Preparation method of waterproof type high-toughness coating material

A coating material and high toughness technology, applied in the field of preparation of waterproof high toughness coating materials, can solve problems such as poor mechanical strength, poor hydrophobicity, insufficient toughness, etc., and achieve improved mechanical properties, improved adhesion effect, and improved The effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

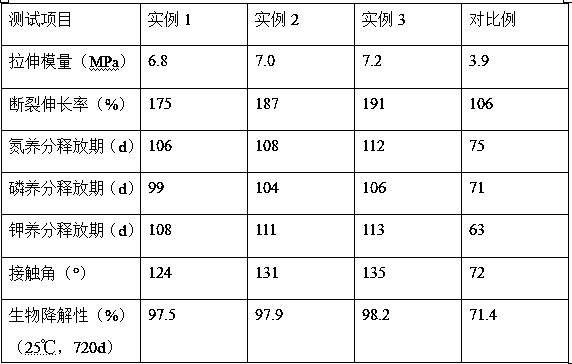

Examples

Embodiment Construction

[0024]Put reed leaves and reed stalks into a beaker at a mass ratio of 1:4, impregnate the reed leaves and reed stalks with hydrochloric acid with a mass fraction of 8-12%, place the beaker in an ultrasonic oscillator, and set the beaker at an ultrasonic frequency of 35-38kHz. Shake for 4-6 hours under the same conditions, filter to obtain filter residue after shaking, wash 3-5 times with distilled water, put it into a grinder and grind for 1-2 hours to obtain a ground product; mix the above-mentioned ground product with 40-50% acetic acid Put the solution into a beaker and mix evenly to obtain a suspension, add citric acid crystals with a mass of 12-15% of the suspension to the beaker, and mix and stir with a stirrer at a speed of 500-550r / min for 30-40min to obtain a mixed solution , put the mixed solution in a high-temperature and high-pressure reactor, and react at a constant temperature and pressure for 30-40 minutes at a temperature of 180-200°C and an air pressure of 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com