High-strength pressure-resistant foam glass preparation method

A foam glass and high-strength technology, which is applied in the field of preparation of high-strength pressure-resistant foam glass, can solve the problems of poor strength, poor impact resistance, and easy fracture of foam glass, and achieve enhanced internal space structure, good toughness, and improved The effect of mechanical strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

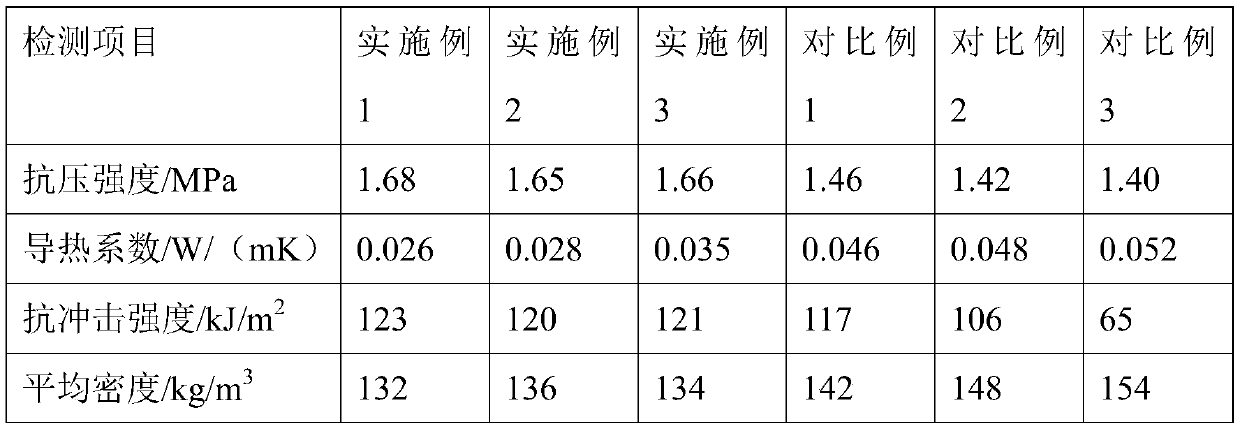

Examples

Embodiment 1

[0031] (1) Put bamboo chips and phosphoric acid solution with a mass fraction of 8% into a beaker at a mass ratio of 1:5, place the beaker in a water bath with a water bath temperature of 70°C, let it stand at a constant temperature for 2 hours, and filter after standing to obtain a filter residue , wash the filter residue 3 times with distilled water, place the filter residue in a planetary ball mill, and grind for 50 min under the condition that the ball-to-material ratio is 10:1 to obtain a grinding product;

[0032] (2) Put the above-mentioned grinding product and the hydrochloric acid solution with a mass fraction of 6% into the reactor at a mass ratio of 1:10, mix and stir with a stirring device at a speed of 300r / min for 2 hours to obtain a solid-liquid mixture, and pour it into the reactor Add citric acid crystal powder with 5% mass of the solid-liquid mixture, increase the temperature in the reactor to 50° C., and let stand at constant temperature for 3 hours to prepar...

Embodiment 2

[0038] (1) Put bamboo slices and phosphoric acid solution with a mass fraction of 12% into a beaker at a mass ratio of 1:5, place the beaker in a water bath with a water bath temperature of 80°C, let it stand at a constant temperature for 3 hours, and filter after standing to obtain a filter residue , wash the filter residue 5 times with distilled water, place the filter residue in a planetary ball mill, and grind for 60 minutes under the condition that the ball-to-material ratio is 10:1 to obtain a grinding product;

[0039] (2) Put the above-mentioned grinding product and the hydrochloric acid solution with a mass fraction of 8% into the reaction kettle at a mass ratio of 1:10, mix and stir for 3 hours with a stirring device at a speed of 350r / min to obtain a solid-liquid mixture, and pour it into the reaction kettle Add citric acid crystal powder with a mass of 7% of the solid-liquid mixture, raise the temperature in the reactor to 60° C., and let stand at constant temperatu...

Embodiment 3

[0045] (1) Put bamboo chips and phosphoric acid solution with a mass fraction of 10% into a beaker at a mass ratio of 1:5, place the beaker in a water bath with a water bath temperature of 75°C, let it stand at a constant temperature for 2.5 hours, and filter after standing to obtain For the filter residue, wash the filter residue 4 times with distilled water, place the filter residue in a planetary ball mill, and grind for 55 minutes under the condition that the ball-to-material ratio is 10:1 to obtain a grinding product;

[0046] (2) Put the above-mentioned grinding product and the hydrochloric acid solution with a mass fraction of 7% into the reactor at a mass ratio of 1:10, mix and stir with a stirring device at a speed of 320r / min for 2.5h to obtain a solid-liquid mixture, and pour it into the reactor Add citric acid crystal powder with a mass of 6% of the solid-liquid mixture to the mixture, raise the temperature in the reactor to 55° C., and let it stand at a constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com