Double-acting plunger pump

A plunger pump, double-acting technology, applied in the field of hydraulic components, to achieve the effect of convenient operation, low noise pollution, low friction and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

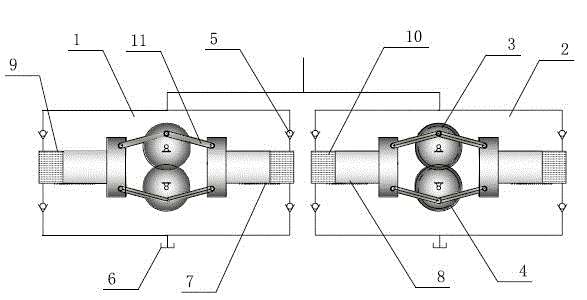

[0025] Embodiment one: see figure 1 As shown, a double-acting plunger pump includes a left hydraulic pump 1 and a right hydraulic pump 2. The hydraulic pump includes symmetrically arranged left and right hydraulic mechanisms, and a driving gear 3 is arranged between the left and right hydraulic mechanisms. A driven gear 4 is meshed with the driving gear 3, the driving end of the driving gear 3 is connected to the servo motor, and the left and right hydraulic mechanisms are connected to the driving gear 3 and the driven gear 4 through a crank transmission mechanism, so The oil outlets of the left and right hydraulic mechanisms are respectively connected to the actuator through the one-way valve 5, and the oil return ports of the left and right hydraulic mechanisms are respectively connected to the oil tank 6 through the one-way valve 5. The hydraulic mechanism includes a hydraulic Cylinder 7, the hydraulic cylinder 7 is provided with a piston 8, the inner end of the piston 8 an...

Embodiment 2

[0027] Embodiment two: the structure is the same as that of embodiment one.

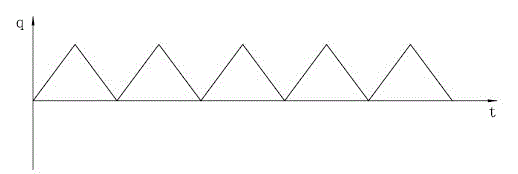

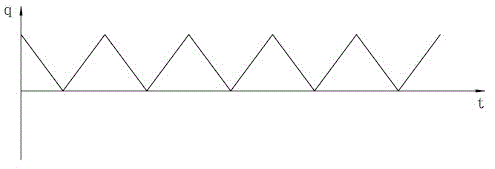

[0028] When the device is in use, it adopts the constant acceleration-uniform speed-equal deceleration trapezoidal waveform speed curve, and the flow curve of the left hydraulic pump or the right hydraulic pump is as follows: Figure 5 and Image 6 As shown, the flow curve after the two pumps are connected in parallel is as follows Figure 7 As shown, so as to achieve constant current output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com