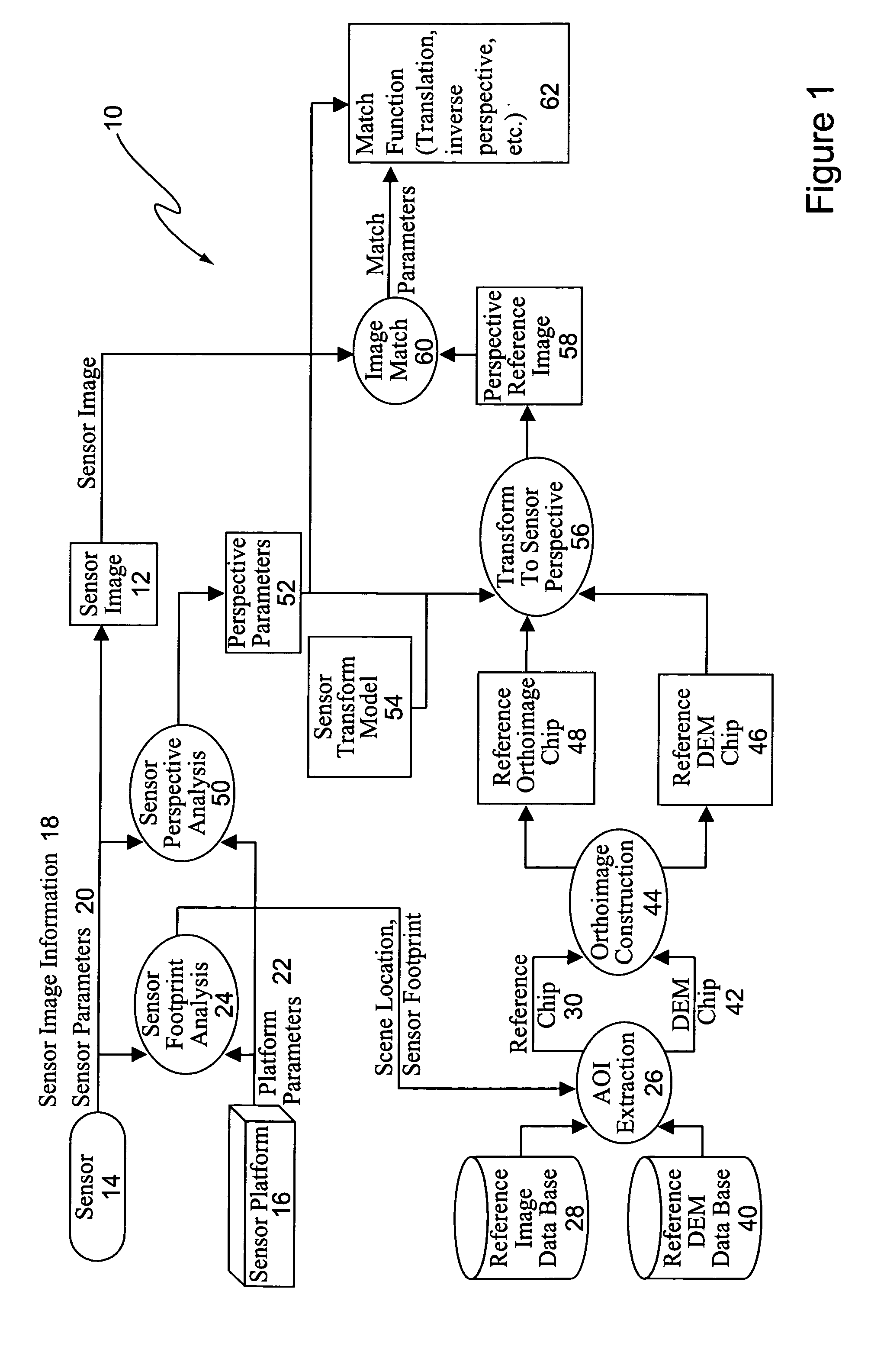

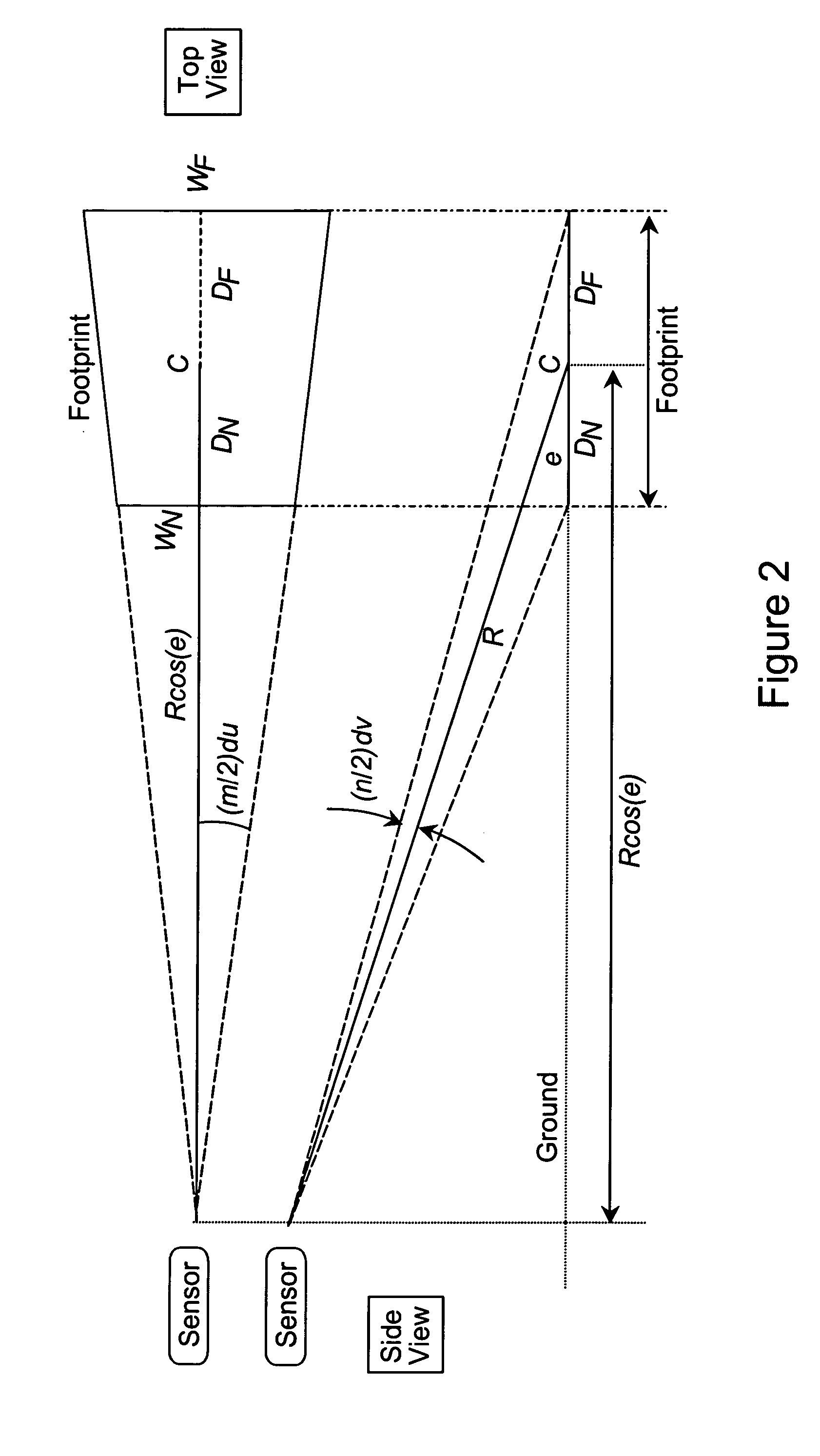

Processing architecture for automatic image registration

InactiveUS20050220363A1Improve accuracyPrecise positioningImage analysisPhotogrammetry/videogrammetryReference imageAutomatic image registration

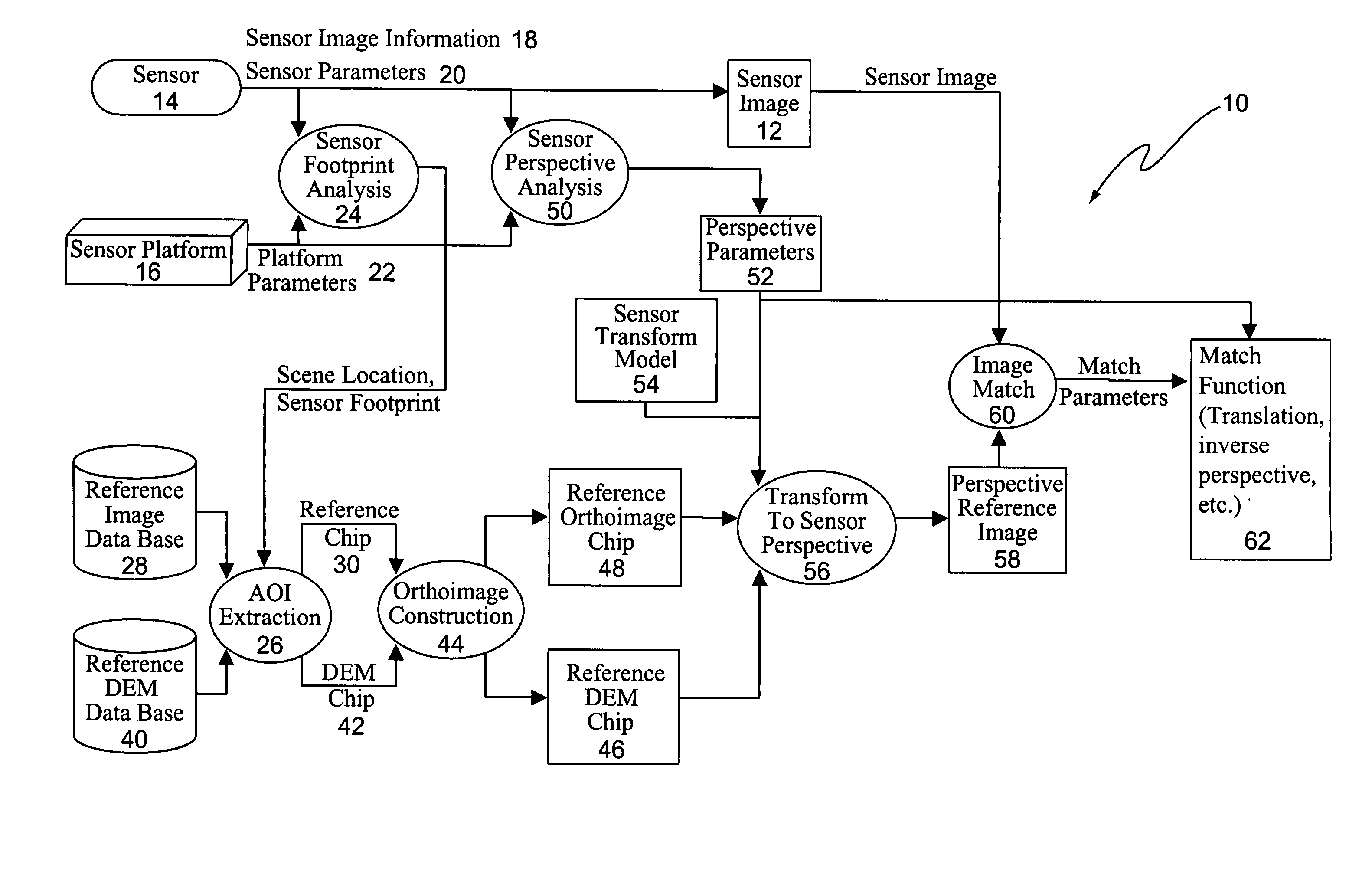

An image registration method and apparatus for automatically registering images of different perspectives, and where a sensor image is registered with a more precise reference image such that the geocoding of the reference image can be transferred to the sensor image.

Owner:THE BOEING CO

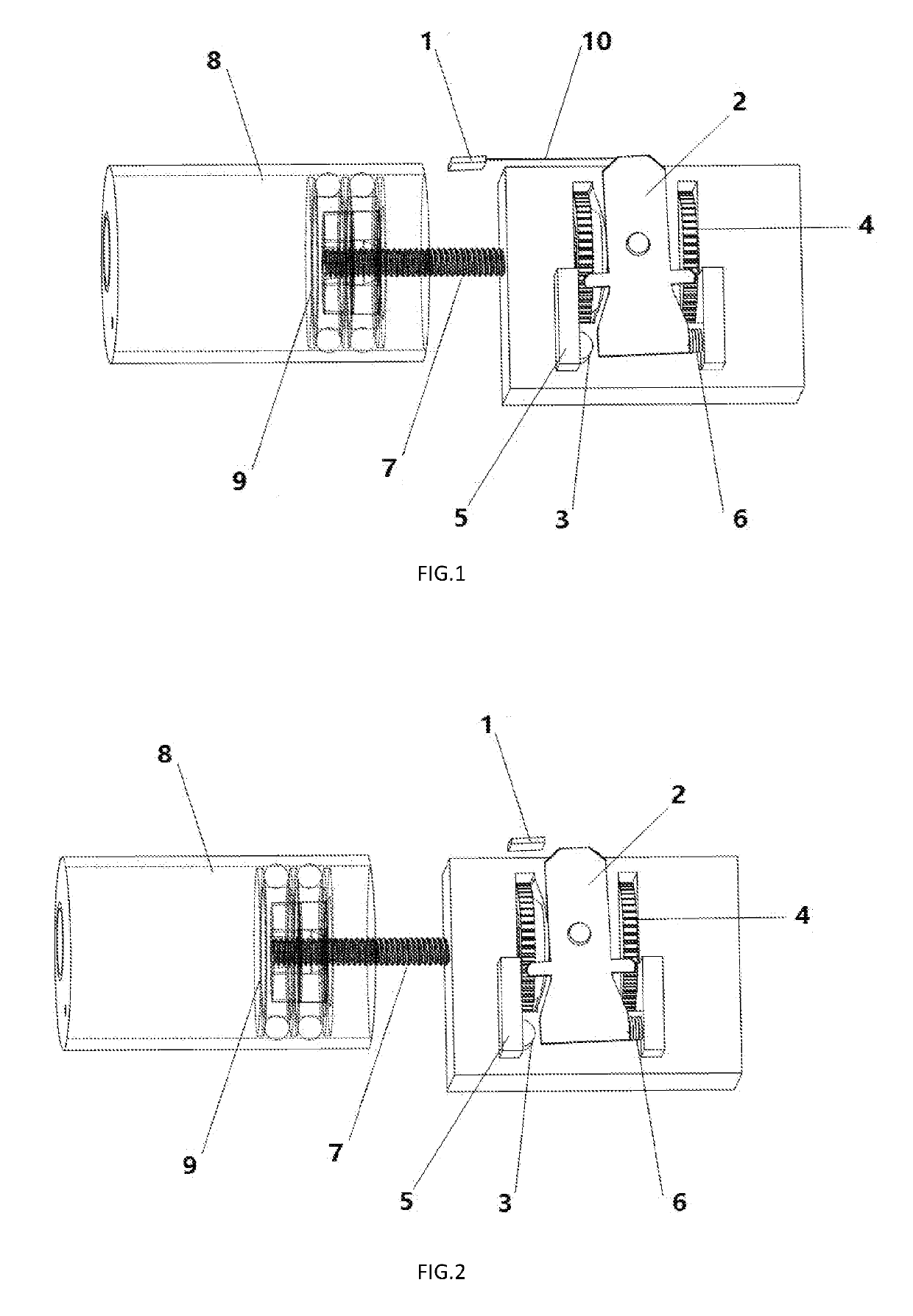

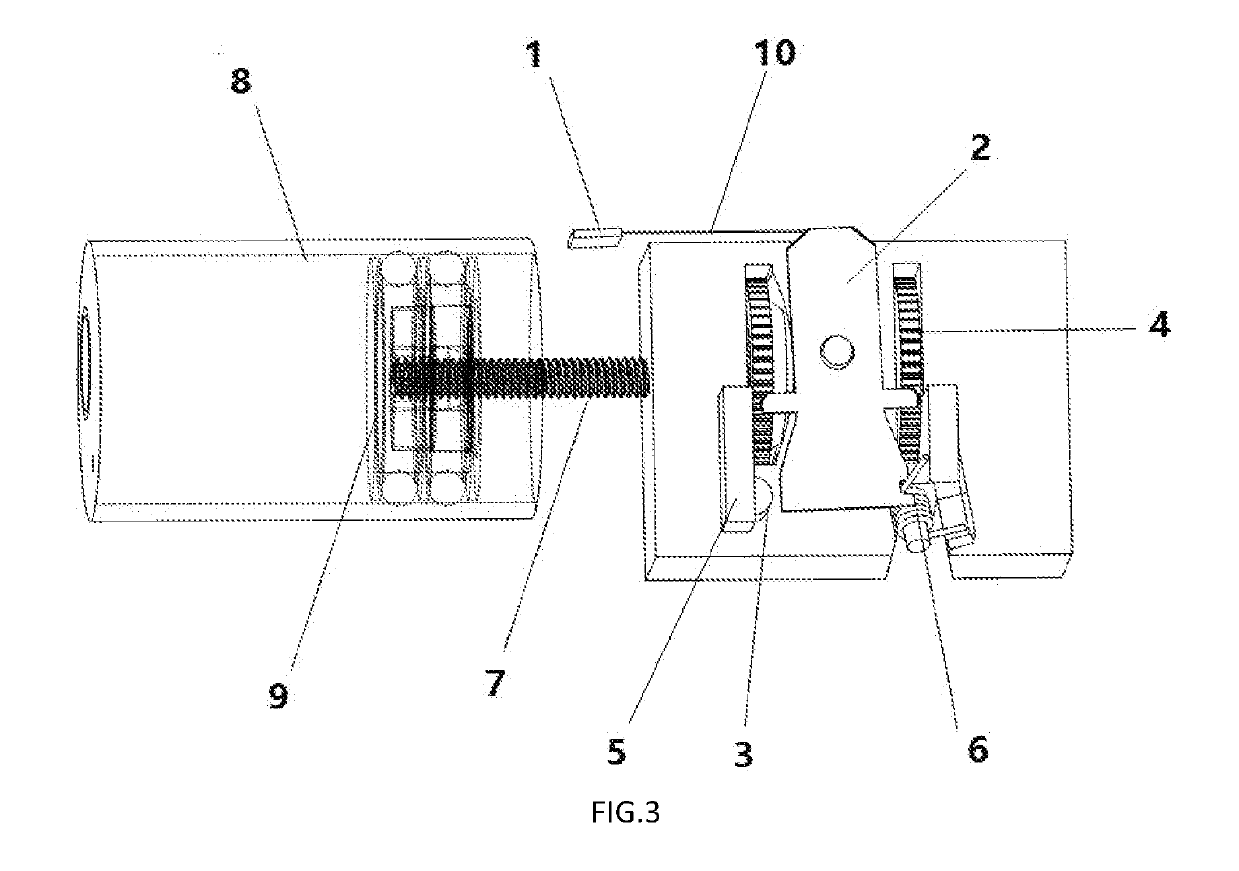

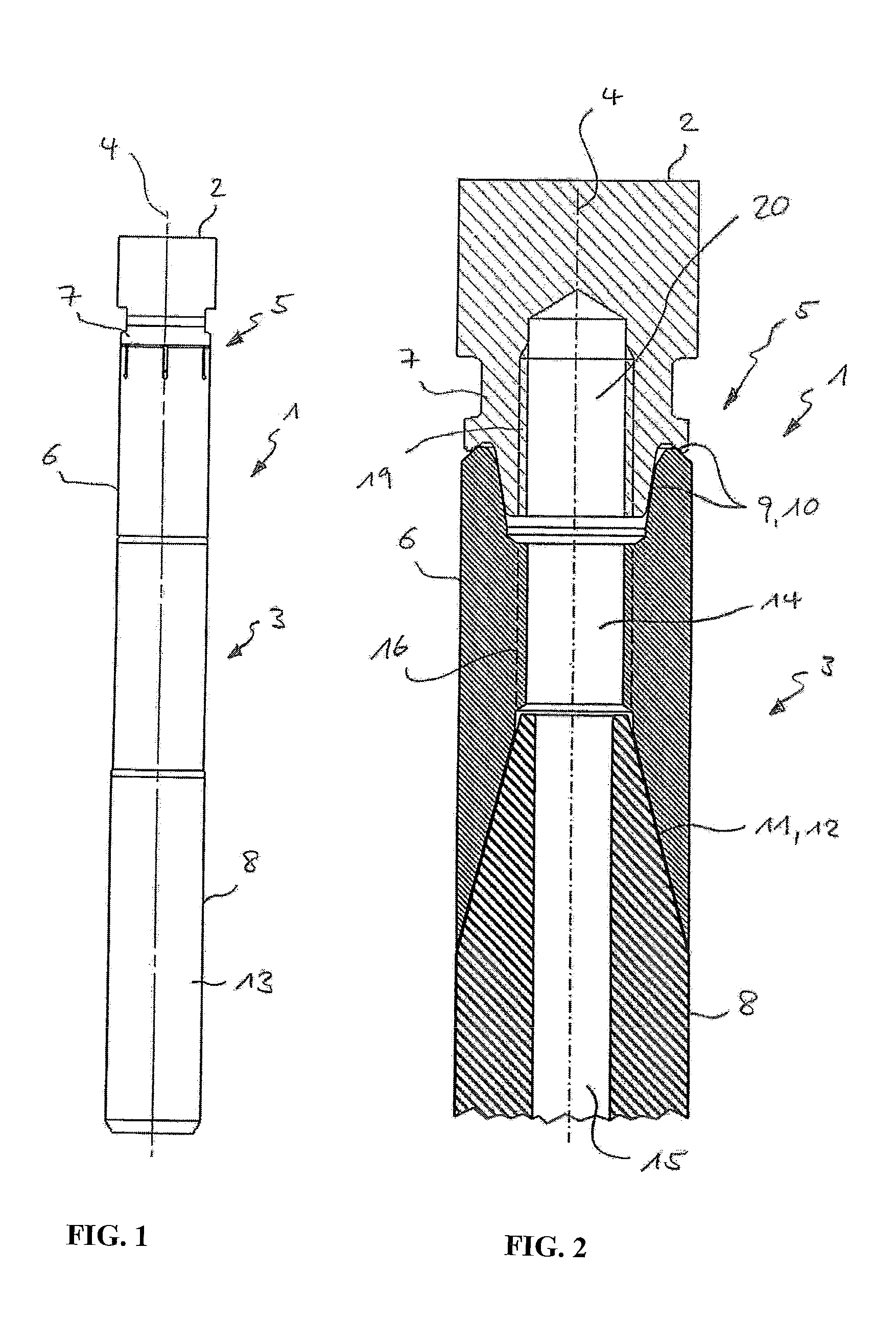

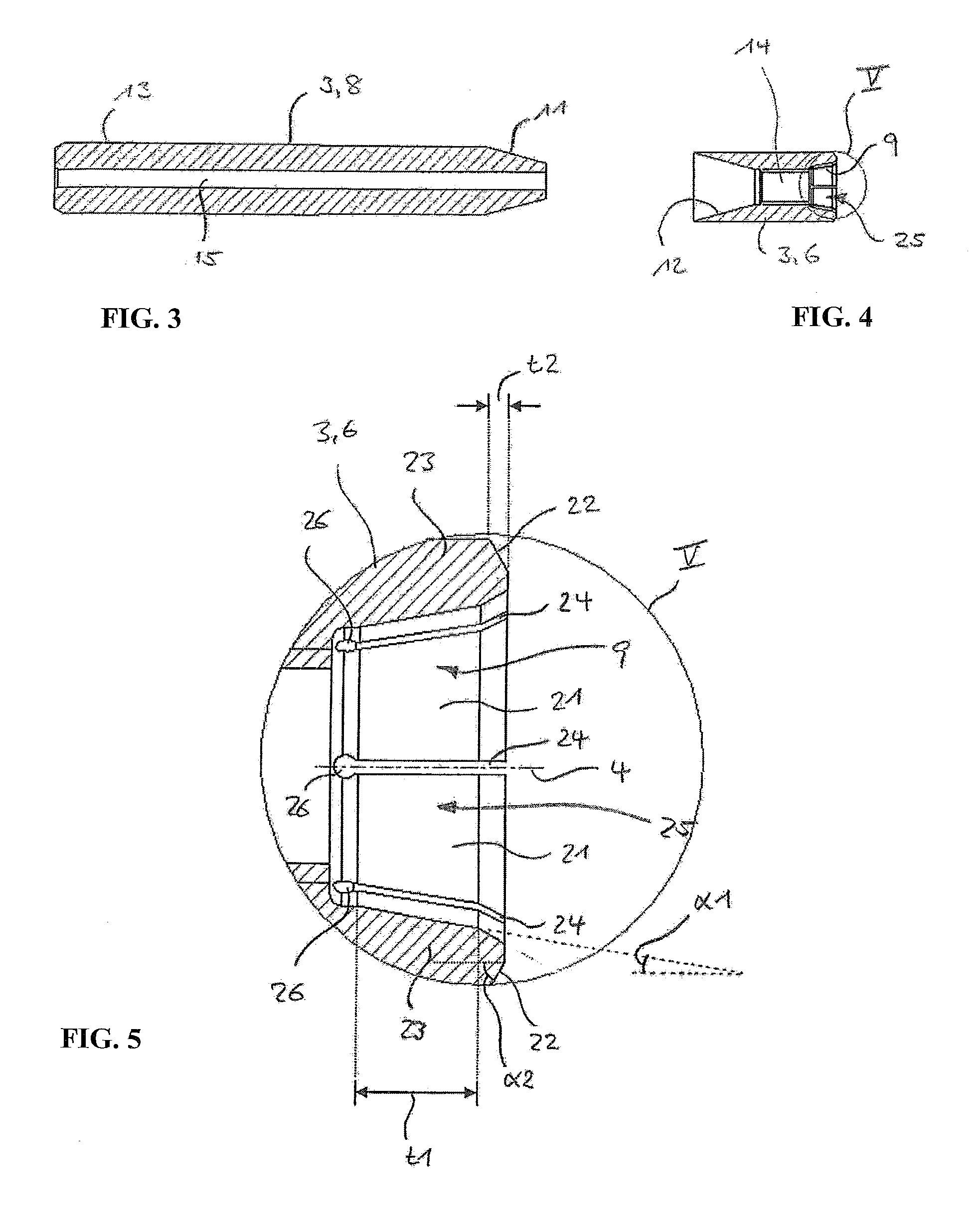

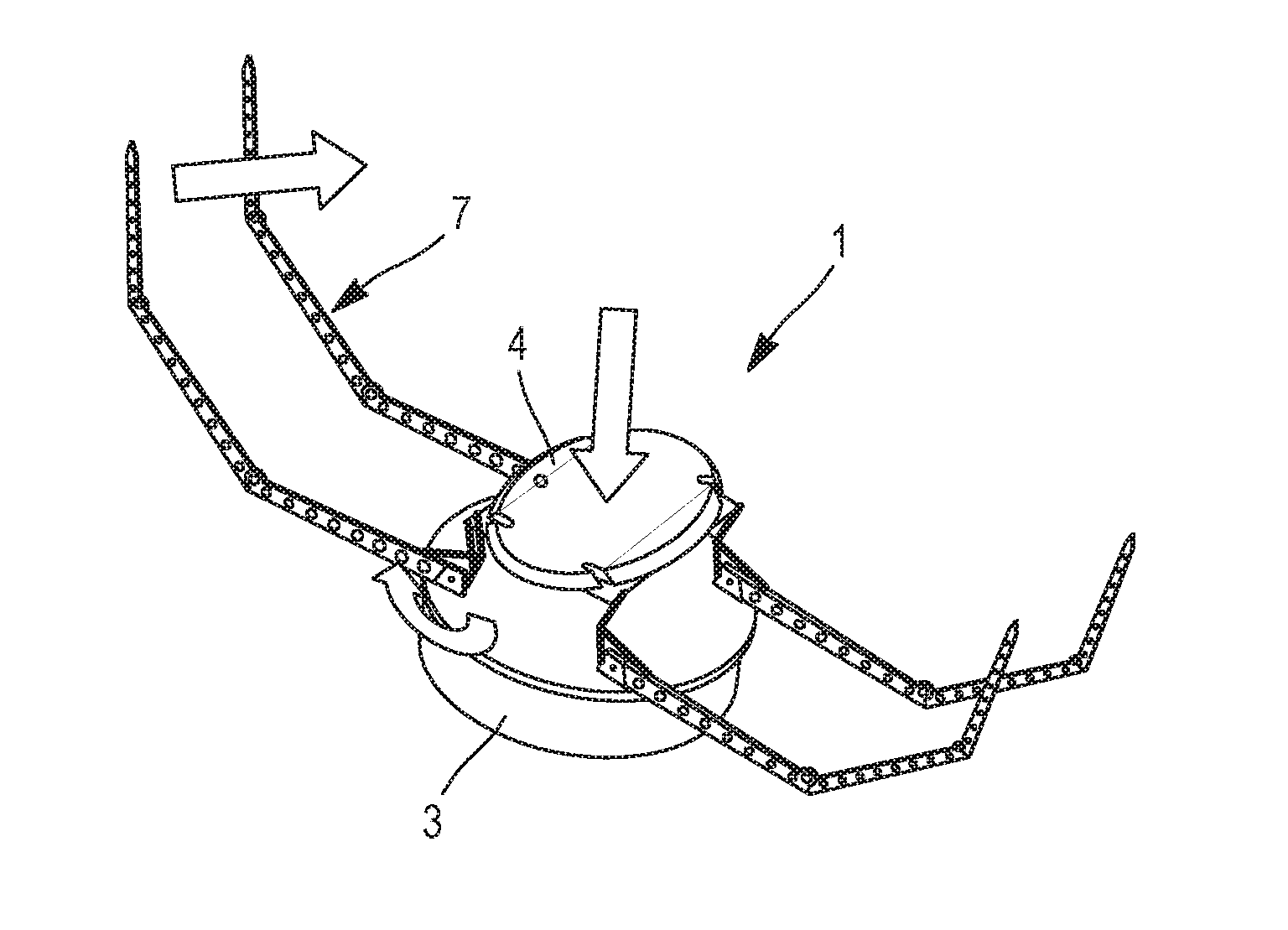

Unilateral driving mechanism for a portable infusion system

ActiveUS20190117881A1Increase in sizeIncrease power consumptionPressure infusionFlow controlGear wheelEngineering

A unilateral driving mechanism for a portable infusion system is provided. The unilateral driving mechanism comprises an actuator (1), a swinging part (2), gears (4), blockers (5), a compression spring (6), a rod (7), a reservoir (8), a plunger (9) and a control circuit. One end of the rod (7) is connected with the gears (4), the other end of the rod (7) is connected with the plunger (9), and one lower limb of the swinging part (2) is connected with the spring (6). The unilateral driving mechanism for a portable infusion system has advantages of compact structure, small volume, low power consumption, low cost, high precision and convenience in use.

Owner:MEDTRUM TECH

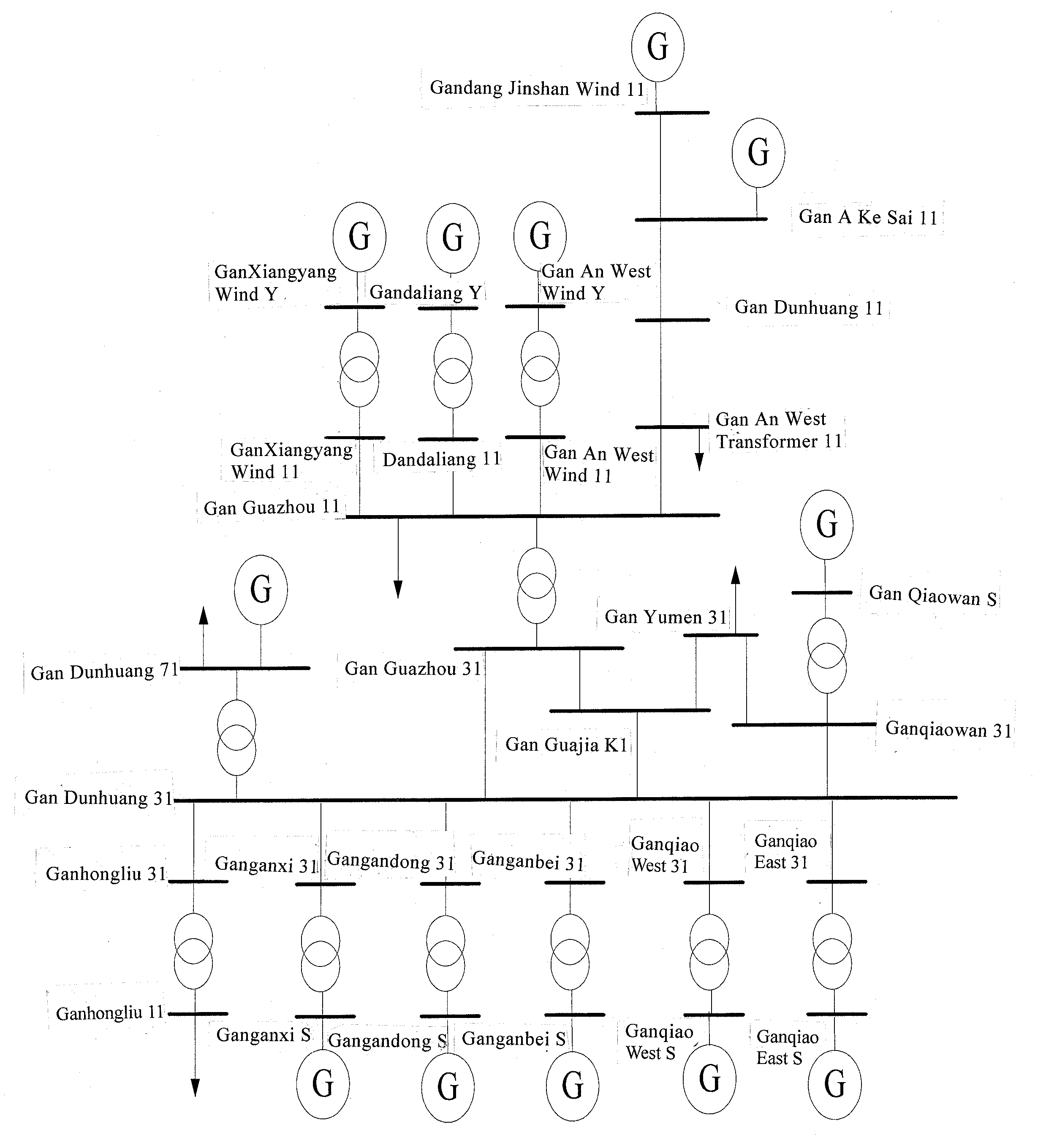

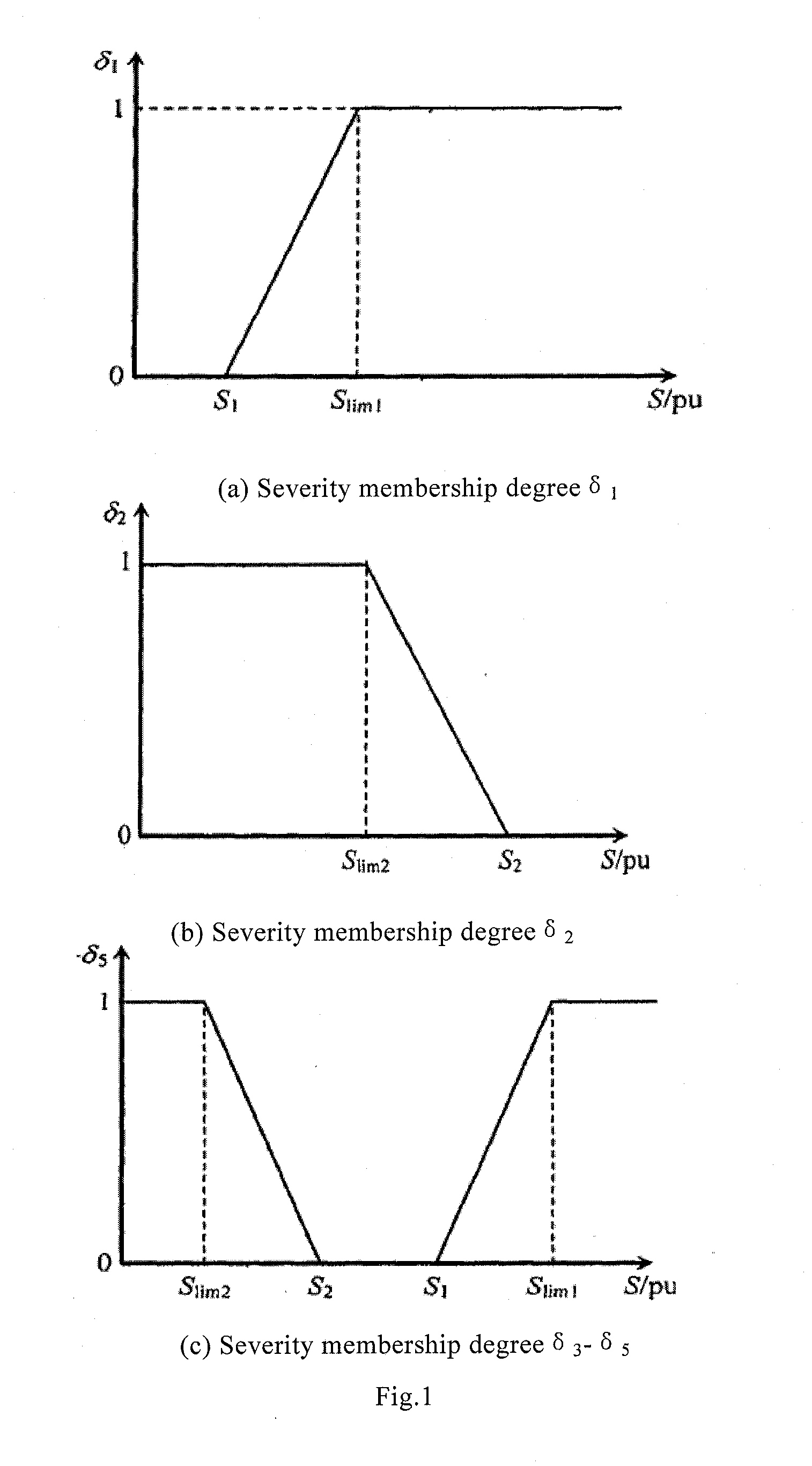

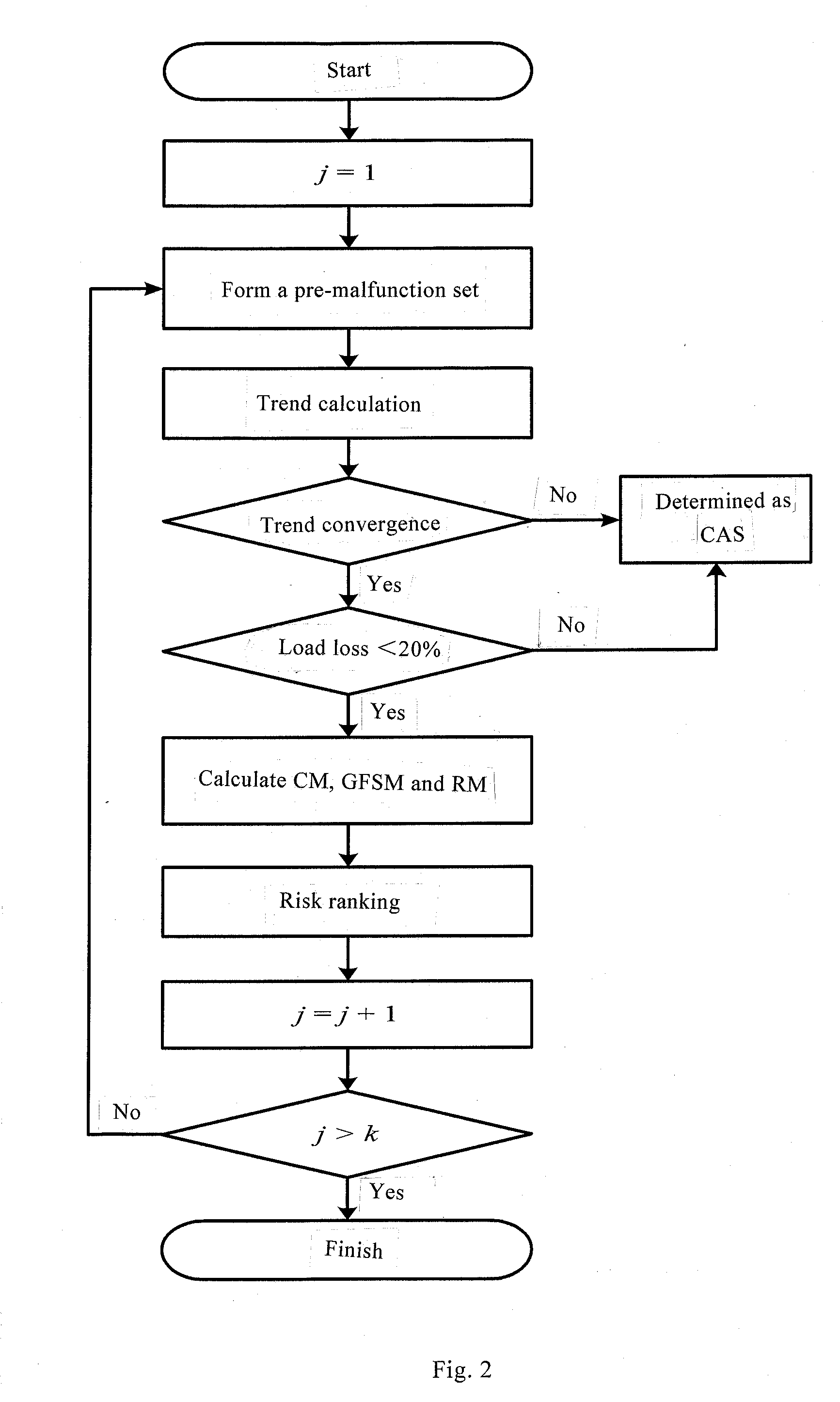

Svc compensation strategy optimization method

InactiveUS20160094033A1Improve reliabilityImprove accuracyFlexible AC transmissionNuclear monitoringDependabilityCompensation strategy

An SVC compensation strategy optimization method, comprising: calculating a weak voltage node in a fault state based on risk measure; calculating the weak voltage node in a normal state based on a static stability margin; and determining an optimal SVC distribution point and calculating the optimal configuration of SVC capacity. The SVC compensation strategy optimization method overcomes the defects in the prior art, such as low reliability, low optimization precision, poor applicability, etc., and has the advantages of high reliability, high optimization precision, and good applicability.

Owner:STATE GRID CORP OF CHINA +3

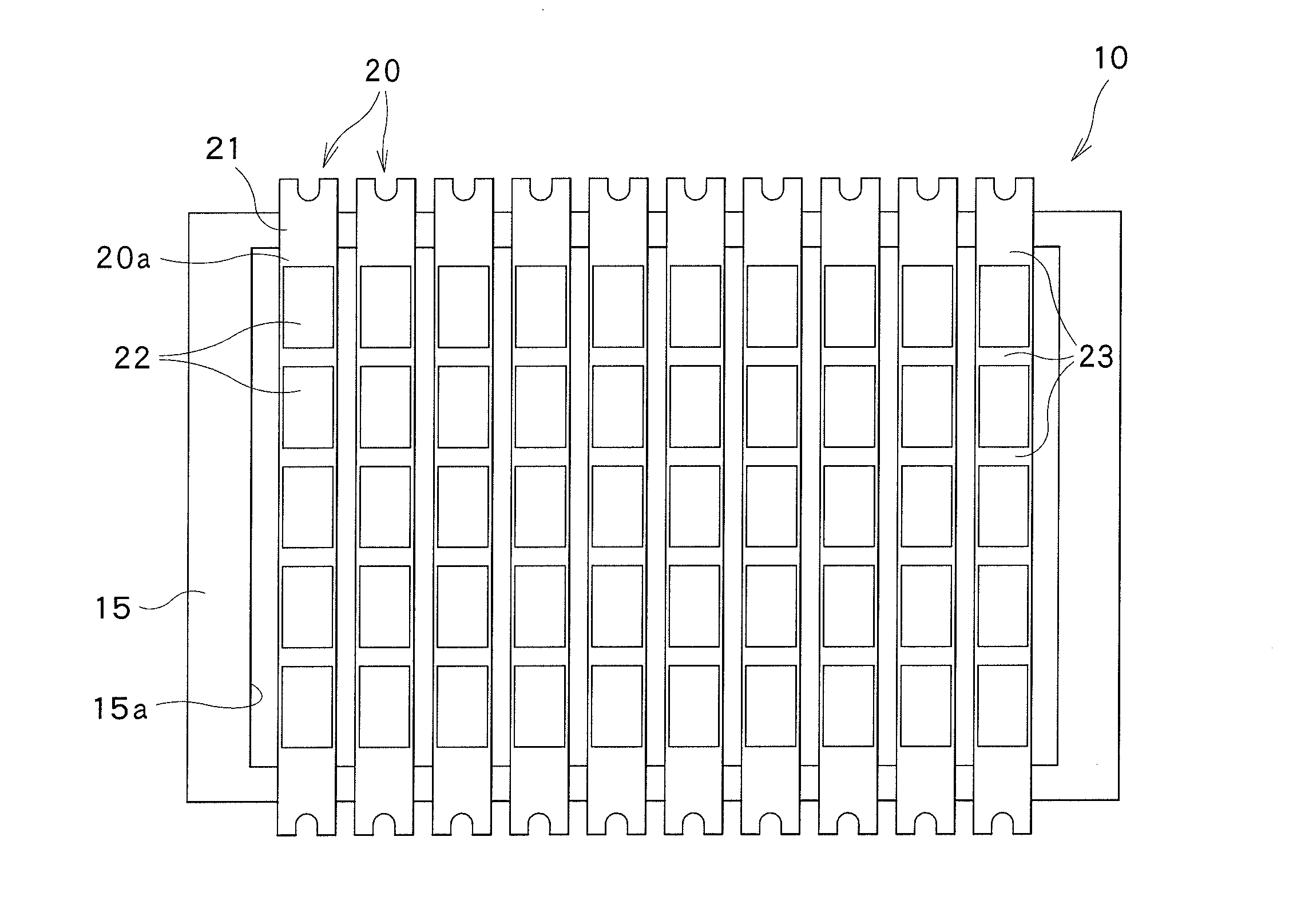

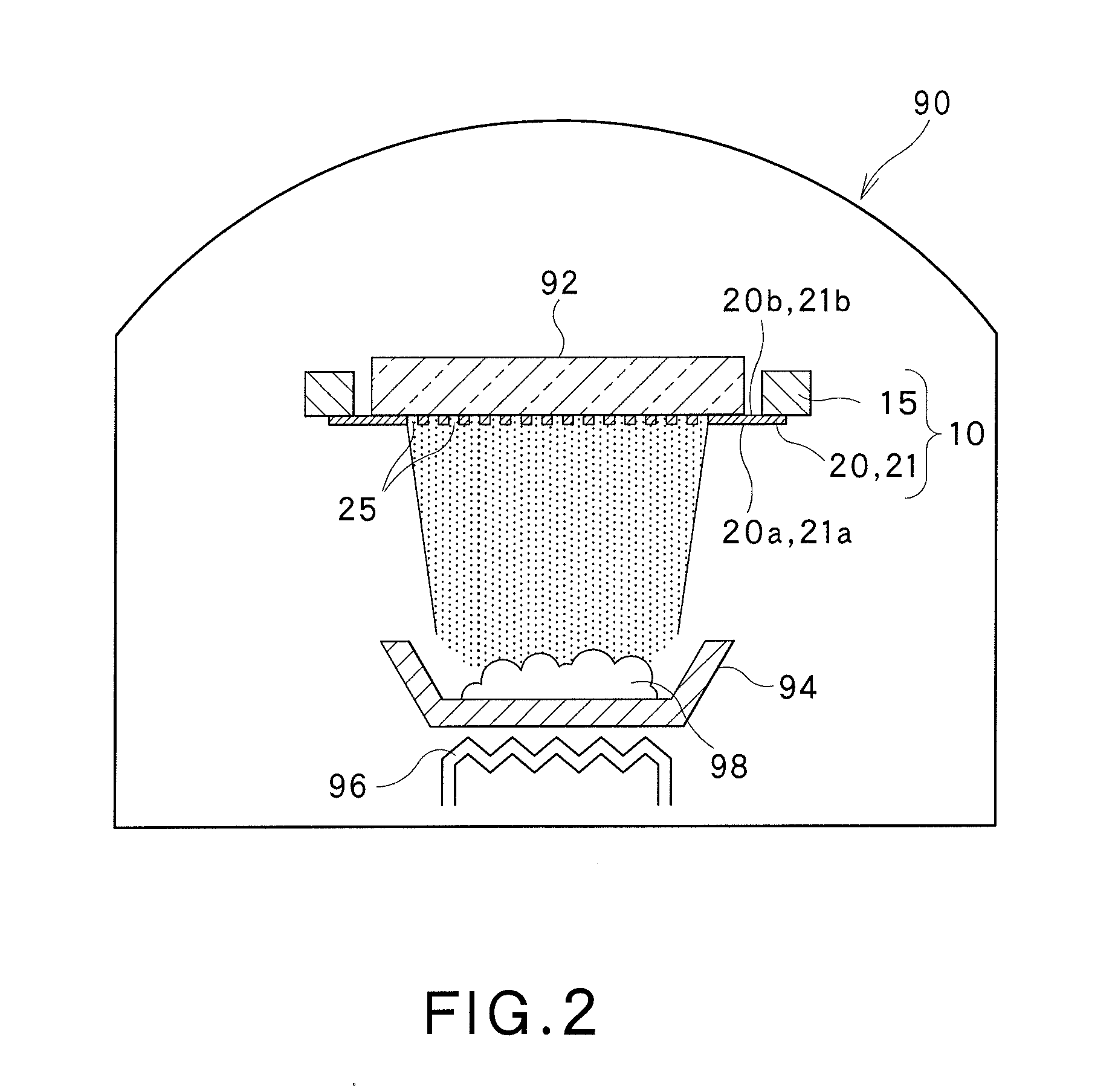

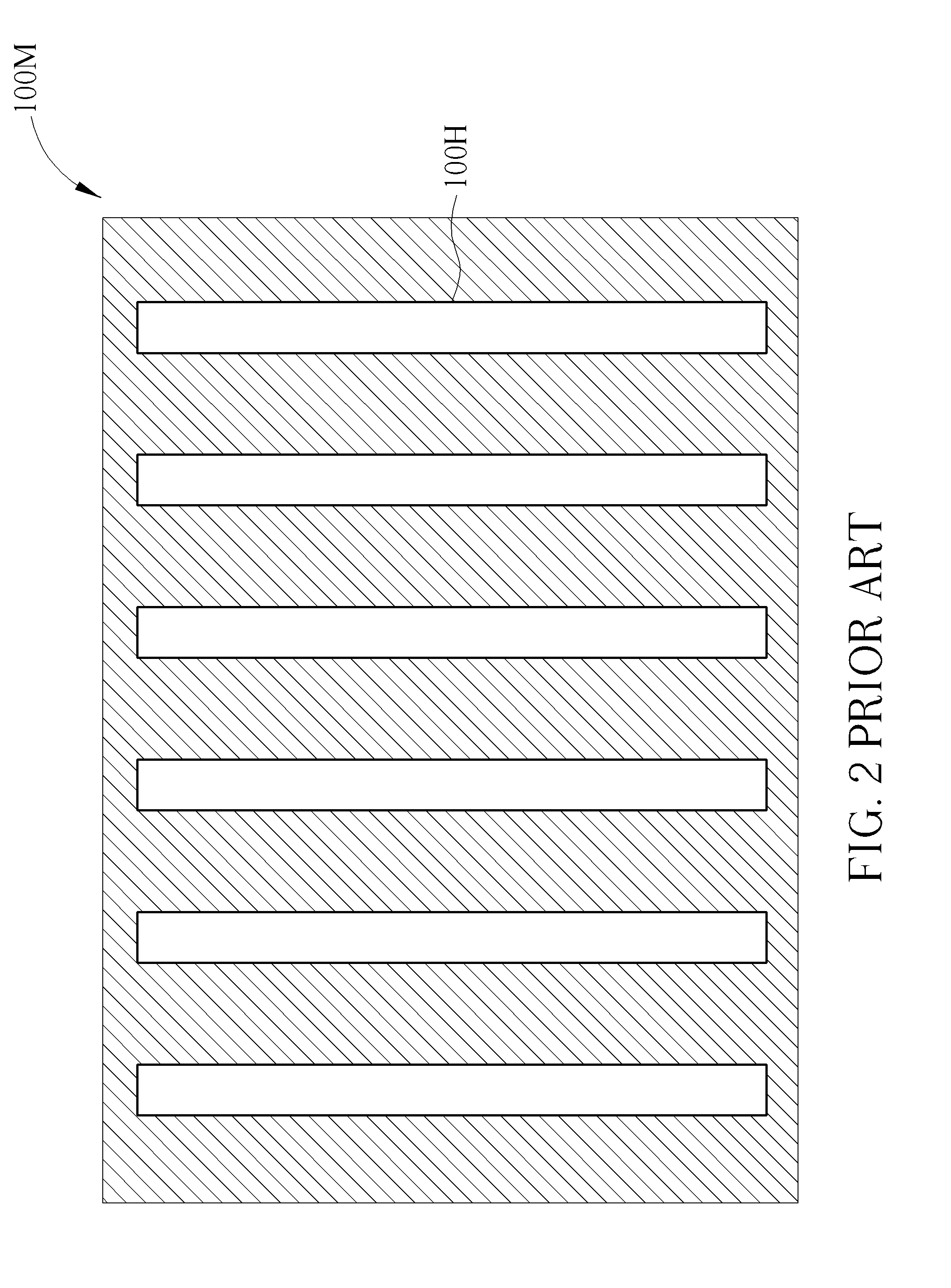

Metal plate, method of manufacturing metal plate, and method of manufacturing mask by use of metal plate

ActiveUS20160208392A1Reduced luminous efficiencySolve high precisionLayered productsExtrusion containersMetalMaterials science

The object of the present invention is to provide a metal plate having an excellent transportability. A maximum value of a steepness degree at a central area in a width direction of the metal plate is not more than 0.4%. In addition, the maximum value of the steepness degree at the central area is not more than a steepness degree at one end side area, and is not more than a steepness degree at the other end side area. Further, a difference between the maximum value of the steepness degree at the one end side area and the maximum value of the steepness degree at the other end side area is not more than 0.4%.

Owner:DAI NIPPON PRINTING CO LTD

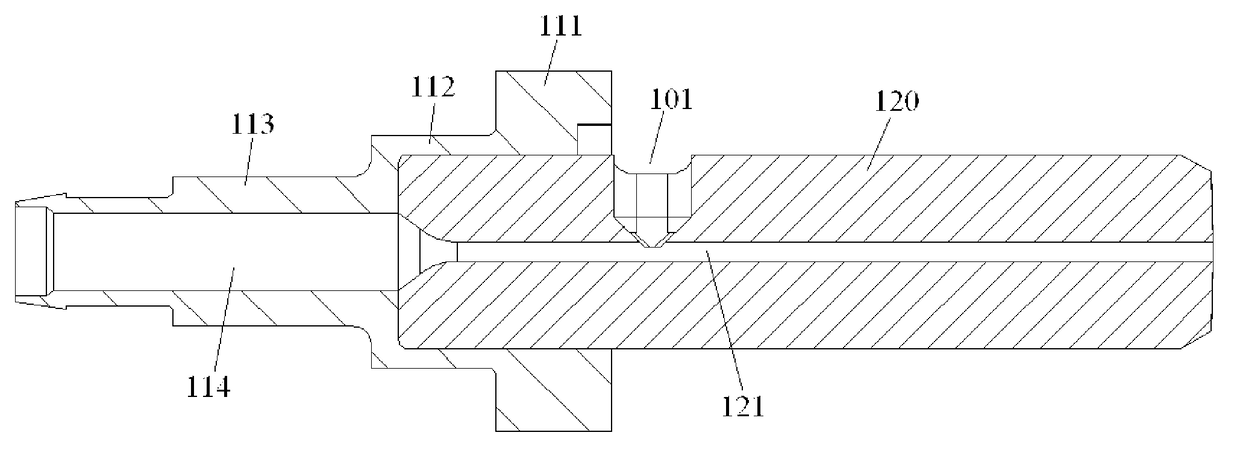

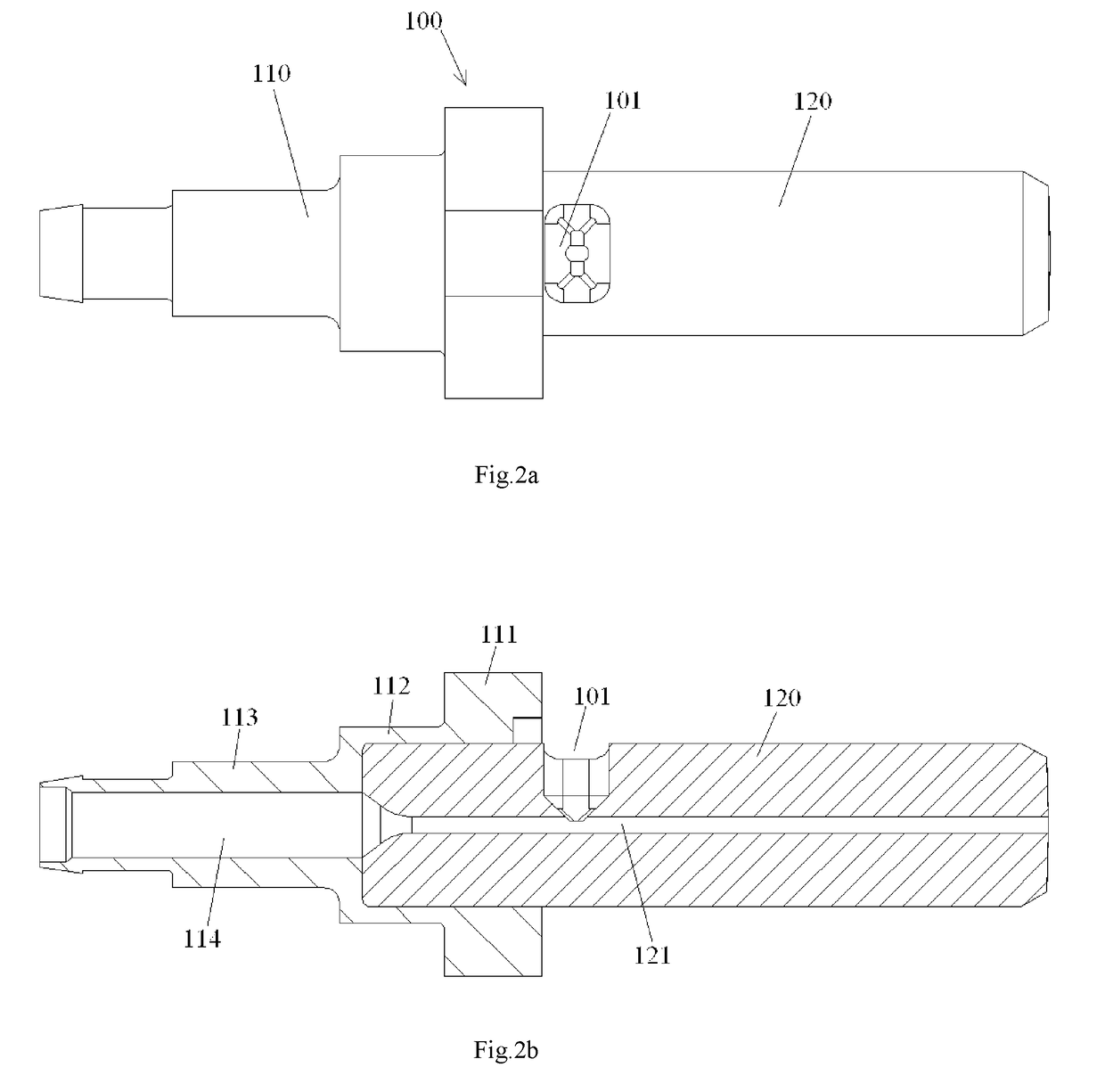

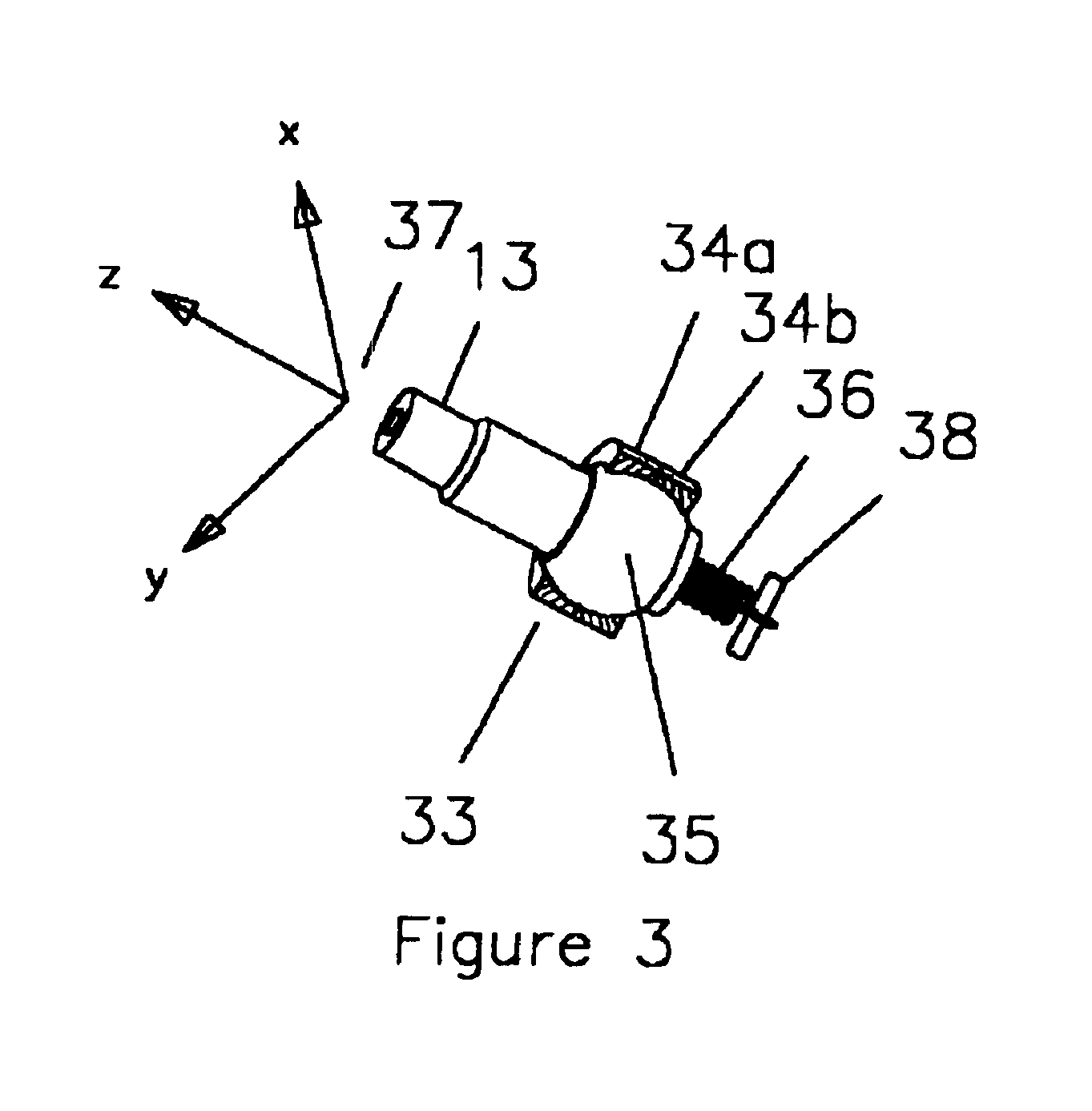

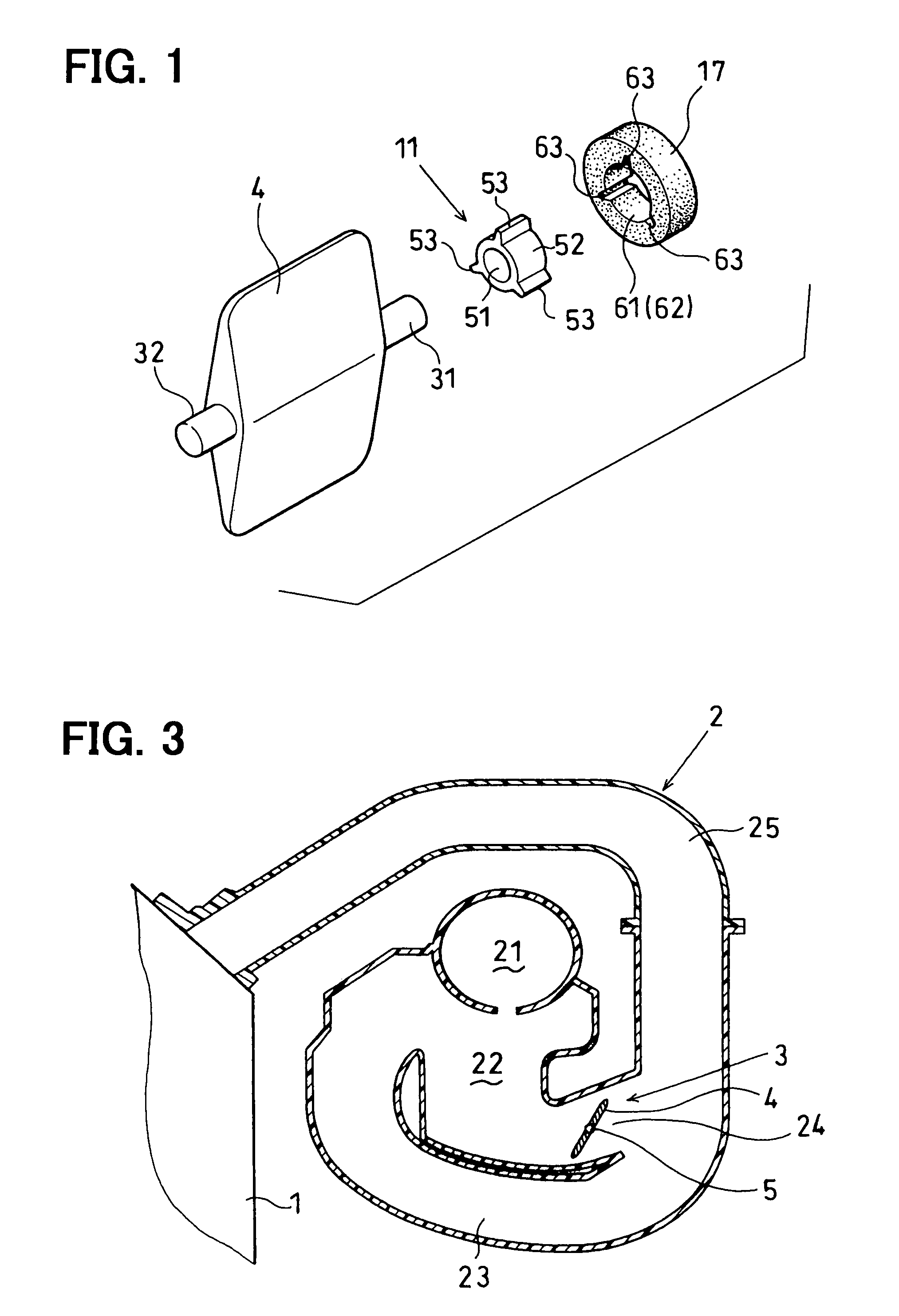

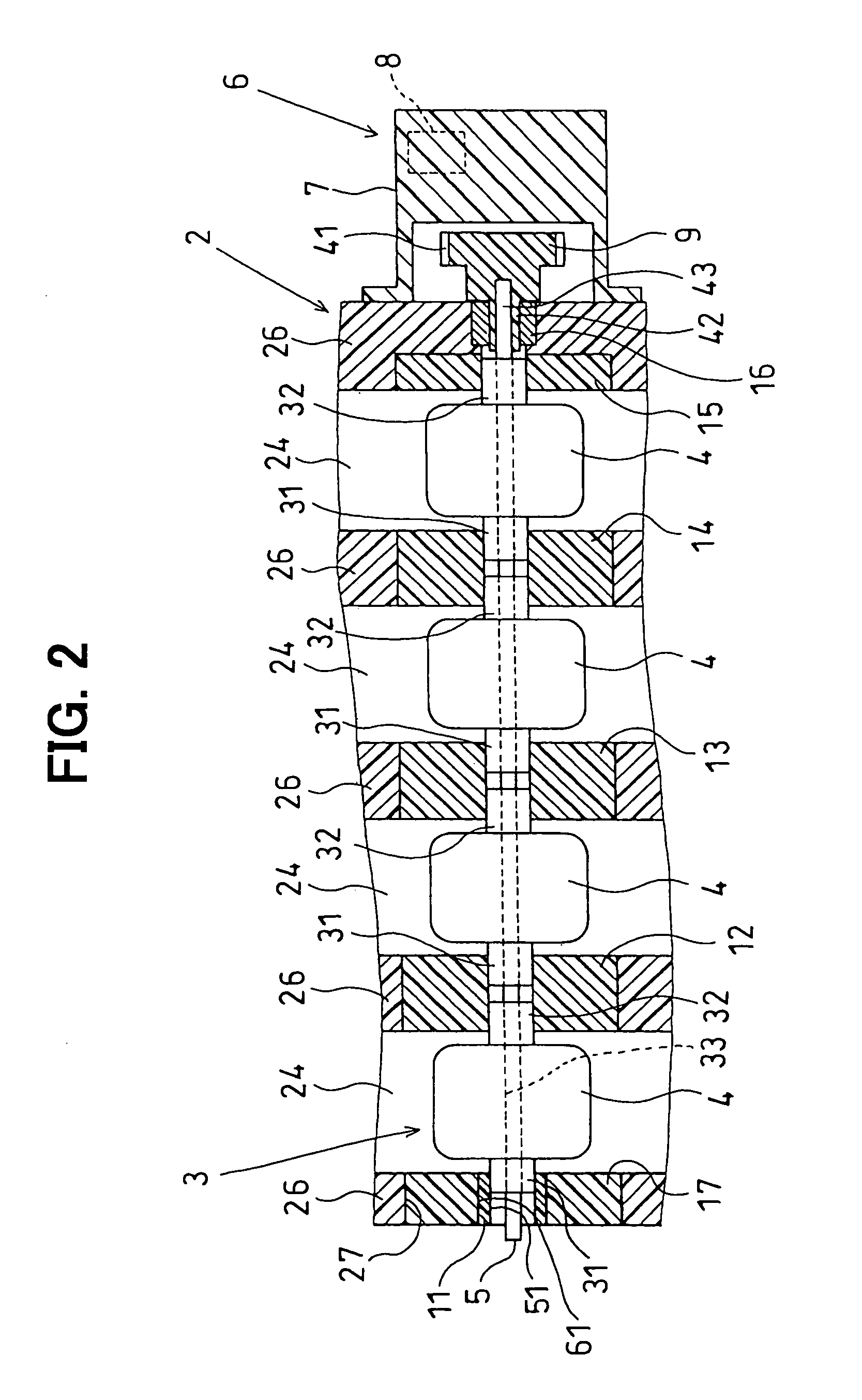

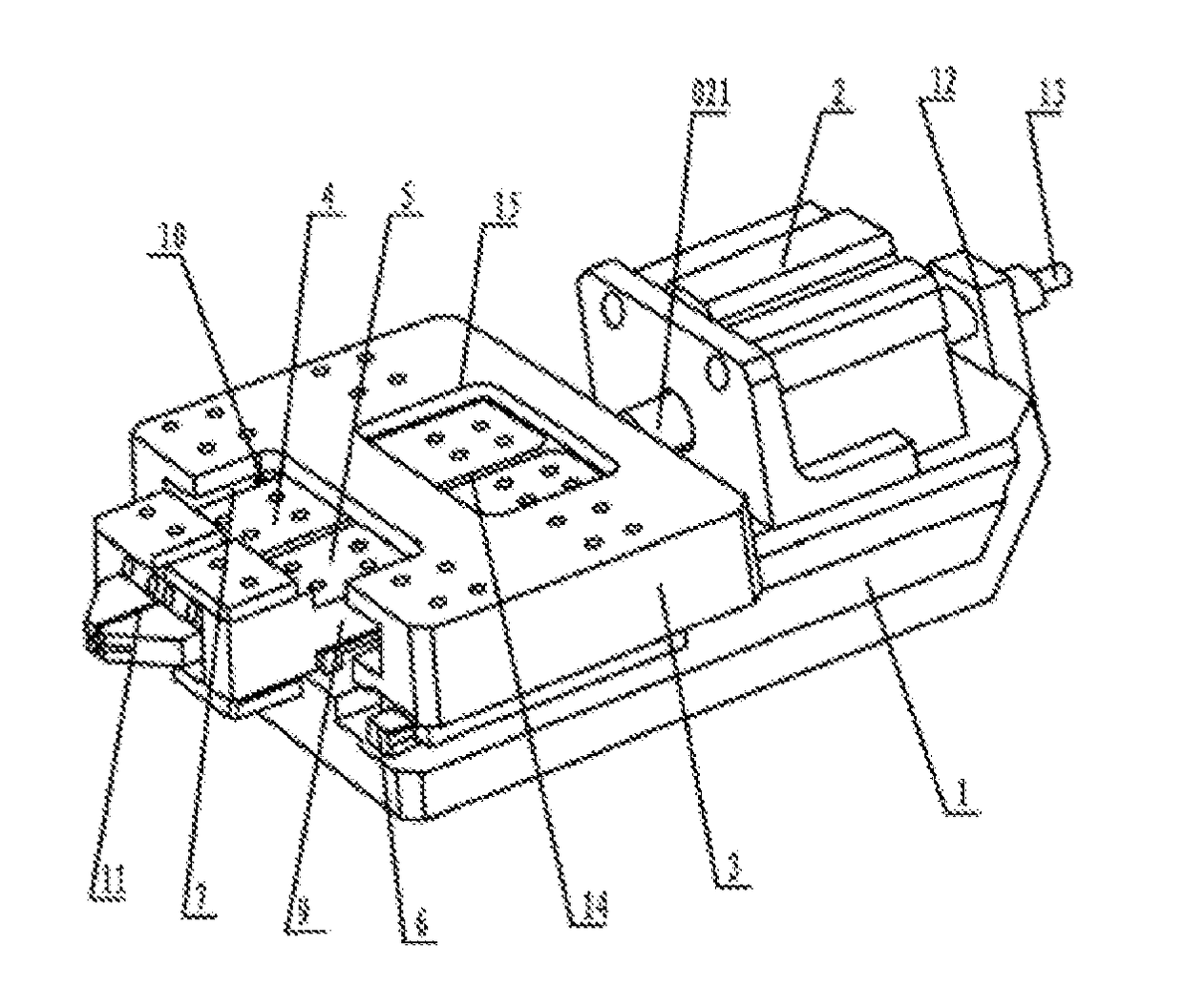

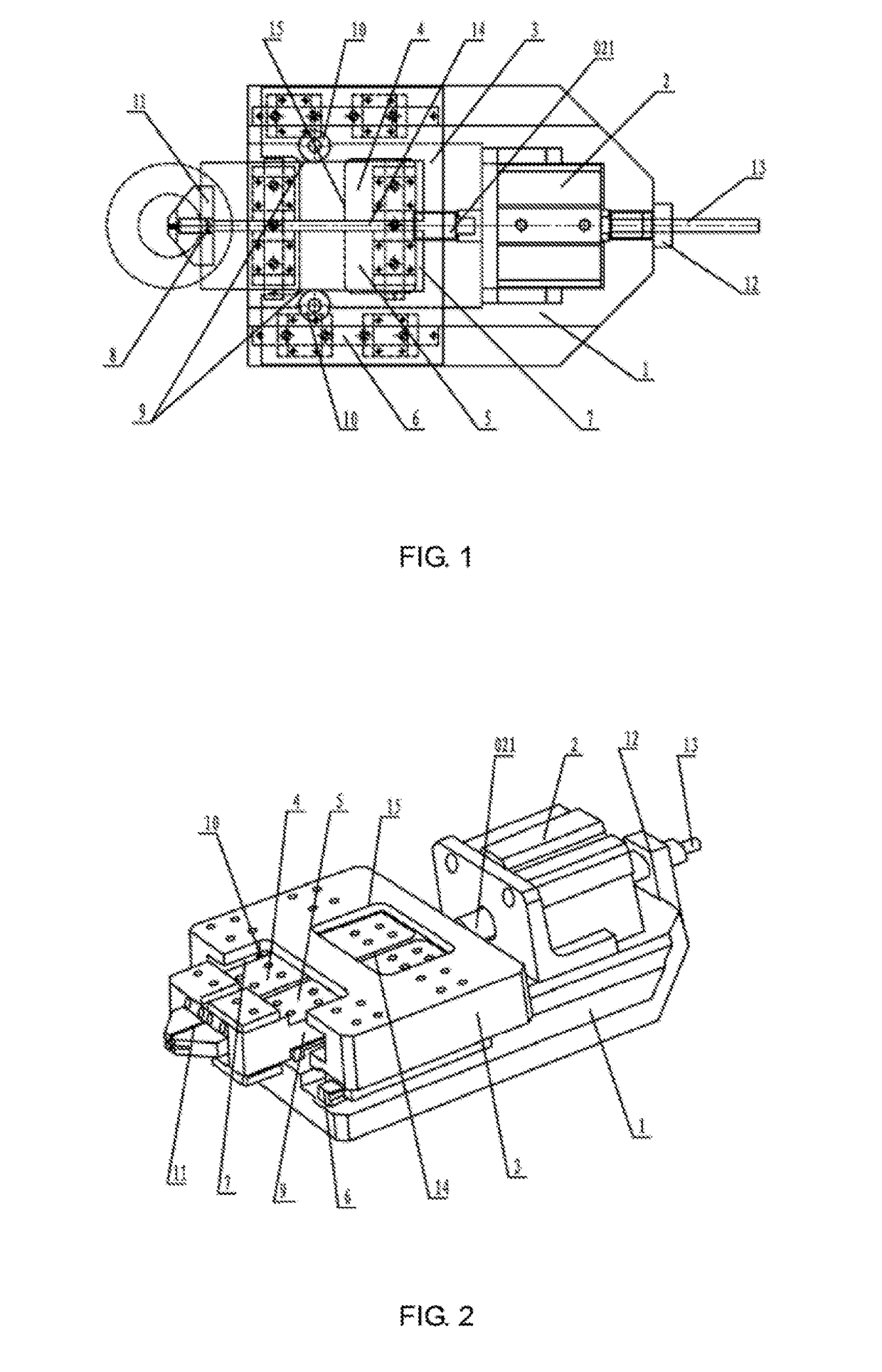

Ferrule device, apparatus and method for manufacturing the same

InactiveUS20170160492A1Good optical performanceImproves random mating propertyCoupling light guidesFiberAdhesive

An apparatus for manufacturing a ferrule device, including: a ferrule clamping module configured to clamp and position a plurality of ferrule assemblies; a fiber / cable clamping module adapted to be engaged to a rear side of the ferrule clamping module, and configured to clamp and position a section of the respective optical cable behind the ferrule clamping module; a vacuum suction module adapted to be engaged to a front side of the ferrule clamping module, and configured to suck an adhesive filled in the respective ferrule assembly from the front end of the ferrule assembly, so that the adhesive flows to a front end surface of the ferrule assembly through a gap between the fiber and the fiber bore until a predetermined size of adhesive bump is formed on the front end surface of the ferrule assembly; and a fiber alignment module adapted to be engaged to the front side of the ferrule clamping module, and configured to calibrate position accuracy of the respective fiber inserted into the fiber bore of the respective ferrule assembly and adjust an eccentricity orientation of the center of the respective fiber to a predetermined orientation. By the apparatus a plurality of fiber optic ferrule devices may be manufactured at the same time, increasing the production efficiency.

Owner:ADC TELECOMM SHANGHAI CO LTD

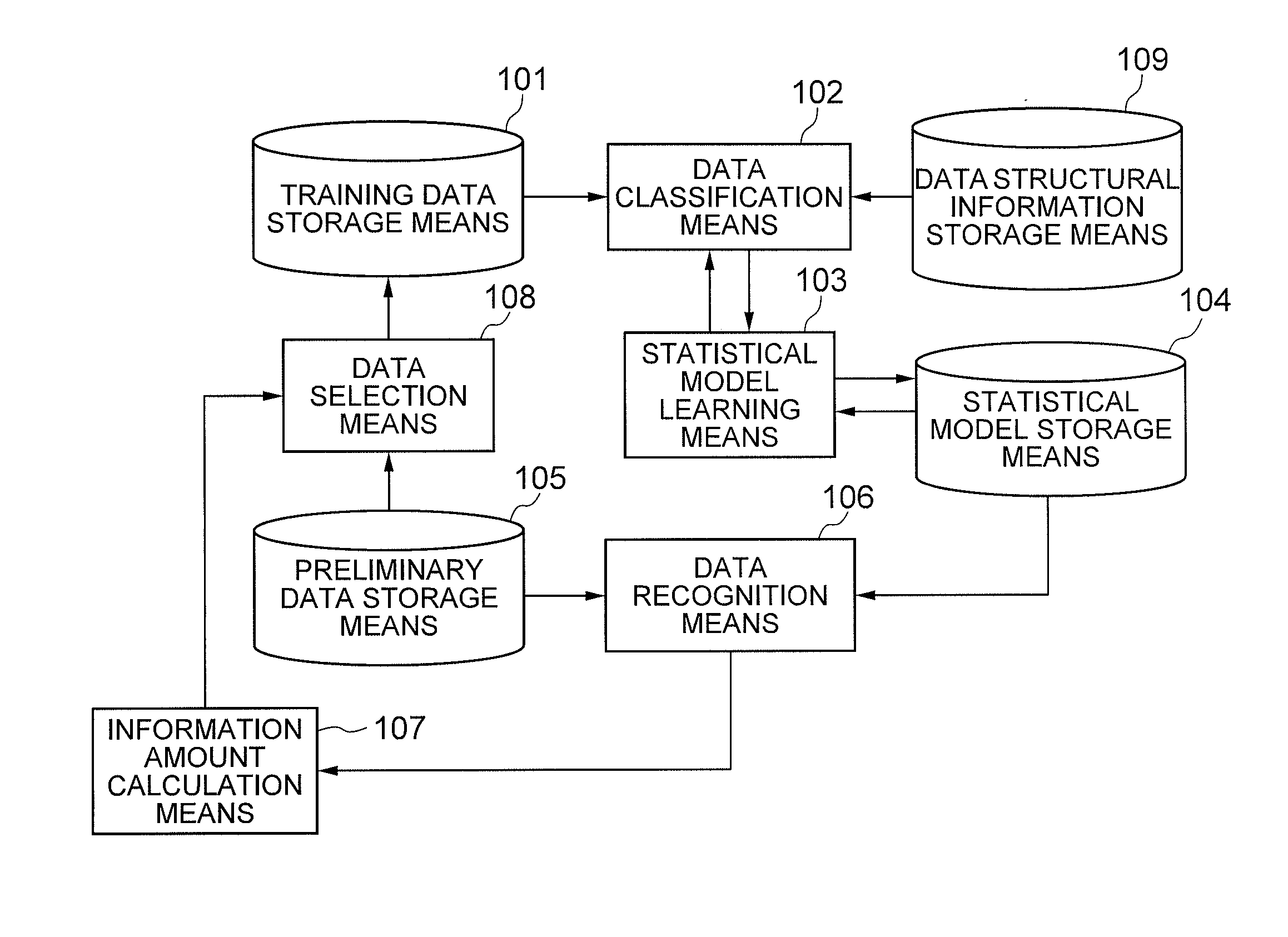

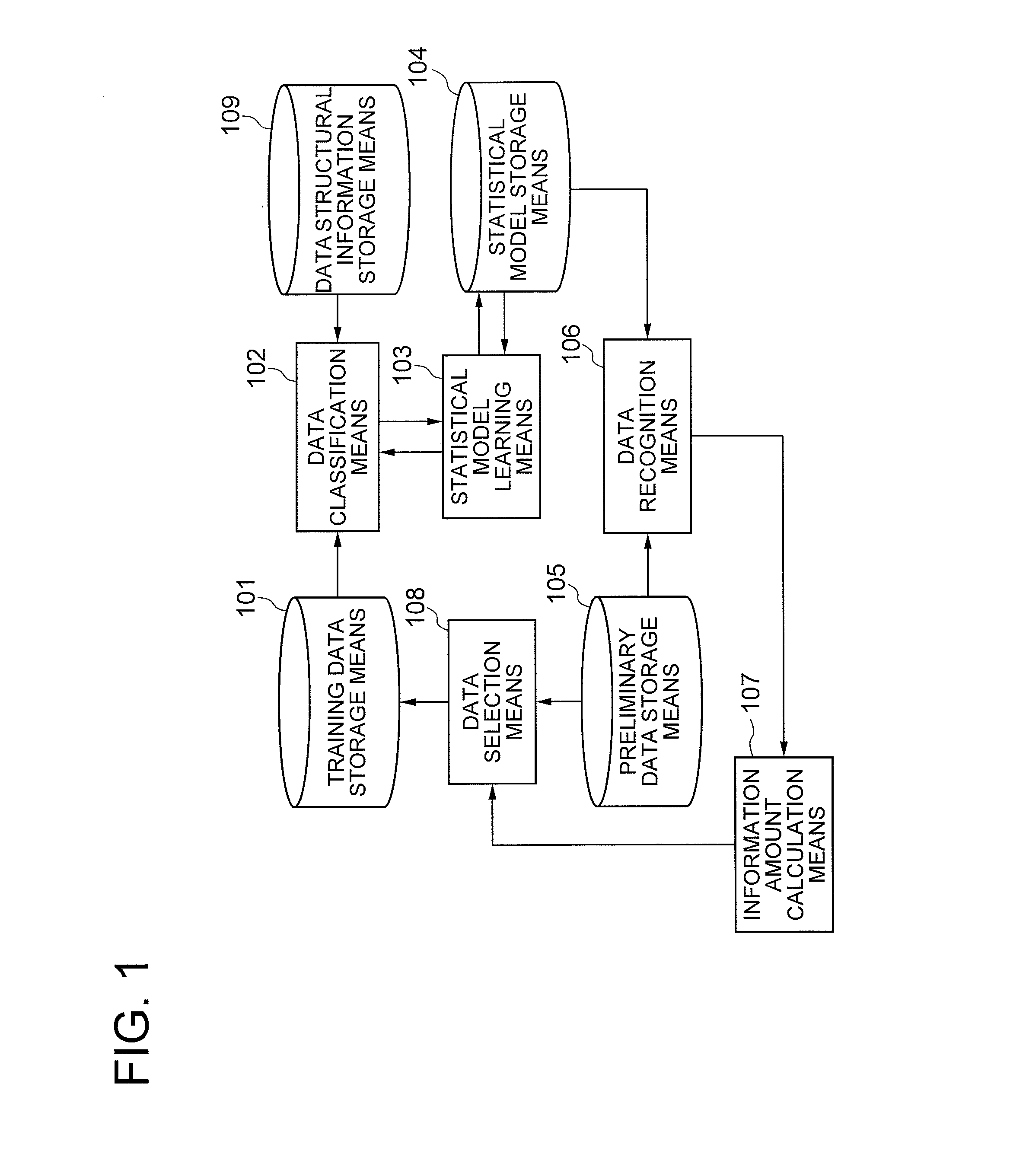

Statistical model learning device, statistical model learning method, and program

InactiveUS20110202487A1Valid choiceQuality improvementKernel methodsDigital computer detailsAlgorithmData selection

A statistical model learning device is provided to efficiently select data effective in improving the quality of statistical models. A data classification means 601 refers to structural information 611 generally possessed by a data which is a learning object, and extracts a plurality of subsets 613 from the training data 612. A statistical model learning means 602 utilizes the plurality of subsets 613 to create statistical models 614 respectively. A data recognition means 603 utilizes the respective statistical models 614 to recognize other data 615 different from the training data 612 and acquires each recognition result 616. An information amount calculation means 604 calculates information amounts of the other data 615 from a degree of discrepancy among the statistical models of the recognition results. A data selection means 605 selects the data with a large information amount and adds the same to the training data 612.

Owner:NEC CORP

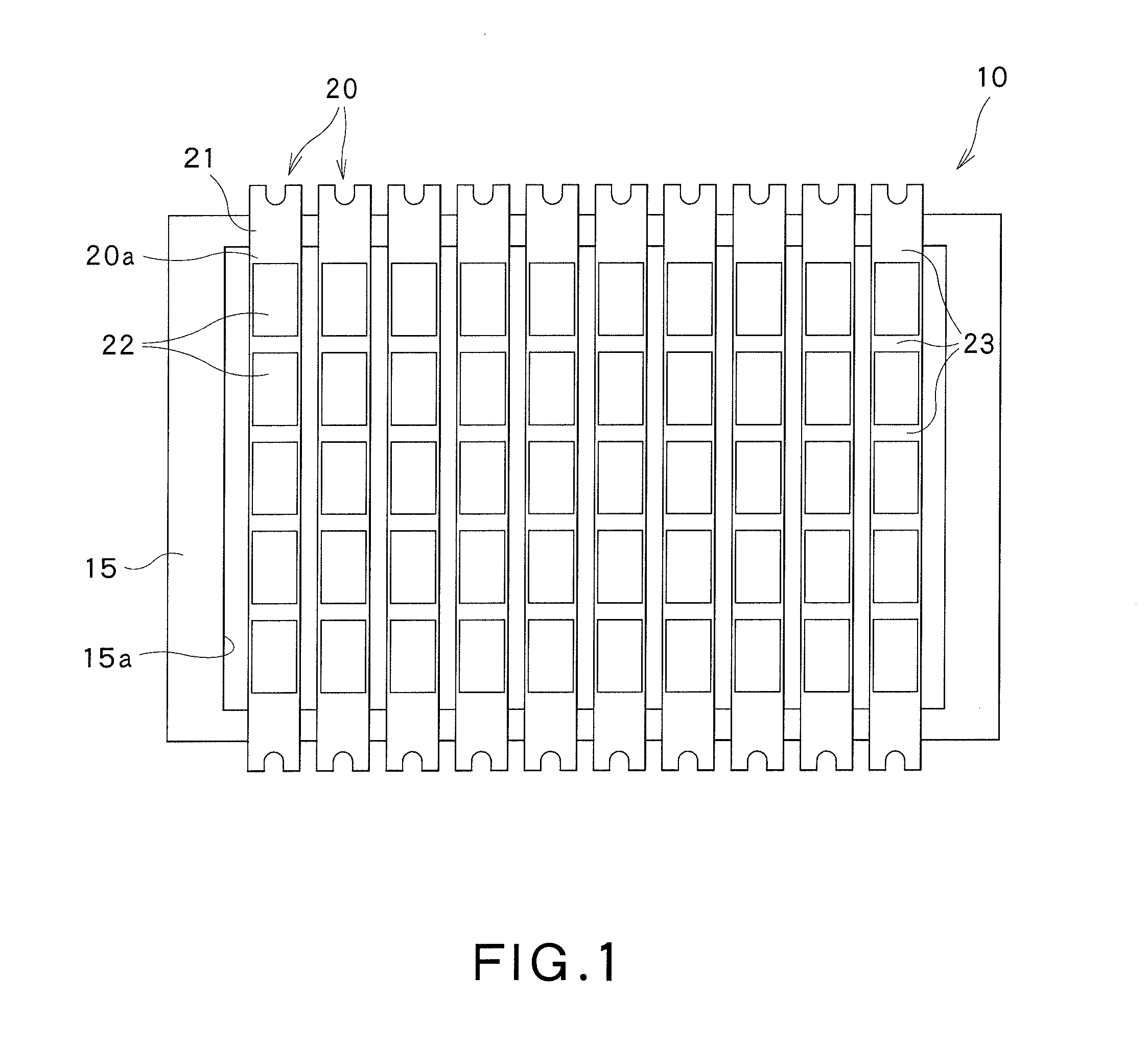

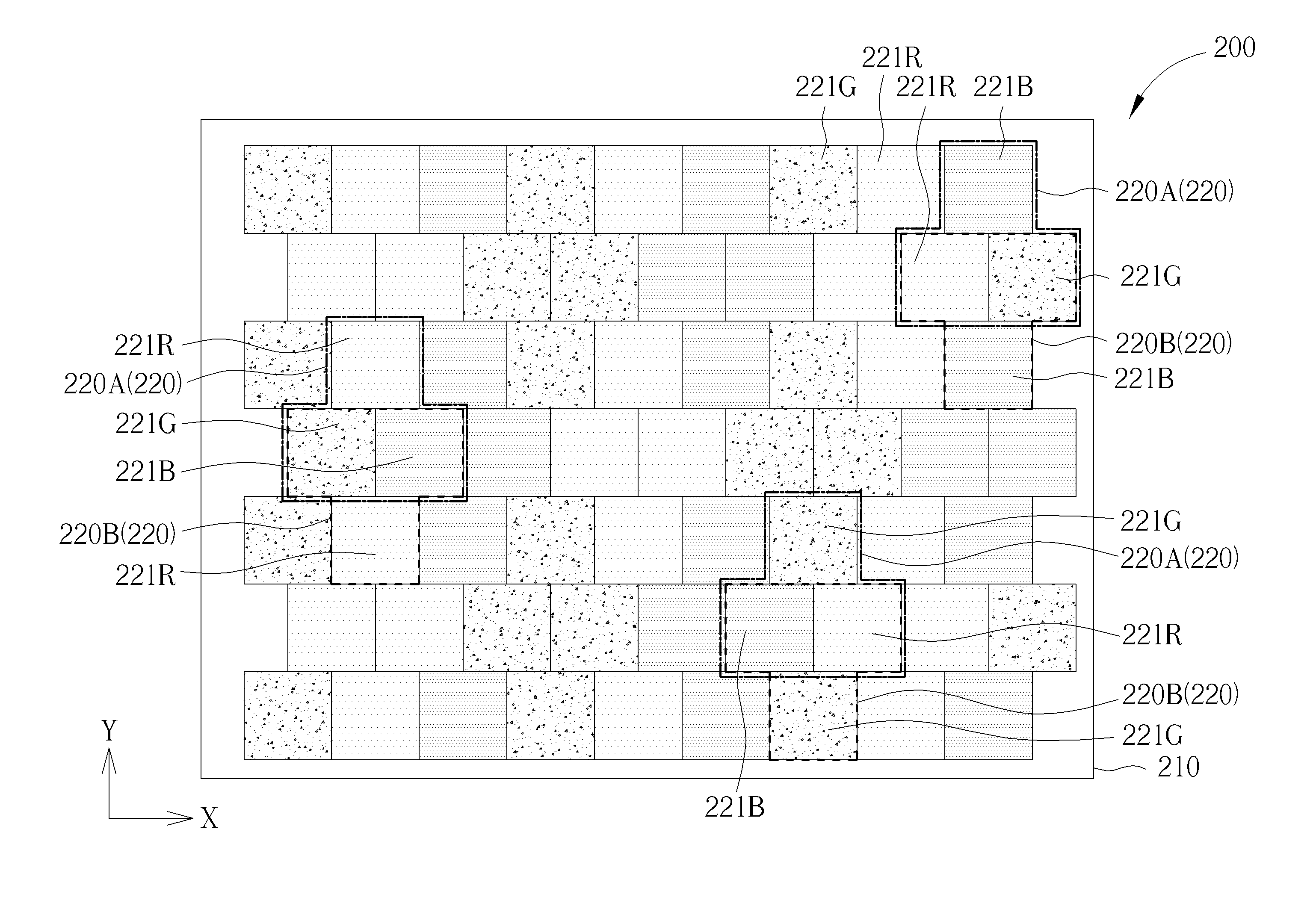

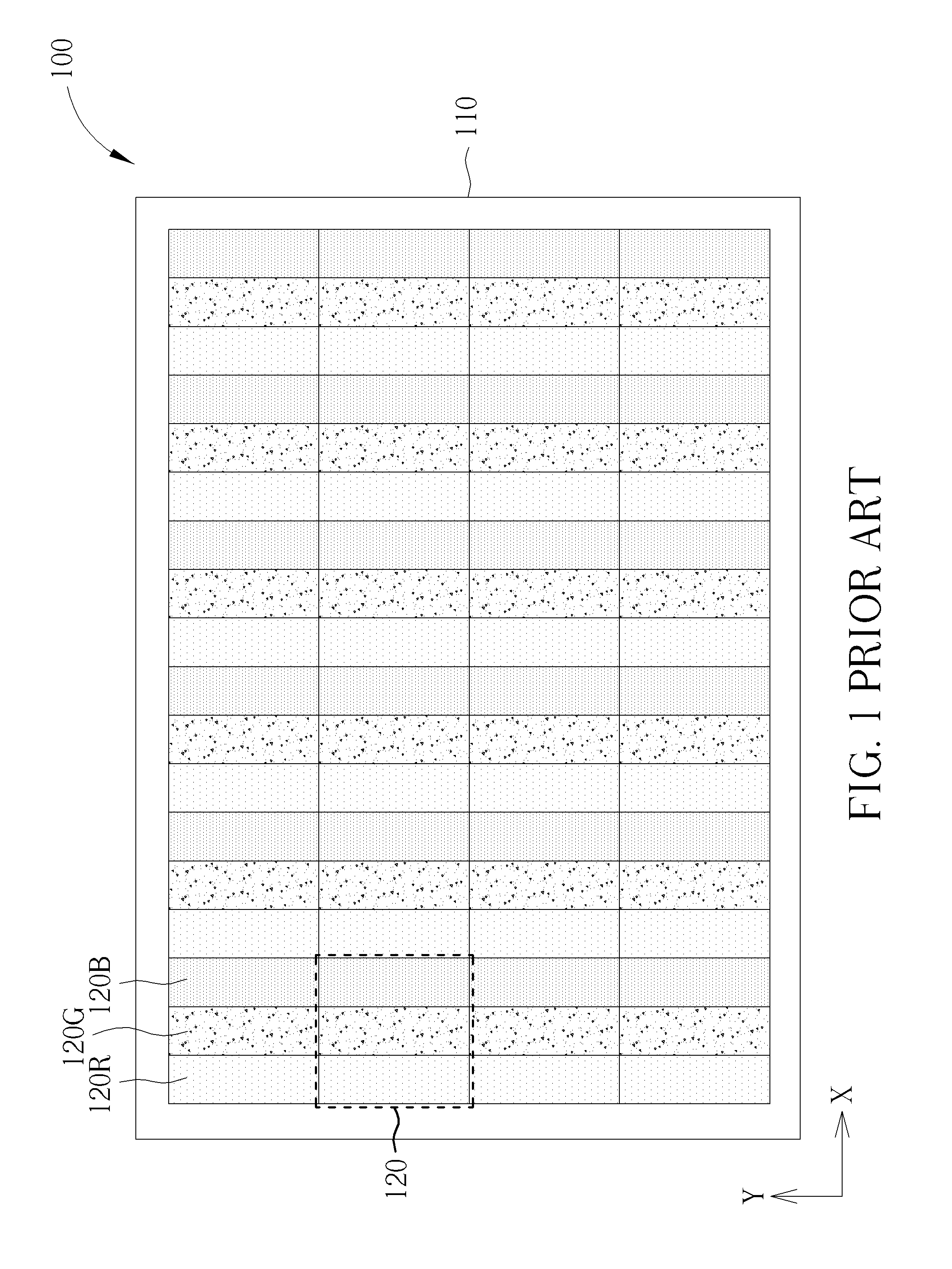

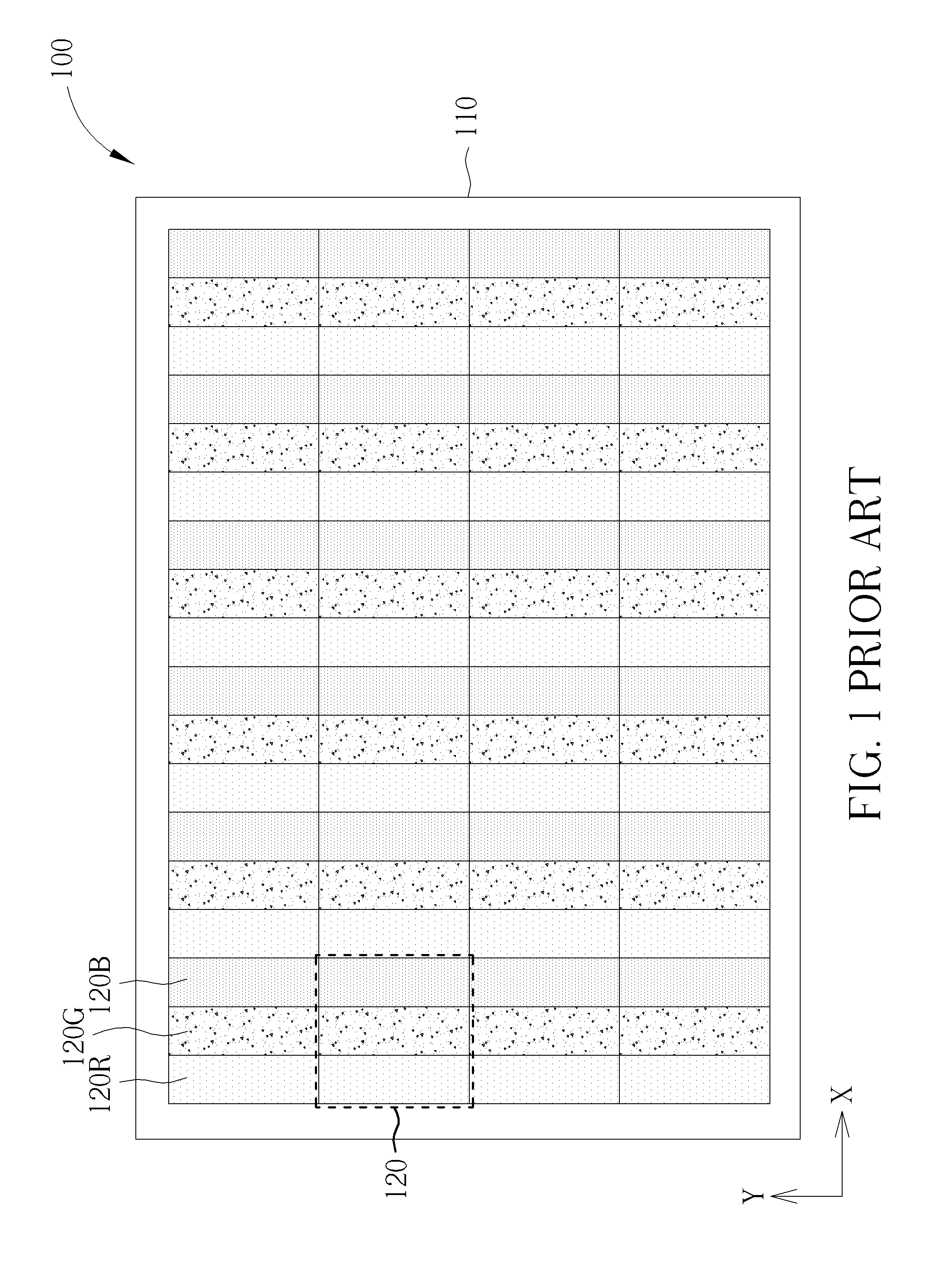

Pixel structure of organic light emitting display device

InactiveUS8896200B2Solve high precisionImprove processing stabilityDischarge tube luminescnet screensLighting support devicesComputer graphics (images)Display device

A pixel structure of an organic light emitting display device includes a substrate and a plurality of display pixel units disposed on the substrate. Each of the display pixel units includes a first sub-pixel, a second sub-pixel and a third sub-pixel disposed adjacently to one another. The first sub-pixel in each of the display pixel units is disposed adjacently to three first sub-pixels respectively disposed in three adjacent display pixel units to form a first pixel unit. The second sub-pixel in each of the display pixel units is disposed adjacently to three second sub-pixels respectively disposed in three adjacent display pixel units to form a second pixel unit. The third sub-pixel in each of the display pixel units is disposed adjacently to three third sub-pixels respectively disposed in three adjacent display pixel units to form a third pixel unit.

Owner:CHUNGHWA PICTURE TUBES LTD

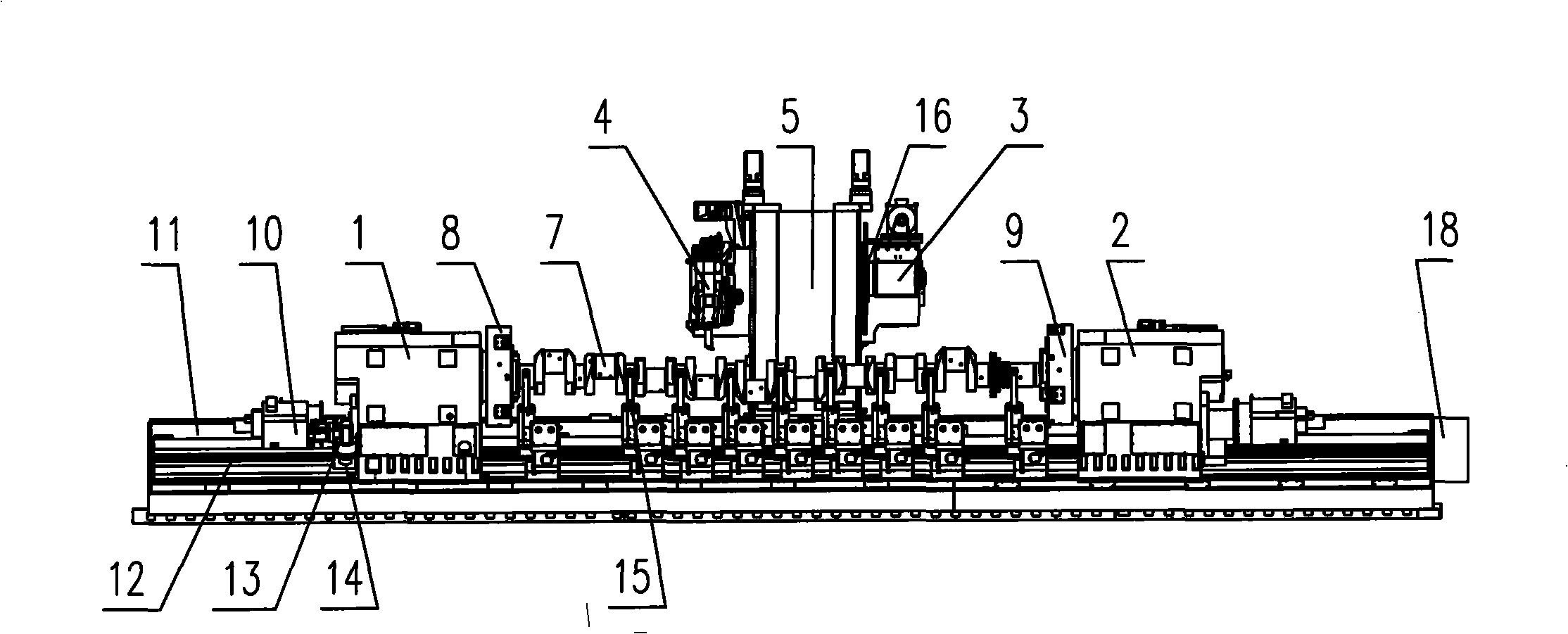

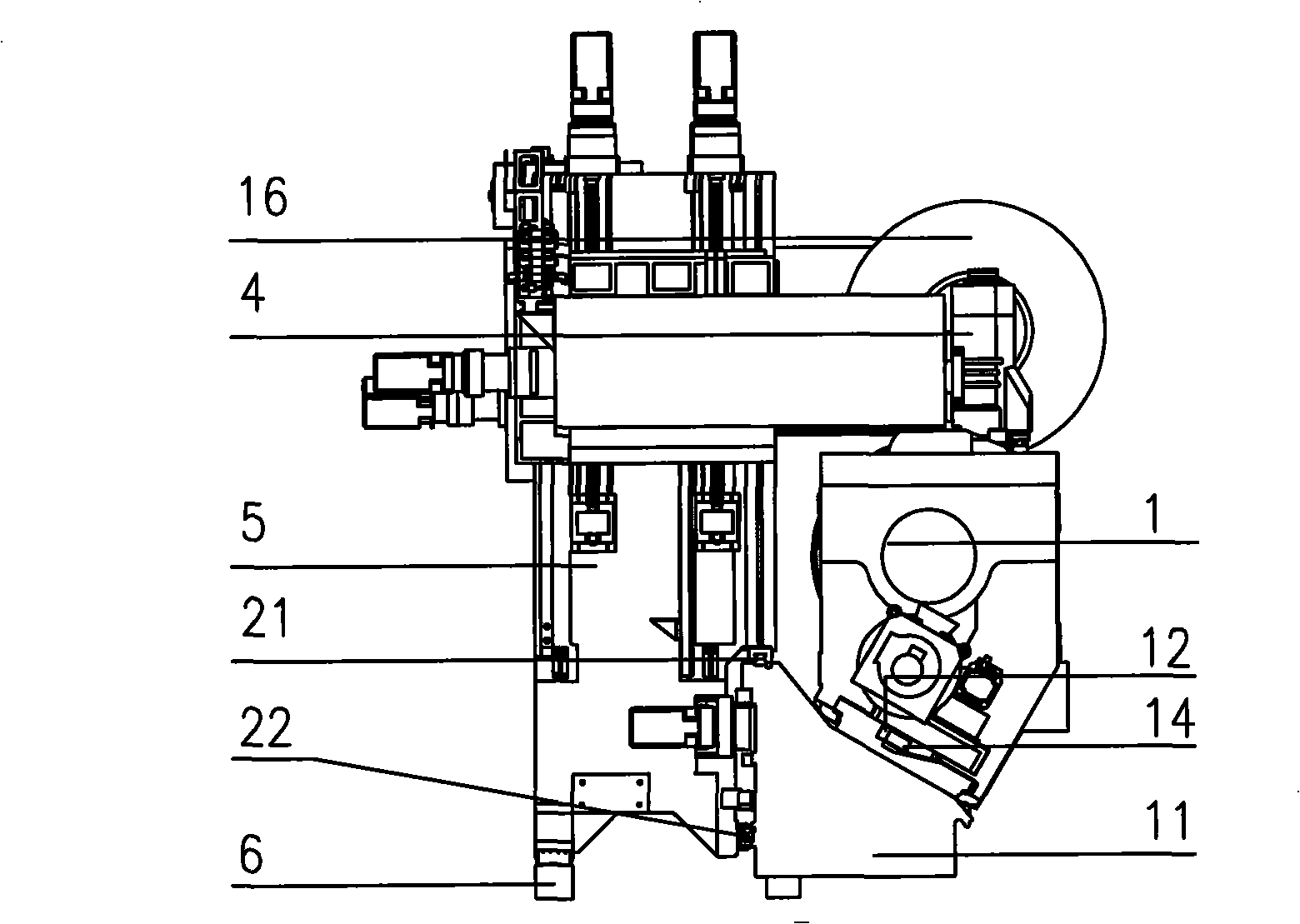

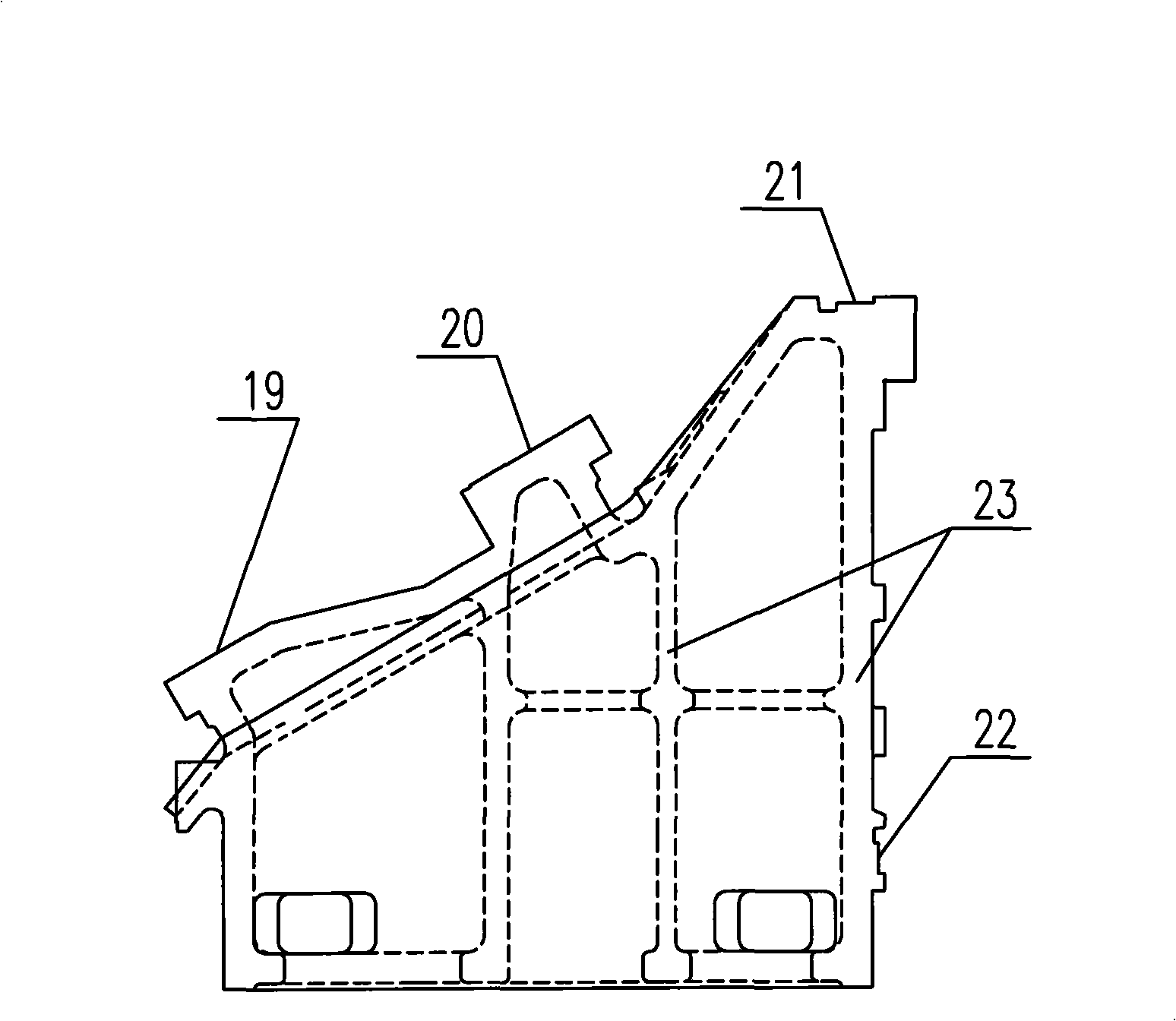

Integral structure of a turn-milling complex machining center

ActiveCN101513720AGuaranteed stabilityWeight optimizationMetal working apparatusMilling cutterHeavy load

An integral structure of a turn-milling complex machining center is disclosed, characterized by a single post and feeding boxes hung at two sides. The left-suspending feeding box is provided with a B-axis cutter holder device with cutters at three locations. The B-axis cutter holder device is used for the working procedures for crank machining like turning, milling, boring, deep-hole drilling, threading and the like. The right-suspending feeding box can be provided with a large-scale milling cutter disc for external milling machining of the crank shaft. Two spindle boxes have two Cf-axis structures, the two spindle boxes are movable along a Z-axis on the machine body, and the tip of the right spindle box is stretchable. The machine is fitted with a plurality of hydraulic self-centering center rests that have high precision retentivity. A guide rail on the machine body forms an angle of inclination of 30 degrees with a horizontal plane, and the plane of the machine body is completely ground to ensure the absence of scraps and dead corners. The entire machine is fully protected. An inner cavity of the guide rail for the operation of the single post of the machine body is supported by double ribs, and two sets of corners remain stressed all the time in the process of the operation of the post. A front support bearing of the spindle employs an imported large-diameter double-column cylindrical roller bearing. The invention solves three problems and the machining for parts of a main journal and a connecting journal of the crank prior to grinding can be completed by one-time mounting on a machine, thus realizing high-precision and high efficient machining for the crank shaft of a medium speed machine for ships; in addition, the invention bears heavy load and is fully-protected.

Owner:通用技术集团沈阳机床有限责任公司

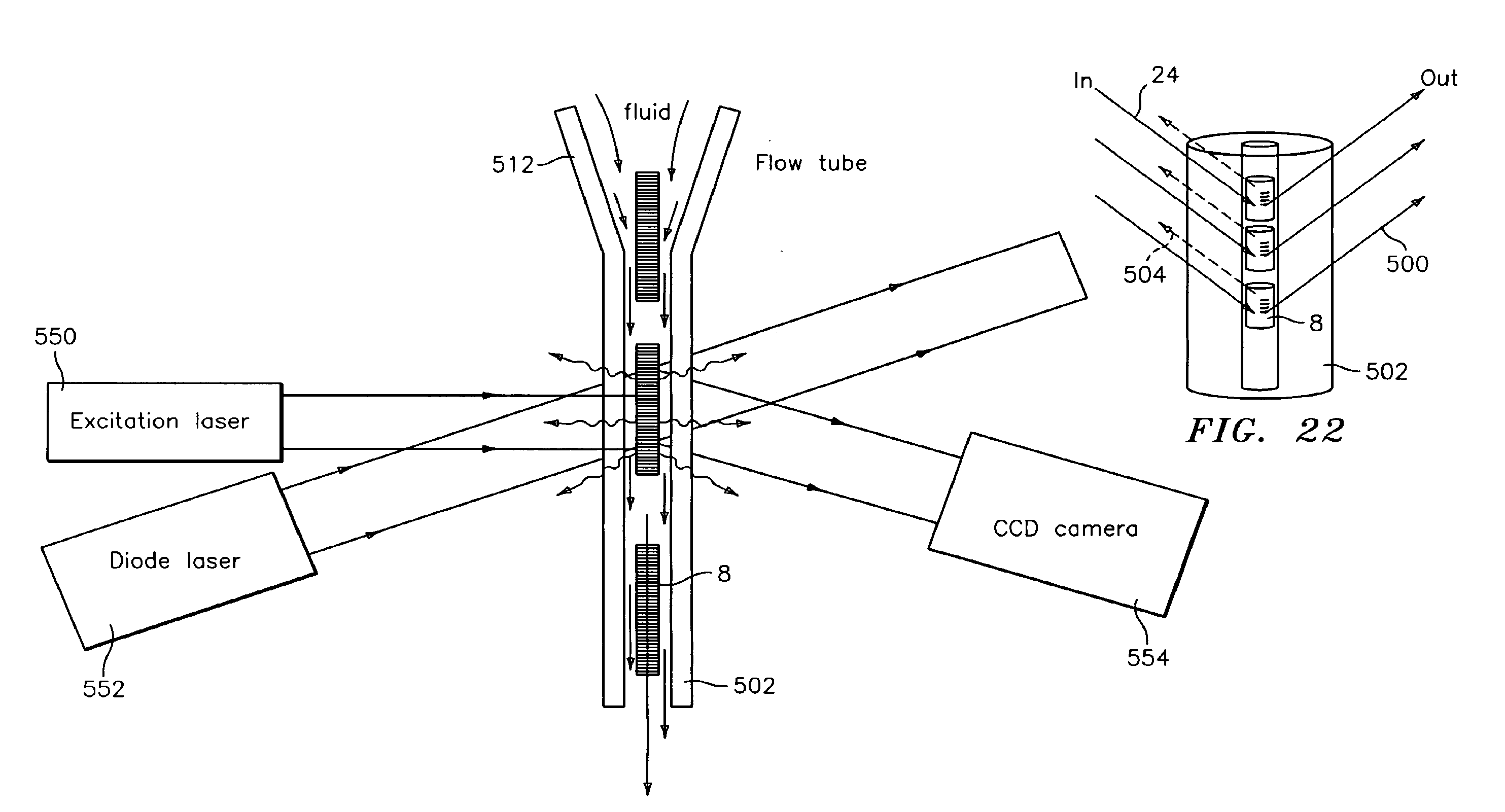

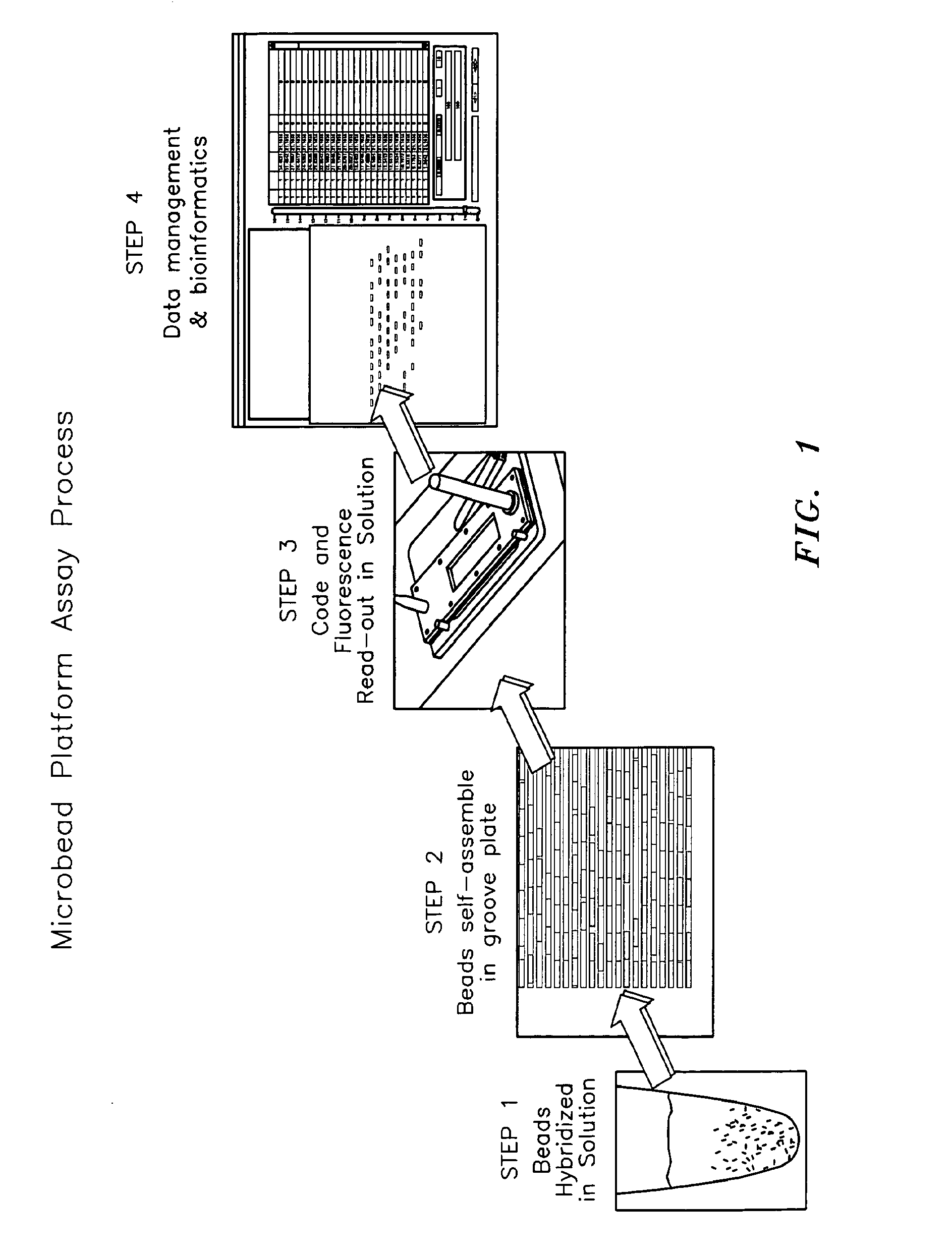

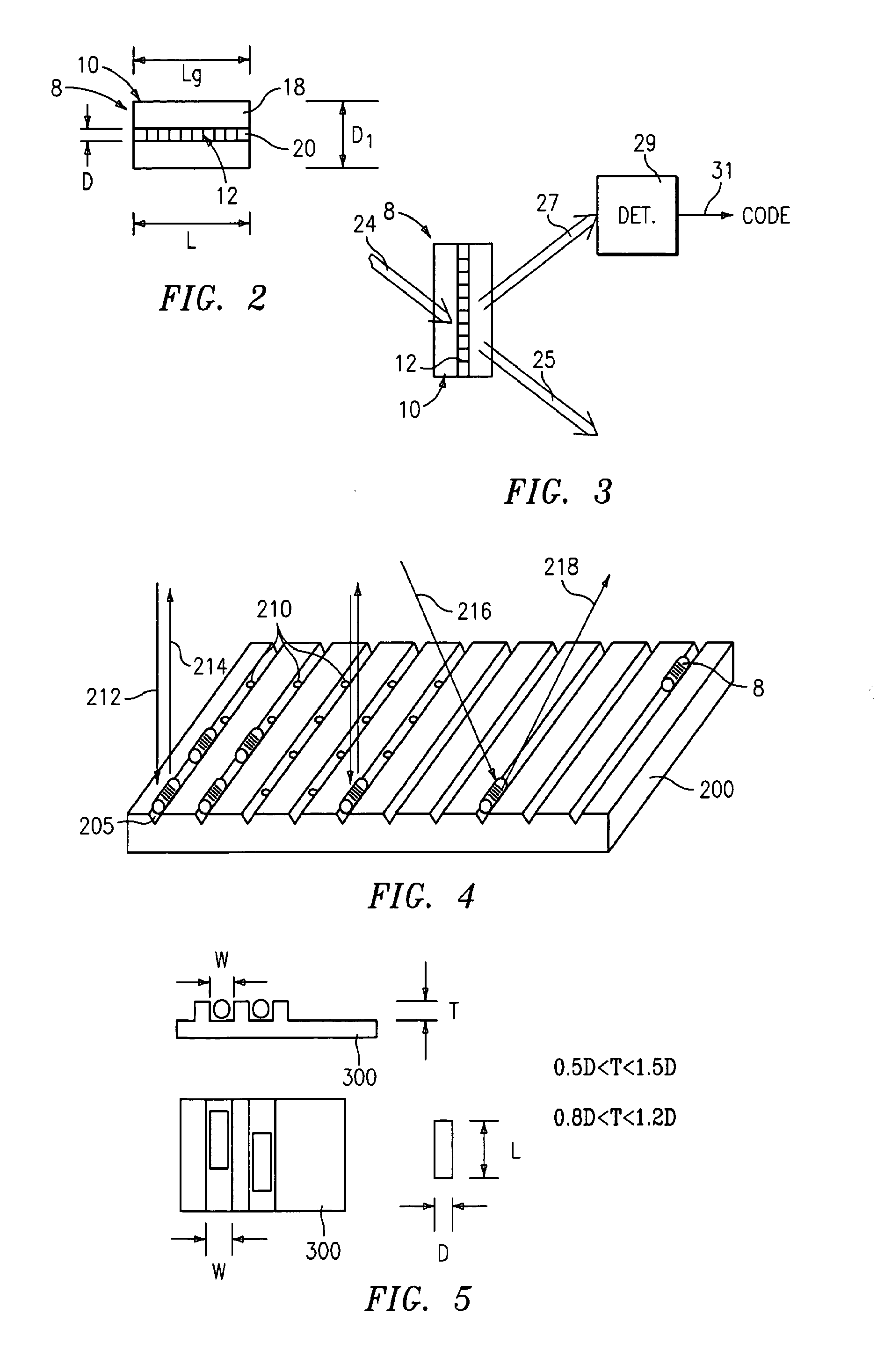

Method and apparatus for aligning microbeads in order to interrogate the same

InactiveUS20100072278A1Fast readoutQuick alignmentBioreactor/fermenter combinationsBiological substance pretreatmentsMicroparticleOptical reader

Owner:ILLUMINA INC

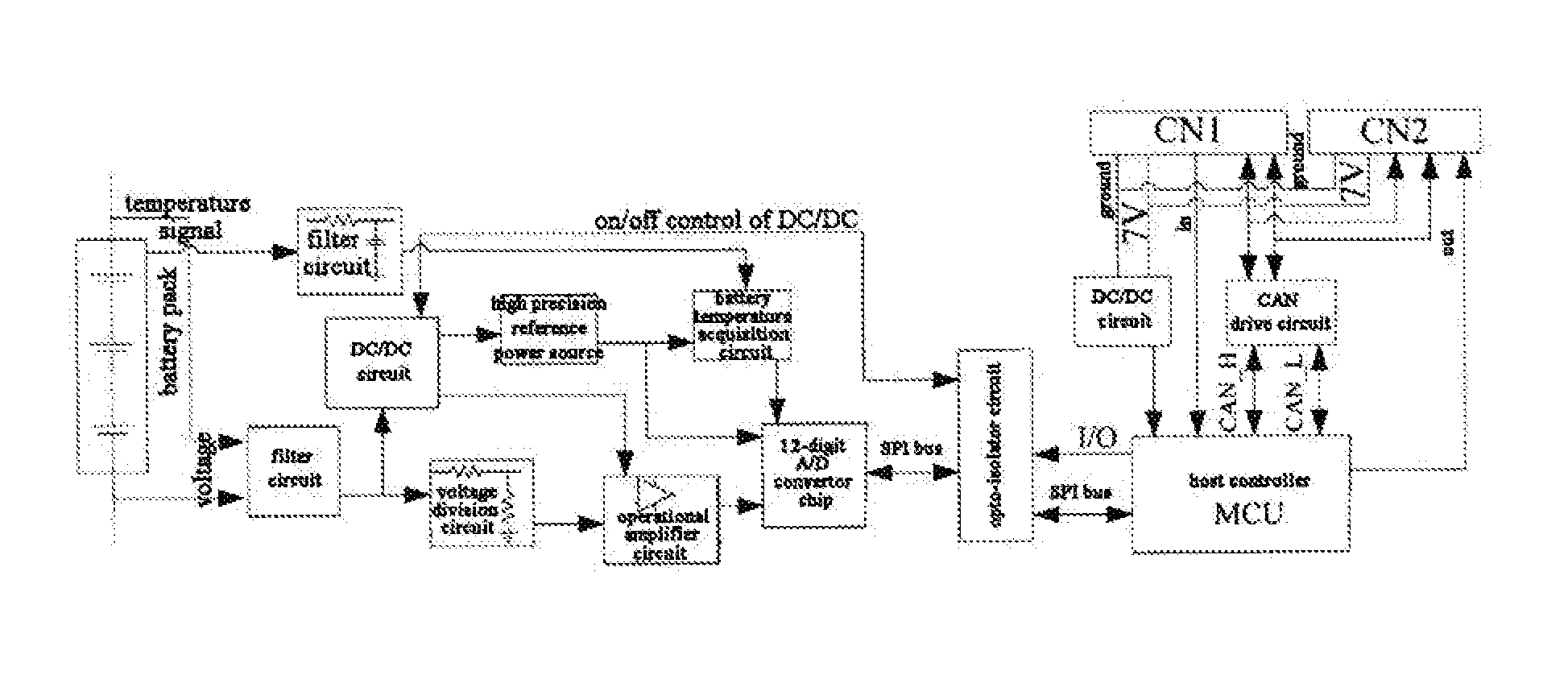

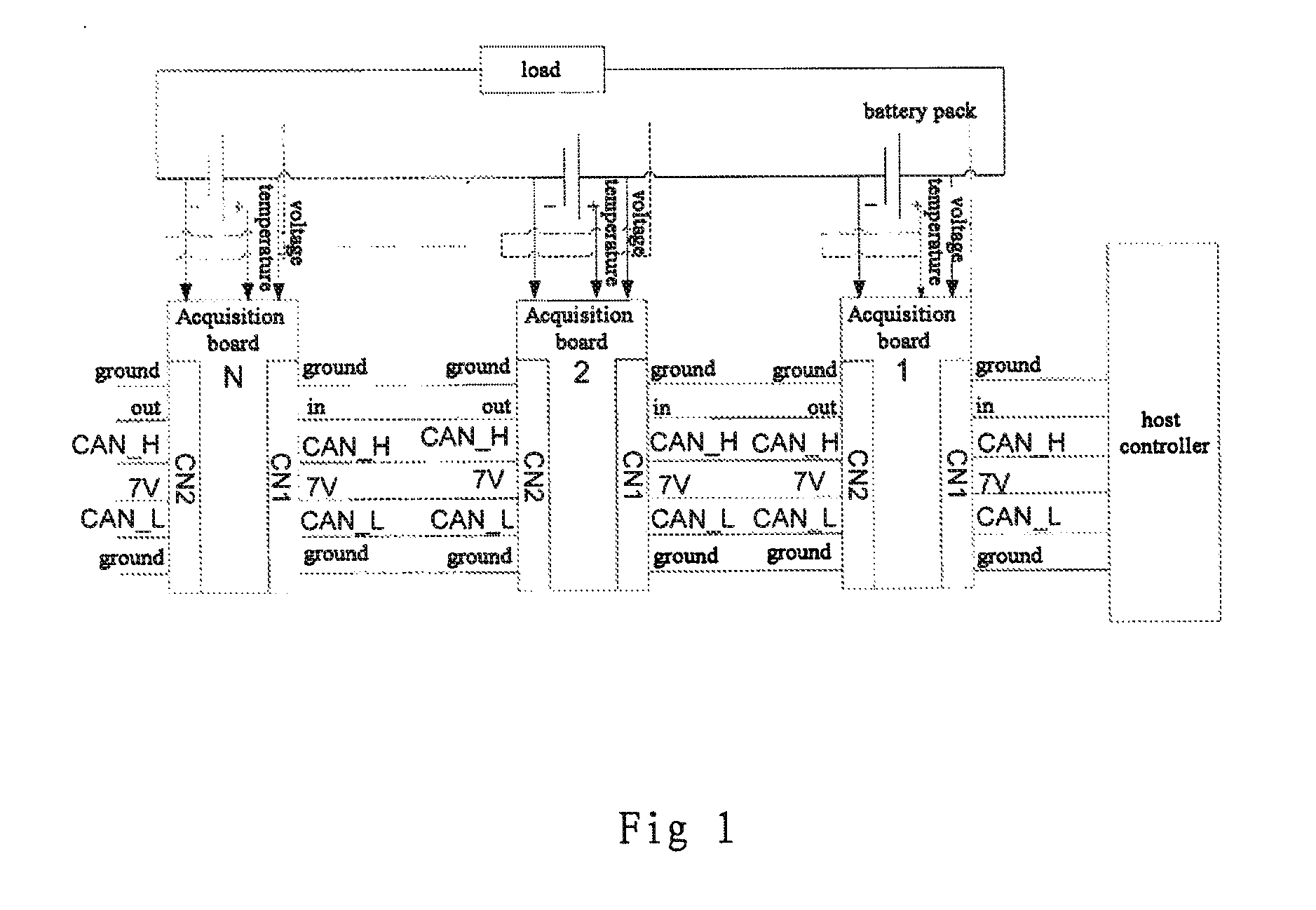

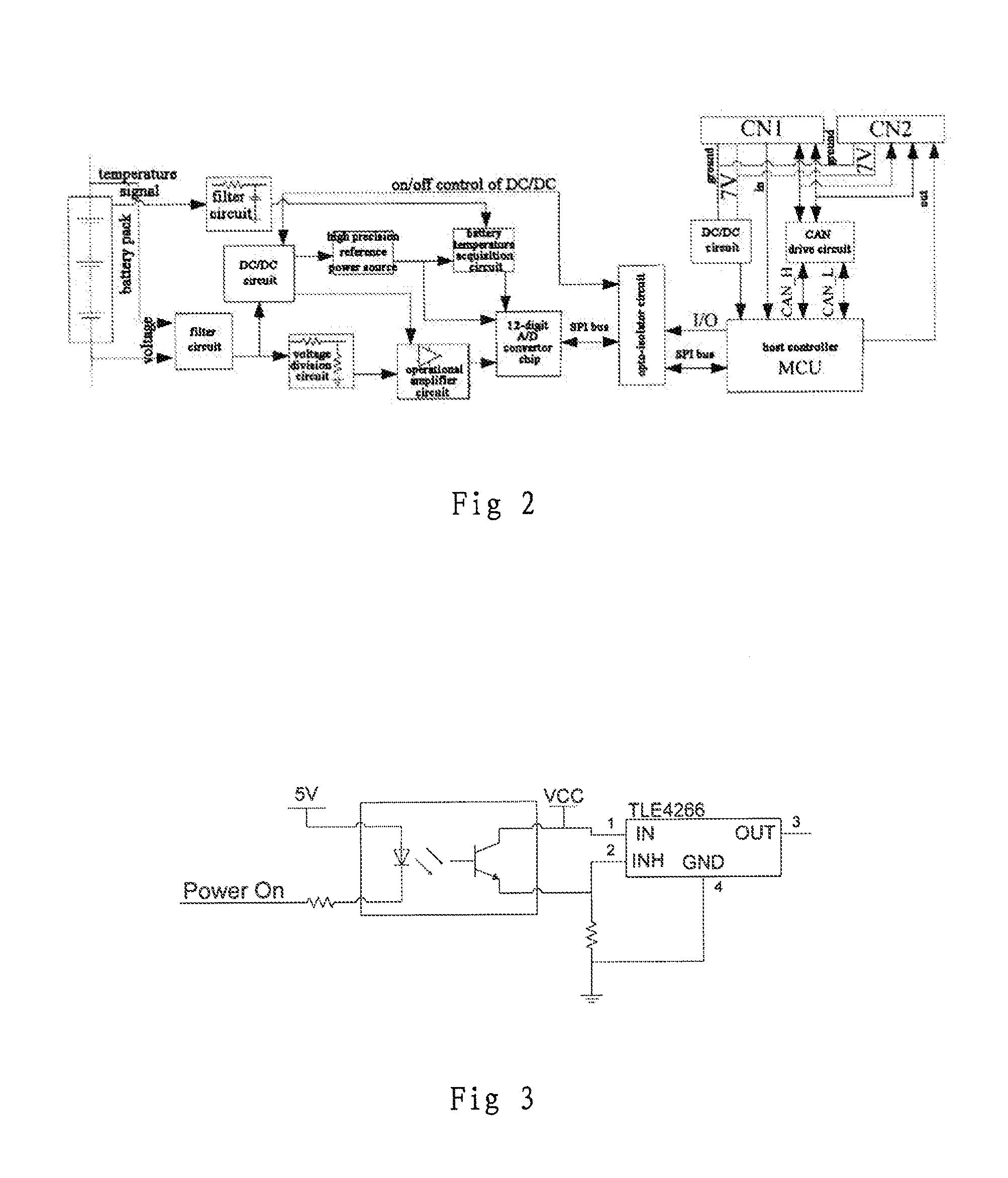

Apparatus for Monitoring Battery Voltage and Temperature

ActiveUS20110218748A1Increase manufacturing costSimple structureElectrical testingElectric vehicle charging technologyElectrical batteryHigh voltage battery

An apparatus for monitoring battery voltage and temperature includes a host controller and acquisition boards, and every acquisition board for the battery includes a voltage acquisition module, a temperature acquisition module, a host control chip MCU, A / D convertor module, an opto-isolator module, a CAN bus communication module and two external connection ports CN1, CN2. The input end of the AD transformation module is connected with the output end of the voltage acquisition module and the temperature acquisition module, and the output end of the A / D convertor module is connected with the opto-isolator module via a SPI bus, and the I / O port of the SPI bus module in the main control chip MCU is connected with the opto-couple isolation module, and the host control chip MCU is connected with the CAN bus communication module of the host controller via the CAN bus communication module, and the acquisition boards are connected via a socket piece in turn. The present invention is simple in structure, convenient in operation, high in data precision and high in the consistency and interchangeability of each acquisition board. Furthermore, the present invention utilizes opto-isolator module to isolate the high-voltage battery with the host controller circuit, so as to avoid the problem of common mode interference.

Owner:CHERY AUTOMOBILE CO LTD

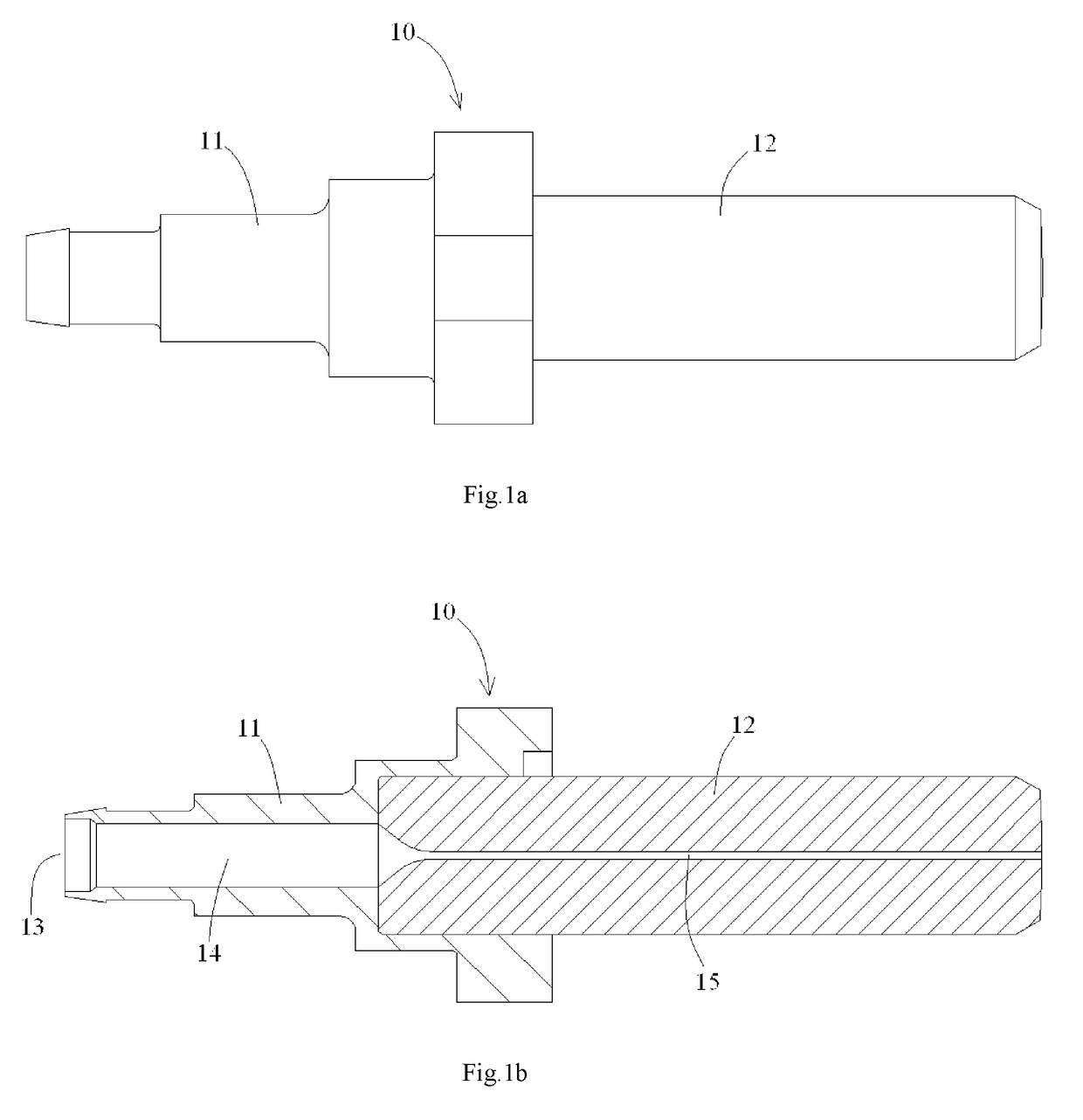

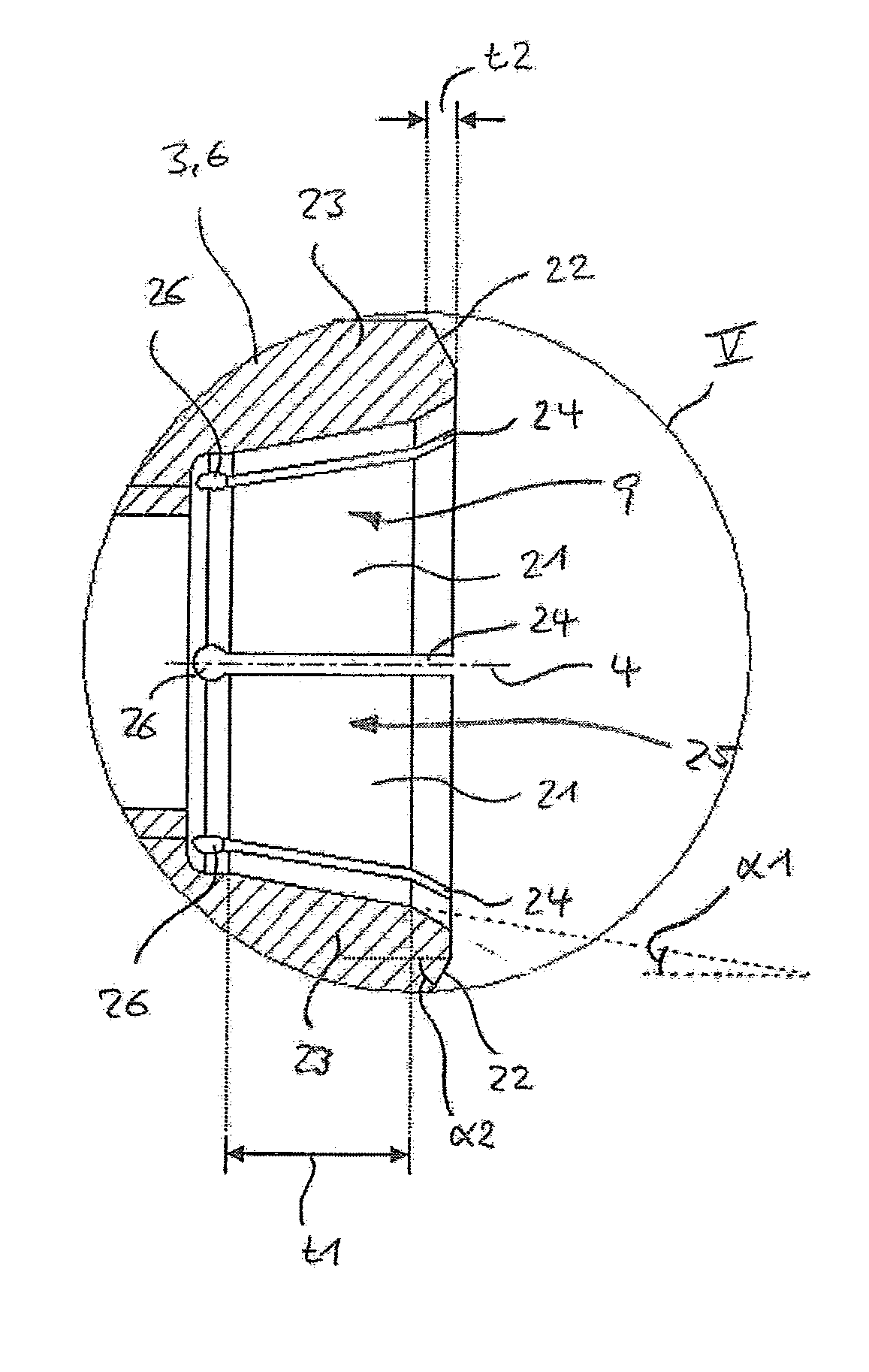

Tool interface

InactiveUS20110081212A1Improve stabilityAvoid the notch effectSleeve/socket jointsThread cutting machinesEngineeringMechanical engineering

A tool interface (5) that is easy to produce but also precise for coupling a tool head (2) to a tool shank (3) in a centered manner in respect of a shank axis (4), comprises a first interface part (6) that is connected to the tool shank (3) or to the tool head (2), and a second interface part (7) that is connected to the respectively other tool part, namely, to the tool head (2) or to the tool shank (3). The two interface parts (6, 7) have interface surfaces (9, 10) that substantially complement each other and are intended to bear flatly on each other. The interface surface (9) of the first interface part (6) comprises an inner cone surface (21) and an outer cone surface (22), which surrounds the latter on the outside and coaxially. The interface surface (9) of the second interface part (7) comprises an outer cone surface (27), which corresponds with the inner cone surface (21) of the first interface part (6), and an inner cone surface (28), which corresponds with the outer cone surface (22) of the first interface part (6). In the case of a first invention variant, an annular web (23) formed between the inner cone surface (21) and the outer cone surface (22) of the first interface part (6) is slotted by at least one recess (24). In the case of a second invention variant, the second interface part (7) has a central bore (20) surrounded coaxially by its outer cone surface (27), an annular web (29) formed between the outer cone surface (27) and this bore (20) being in this case slotted by at least one recess (24).

Owner:KENNAMETAL INC

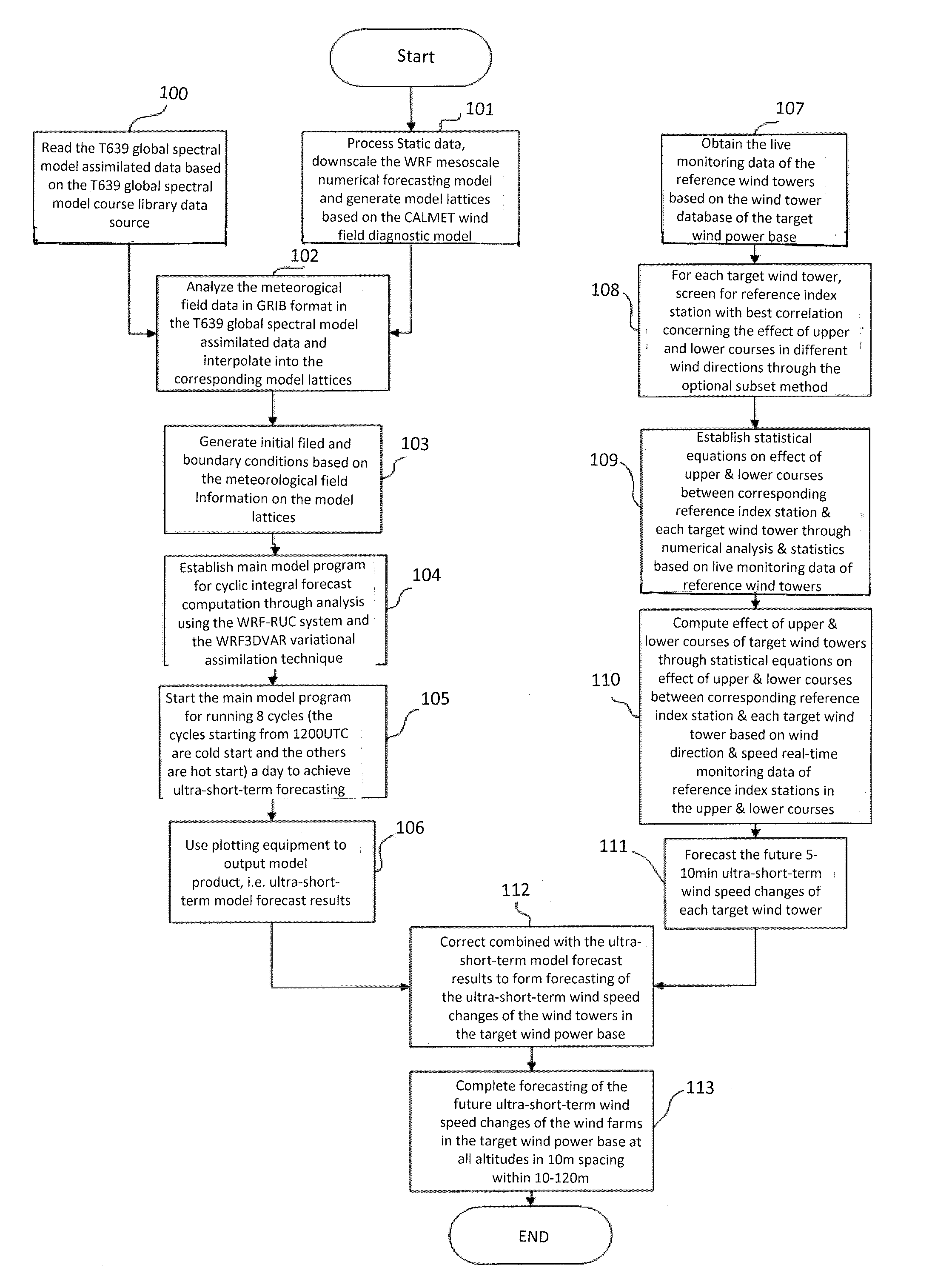

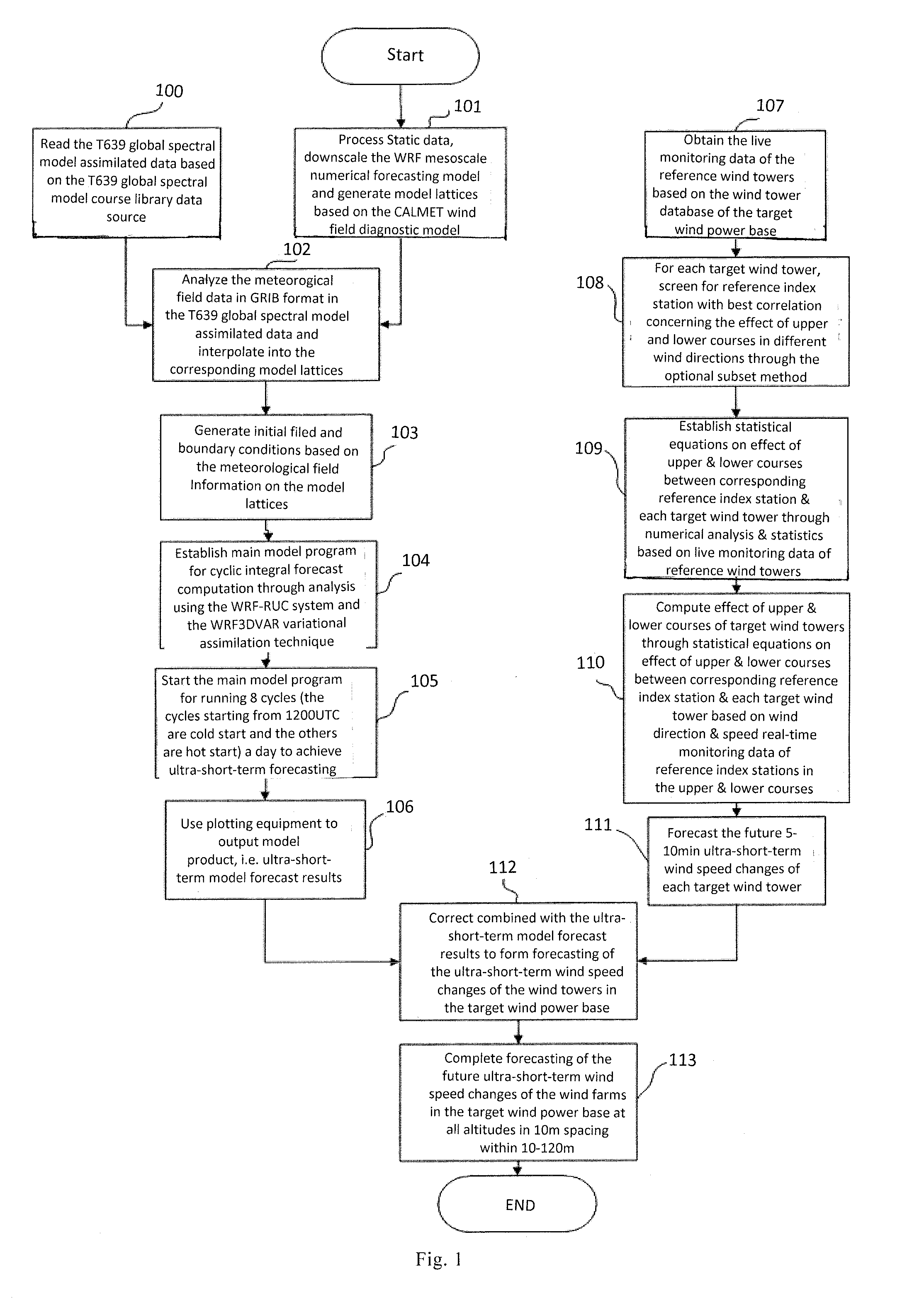

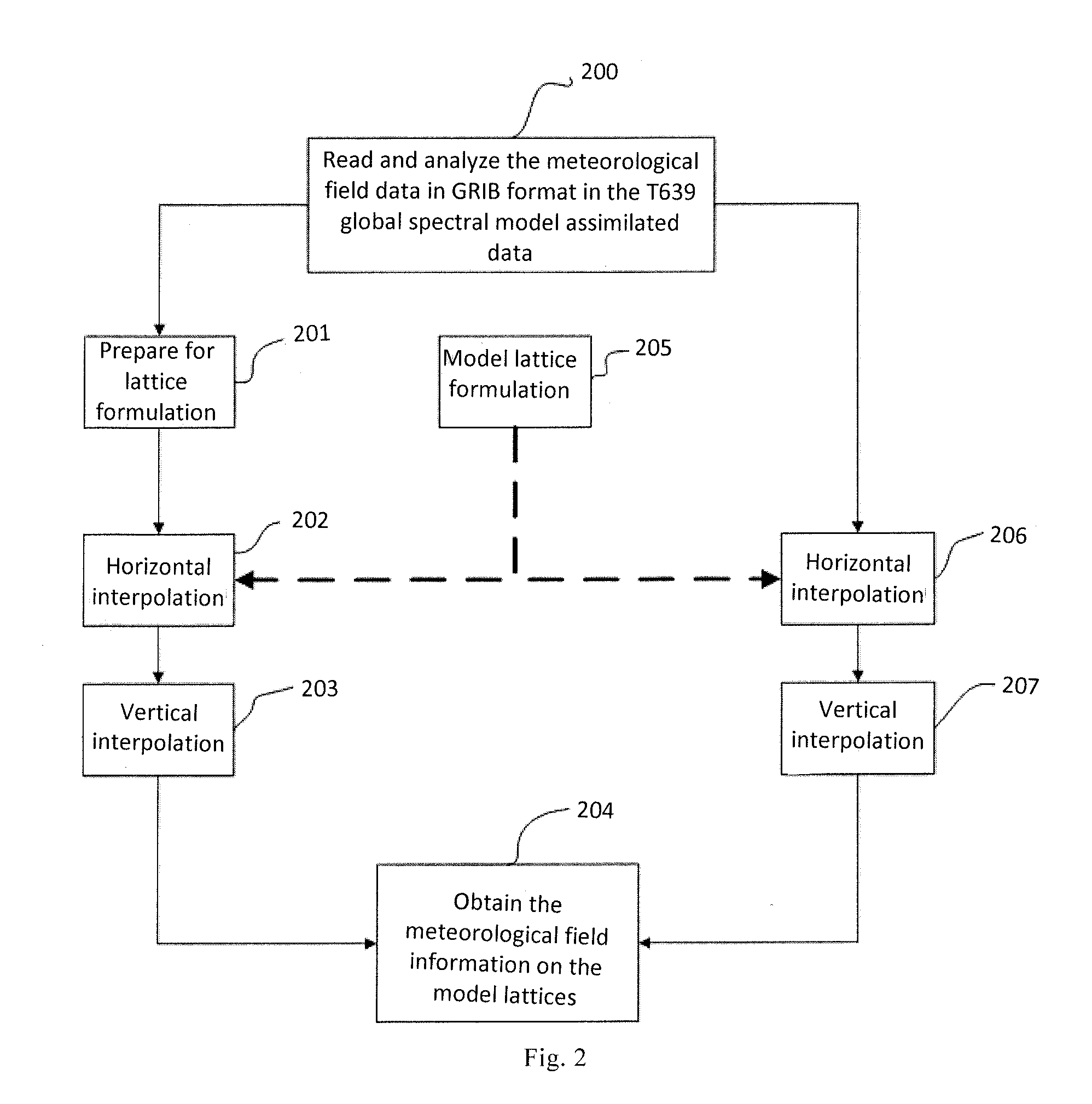

Ultra-short-term forecasting method including real-time monitoring of the effect of upper and lower courses

InactiveUS20150039228A1Improve accuracyImprove forecast accuracyWeather condition predictionIndication of weather conditions using multiple variablesShort termsDiagnostic model

An ultra-short-term forecasting method including real-time monitoring of the effect of upper and lower courses, comprising: obtaining ultra-short-term model forecast results through the model lattices based on the T639 global spectral model course library data source, the CALMET wind field diagnostic model and static data; establishing statistical equations on the effect of upper and lower courses between the corresponding reference index station and each target wind tower for obtaining the effect of upper and lower courses of the target wind towers based on the wind tower database of the target wind power base and combined with the wind direction and speed real-time monitoring data of the reference index stations in the upper and lower courses, forecasting the ultra-short-term wind speed changes of each target wind tower and correct combined with the ultra-short-term model forecast results to form forecasting of the ultra-short-term wind speed changes of the wind towers in the target wind power base; after repeated cycling, obtaining forecasting of the future ultra-short-term wind speed changes of the wind farms in the target wind power base at all altitudes in the target area. The forecasting method has high forecasting precision, good prediction accuracy and wide application range.

Owner:STATE GRID CORP OF CHINA +2

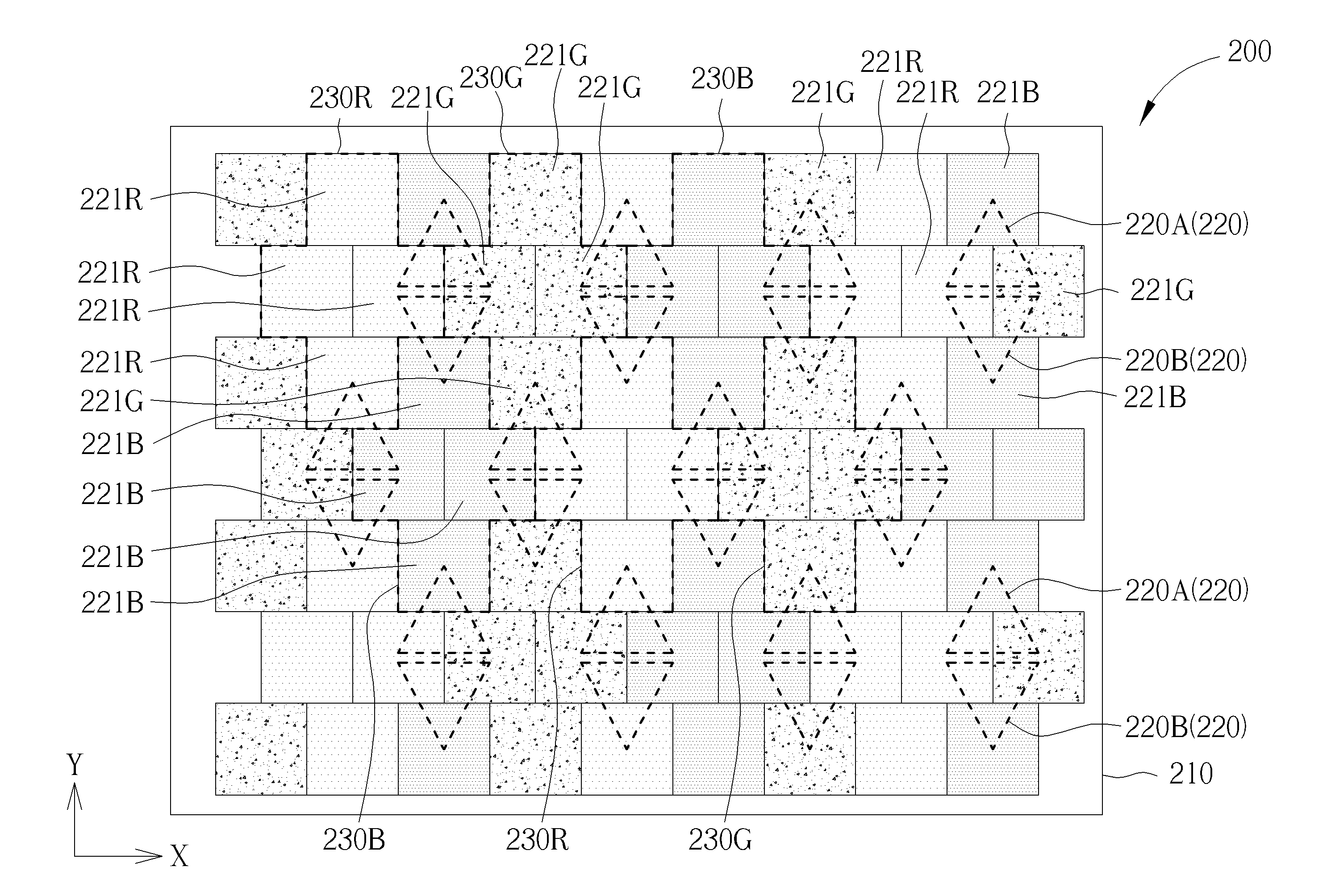

Pixel structure of organic light emitting display device

InactiveUS20140226323A1Solve high precisionHigh manufacturing stabilityLighting support devicesElectric lightingComputer graphics (images)Display device

A pixel structure of an organic light emitting display device includes a substrate and a plurality of display pixel units disposed on the substrate. Each of the display pixel units includes a first sub-pixel, a second sub-pixel and a third sub-pixel disposed adjacently to one another. The first sub-pixel in each of the display pixel units is disposed adjacently to three first sub-pixels respectively disposed in three adjacent display pixel units to form a first pixel unit. The second sub-pixel in each of the display pixel units is disposed adjacently to three second sub-pixels respectively disposed in three adjacent display pixel units to form a second pixel unit. The third sub-pixel in each of the display pixel units is disposed adjacently to three third sub-pixels respectively disposed in three adjacent display pixel units to form a third pixel unit.

Owner:CHUNGHWA PICTURE TUBES LTD

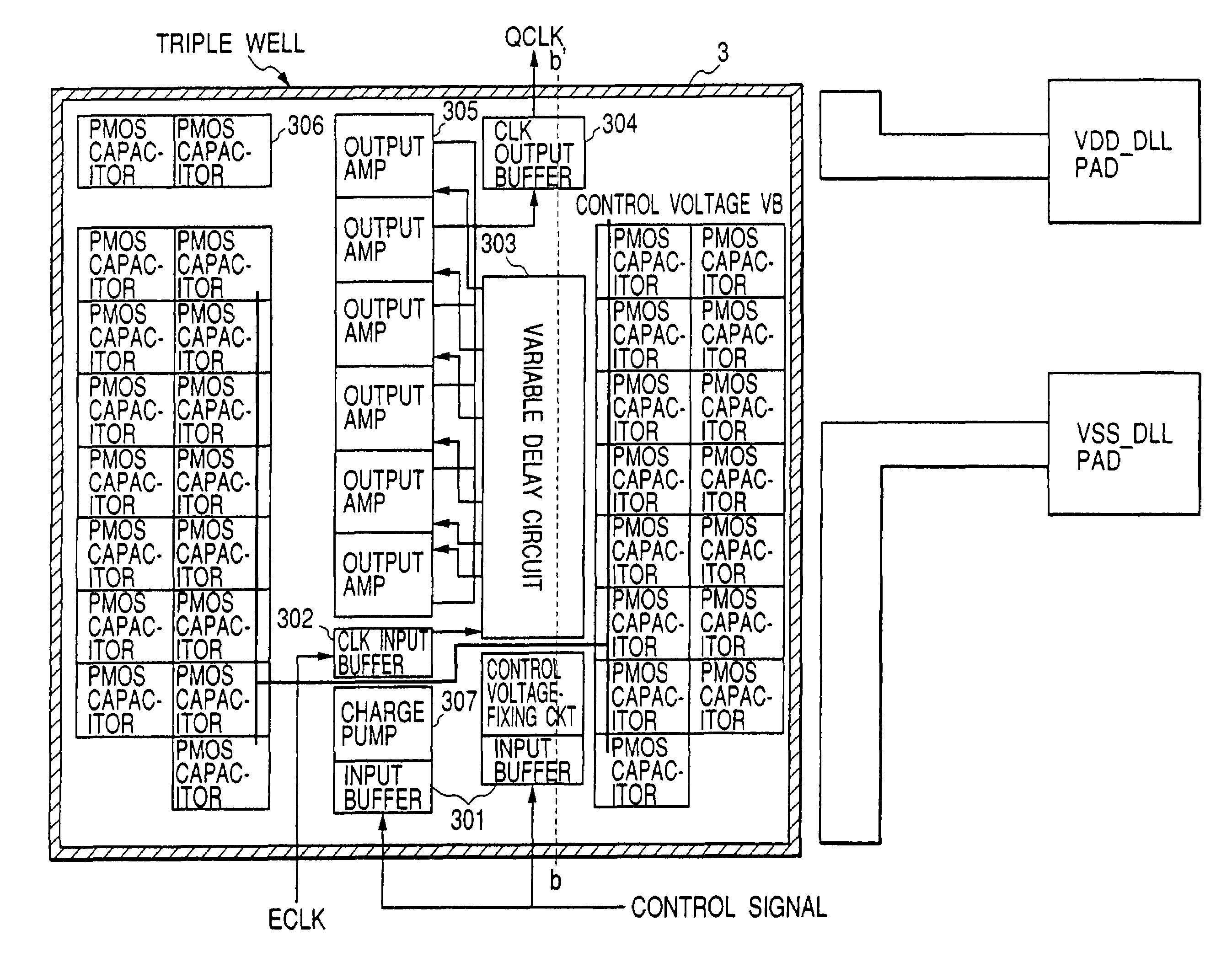

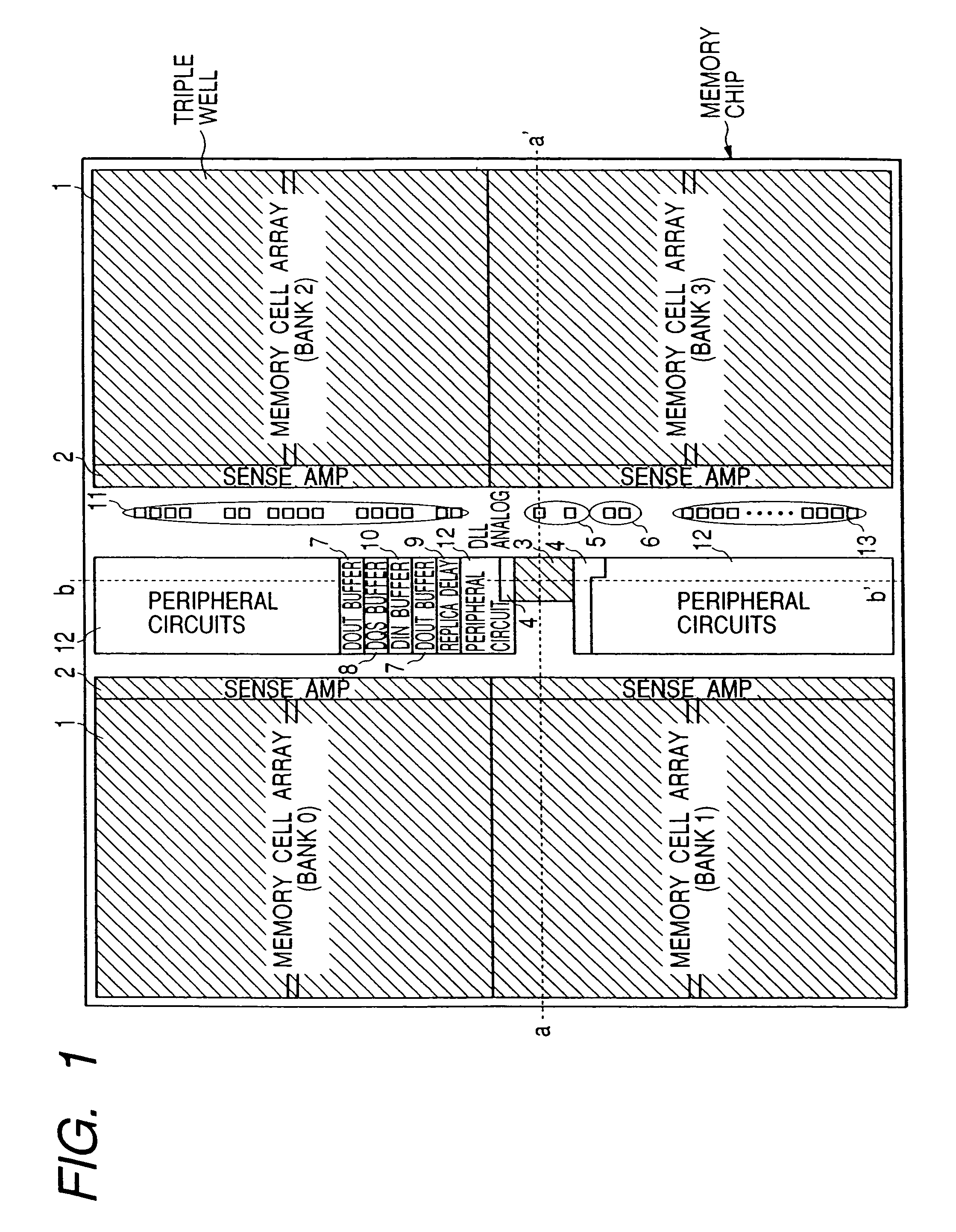

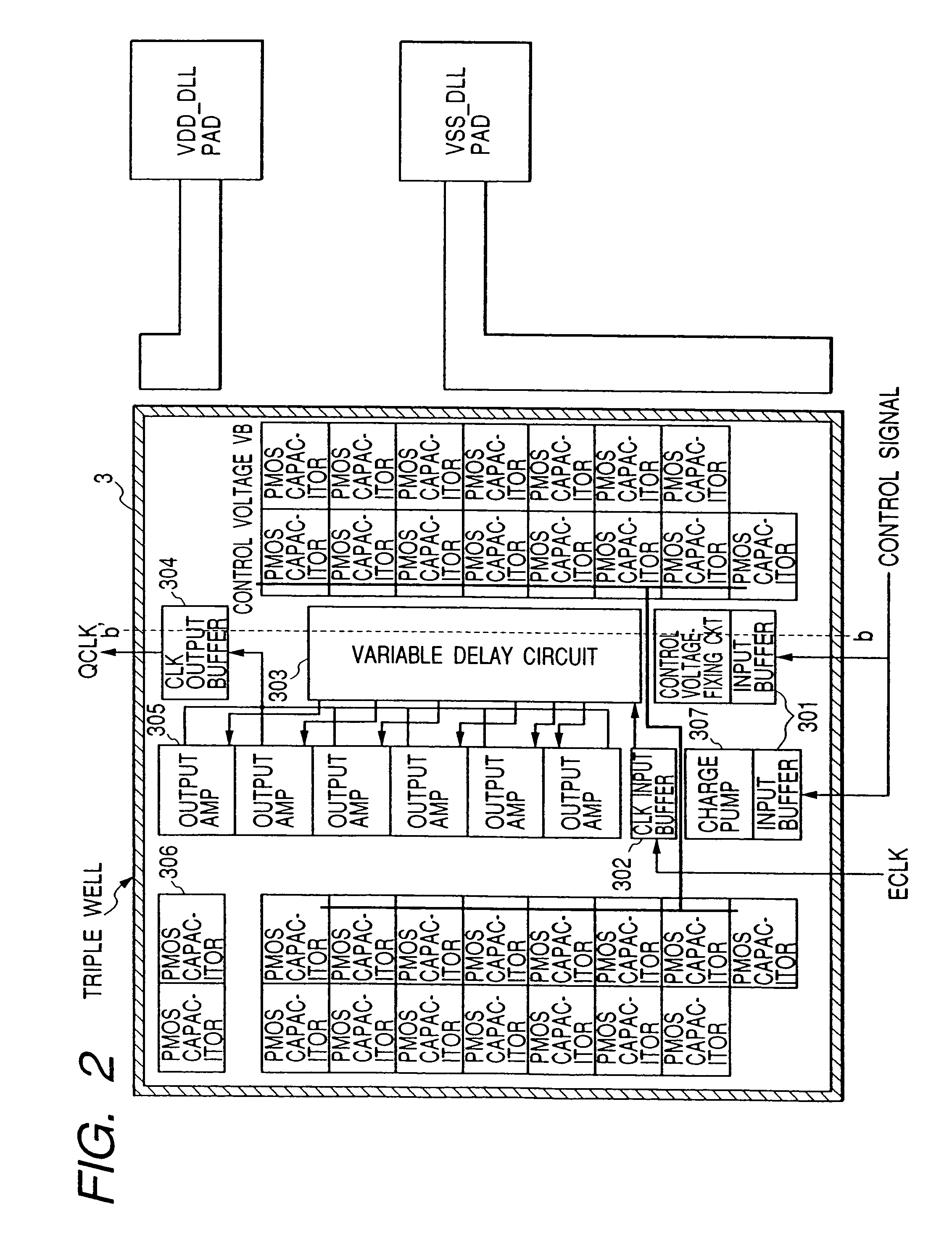

Semiconductor integrated circuit device

InactiveUS7072242B2Solve high precisionShort lock-in cycleTransistorPulse automatic controlComparators circuitsCircuit delay

A clock-generating circuit for forming internal clock signals by comparing a signal obtained by delaying, through a variable delay circuit, an input clock signal input through an external terminal with the input clock signal through a phase comparator circuit, and so controlling the delay time of the variable delay circuit that they are brought into agreement with each other, wherein the clock-generating circuit and an internal circuit to be operated by the clock signals formed thereby are formed on a common semiconductor substrate, and an element-forming region in which the clock-generating circuit is formed is electrically isolated from an element-forming region in which the digital circuit is constituted on the semiconductor substrate relying upon the element-isolation technology. The power-source passages, too, are formed independently of other digital circuits.

Owner:RENESAS ELECTRONICS CORP

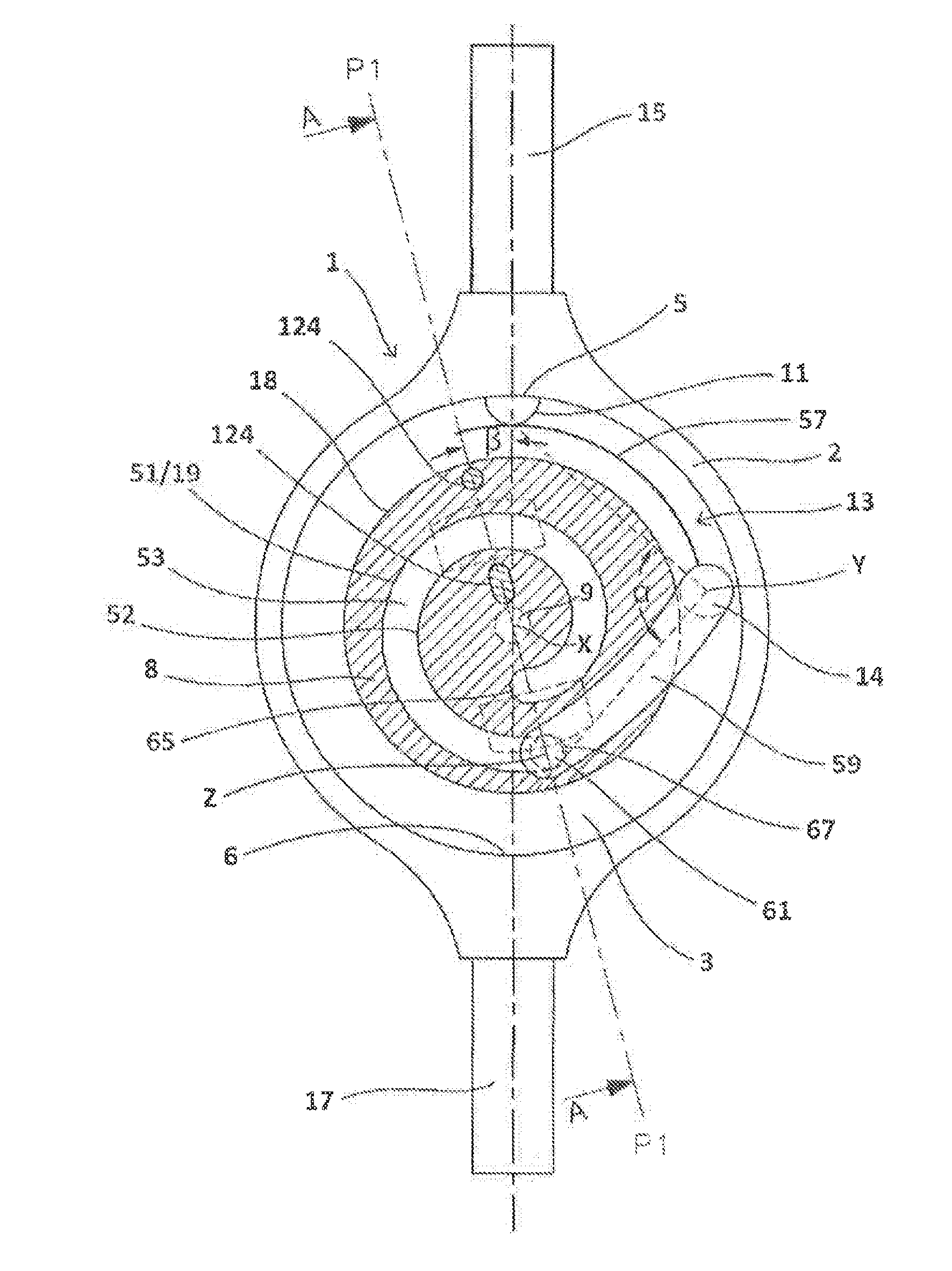

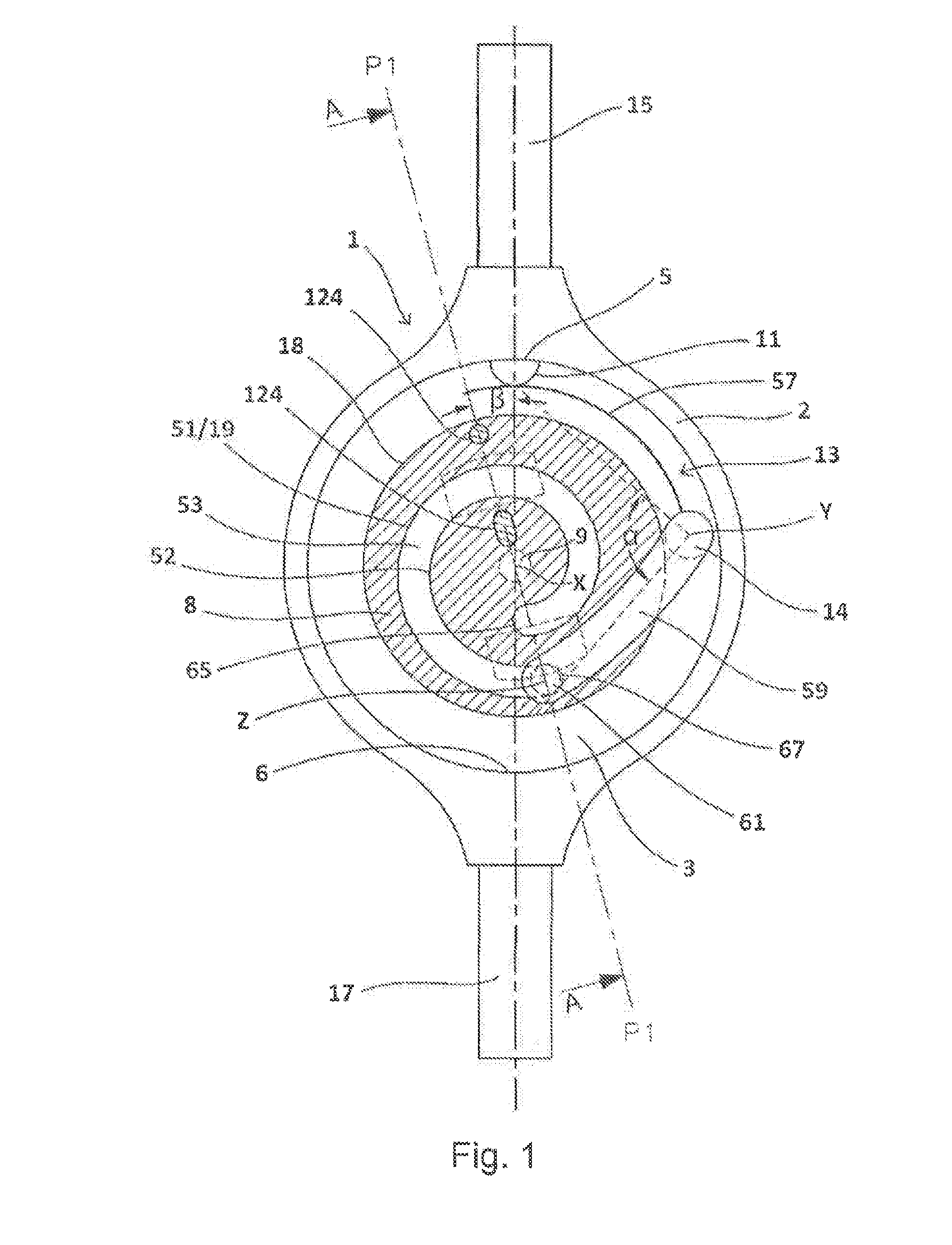

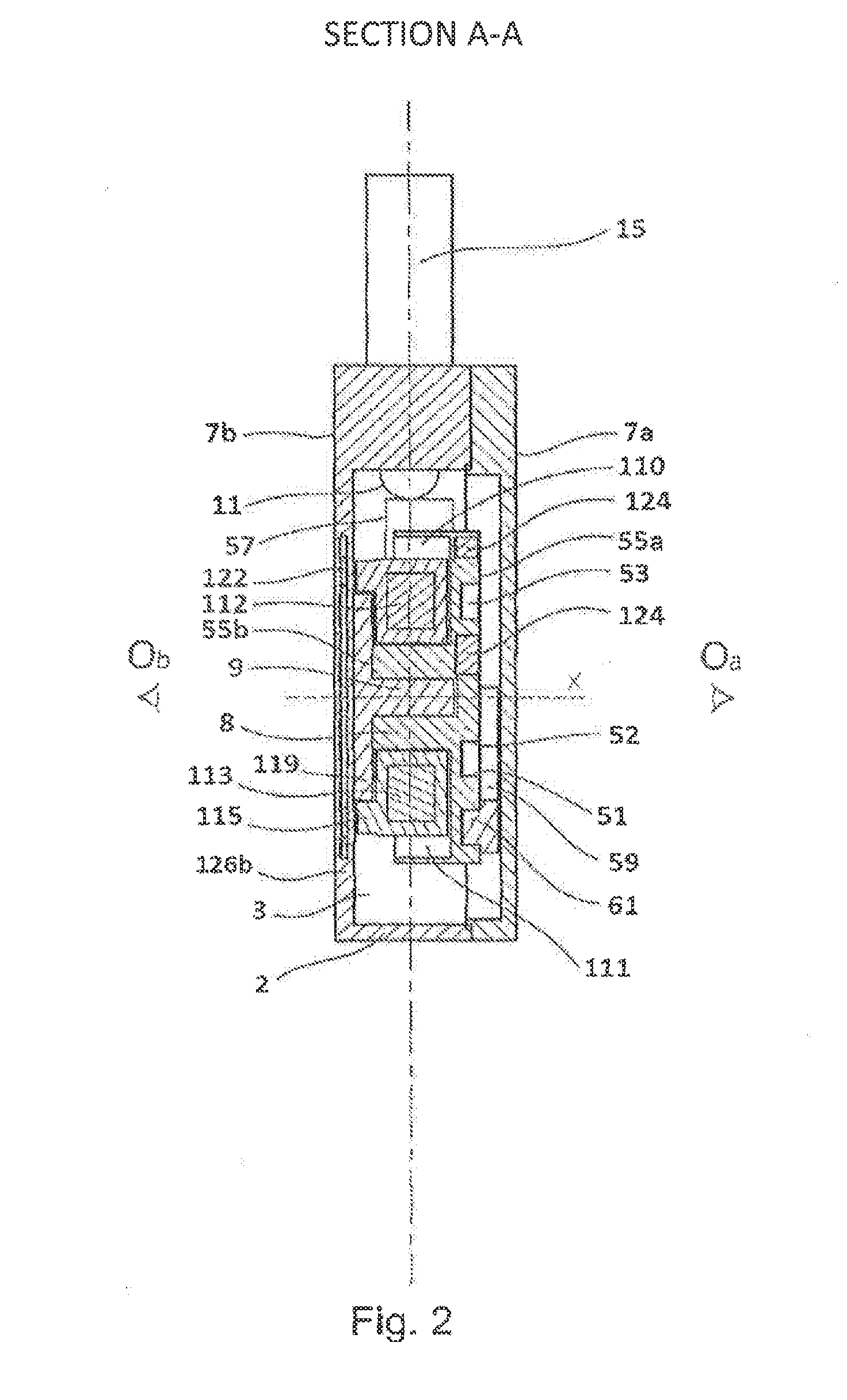

Adjustable drainage valve

ActiveUS20160220794A1Good precisionHigh mechanical precisionWound drainsMedical devicesEngineeringCam

A drainage valve intended to be implanted and to drain the cerebrospinal fluid, including: a body defining a chamber into which there open an inlet port and an outlet port, a stopper capable of at least partially, or indeed completely, closing off the inlet port, a resilient return member exerting a resilient push force on the stopper towards the inlet port in order to open or close the port, a rotor housed in the chamber, able to rotate about an X-axis pivot and including a cam track on which the resilient return member rests such that the force exerted by the resilient return member on the stopper is modified by the rotation of the rotor.

Owner:SOPHYSA SA

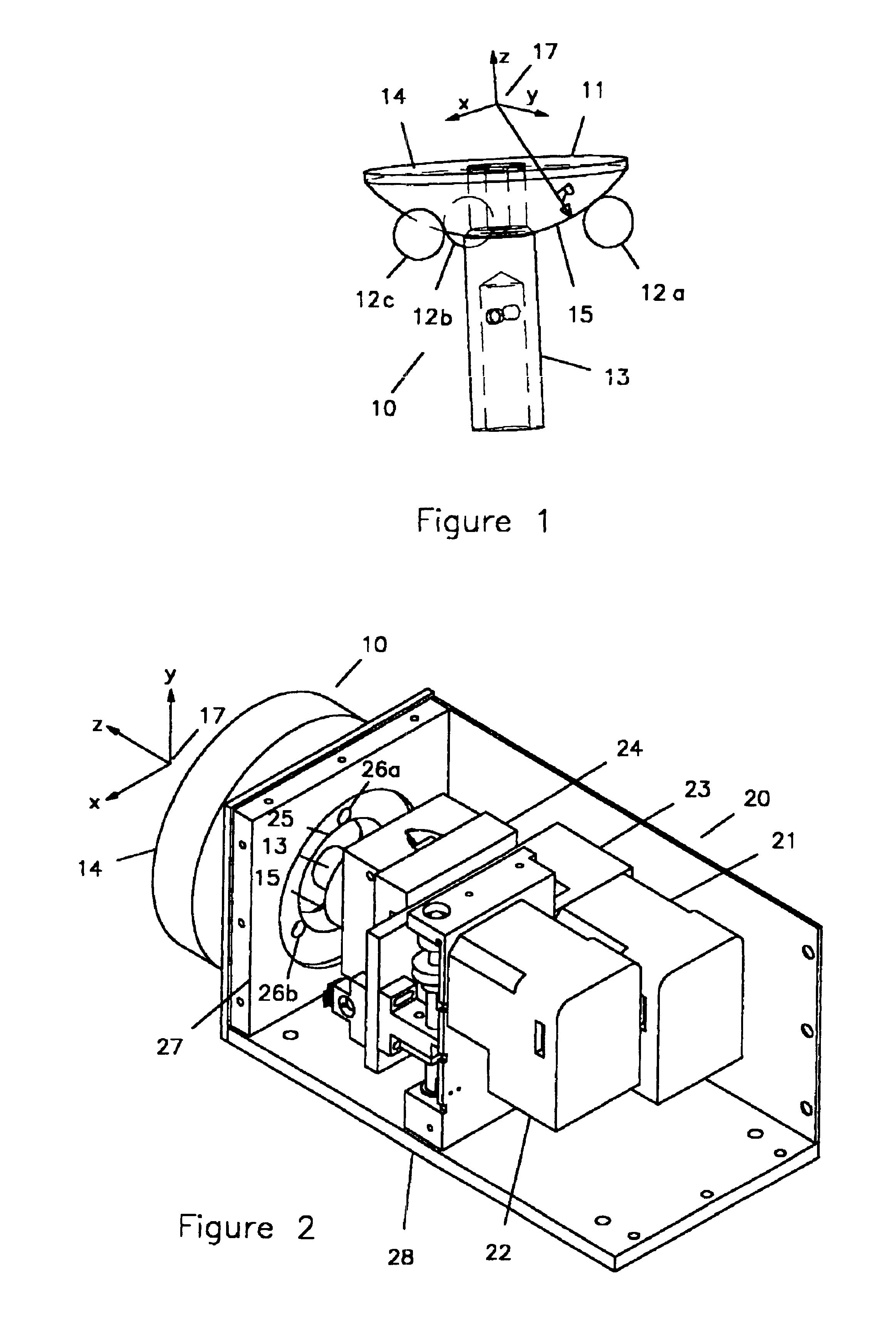

Low-cost, high precision goniometric stage for x-ray diffractography

InactiveUS6888920B2Solve high precisionImprove accuracyHandling using diffraction/refraction/reflectionMountingsRotational axisStepper

A low-cost, high precision goniometric stage, for use in x-ray diffractography or in optical systems, with a spherical sector supported on at least one bearing, a top surface of the spherical sector that is used for mounting an object, a center of rotation located within the object, a rod or other member that is disposed below the spherical bearing surface, preferably orthogonal to the rotational axes, stepper motors or other actuators to move the device and a mechanical linkage between the rod and the motors.

Owner:ADVANCED DESIGN COSULTING USA

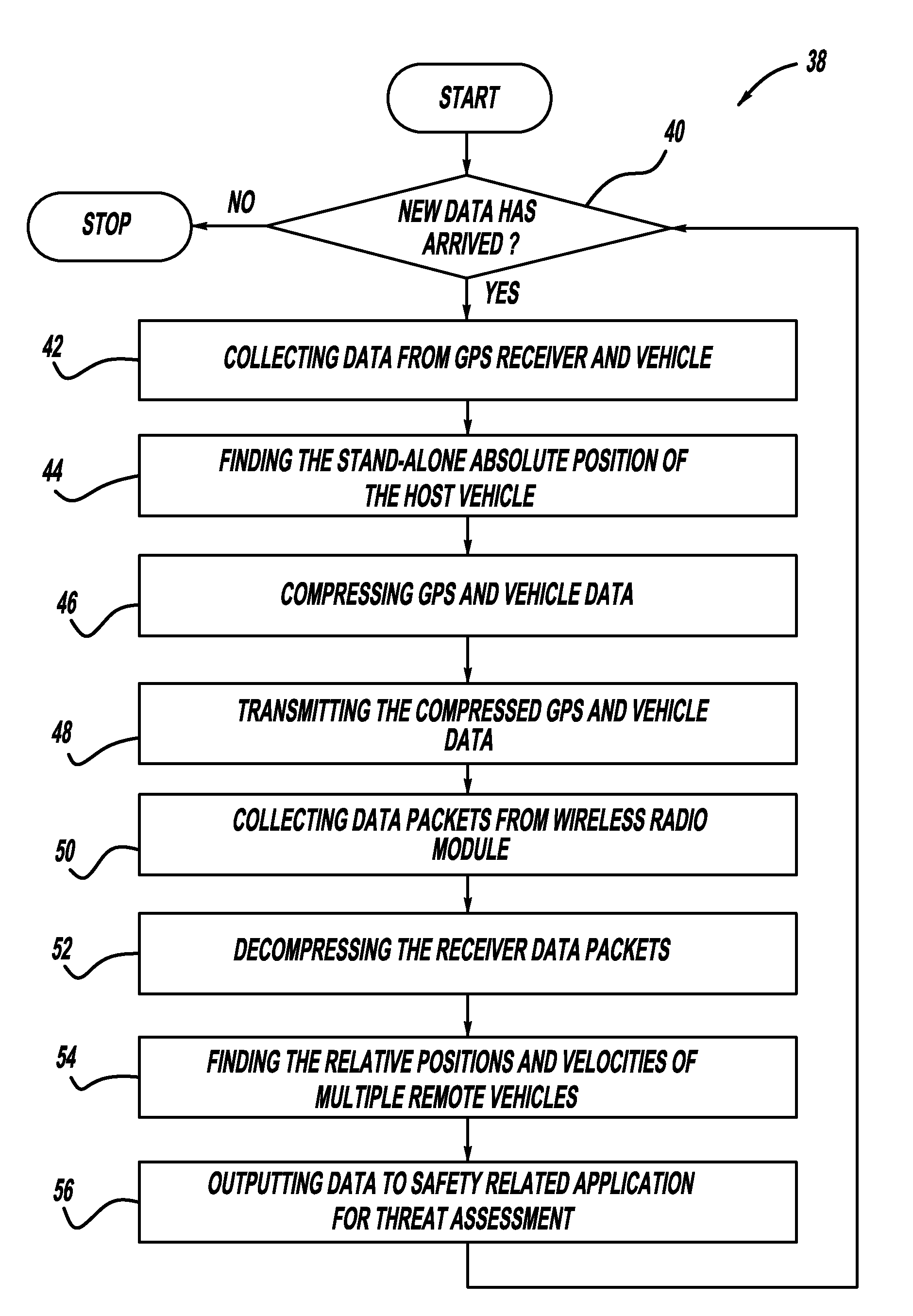

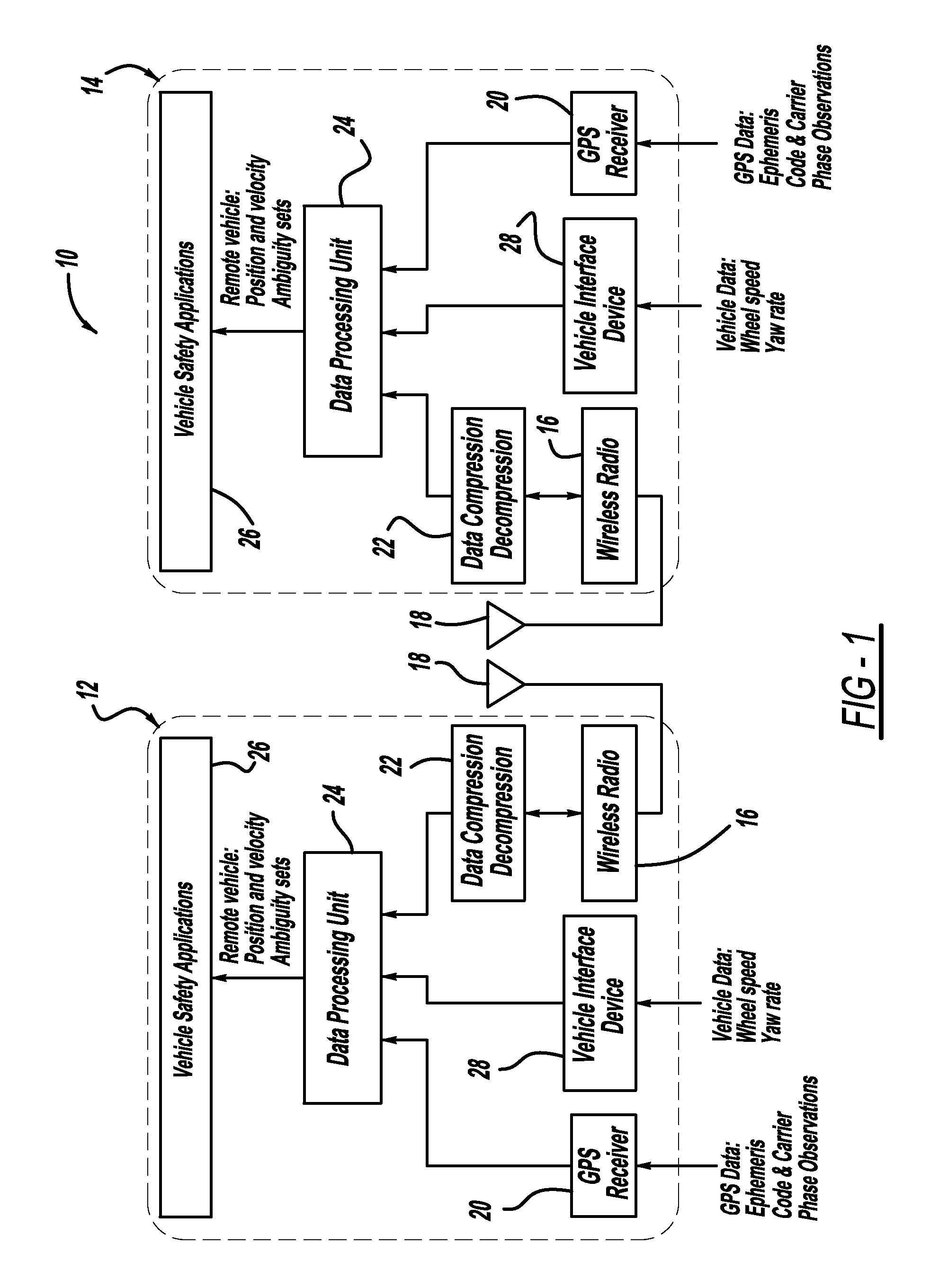

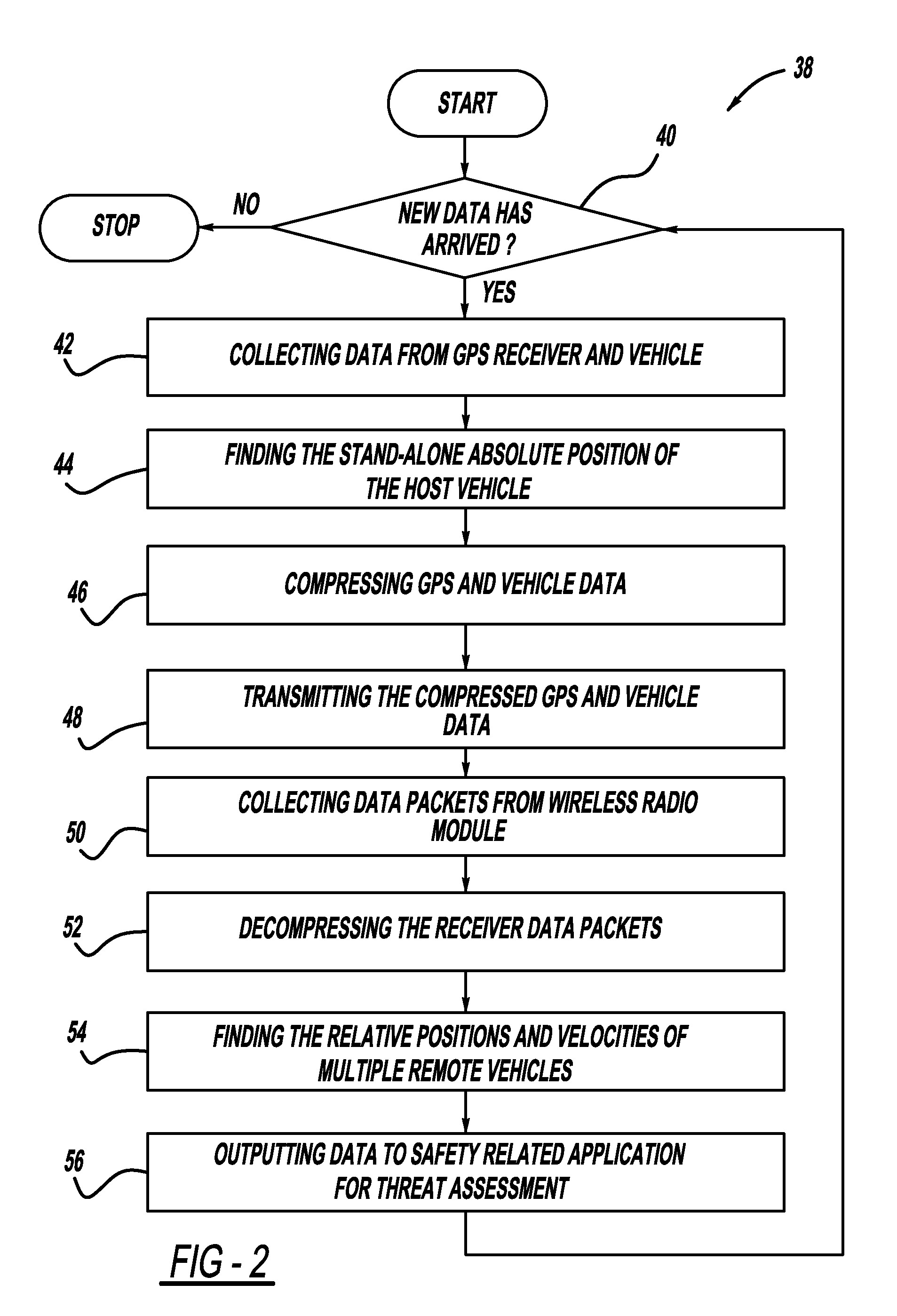

Method and apparatus for precise relative positioning in multiple vehicles

InactiveUS20100245171A1Solve high precisionDirection finders using radio wavesPosition fixationGraphicsEngineering

A system and method for determining the position and velocity of a plurality of vehicles relative to a host vehicle using GPS data. The method includes building a graph of the vehicles that define weighted baselines between each of the vehicles and the host vehicle and each of the vehicles where the weighted baselines define a geometric dilution of precision between the vehicles. The method then determines the optimal baseline between the host vehicle and each of the other vehicles using the weighted baselines based on the lowest geometric dilution of precision. The method then computes the relative position and velocity between all of the vehicles and the host vehicle using the optimal baselines.

Owner:GM GLOBAL TECH OPERATIONS LLC

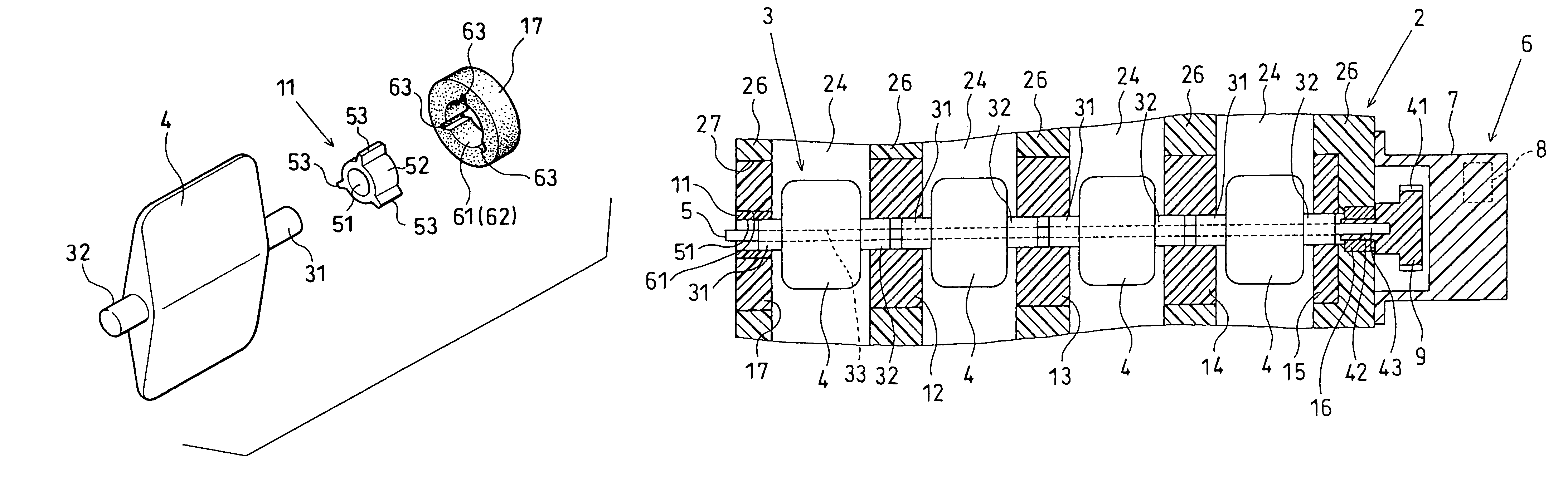

Bearing support device

InactiveUS7219652B2Easy to assembleSolve high precisionInternal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringMechanical engineering

A bearing support device includes a rotor, a bearing member, and a bearing holding member. The rotor rotates about a rotation center axis. The bearing member rotatably supports the rotor within a bearing hole passing through the bearing member. The bearing holding member holds the bearing member in a secure manner within a fitting hole that passes through the bearing holding member along the center axis of the rotor via an engagement force produced by tightly fitting the bearing member. The rotor and bearing member are made of a resin. An engagement section is provided for tightly fitting the bearing member into the fitting hole relative to the bearing hole to enable an engagement force produced by the tight fitting to act in a direction that does not affect an inner diameter dimension of the bearing hole.

Owner:DENSO CORP

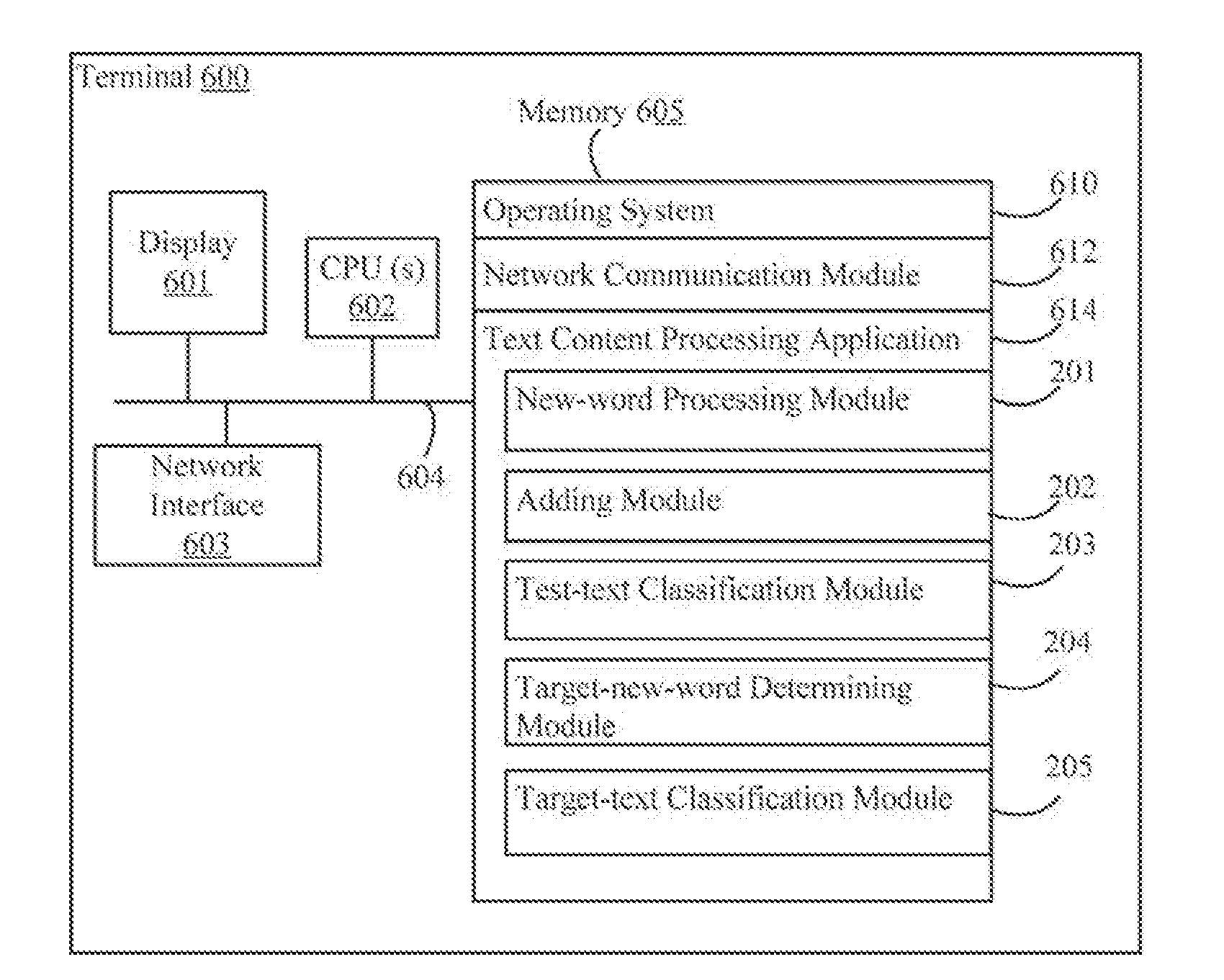

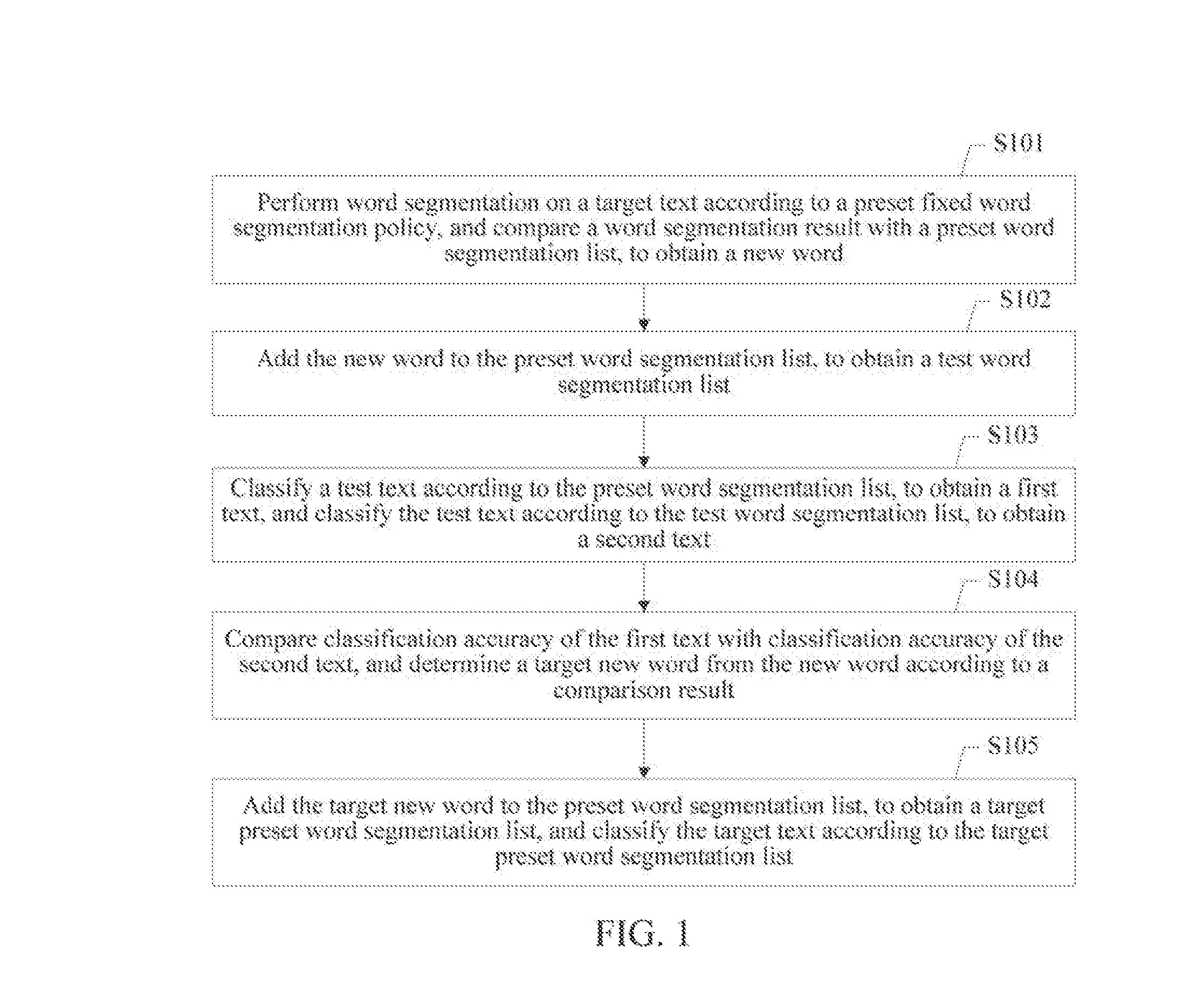

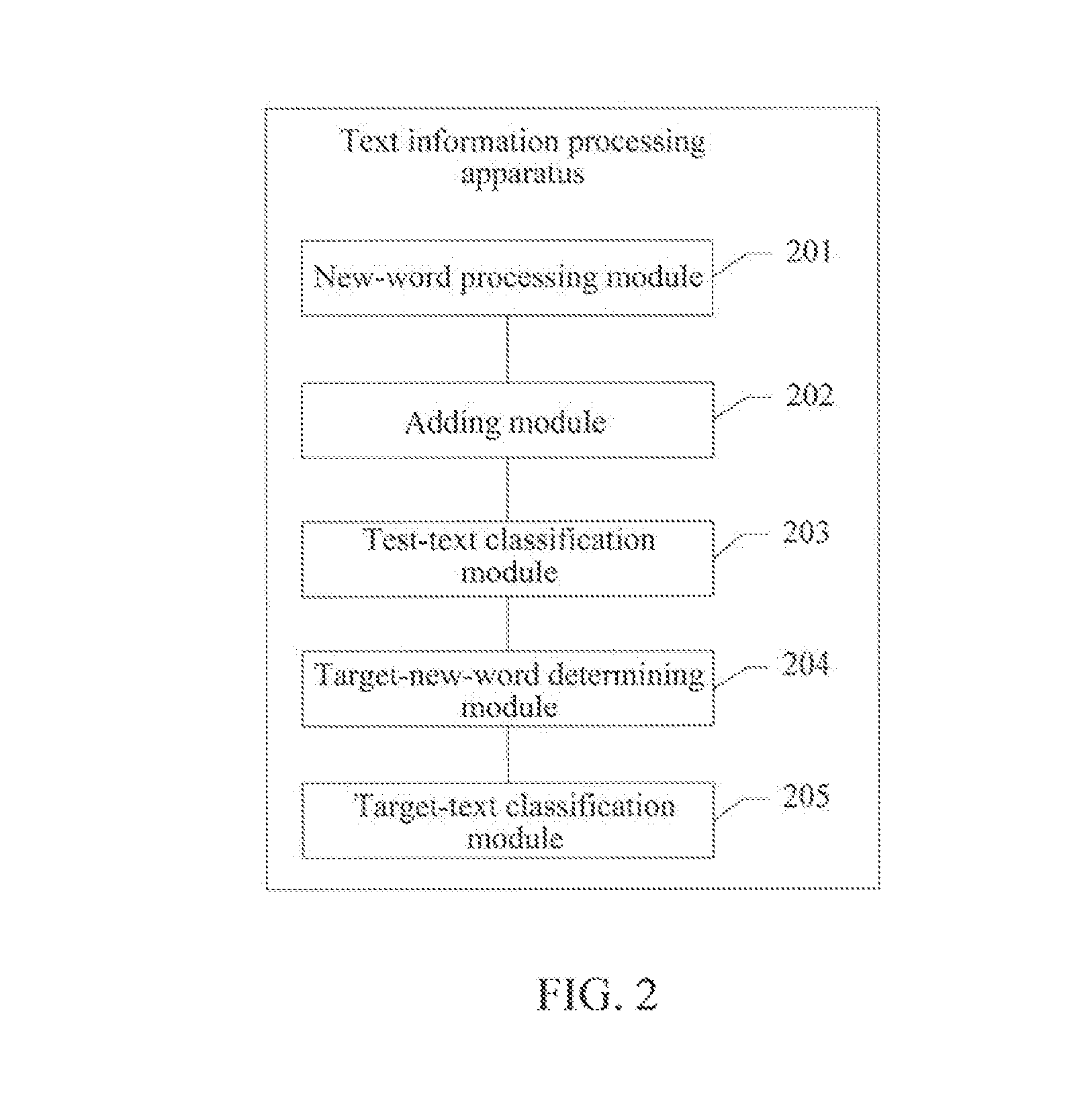

Method, apparatus, and storage medium for text information processing

ActiveUS20160283583A1High precisionSolve high precisionNatural language translationKnowledge representationInformation processingTarget text

Method, apparatus, and storage medium for text information processing are provided. The method includes: performing word segmentation on a target text according to a preset fixed word segmentation policy, and comparing a word segmentation result with a preset word segmentation list, to obtain a new word; adding the new word to the preset word segmentation list, to obtain a test word segmentation list; classifying a test text according to the preset word segmentation list, to obtain a first text, and classifying the test text according to the test word segmentation list, to obtain a second text; comparing classification accuracy of the first text with classification accuracy of the second text, and determining a target new word from the new word according to a comparison result; and adding the target new word to the preset word segmentation list, and classifying the target text.

Owner:TENCENT TECH (SHENZHEN) CO LTD

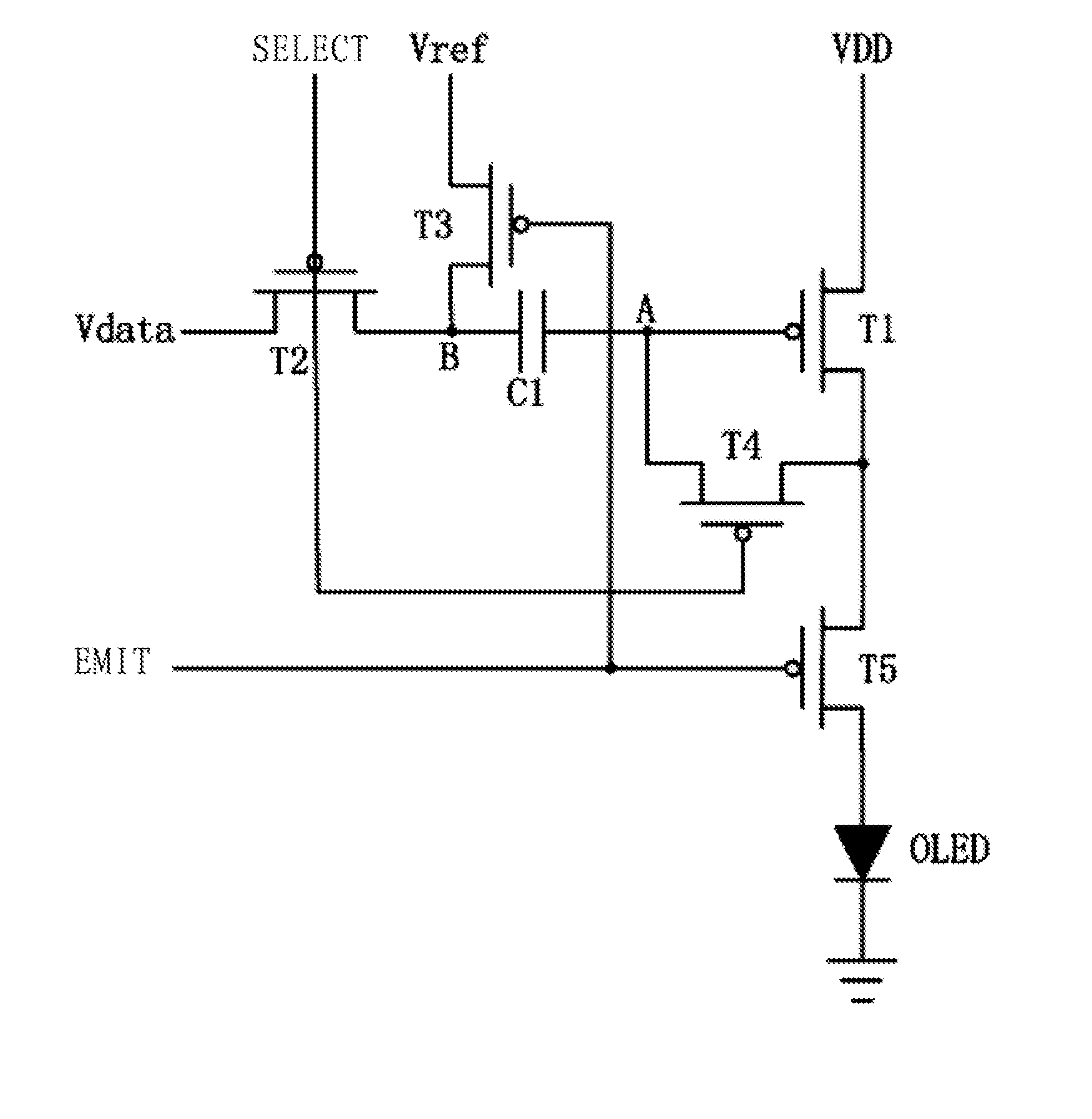

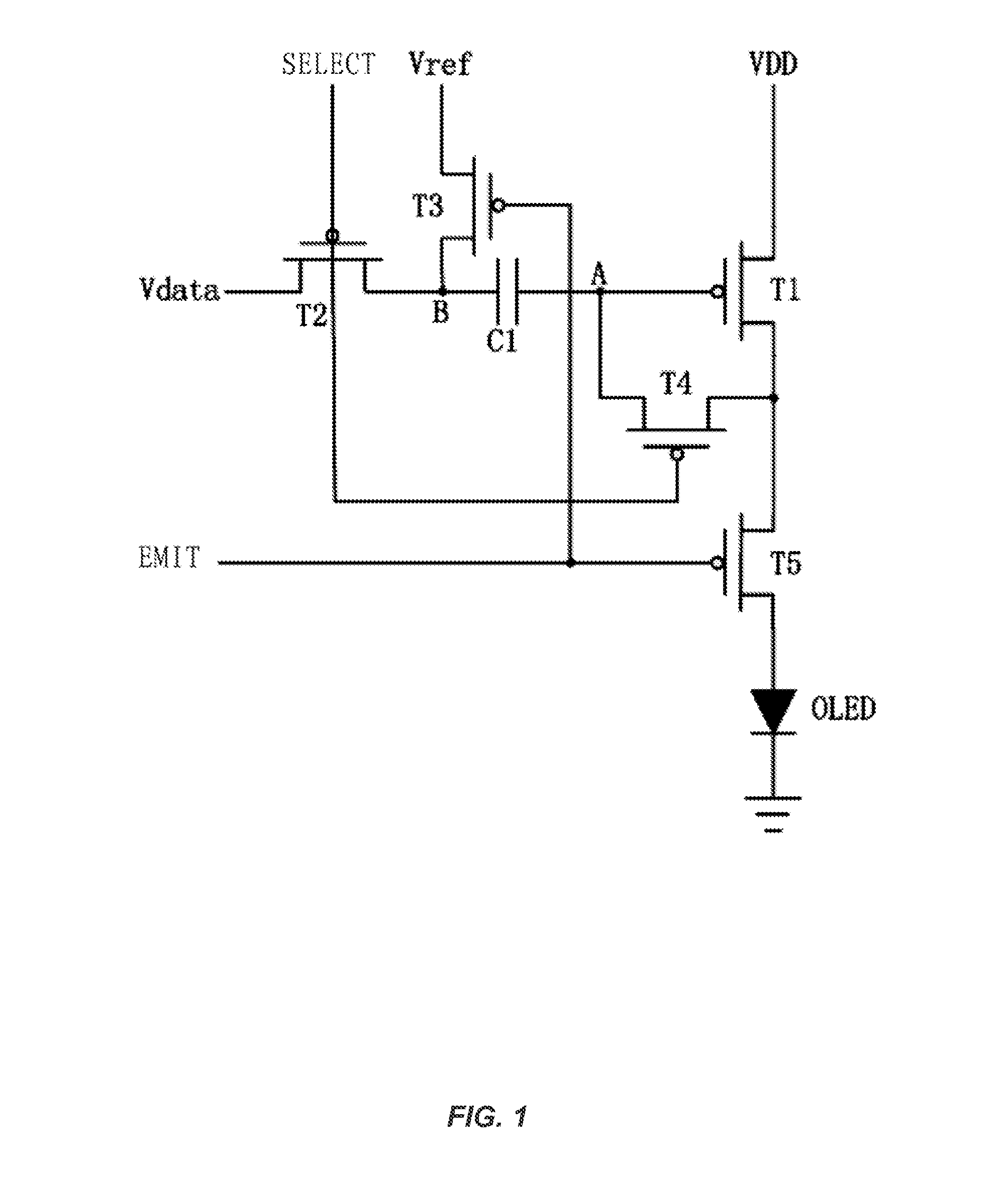

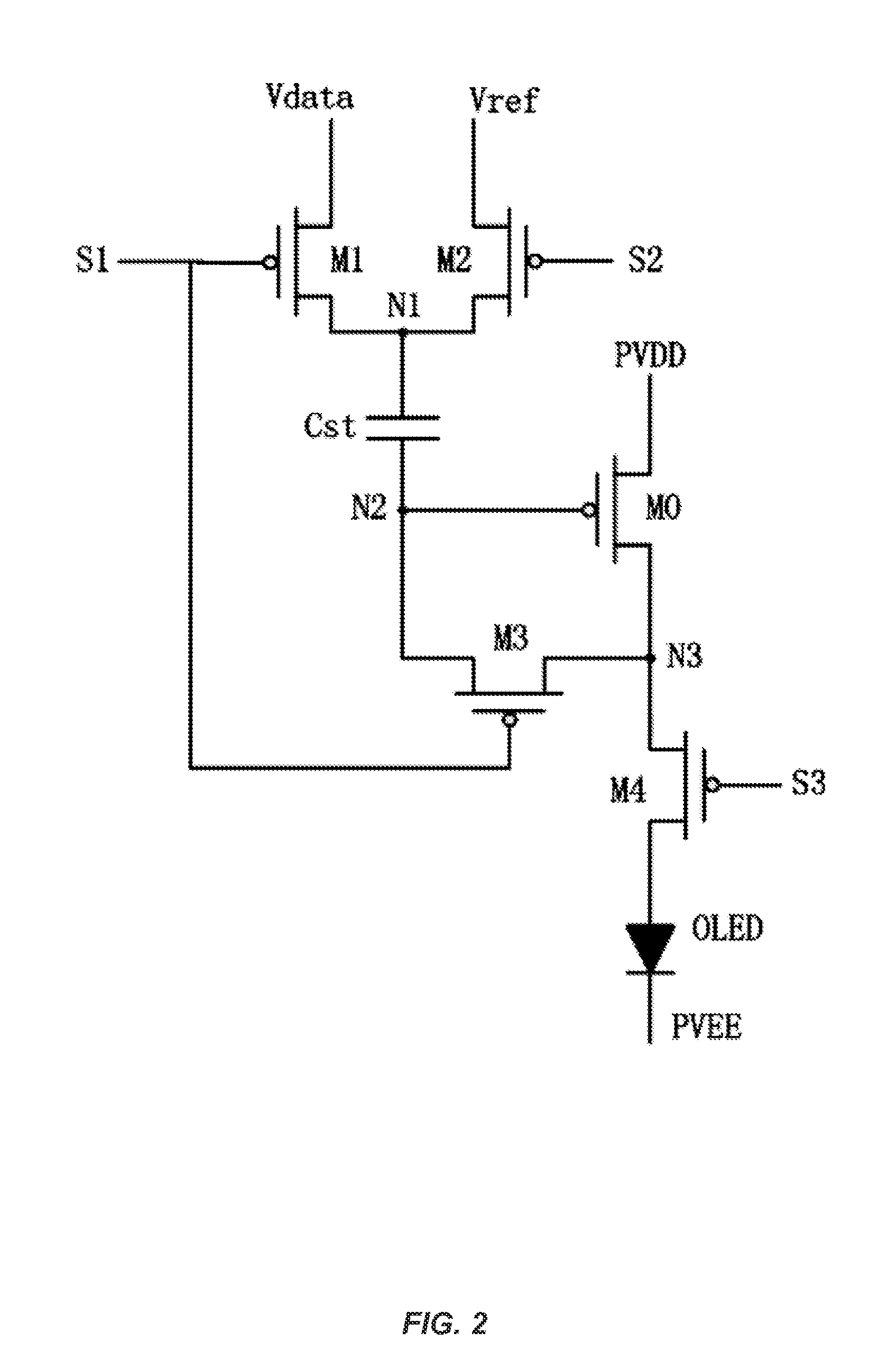

Organic light emitting display and pixel compensation circuit and method for organic light emitting display

ActiveUS20150187266A1Solve high precisionAccurate compensationStatic indicating devicesDriving currentPower flow

The present invention discloses a pixel compensation circuit and method for an organic light emitting display. The circuit comprises a first transistor, a second transistor, a third transistor, a fourth transistor, a driving transistor, a capacitor, and an organic light emitting element. The first transistor transmits a data signal to a first plate of the capacitor; the second transistor applies a reference voltage to the first plate of the capacitor; the driving transistor determines a magnitude of a driving current; the third transistor establishes a connection between the gate electrode and the drain electrode of the driving transistor; the fourth transistor passes the driving current from the driving transistor to the organic light emitting element; and the organic light emitting element emits light in response to the driving current.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

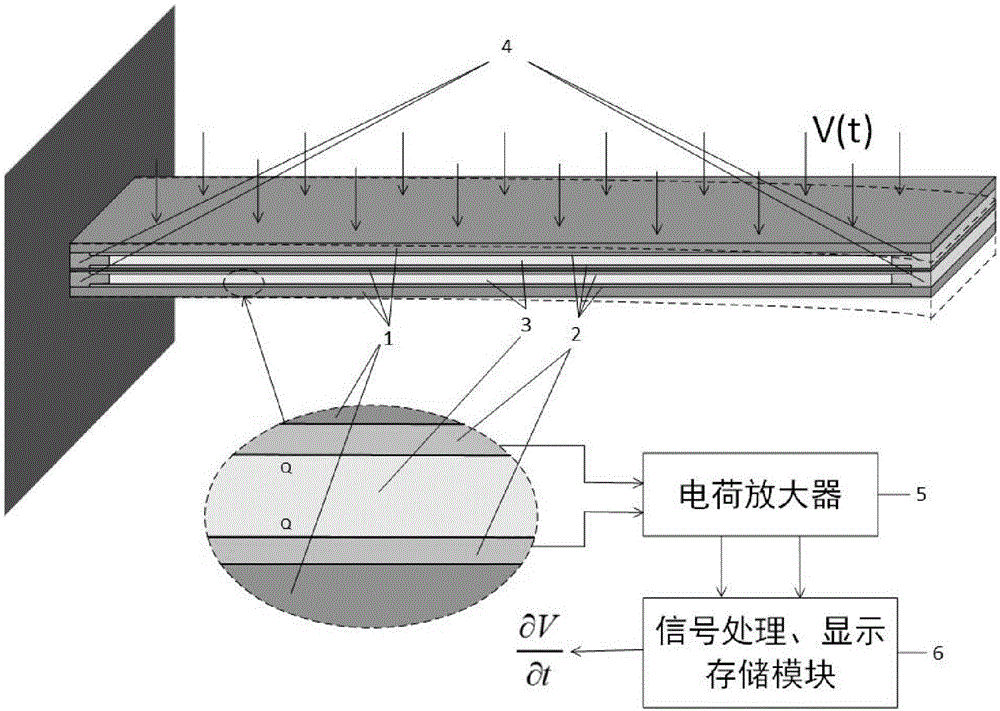

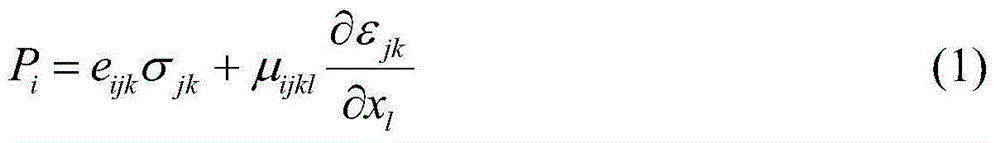

Flow speed change rate sensing structure based on flexoelectric effect and measuring method thereof

ActiveCN105137118AGood real-time performanceSimple structureAcceleration measurement using interia forcesMeasurement precisionSpare part

The invention provides a flow speed change rate sensing structure based on the flexoelectric effect and a measuring method thereof. The measuring structure comprises insulating layers, electrode layers and flexoelectric material layers. The multiple layers are repeatedly superposed and the spare parts are filled by insulating adhesive material. The electrode layers are externally connected with conductive wires so as to form a laminated measuring element which is connected with a charge amplifier. The output end of the charge amplifier is connected with signal processing, display and storage modules. When flow speed change rate is measured, the laminated measuring element is arranged in a flow field to be measured, liquid or gas in the flow field impacts the laminated measuring element and each layer is enabled to deform, the flexoelectric material layers deflect and deform, strain gradient is generated in deflection direction, polarized charges are generated at upper and lower surfaces and transmitted to the charge amplifier via the electrode layers, and flow speed change rate is displayed through processing. The laminated measuring element based on the flexoelectric principle is small, and low in influence on the flow field with no requirement for supplying power to the laminated measuring element, and thus the measuring structure has characteristics of being high in measuring precision without external mass blocks.

Owner:XI AN JIAOTONG UNIV

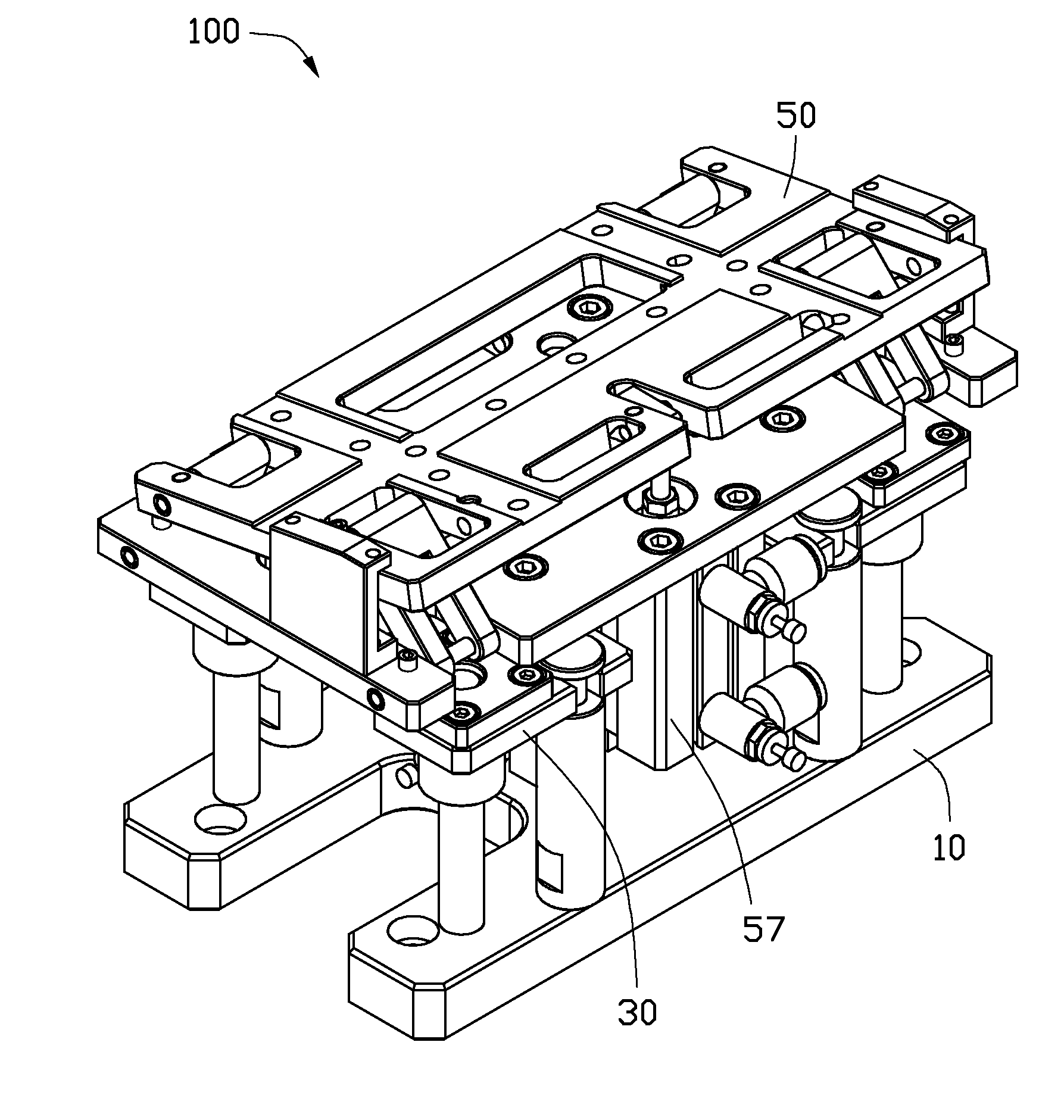

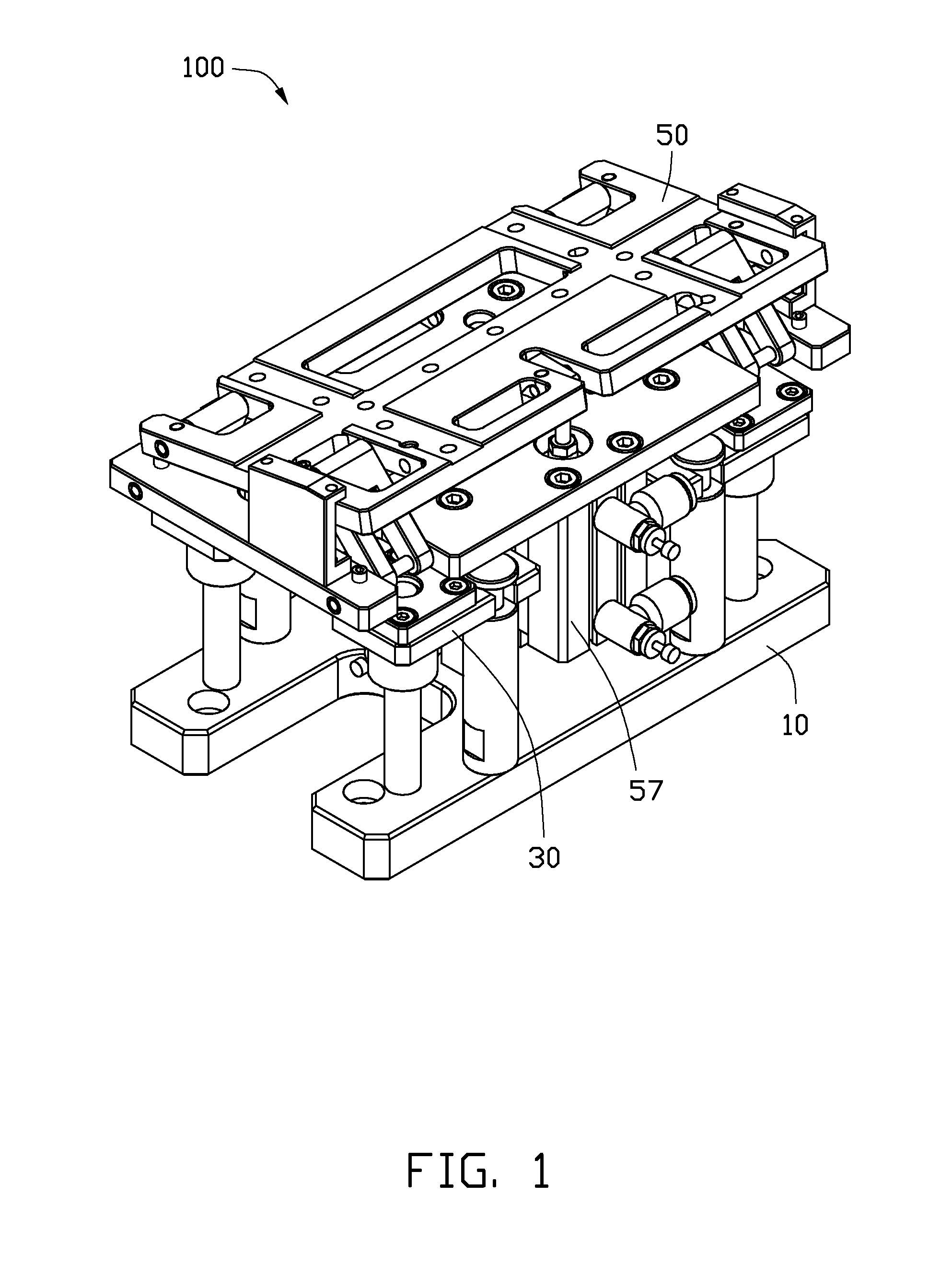

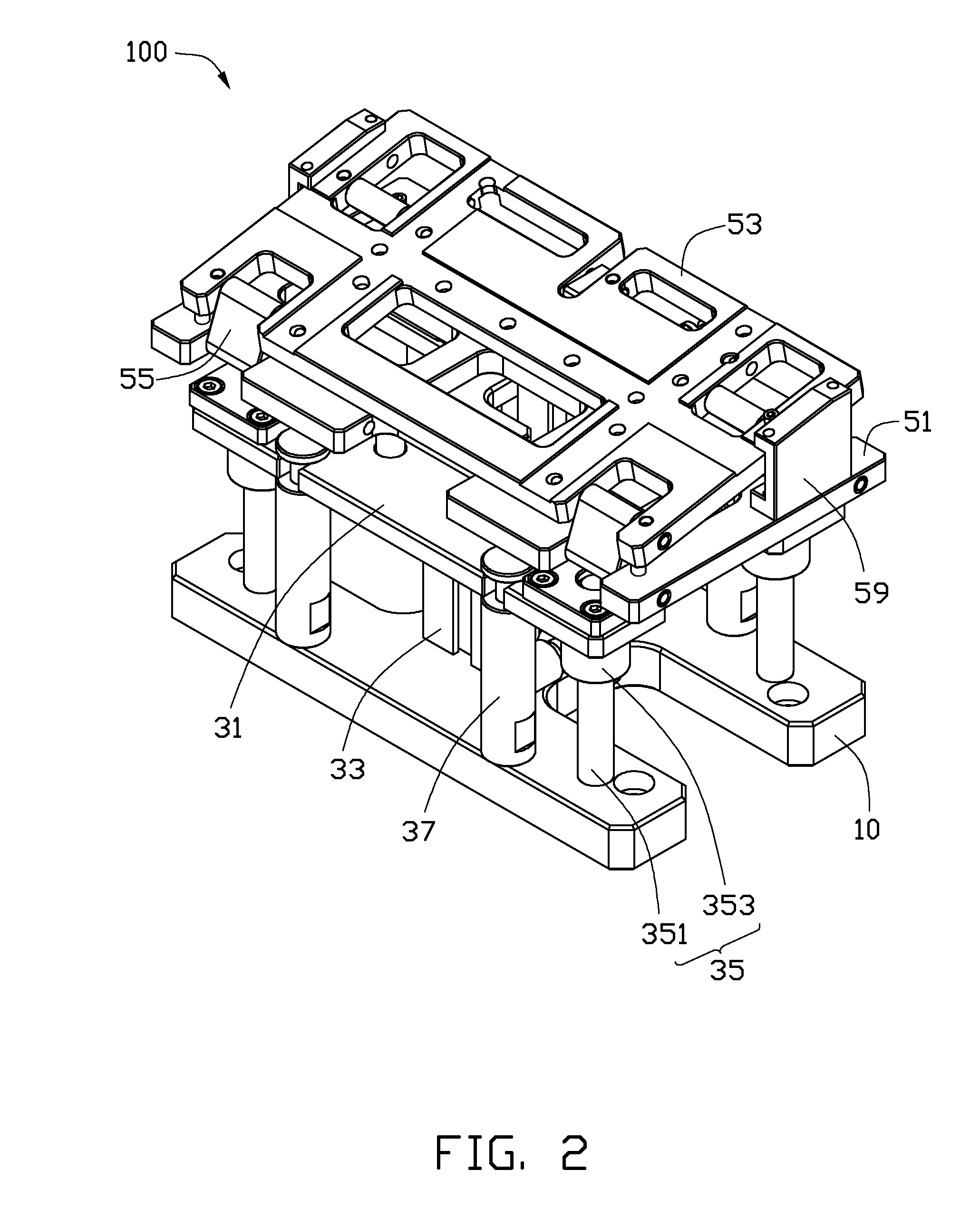

Positioning apparatus

ActiveUS20120161378A1Small sizeSolve high precisionWelding/cutting auxillary devicesAuxillary welding devicesRocker armEngineering

A positioning apparatus includes a base plate and a deflection mechanism mounted upon the base plate. The deflection mechanism includes a stationary platform, a rocker assembly and a deflection platform. The stationary platform is mounted over the base plate for placing and positioning a workpiece. The deflection platform is tiltably mounted over the stationary platform via the rocker assembly and the height of the stationary platform itself is adjustable. The rocker assembly comprises a first rocker and a second rocker of different lengths.

Owner:CLOUD NETWORK TECH SINGAPORE PTE LTD +1

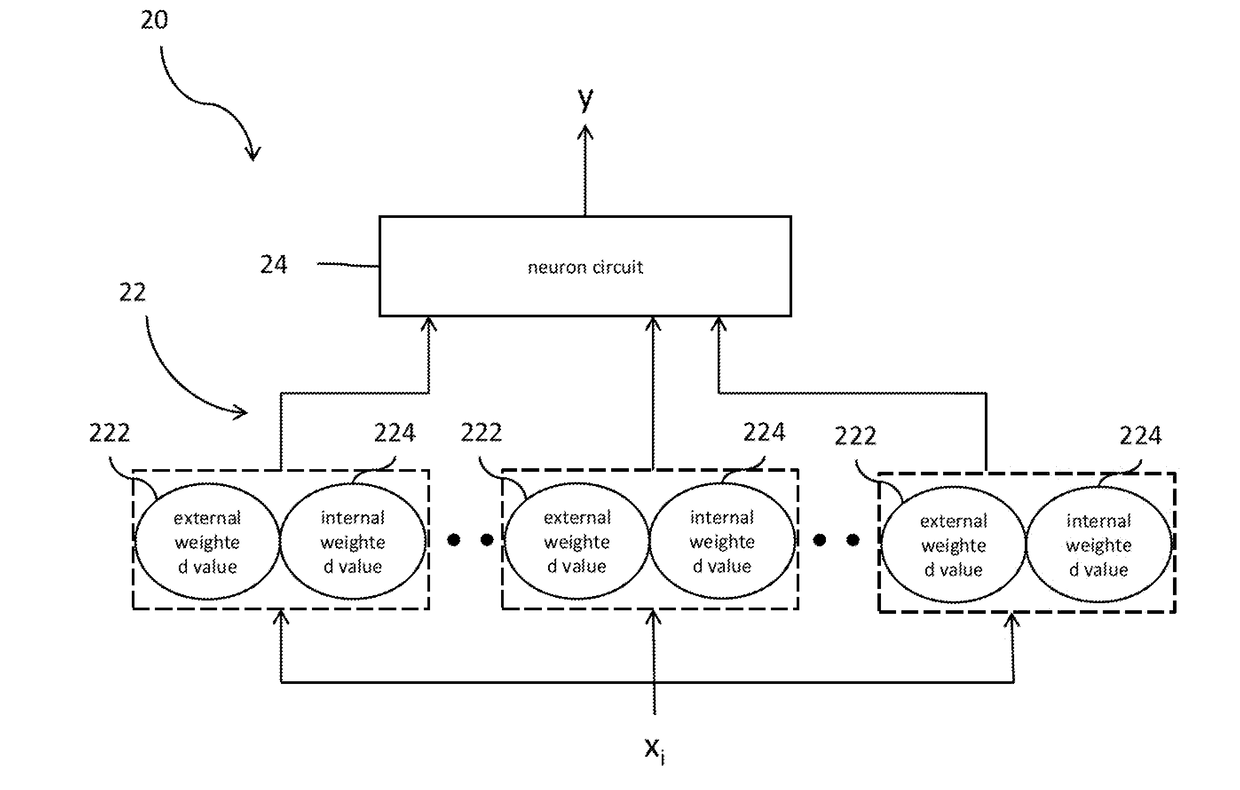

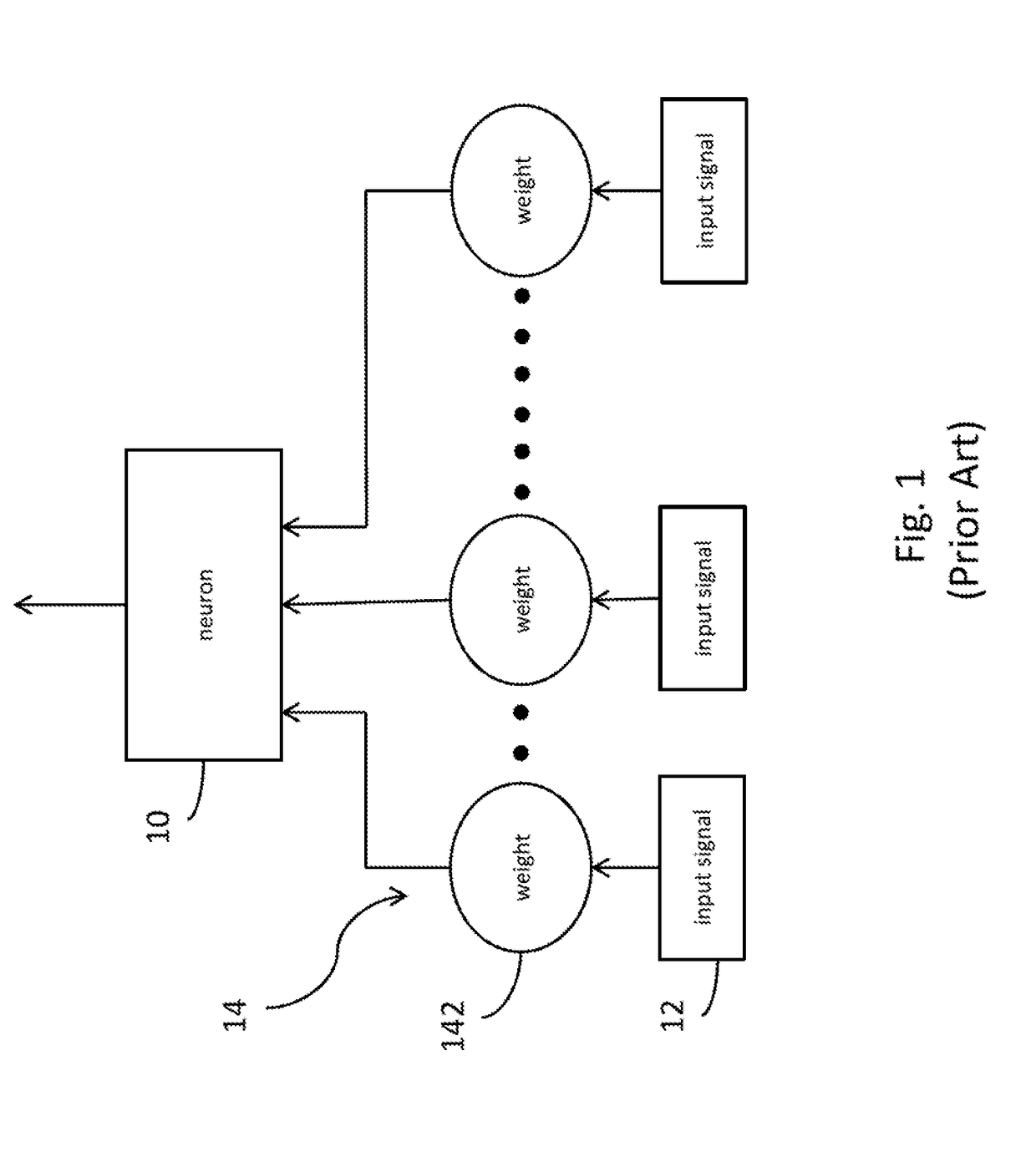

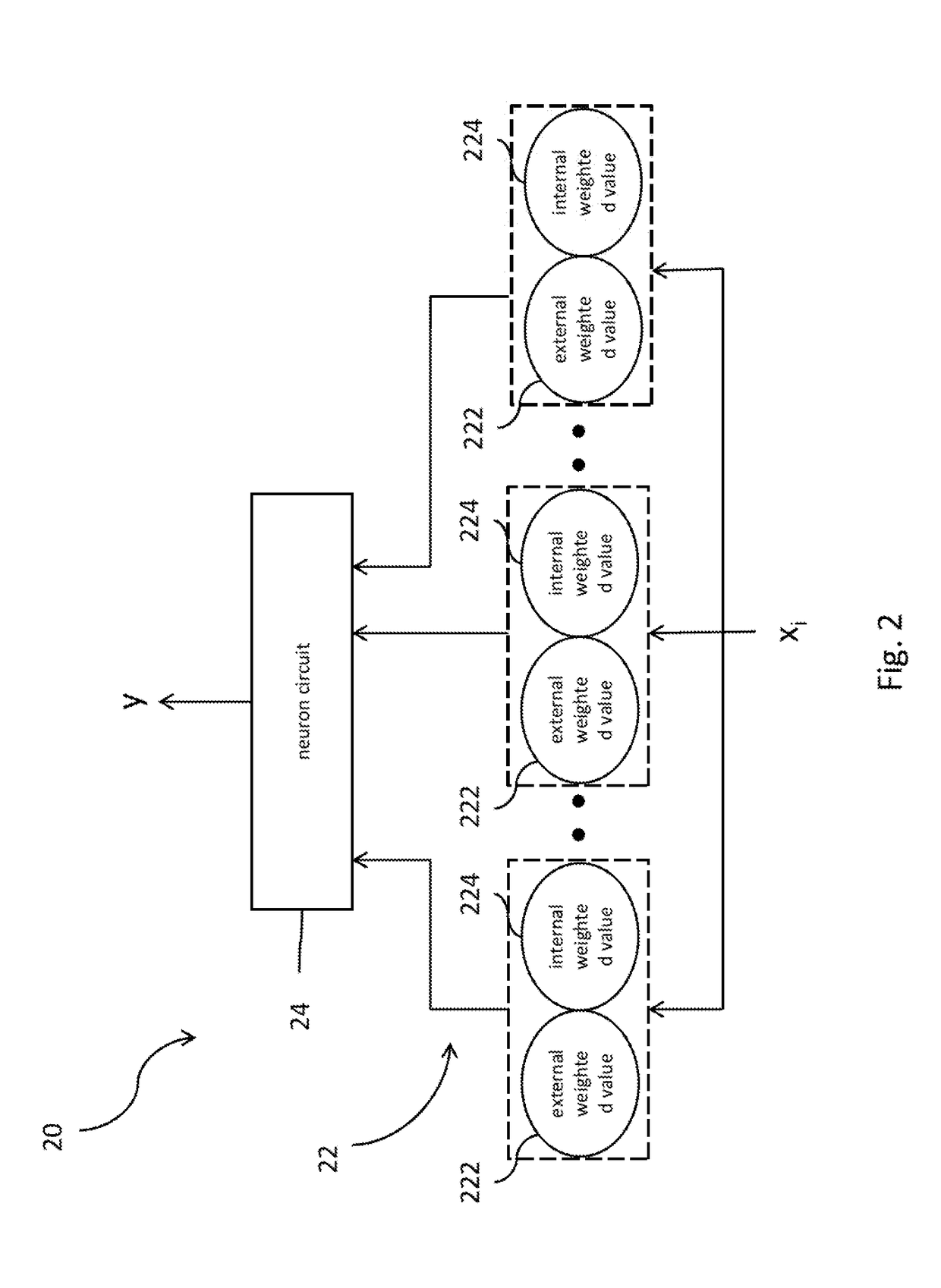

Neural network processing system

ActiveUS20180330236A1Solve high precisionOvercomes drawbackCharacter and pattern recognitionProbabilistic networksSynapseNeuronal circuitry

A neural network processing system includes at least one synapse and a neuron circuit. The synapse receives an input signal and has an external weighted value and an internal weighted value, and the internal weighted value has a variation caused by an external stimulus. When the variation of the internal weighted value accumulates to a threshold value, the external weighted value varies and the input signal is multiplied by the external weighted value of the synapse to generate a weighted signal. A neuron circuit is connected with the synapse to receive the weighted signal transmitted by the synapse, and calculates and outputs the weighted signal. The present invention can simultaneously accelerate the prediction and learning functions of the deep learning and realize a hardware neural network with high precision and real-time learning.

Owner:NATIONAL CHIAO TUNG UNIVERSITY

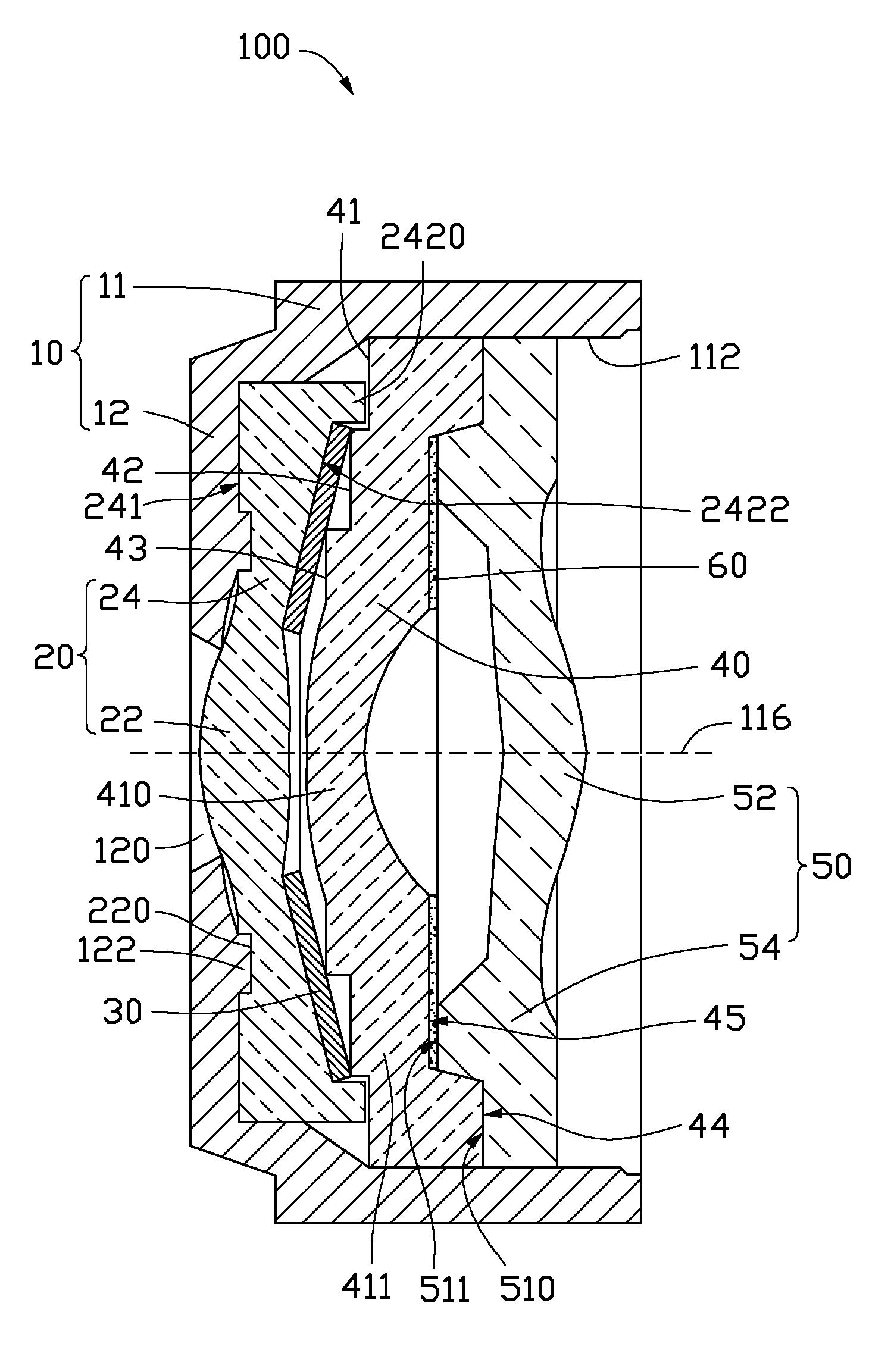

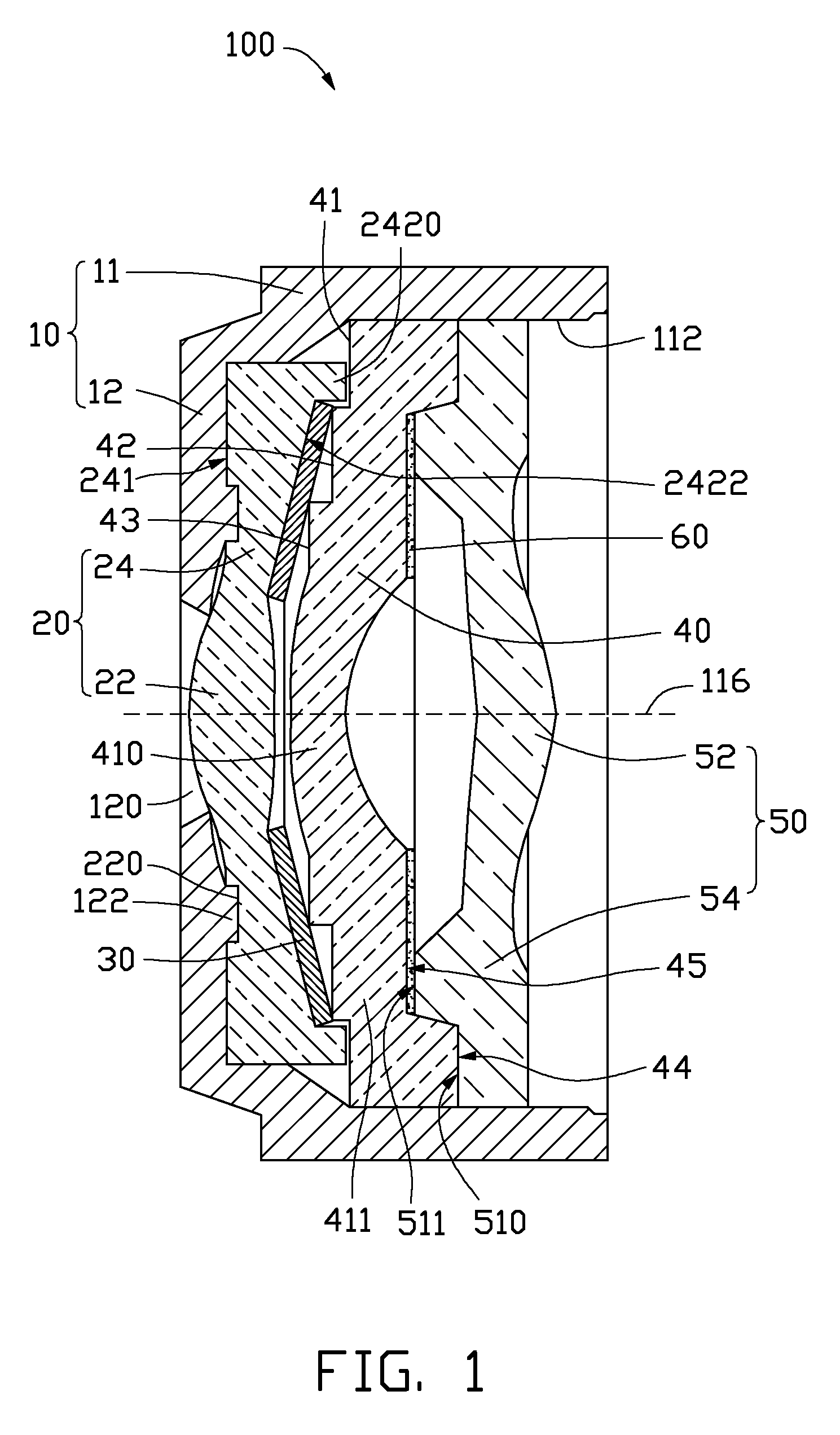

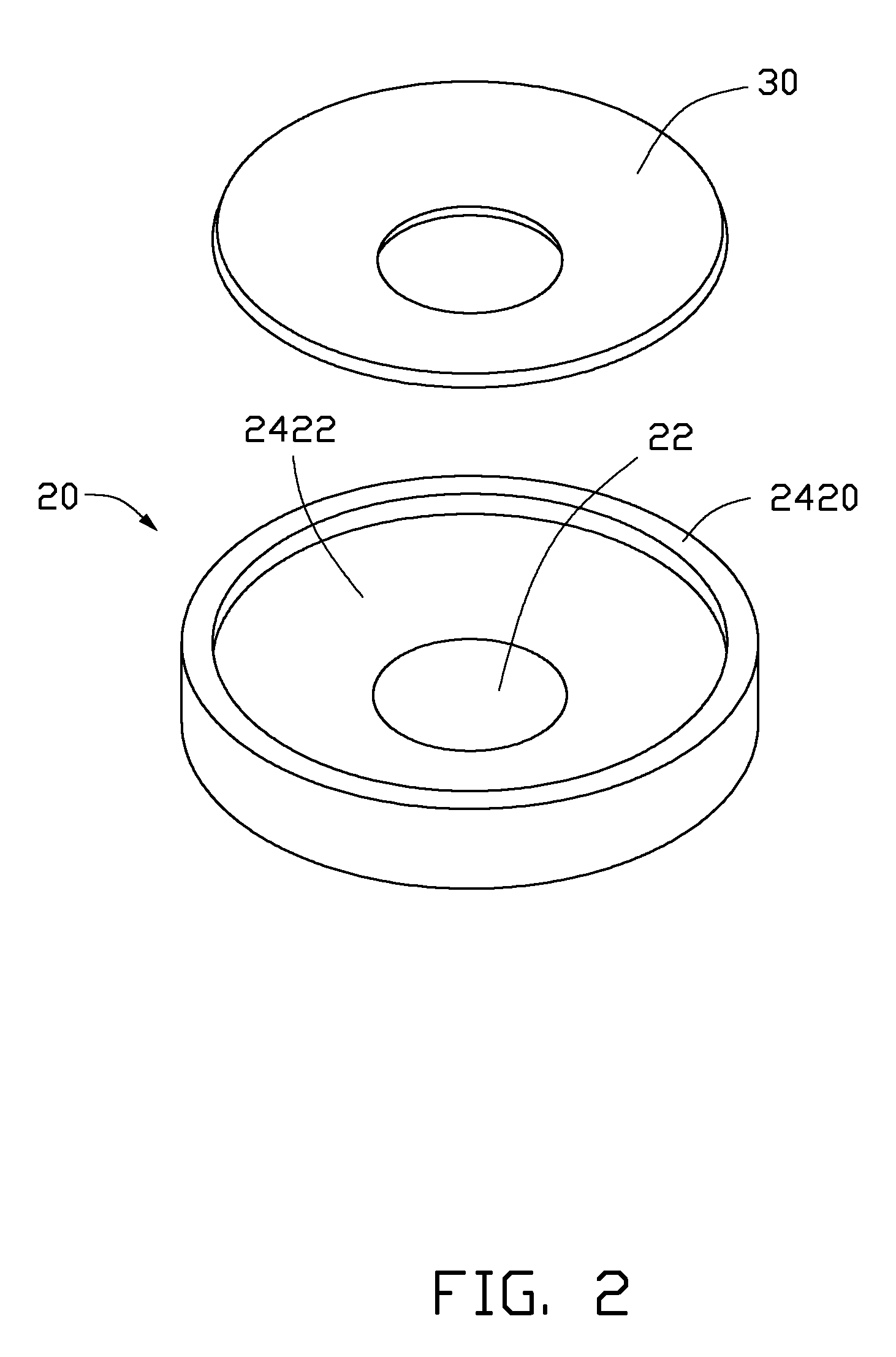

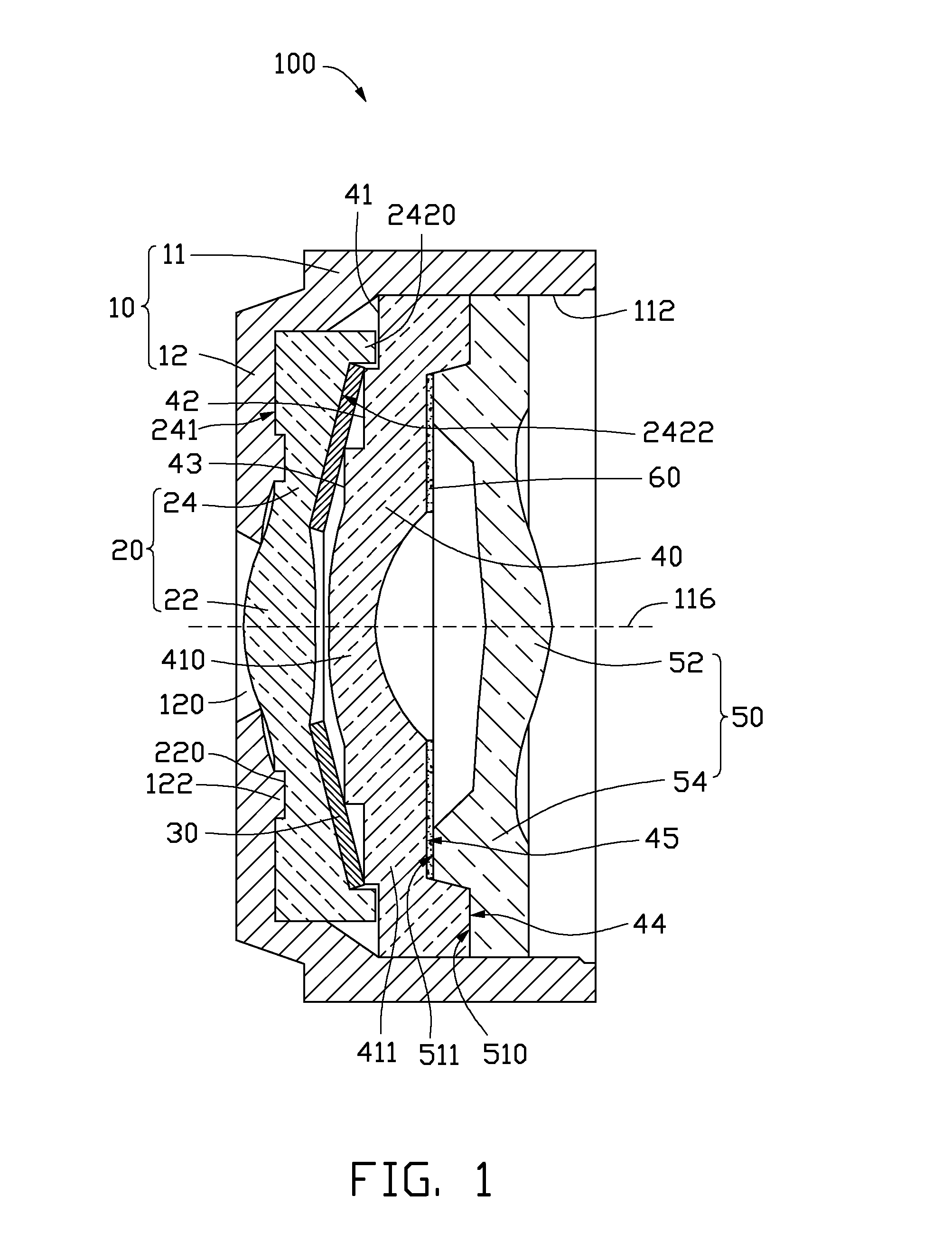

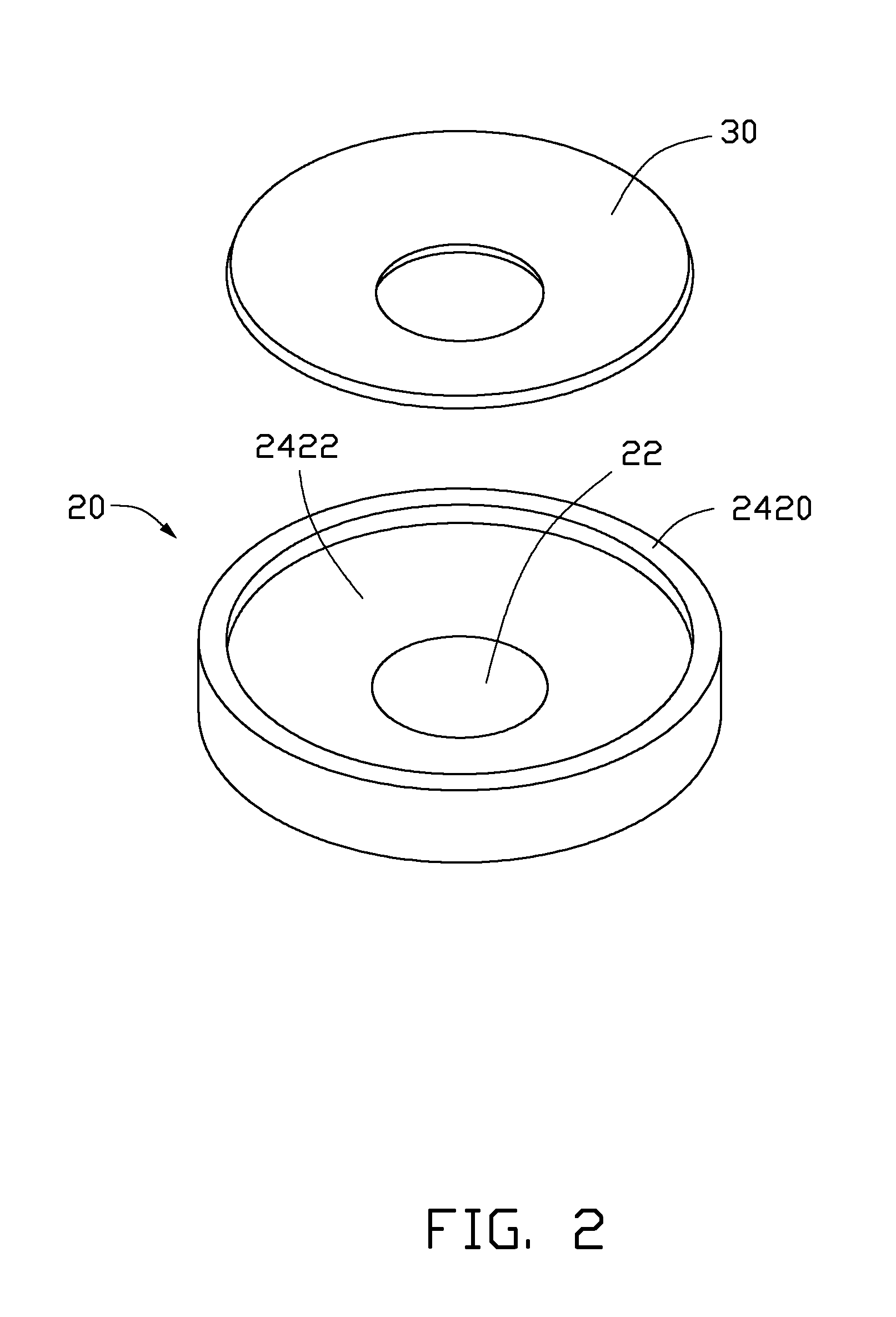

Lens module

InactiveUS8320059B2Solve high precisionAffect qualityTelevision system detailsMountingsCamera lensTwo step

A lens module includes a lens barrel, a first lens, an opaque plate, and a second lens. The first lens includes an imaging portion and a non-imaging portion surrounding the imaging portion. The non-imaging portion defines an annular conic surface. The opaque plate is annular conic shaped and contacts with the annular conic surface. The second lens includes an imaging portion and a non-imaging portion surrounding the imaging portion. The object-side surface of the non-imaging portion of the second lens is step-like shaped and includes at least two step surfaces. A junction of two adjacent step surfaces abuts against the opaque plate.

Owner:HON HAI PRECISION IND CO LTD

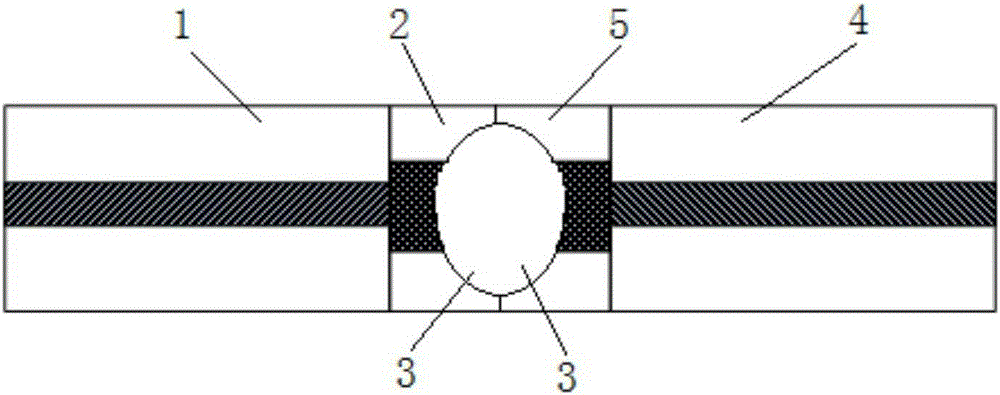

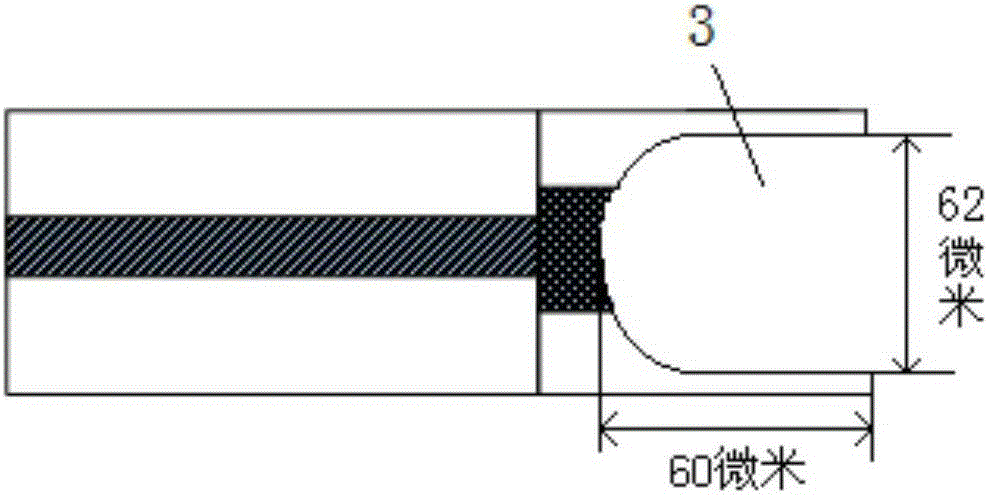

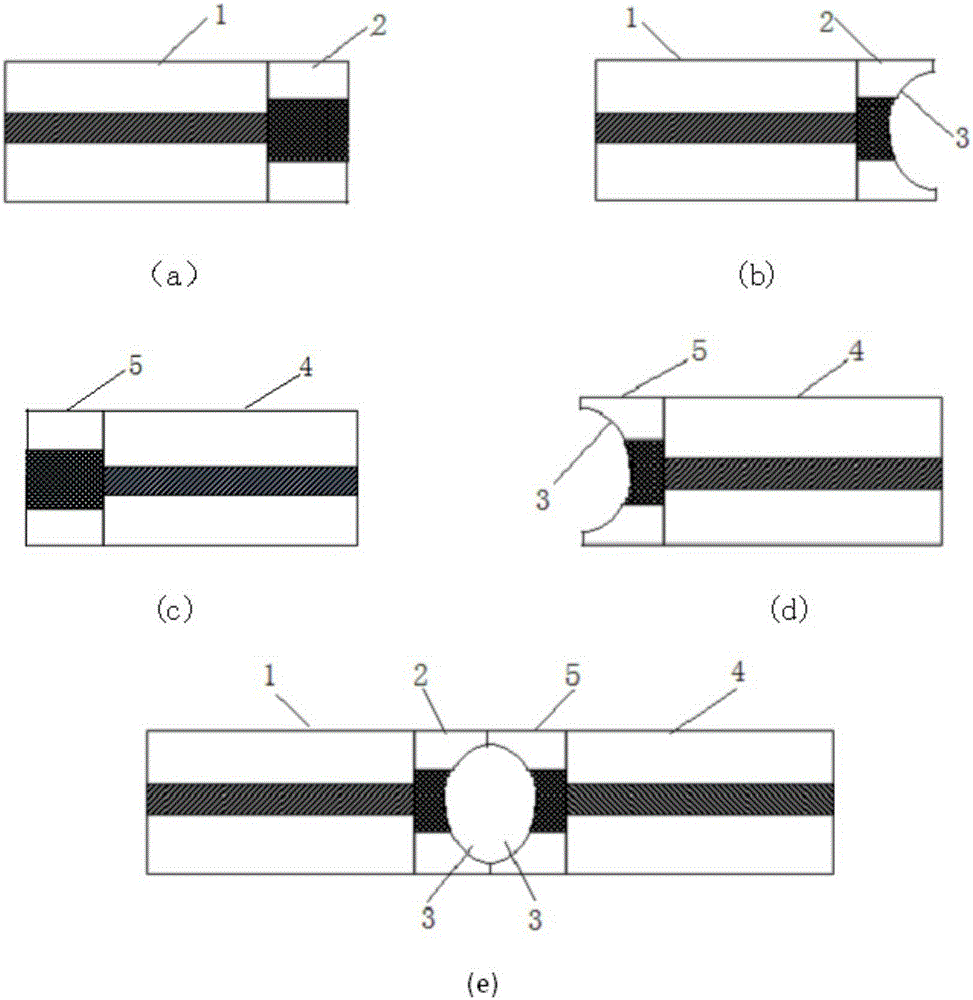

Symmetrical all-fiber Fabry-Perot sensor and manufacturing method thereof

ActiveCN105180980AStructural symmetryCompact structureConverting sensor output opticallyButt jointFourier transform on finite groups

The invention discloses a symmetrical all-fiber Fabry-Perot sensor, a first single-mode fiber is welded with a first multi-mode fiber, and a second single-mode fiber is welded with a second multi-mode fiber; tail ends of the first multi-mode fiber and the second multi-mode fiber are provided with concave cavities; the concave cavities of the first multi-mode fiber and the second multi-mode fiber are in butt joint with each other to form an FP cavity. According to the symmetrical all-fiber Fabry-Perot sensor and the manufacturing method thereof provided by the invention, the structure is small and exquisite, manufacture is easy and cost is low, the fiber sensor can utilize a chemical corrosion method to obtain a long Fabry-Perot cavity, is symmetrical in structure and low in stripe fineness, is little affected by temperature, and can utilize a phase method based on Fourier transform to realize measurement of pressure and strain under high temperature.

Owner:广州顶盛益电子科技有限公司

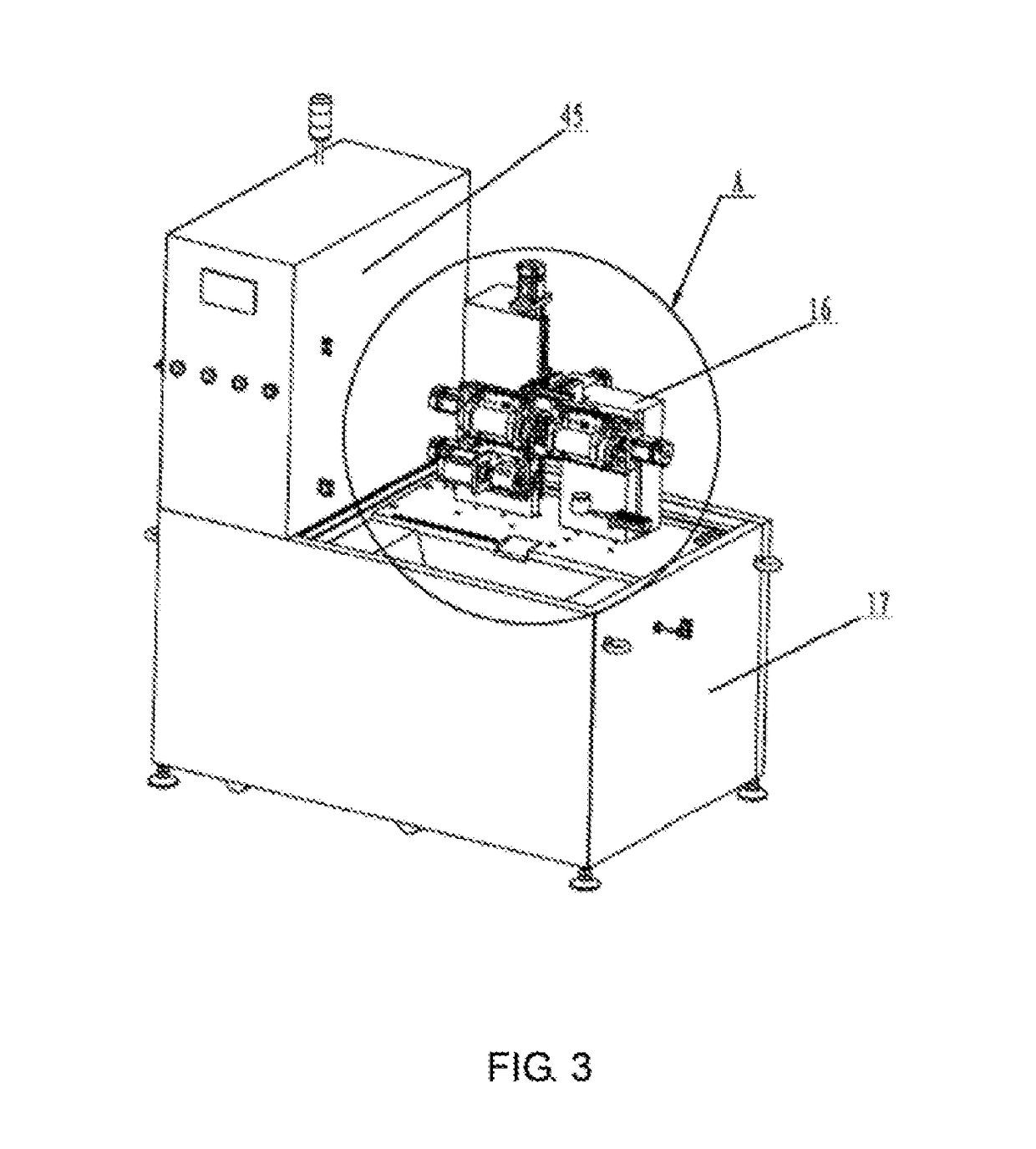

High-precision two-part flat chuck device and processing apparatus installed there-with

A high-precision two-part flat chuck device includes: a base, a cylinder, a sliding plate, a first clamping plate and a second clamping pate. A piston rod of the cylinder is connected with the sliding plate. Precision sliding rails are arranged at two sides of the base, and two sides of the sliding plate are respectively matched with the precision sliding rails in a sliding manner. An accommodating groove is arranged in a middle part of the sliding plate. The first and second clamping plates are symmetrically distributed in the accommodating groove along a center of the sliding plate, and a spring is arranged between the first and second clamping plates. Side surfaces of the first and second clamping plates are inclined planes, and chucks matched with each other are arranged at end parts of the first and seconding clamp plates.

Owner:JIAXING CLG PRECISION AUTOMATION MACHINE WIRING CO LTD

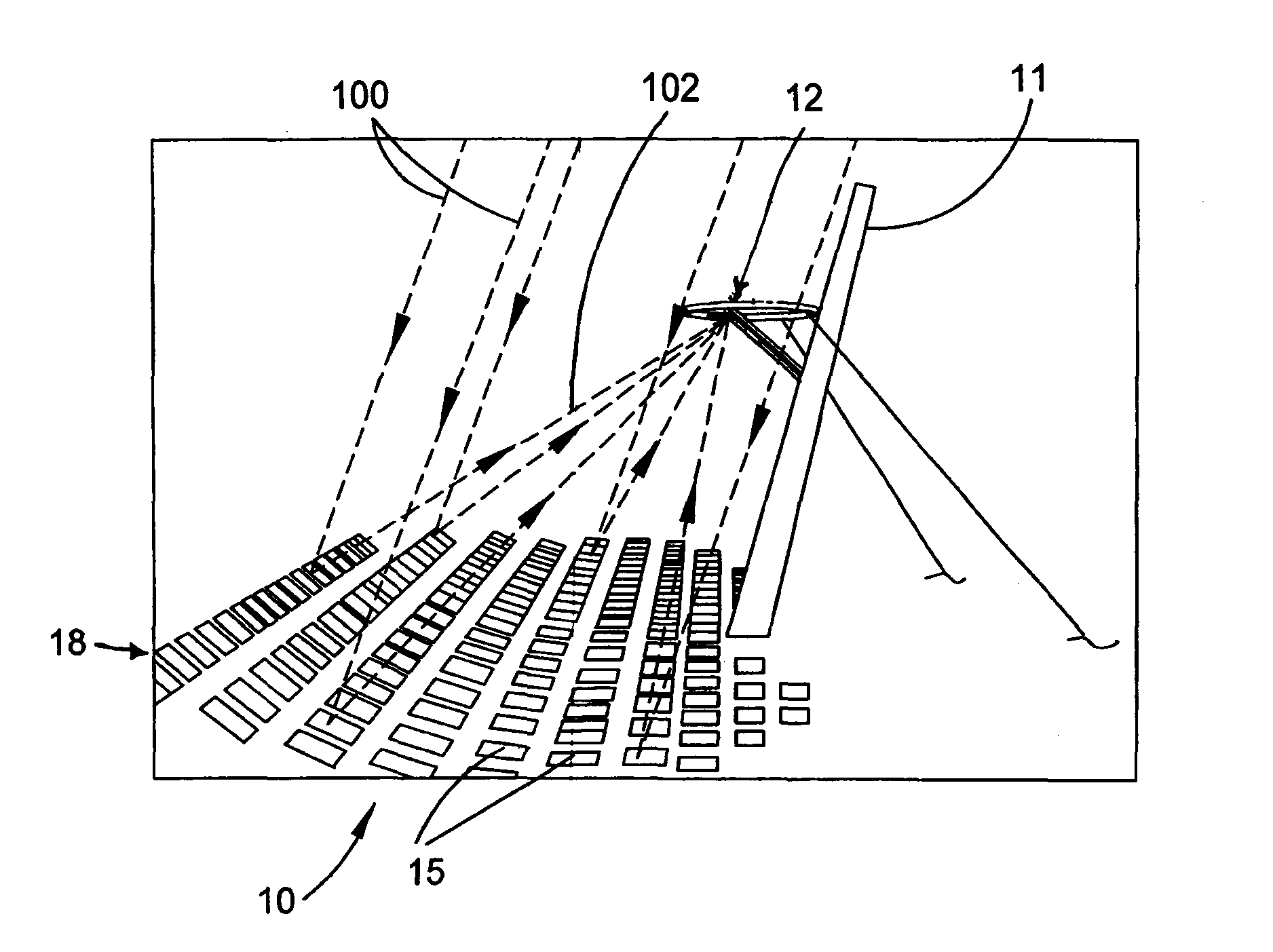

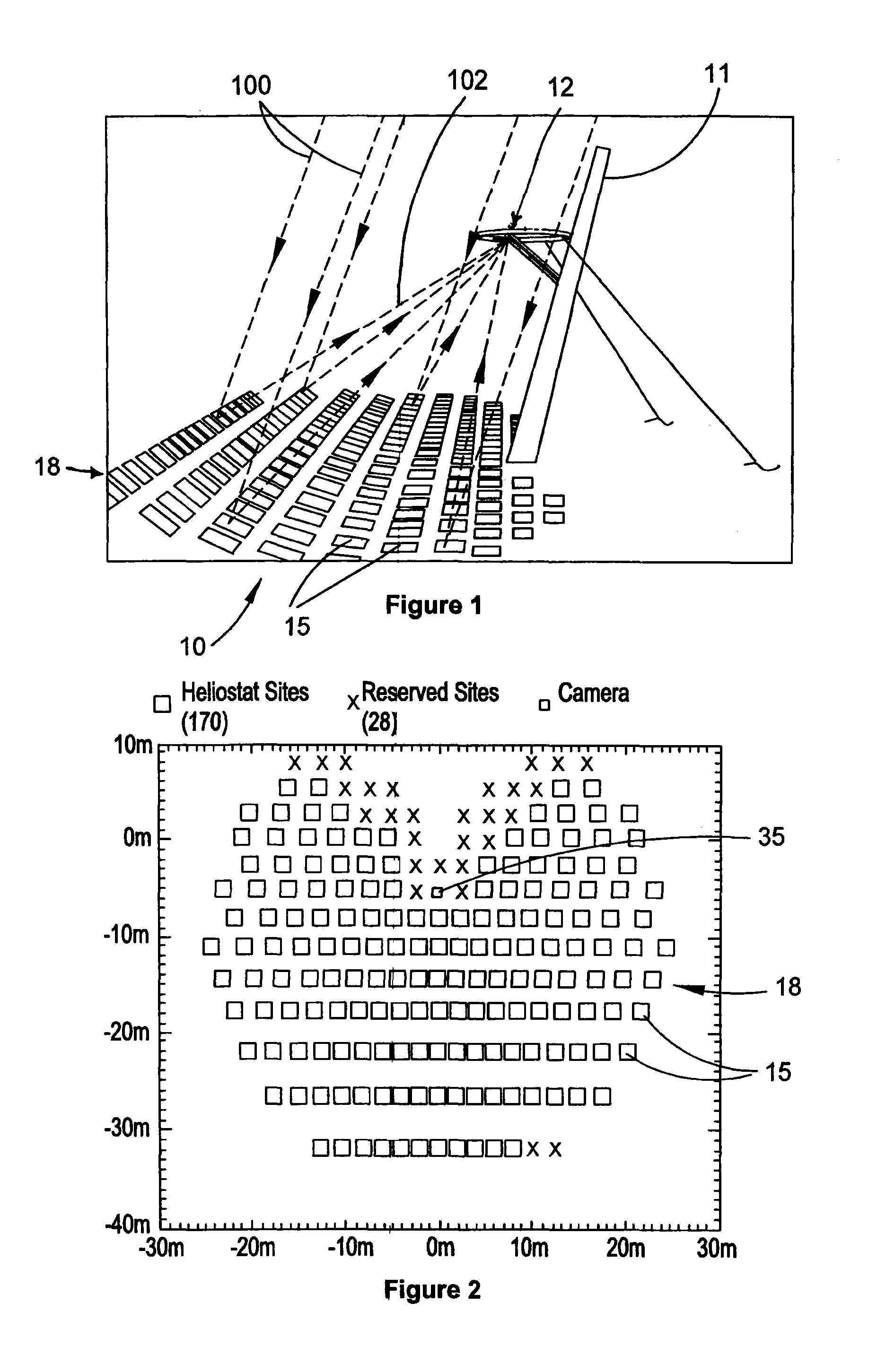

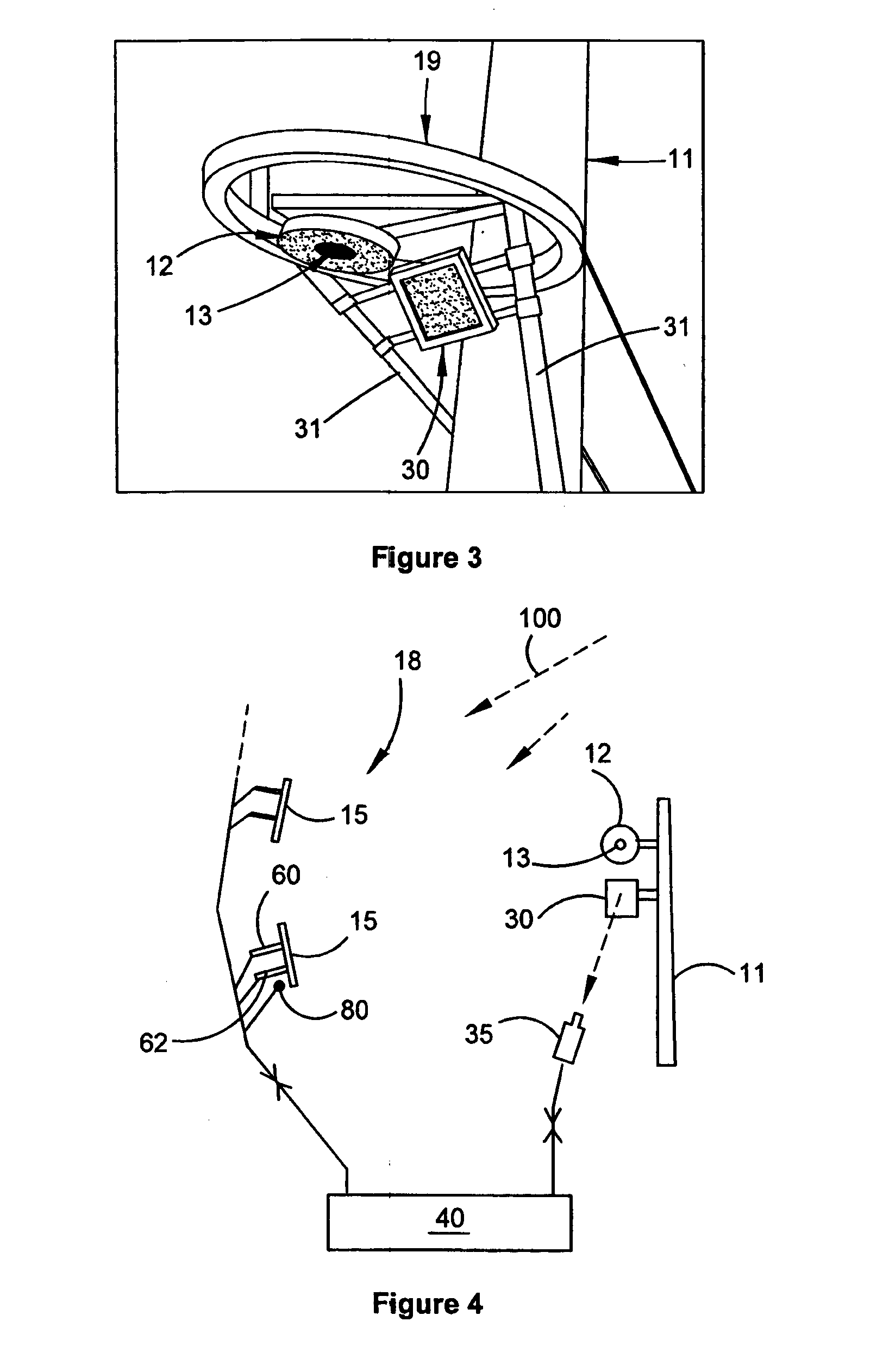

Heliostat calibration and control

InactiveUS20130284162A1Improve accuracyHigh precisionSolar heating energySolar heat collector controllersHeliostatLight beam

A solar energy collector including a solar energy receiver defining a primary target; and a field of heliostats mounted for angular adjustment to receive and direct sunlight to the primary target and an actuator to effect the angular adjustment of each heliostat. A secondary target at or spaced from the primary target. A controller coupled to the actuator configured to sequentially cause, a temporary angular adjustment of the respective the heliostats so as to divert the beam of sunlight received at each heliostat to the secondary target for a predetermined period of time. A recorder to record a representation of each diverted beam at the secondary target. The controller is coupled to the recorder and further configured to respond to the representation of the diverted beam for the respective heliostats when a parameter deviates from norm, by activating the actuator to angularly adjust the corresponding heliostat.

Owner:COMMONWEALTH SCI & IND RES ORG

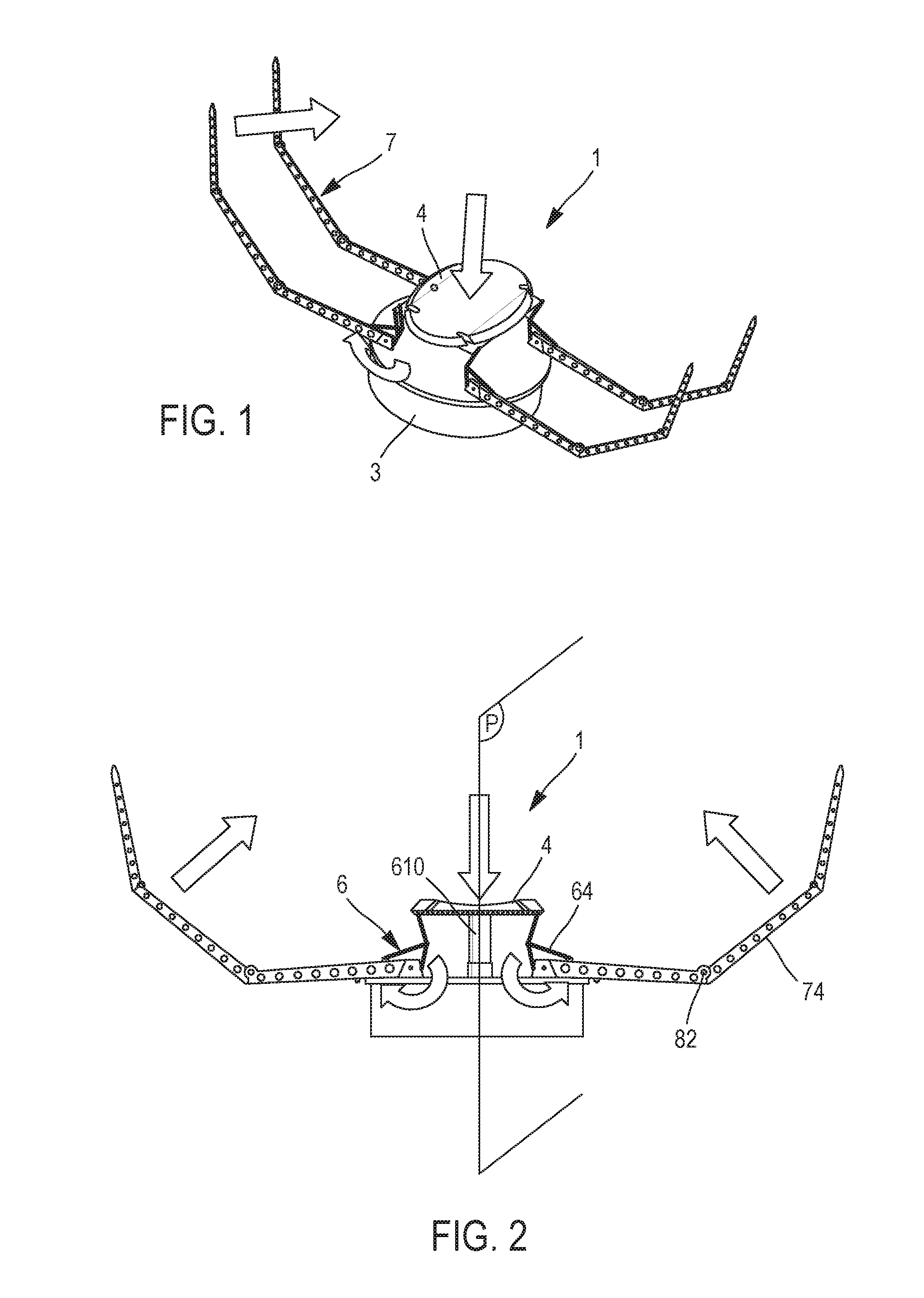

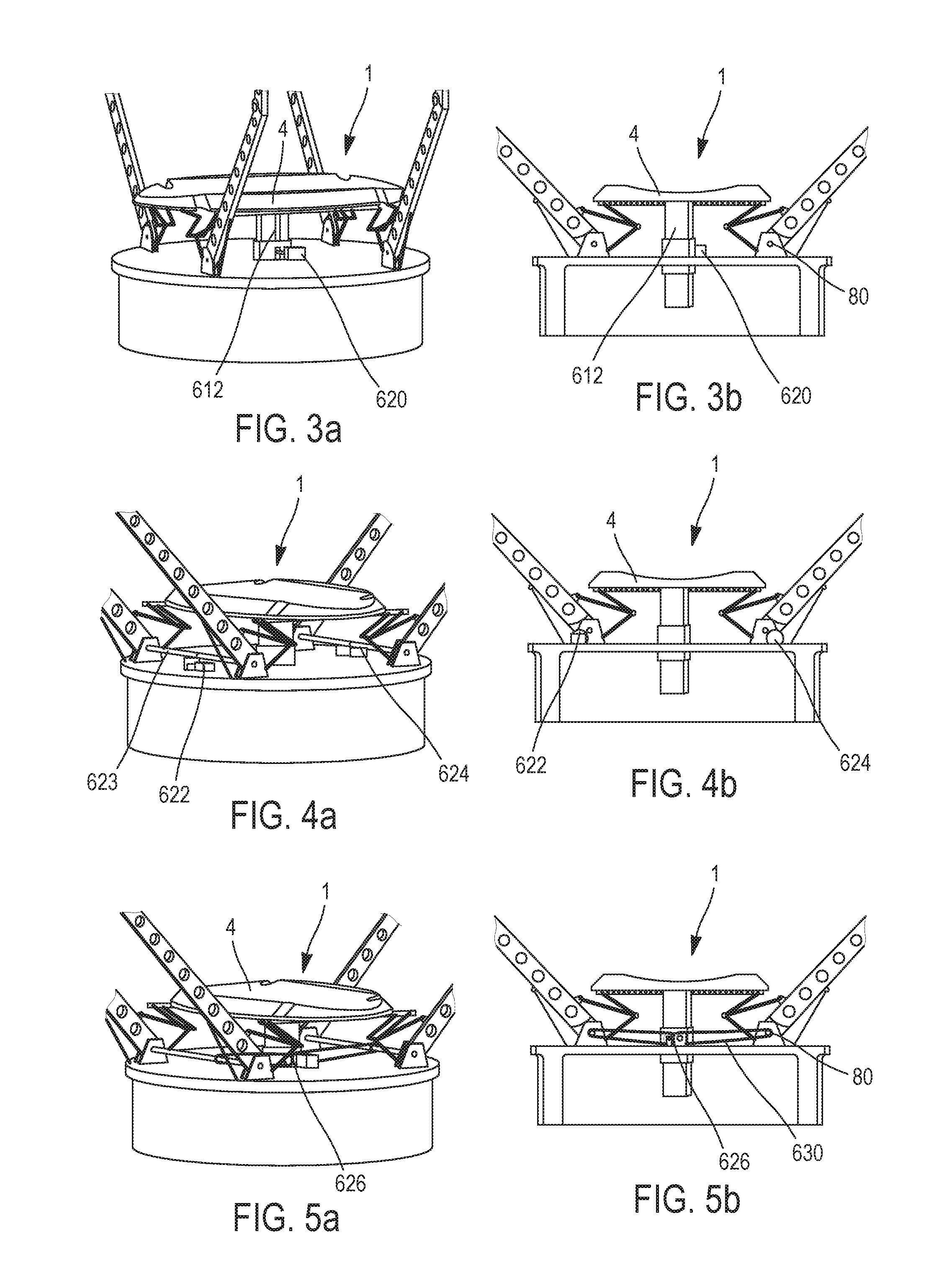

Device for sensing a space object, including a pressure element and at least two resealable elements on the space object

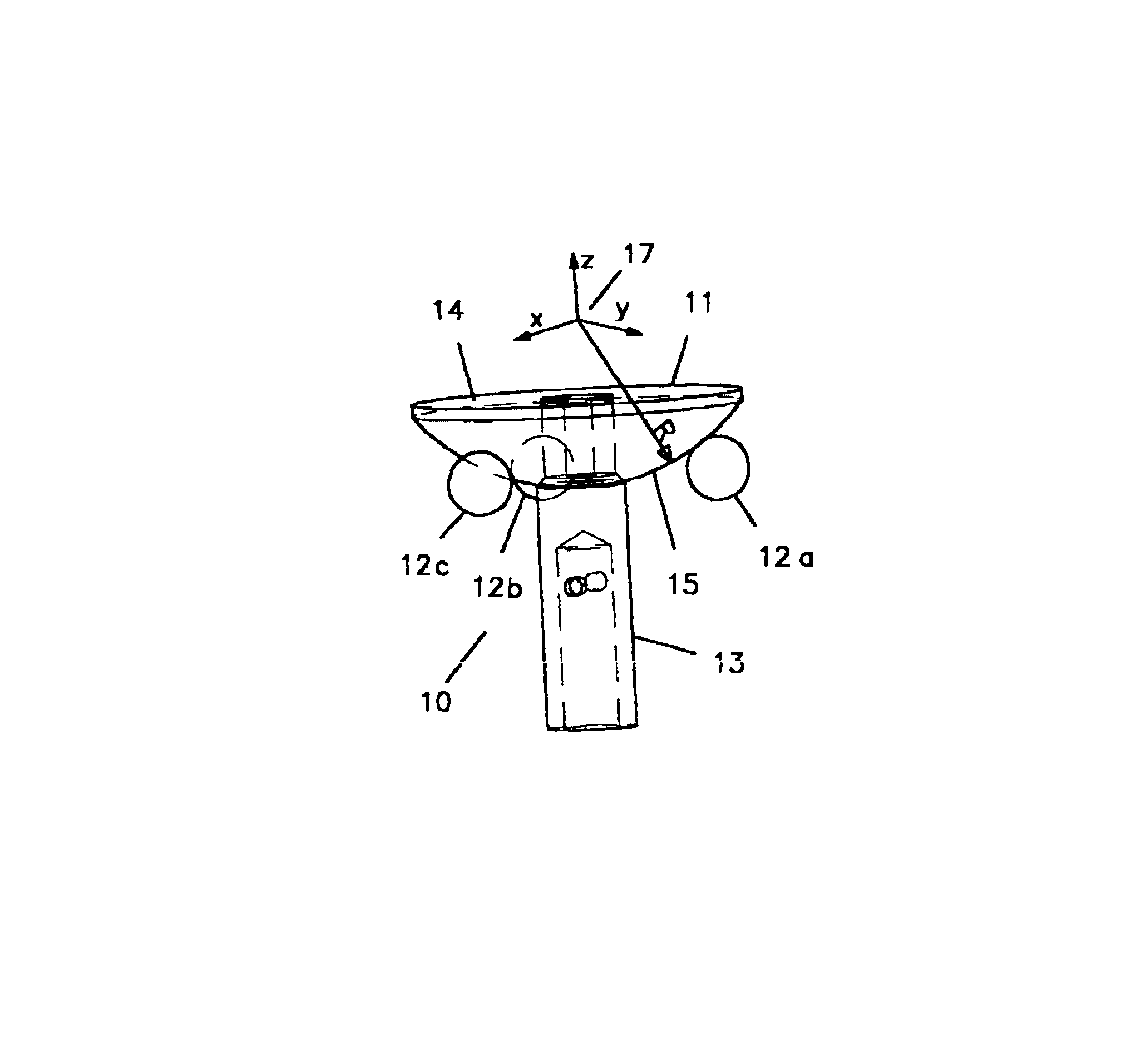

ActiveUS20160130020A1Solve high precisionEasy to catchCosmonautic vehiclesToolsSpace objectEngineering

A device for capturing a space object, the device comprising a pressure element configured to come into direct mechanical contact with the space object to be captured. The device comprises at least two reclosable elements movable between an open position for capturing the space object and a closed position for retaining the space object. The device also comprises an apparatus to mechanically transmit movement from the pressure element to each reclosable element, the mechanical transmission apparatus being configured to entrain each reclosable element in displacement between the open position and the closed position by pressure of the space object on the pressure element.

Owner:AIRBUS DEFENCE & SPACE

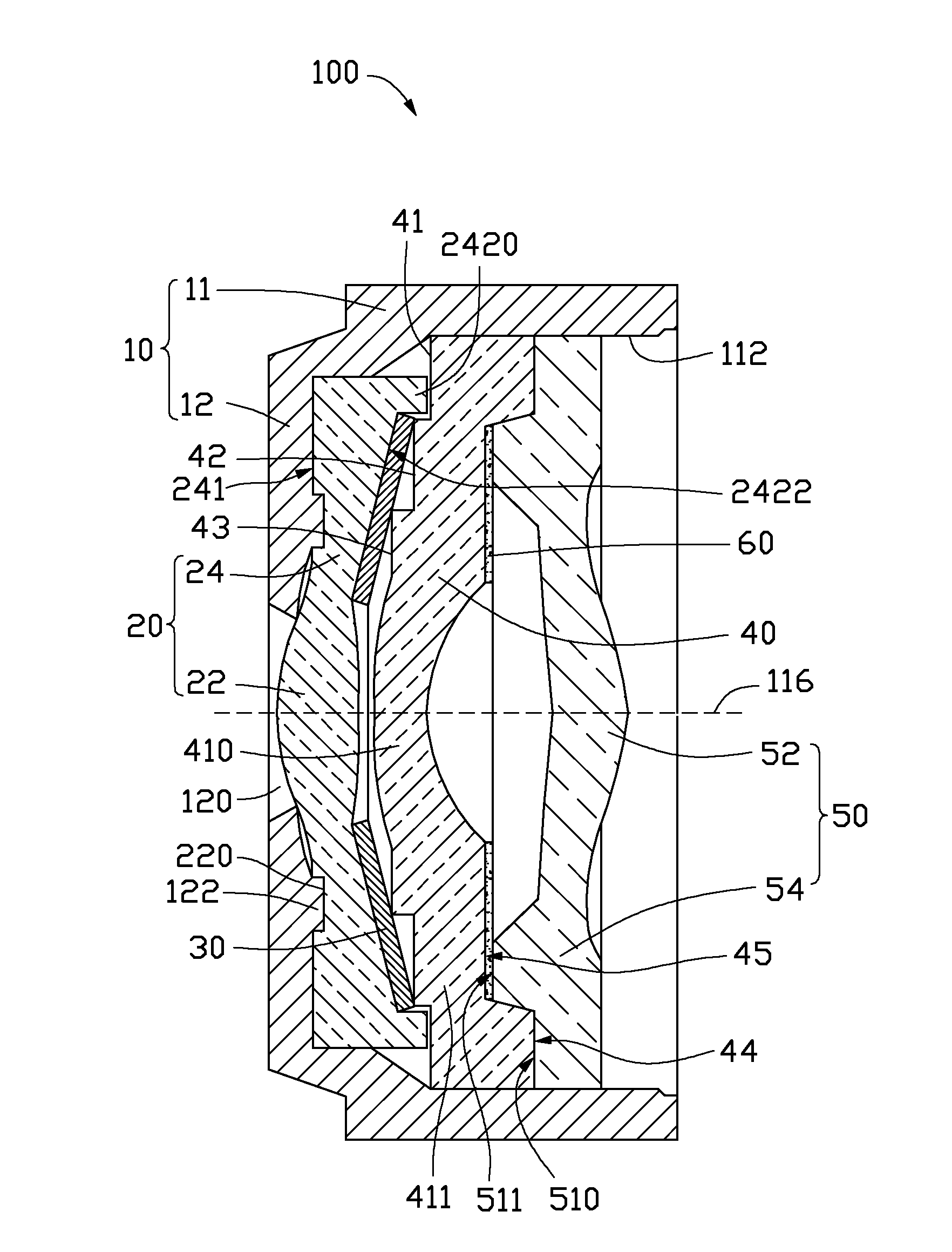

Lens module

InactiveUS20110102901A1Solve high precisionAffect qualityTelevision system detailsMountingsCamera lensTwo step

A lens module includes a lens barrel, a first lens, an opaque plate, and a second lens. The first lens includes an imaging portion and a non-imaging portion surrounding the imaging portion. The non-imaging portion defines an annular conic surface. The opaque plate is annular conic shaped and contacts with the annular conic surface. The second lens includes an imaging portion and a non-imaging portion surrounding the imaging portion. The object-side surface of the non-imaging portion of the second lens is step-like shaped and includes at least two step surfaces. A junction of two adjacent step surfaces abuts against the opaque plate.

Owner:HON HAI PRECISION IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com