Four freedom parallel robot mechanism with passive bound branch

A technology of passive restraint and robotics, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as prone to bending moments and shear forces, unfavorable normal movement of driving devices and mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

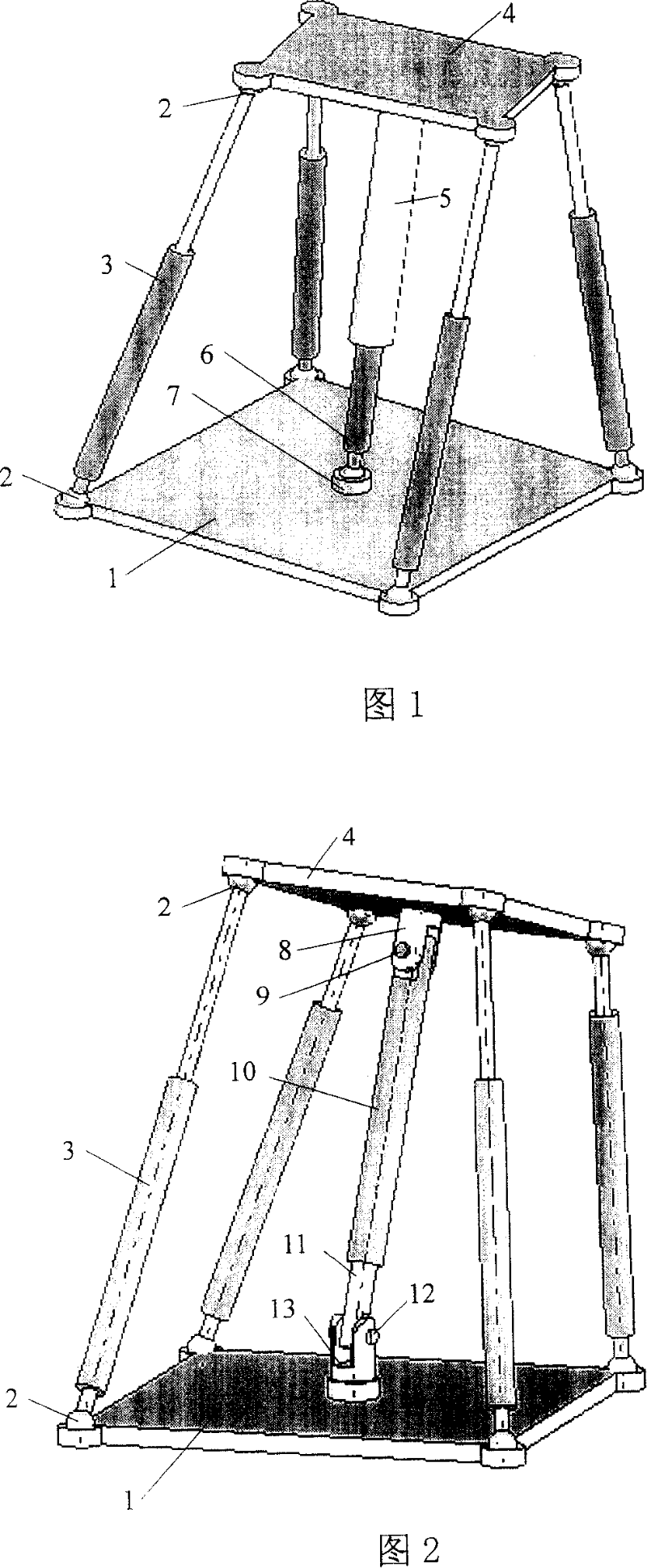

[0011] Accompanying drawing 1 is an embodiment disclosed by the present invention, this four-degree-of-freedom parallel mechanism with passive restraint branch PS includes base 1, upper platform 4, and four linear drive branches connecting base 1 and upper platform 4 and It consists of a passive restraint branch, the base 1 and the upper platform 4 are square and rectangular respectively. The kinematic chain structure of the four linear drive branches is the same, and they are distributed at the corners of the base 1 and the upper platform 4. There are ball joints 2 at both ends of the linear drive branch, and a drive movement pair 3 in the middle. The axis of the drive movement pair 3 is connected to the ball Hinge 2 centers coincide. The passive restraint branch is located in the center of the rectangle. It has a moving pair and a spherical hinge to form a PS series structure branch. The moving pair is composed of a moving pair sleeve 5 and a spherical hinge input rod 6. The...

Embodiment 2

[0013] Accompanying drawing 2 is another embodiment disclosed by the present invention, this RPT four-degree-of-freedom parallel mechanism with passive constrained branches includes a base 1, an upper platform 4, and four linear drive branches connecting the base 1 and the upper platform 4 and a passive restraint branch, the base 1 and the upper platform 4 are rectangle and square respectively. The kinematic chain structure of the four linear drive branches is the same, and they are distributed at the corners of the base 1 and the upper platform 4. There are ball joints 2 at both ends of the linear drive branch, and a drive movement pair 3 in the middle. The axis of the drive movement pair 3 is connected to the ball Hinge 2 centers coincide. The passive restraint branch is located in the center of the rectangle. It consists of a rotating pair, a moving pair and a universal hinge to form a RPT series structure branch. The input rod 8 of the rotating pair is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com