Three freedoms parallel robot mechanism with different structure drive branches

A technology of driving branches and degrees of freedom, which is applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of high sensitivity to manufacturing errors, complex driving branch structures, and poor bearing capacity of kinematic pairs, so as to achieve large mechanism bearing capacity and mechanism No self micro-motion, simple mechanism effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

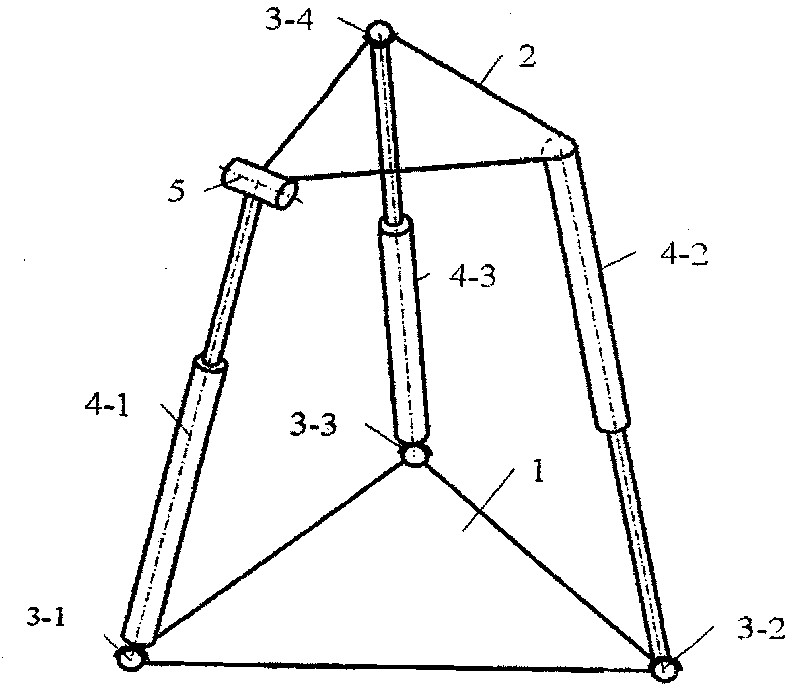

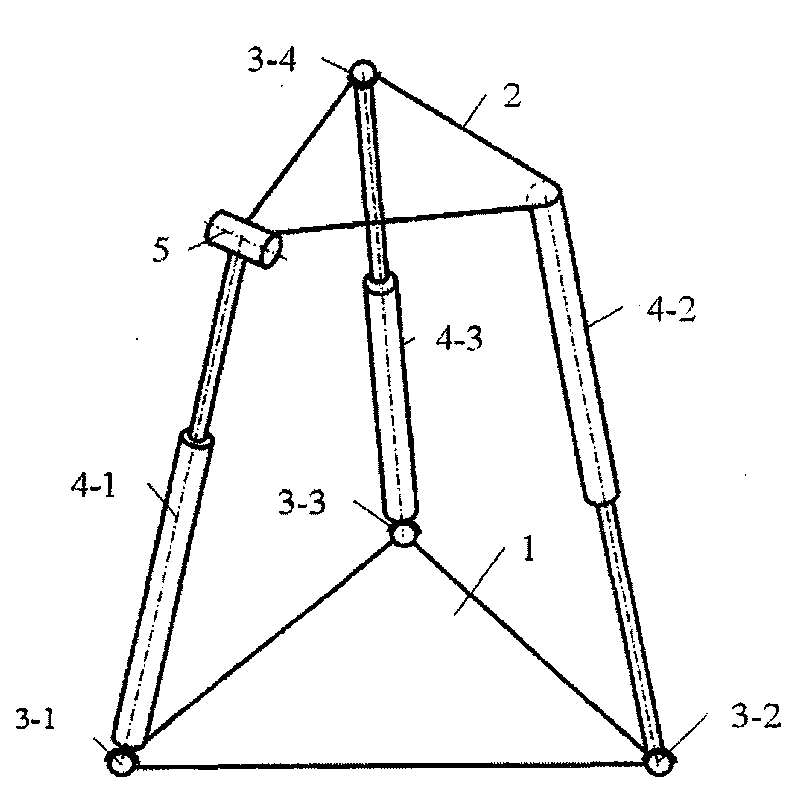

[0012] As an embodiment disclosed by the present invention, such as figure 1 As shown, this three-degree-of-freedom parallel robot mechanism with different structural drive branches includes base 1, upper platform 2 and three linear drive branches with different structures connecting base 1 and upper platform 2, base 1 and platform 2 are equilateral triangles; the structures of the three linear drive branch kinematic chains are different, and they are distributed at the triangular vertices of base 1 and platform 2; the kinematic chain structures of the three linear drive branches are SPR, SP and SPS respectively. The SPR branch includes a spherical joint 3 - 1 , a linearly driven moving pair 4 - 1 and a rotating pair 5 . The rotating pair 5 connects the upper end of the linear drive moving pair 4-1 rod with the upper platform 2, and the ball joint 3-1 connects the lower end of the linear driving moving pair 4-1 cover with the base 1. The SP branch includes a ball joint 3-2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com