Motor device and electric toothbrush

A motor shaft and casing technology, applied in electromechanical devices, electric components, dentistry, etc., can solve the problems of reducing the assembly efficiency of motor devices, inability to accommodate electromagnetic components, and inconvenient coil winding, so as to improve high-end experience and improve motor performance. , the effect of reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Attached below figure 2 To attach Figure 8 , and specific embodiments will further illustrate the present invention.

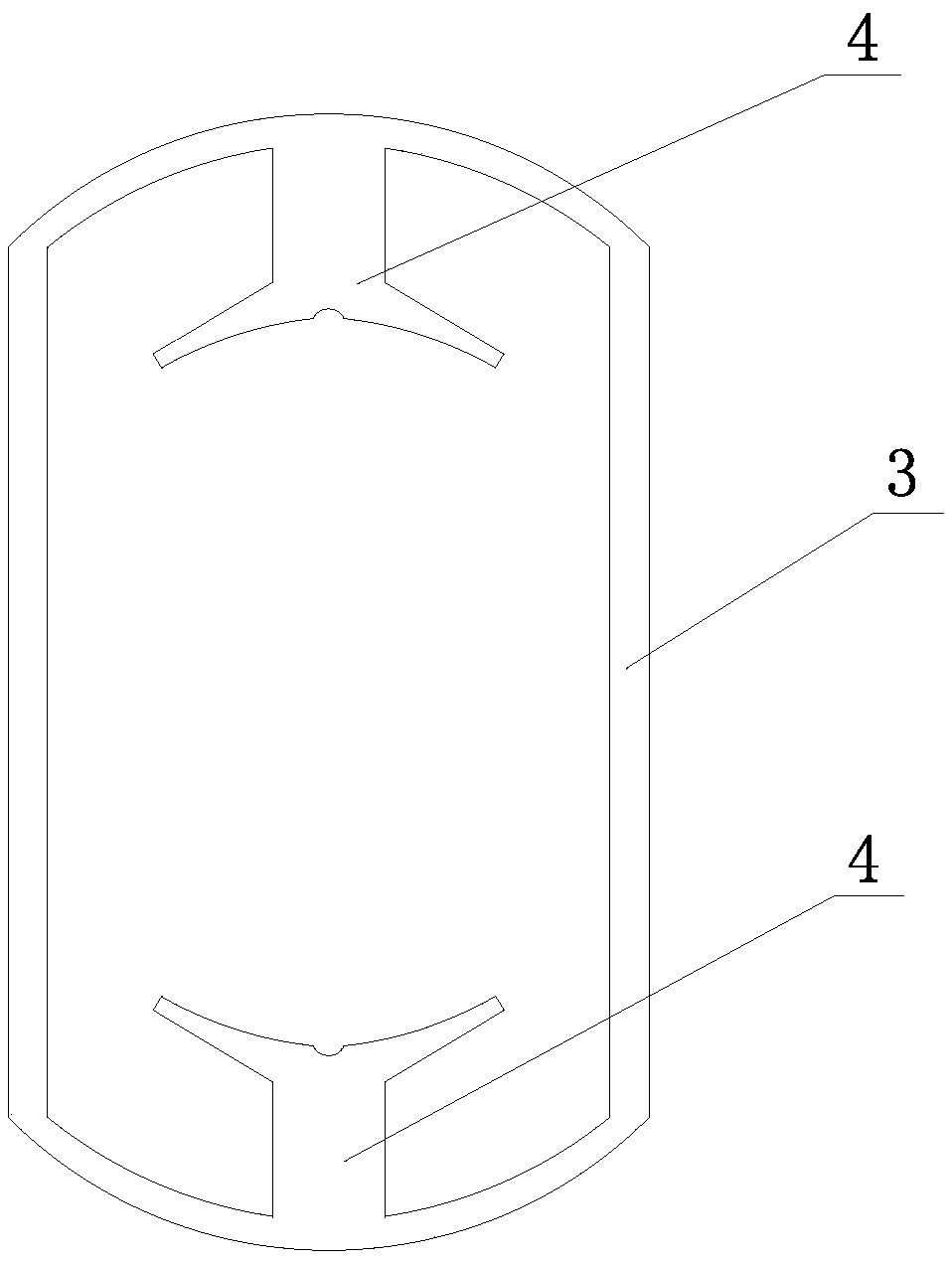

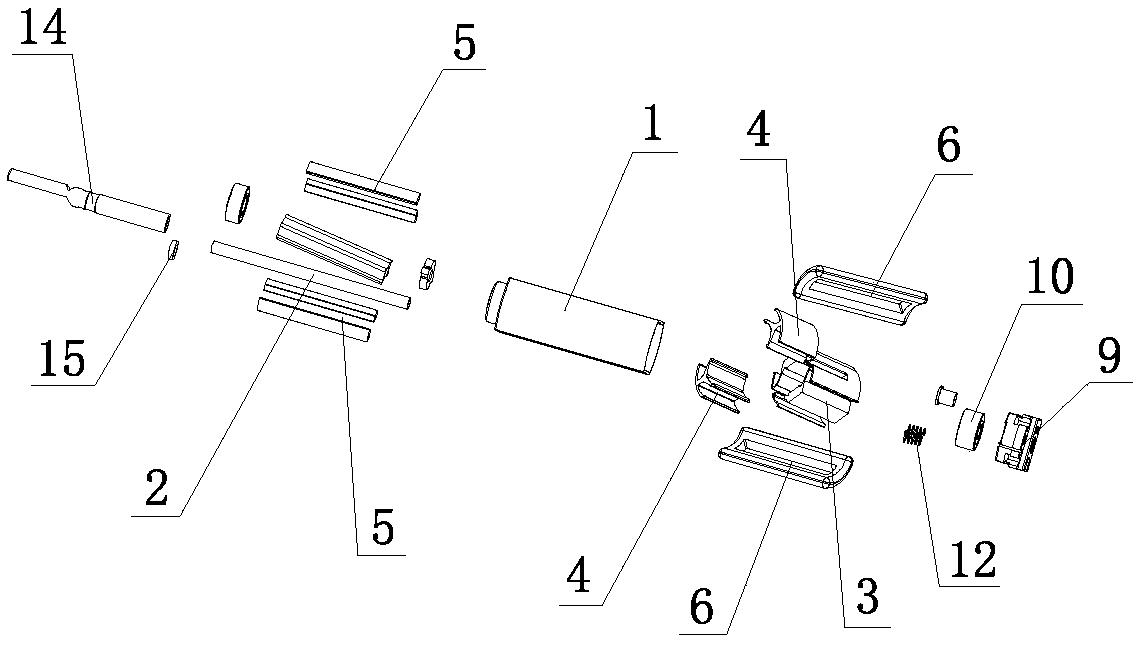

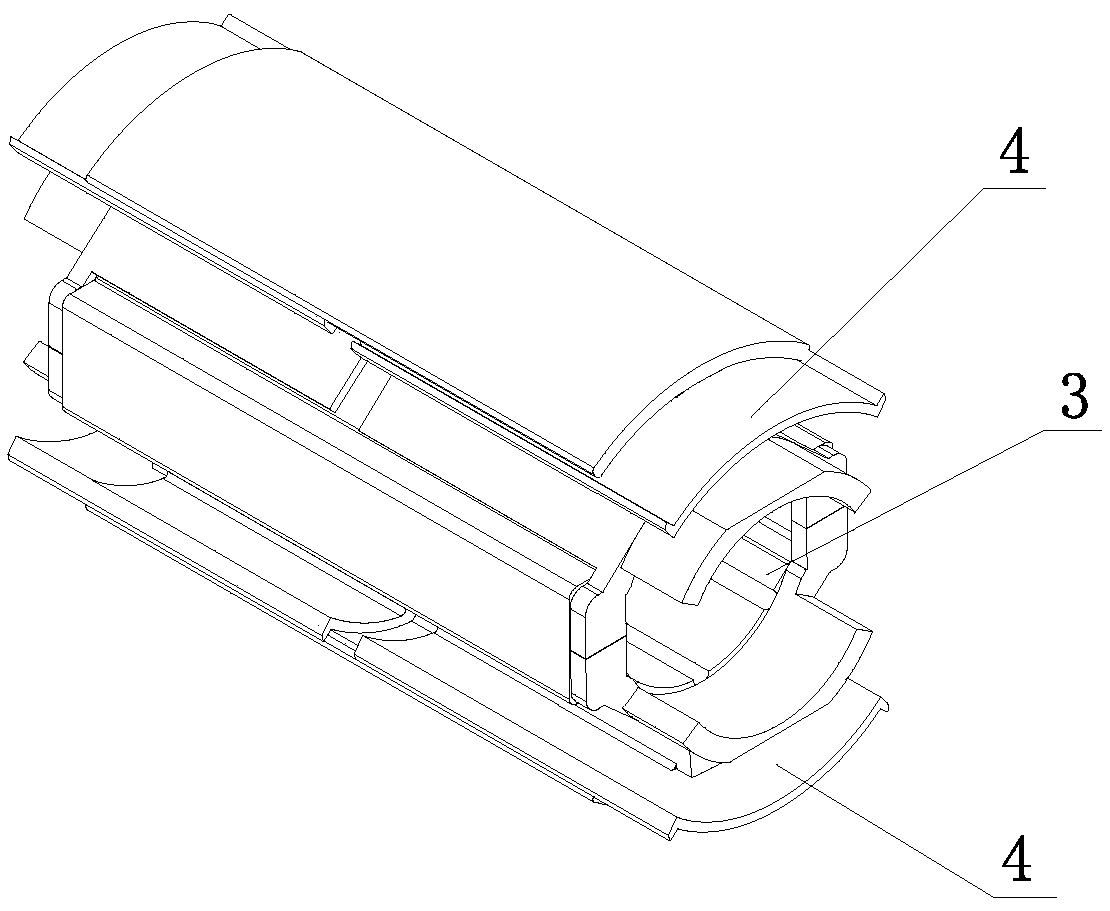

[0026] Such as Figure 2 to Figure 4 As shown, a motor device includes a casing 1, and the casing 1 is provided with a motor shaft 2, an insulating wire frame 3 and at least a pair of stator cores 4, and the stator core 4 is provided with a magnetic steel structure 5. The insulated wire frame 3 includes a first skeleton 31 and a second skeleton 32 arranged below the first skeleton 31, the first skeleton 31 and the second skeleton 32 have the same structure, and the first skeleton 31 and the second A first connecting frame body 33 is arranged between the skeletons 32, and is connected through the first connecting frame body 33; the first skeleton 31 is provided with a slot 34, and the stator core 4 includes a first arc punching piece 41 And the second arc-shaped punch 42 arranged below the first arc-shaped punch 41, a second connecting frame body 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com